6111 automobile body aluminum sheet is a commonly used aluminum alloy material, mainly composed of aluminum, magnesium, silicon, copper and other elements. It has good formability and strength and is suitable for the manufacture of automotive body panels, doors, hoods, trunk lids and other components.Welcome to contact

Why choose Chinalco 6111 T4 T6 auto body aluminum sheet?

Chalco auto body sheet production capacity

Chalcoaluminum has an acid-alkali cleaning and passivation unit for automobile plates, and the heat-treated (such as: T4, T4P, T6, T8X) 6000 series aluminum alloy plates produced can well meet the requirements of automobile shells.

Chalcoaluminum can provide automotive inner panels, outer panels, and automotive structural materials, realizing full coverage of key automotive lightweight panels, and the industrialization of automotive lightweight materials has entered a new stage.

Chalco automotive IATF16949 standard

Chalcoaluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Well-known brand automobile material certification

Chalcoaluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers. Some models of automotive plate material certification.

Specs of 6111 T4 T6 auto body aluminum sheet

| Alloy | 6111 |

| Temper | T4, T6 |

| ABS sheet dimension | Thickness: 0.5-4.0mm |

| Width: 00-2400mm | |

| Length: 2000-6000mm | |

| ABS coil dimension | Thickness: 0.70-1.50mm |

| Width 800-2400mm | |

| Standard | GB/T 33227-2016, JIS H4000, ASTM B209, EN 485 |

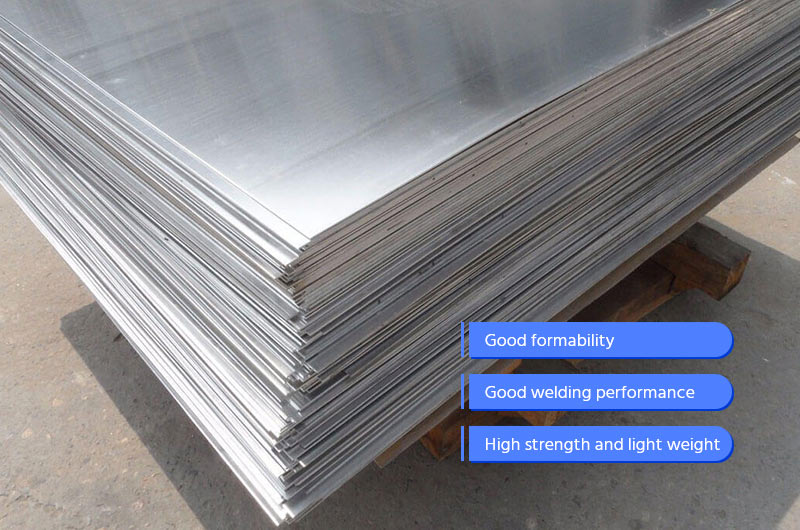

Features of 6111 T4 T6 auto body aluminum sheet

Good formability: 6111 aluminum alloy has high plasticity and formability, can be processed and formed by various processes, and is suitable for the manufacture of various complex automobile body parts.

Good welding performance: 6111 aluminum alloy has good welding performance, and can be welded by various welding processes, such as MIG welding, TIG welding and resistance welding, and it is not easy to crack and deform after welding.

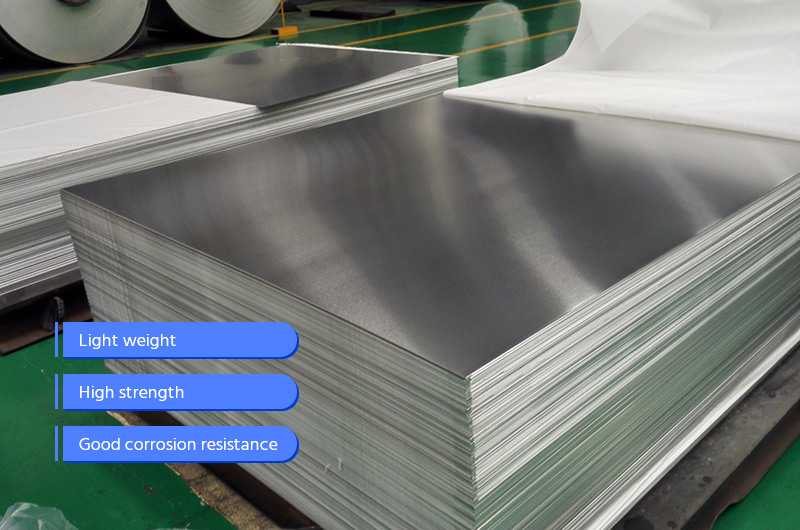

High strength and light weight: compared with traditional steel, 6111 aluminum alloy has higher strength and better corrosion resistance, and at the same time is lighter in weight, which is conducive to the lightweight design of automobiles.

Green and environmental protection: 6111 aluminum alloy is a recyclable material, which is conducive to the environmental protection and sustainable development of the automobile industry.

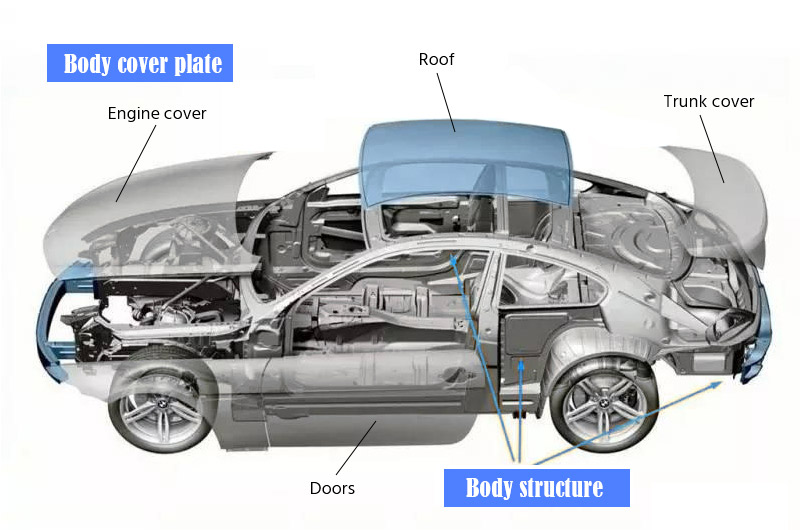

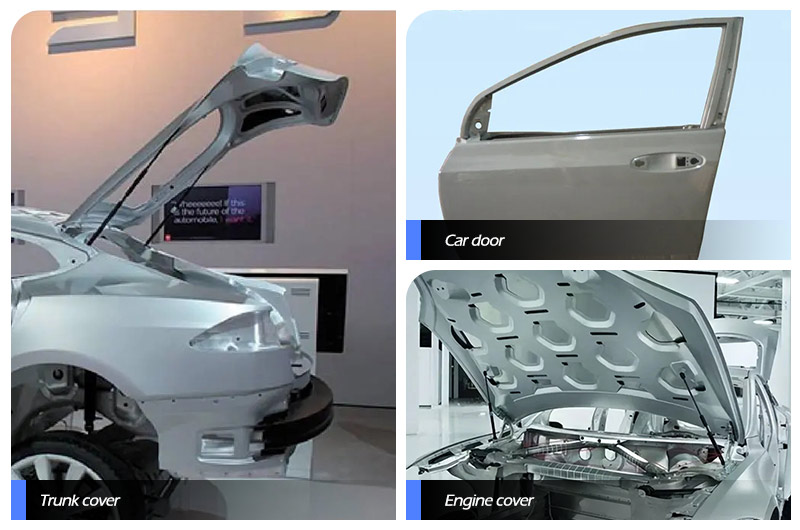

Usage of 6111 T4 T6 auto body aluminum sheet

Doors: aluminum doors can reduce the weight of the vehicle and improve the fuel economy of the vehicle. 6111 T4/T6 aluminum sheets are used in door trim panels, reinforcement panels, and inner panels.

Roof: the aluminum roof has good strength and corrosion resistance, and at the same time is light in weight, which can reduce the weight of the vehicle and improve the driving stability and fuel economy of the car.

Body side: 6111 T4/T6 automobile body aluminum sheet can also be used to manufacture body sides. These parts need to have good strength and rigidity, and lightweight is also an important requirement.

Engine cover: 6111 T4/T6 automobile body aluminum plate can also be used to make engine cover, which requires good strength and rigidity, as well as good corrosion resistance, which can effectively prolong the service life of parts.

Trunk cover: the aluminum trunk cover can not only reduce the weight of the vehicle, but also has good strength and rigidity, which can protect the contents of the vehicle and improve the sports performance of the vehicle.

Frame: 6111 T4/T6 aluminum plate can also be used to manufacture the frame. The aluminum frame has good rigidity and strength, and at the same time is light in weight, which can improve the fuel economy of the vehicle.

Chalco's other aluminum sheets for Automotive Body Sheet

6013 T4/T6 Auto Body Alu Sheet

6013 aluminum sheet for automobile body is an aluminum alloy material…

6014 Alu Auto Body Sheet

6014 automotive aluminum sheet has the characteristics…

6016 Automotive Body Sheet

6016 automotive body sheet has good mechanical…

6A16 T4Pa Auto Body Sheet

6A16 aluminum alloy has the advantages of high strength…

6022 T6Bb Auto Body Sheet

The combination of high strength, good formability…

6181 T4P Auto Body Sheet

6181 aluminum alloy is a material commonly used in automobile…

Precautions for the use of 6111 automobile body aluminum plate

Pay attention to protecting the surface: during the process of handling, transportation, processing and installation, care should be taken to protect the surface of 6111 aluminum alloy to avoid scratches, wear and corrosion.

Control processing parameters: when processing 6111 aluminum alloy, the processing parameters should be well controlled, such as cutting speed, cutting angle, drilling depth, etc., to avoid problems such as deformation and cracks of the plate caused by excessive heat treatment or processing.

Strict control of welding quality: when welding 6111 aluminum alloy, the welding process, welding temperature and welding parameters should be strictly controlled to ensure the quality and reliability of the weld.

Proper storage and storage: when storing 6111 aluminum alloy, it should be kept properly to avoid the influence of damp, heat, corrosion and other factors, so as to ensure the performance and quality of the material.

Pay attention to safe production: when operating 6111 aluminum alloy, safety production regulations should be followed, and protective equipment should be worn correctly to avoid safety accidents.

Chemical composition of 6111 T4 T6 auto body aluminum sheet

| Element | Composition |

| Al | Reminder |

| Fe | <0.7% |

| Si | 0.5-1.0% |

| Cu | 0.15-0.4% |

| Mn | 0.15-0.5% |

| Mg | 0.8-1.3% |

| Ti | <0.10% |

| Zr | <0.10% |

| V | <0.05 |

| Other | <0.15% |

Property of 6111 T4 T6 auto body aluminum sheet

| Temper | T4 | T6 |

| Tensile strength (MPa) | 200-240 | 290-310 |

| Yield strength (MPa) | 100-150 | 240-280 |

| Elongation (%) | 15-20 | 10-15 |

| Hardness (HB) | 50-70 | 80-100 |

Other requirements of aluminum car body sheet metal

| Flange performance | The grade of flanging of panels and strips for body panels is grade 1 or grade 2. If other products require flanging performance, it should be indicated in the order (or contract). |

| Paint brush line | The grade of paint brushing line for panels and samples of body panels is grade 1 or grade 2. When other products require the performance of paint wire, it should be indicated in the order (or contract). |

| Anti-dent performance | When the buyer has requirements on the dent resistance performance of the panels and strips used for body panels, the supplier shall provide relevant data on the dent resistance performance. |

| FLD performance | When the purchaser has FLD performance requirements for panels and strips used for body panels, the supplier shall provide relevant data on FLD performance. |

| High speed tensile properties | When the buyer has high-speed drawing performance requirements for the panels and strips used for body panels, the supplier shall provide relevant data on the high-speed drawing performance. |

| Microstructure | The microstructure of sheets and strips subjected to solution heat treatment is not allowed to be over-burned. |

| Oil amount | The oiling of the product is most determined through negotiation between the supplier and the buyer, and is indicated in the order form (or contract). |

| Passivation film thickness | The passivation film thickness of the product is determined through negotiation between the supplier and the buyer, and is specified in the order form (or contract). |

| Appearance Quality | Defects such as surface roughness, slight unevenness, scratches, color difference and small prints are allowed on the surface of panels and strips for inner panels of body panels and panels and strips for body structural parts, which do not affect the formability. |

| Defects such as cuts and marks that affect the use are not allowed on the outer surface of the panels and strips used for the outer panels of the body panels, and defects such as slight color difference, such as paint openings and cover-ups, are allowed. |

Thickness deviation of 6111 T4 T6 auto body aluminum sheet for body panels

| Thickness mm | Thickness tolerances within the following width ranges | ||

| 800.0-1600.0 | >1600.0-1800.0 | >1800-2400.00 | |

| 0.70-1.00 | ±0.03 | ±0.05 | ±0.08 |

| >1.00-1.20 | ±0.04 | ±0.06 | ±0.09 |

| >1.20-1.50 | ±0.05 | ±0.07 | ±0.10 |

Width deviation of 6111 T4 T6 auto body aluminum sheet for body structural parts

| Thickness mm | Width tolerances within the following width ranges | |||||||

| <100.0 | >100.0-00.0 | >300.0-500.0 | >500.0- 800.0 | >800.0-1 250.0 | >1 250.0-1 800.0 | >1 800.0-2 000.0 | >2 000.0-2 400.0 | |

| 0.30—1.60 | + 0, 3 0 | + 0, 4 0 | + 1.0 0 | + 1.5 0 | + 2, 0 0 | + 3.0 0 | — | — |

| >1.60—3.50 | — | — | — | + 2.0 0 | 4-3.0 0 | + 4.0 0 | + 5.0 0 | + 6.0 0 |

Length deviation of 6111 T4 T6 auto body aluminum sheet and strips for body panels

| Thickness mm | Length tolerances within the following length ranges | |

| 800.0-2 000.0 | >2 000.0 | |

| 0.70-1.50 | + 3.0 0 | + 5.0 0 |

Diagonal deviation of 6111 T4 T6 auto body aluminum sheet and strips for body panel

| Length mm | The allowable deviation of the two diagonal lengths of the board corresponding to the following width W | |

| 800.0-1 600.0 | >1 600.0-2 400.0 | |

| <3 000.0 | 1.2 × W/300 | 1.0 × W/300 |

| >3 000.0 | 1.0 × W/300 | 0.8 × W/300 |

Unevenness of 6111 T4 T6 auto body aluminum sheet and strips for body panel

| Thickness mm | The unevenness of sheets and strips within the following width ranges shall not be greater than | Termination area, warpage height | ||||

| <500.0 | >500.0- 1 000.0 | >1 000.0- 1 500.0 | >1 500.0- 2 000.0 | >2 000.0 | ||

| 0.30-0.50 | 3 | 4 | 4 | 4 | — | ≤25 |

| >0.50-0.80 | 3 | 4 | 4 | 7 | 8 | |

| >0.80-1.60 | 3 | 4 | 4 | 6 | 8 | |

| >1.60-2.00 | 3 | 4 | 4 | 6 | 8 | |

| >2.00-3.50 | 3 | 4 | 4 | 6 | 8 | |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote