6053 automotive aluminum profile is a high-strength, light-weight aluminum alloy profile, which has good corrosion resistance, fatigue resistance and weldability, and can bear important loads and supports in automotive structures. Usually used in automotive Manufacture of important parts of the body and chassis, such as door frames, roofs, suspension systems, bonnets and chassis, etc.Welcome contact

Why choose Chalco Aluminum's 6053 T6 aluminum automotive profile?

Automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Well-known brand material certifications

Serving Tesla, Ford, Shanghai Automobile, Weilai Automobile, BAIC New Energy, Changan Automobile and other famous new energy automobile manufacturers, confirmed the material certification relationship, and completed the parts of many automobile factories such as BAIC New Energy and Weilai Automobile Model car plate material certification.

Specs of 6053 T6 aluminum automotive profile

| Alloy | 6053 |

| Temper | T6 |

| Open profile dimensions | Min. 4mmx3mm, Max. 850mm×50mm. |

| Closed profiles dimension | Min. 6.35mm x 1mm, Max. 573mm× 10mm. |

| Weight per meter | Min. 0.03kg/m, Max. 124kg/m |

| Profile length | Maximum 28m (standard 6000mm) |

| Surface treatment category | anodizing; Anodizing + electrophoretic painting; Powder Coating; liquid spraying |

Chemical composition of 6053 alloy

| Element | Composition |

| Si | Single: 0.05 Total: 0.15 |

| Fe | 0.35 |

| Cu | 1.0 |

| Mn | - |

| Mg | 1.1—1.4 |

| Cr | 0.15-0.35 |

| Ni | -- |

| Zn | 1.0 |

| Ti | -- |

| Al | Remainder |

Mechanical property of 6053 T6 aluminum automotive profile

| Alloy/Temper | 6053 T6 |

| Wall thickness(mm) | ≤25mm |

| Tension strength | 280-340 MPa |

| Yield strength | 240-300 MPa |

| Elongation at break | 6-12%. |

| Hardness / HV | 70-95 HV |

Features of 6053 T6 aluminum automotive profile

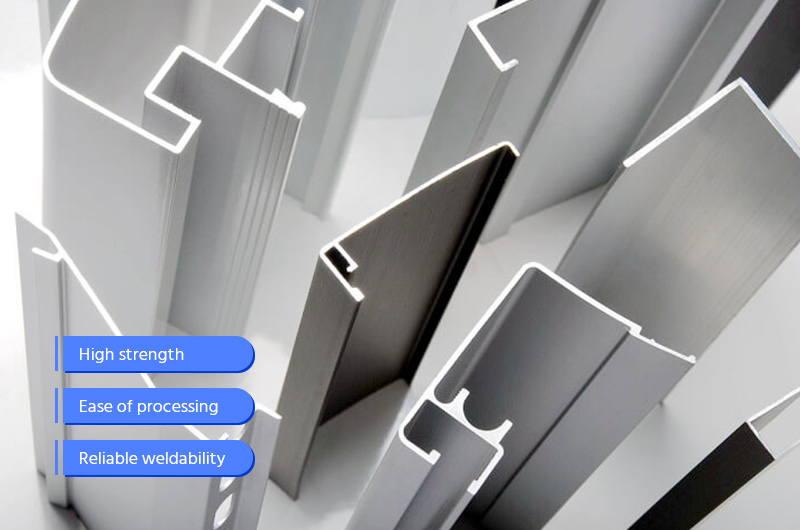

High strength: 6053 aluminum alloy has high tensile strength and yield strength, and can withstand certain loads and stresses.

Good corrosion resistance: aluminum alloy material has good corrosion resistance and can resist the erosion of some corrosive media.

Ease of processing: aluminum profiles have good machinability and plasticity, and can be formed by die-casting, stretching and other processing techniques to meet various shape requirements.

Lightweight: compared with traditional materials such as steel and cast iron, aluminum profiles have a lower density, which can achieve lightweight design, reduce vehicle weight and improve fuel efficiency.

Good high-temperature stability: 6053 aluminum alloy material has good high-temperature stability, is not easy to deform and brittle, and can still maintain good strength and stability in high-temperature environments.

Reliable weldability: aluminum alloy materials have excellent weldability, which can meet the welding requirements in the automobile production process.

Generally speaking, 6053 automotive aluminum profiles have high strength, good corrosion resistance and machinability, and are suitable for the manufacture of structural parts in the fields of automobiles and railways.

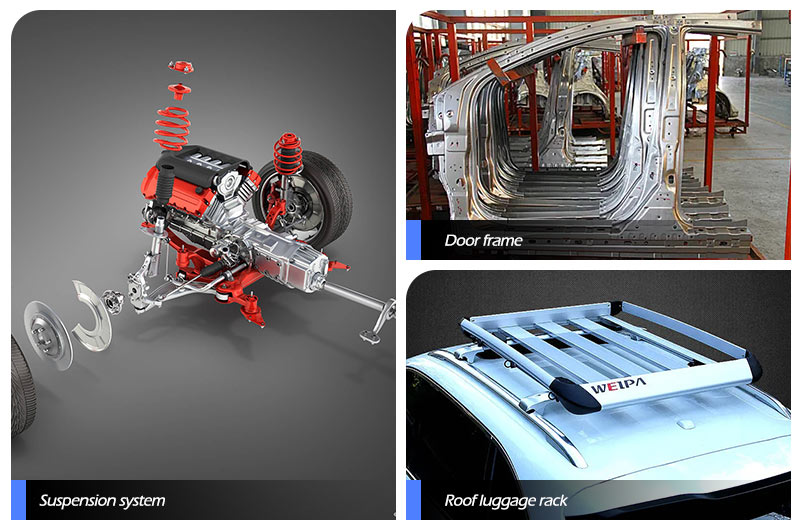

The use of 6053 automotive aluminum profiles

6053 automotive aluminum profile is a high-strength, lightweight aluminum alloy profile specially designed for automotive manufacturing. It has good corrosion resistance, fatigue resistance and weldability, and can take important load and support roles in automotive structures.

Application: 6053 aluminum profiles are usually used in the manufacture of important parts such as car bodies and chassis, such as door frames, roofs, suspension systems, hoods and chassis, etc.

Advantage: the use of 6053 aluminum profiles can significantly reduce the weight of the car and improve fuel efficiency. At the same time, it can also improve the rigidity and stability of the body structure and improve the safety and comfort of the vehicle.

What precautions should be taken when purchasing 6053 T6 automotive aluminum profiles

Understand the specifications and requirements of the profiles: before purchasing, you need to understand the specifications and requirements of the profiles you need, including length, width, thickness, strength and other parameters, to ensure that the profiles meet your needs.

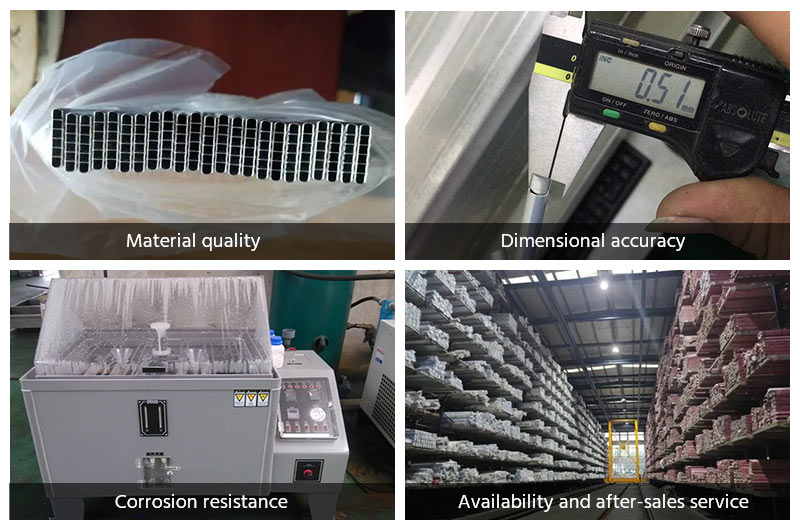

Choose a regular manufacturer: choose a reputable and regular manufacturer to ensure product quality and after-sales service.

Check the surface and internal quality of profiles: when purchasing profiles, you need to check their surface and internal quality to ensure that there are no quality problems such as cracks, pores, and inclusions.

Pay attention to packaging and transportation: when purchasing aluminum profiles, you need to pay attention to their packaging and transportation methods to avoid damage during transportation.

Consult a professional: if you are not sure how to choose a profile or how to process a profile, you can consult a professional engineer or technician for professional advice and help.

In general, when purchasing 6053 automotive aluminum profiles, you need to pay attention to product quality, specification requirements, and processing requirements to ensure high-quality products that meet your needs.