Why choose Chalco 6A61 automotive aluminum profile

Chalco production capacity

Chalco can produce GB/T 33910, ASTM B221, EN755 copper aluminum alloy grade extrusions profile 6S02 T6 for automotive, has IATF16949 automotive material certification, used to windshield frames, luggage racks, seat rails, sliding door rails, door accessories, ABS valve bodies, etc.

Automotive IATF16949 standard

The 6S02 T6 Aluminum auto profiles produced by Chalco adopt a strict quality and environmental management system, and have passed ISO 9001 and ISO 14001 certification, and IATF16949 certification.

Well-known brand material certifications

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers. Some models of automotive plate material certification.

Specifications of Chalco aluminium alloy 6S02 T6 automotive extrusion

| Alloy | 6S02 T6 |

| Temper | T6 |

| Production standards | GB/T 33910, ASTM B221, EN755 |

| Size |

circular profiles with diameter 10-250mm, thickness 0.5-50mm; rectangular profiles with length, width and height 20-100mm, 10-80mm, 0.5-10mm; special shaped profiles of different sizes. |

| Length and Width | according to specific vehicle and application |

| Aluminum profile surface treatment |

Anodizing, electrophoretic coating, sandblasting and other methods |

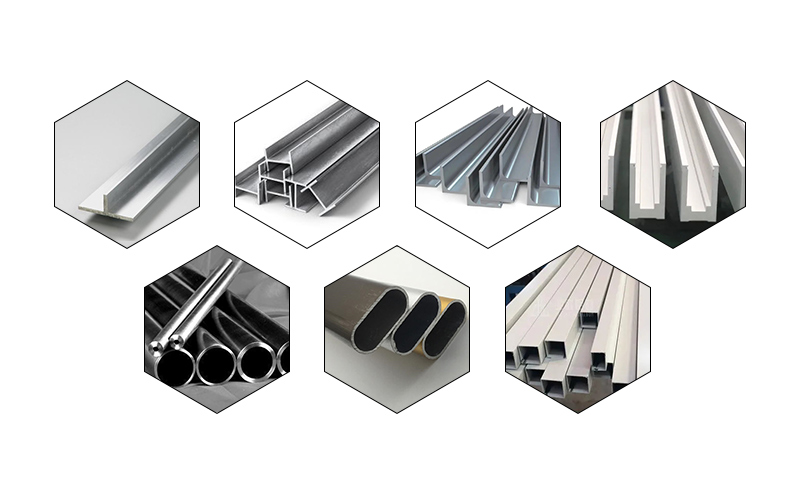

| Common shapes |

6S02 T6 aluminum alloy round tube, 6S02 T6 aluminum alloy square tube, 6S02 T6 aluminum alloy angle aluminum, 6S02 T6 aluminum alloy U profile, 6S02 T6 aluminum alloy T profile, 6S02 T6 aluminum alloy Z profile, 6S02 T6 aluminum alloy H profile. |

Chemical composition of Chalco 6S02 T6A automotive aluminum alloy

| Element | Composition % |

| Si | 0.9-1.15 |

| Fe | 0.3 |

| Cu | 0.32-0.5 |

| Mn | 0.15-0.4 |

| Mg | 0.5-0.7 |

| Ti | 0.05 |

| Cr | 0.1-0.3 |

| Zn | 0.08 |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |

Mechanical properties of Chalco 6S02 T6 automotive high quality extrusion

| Tensile strength | 315MPa |

| Yield strength | 285Min MPa |

| Elongation | 15% |

Product features of Chalco 6S02 T6 automotive aluminum alloy extrusion

High strength: 6S02 T6 aluminum profile has extremely high strength, which is much stronger than ordinary aluminum profile and can withstand greater load and pressure.

Lightweight: compared with steel, aluminum has a lower density, and 6S02 T6 aluminum profile is no exception, so it can reduce the weight of the vehicle and improve fuel efficiency while ensuring strength.

Corrosion resistance: aluminum alloy has good corrosion resistance, is not easy to rust, and can be used in harsh environments.

Good machinability: 6S02 T6 aluminum profile can be drilled, cut, welded, bent, etc., which is very suitable for the production of parts with diverse needs.

Good thermal conductivity: aluminum alloy has good thermal conductivity, which can effectively dissipate heat and keep the vehicle at a stable temperature.

Beautiful appearance: the surface of 6S02 T6 aluminum profile is flat and smooth, and the appearance is beautiful. It is suitable for high-end automobiles, motorcycles, bicycles and other manufacturing fields.

Application of Chalco 6S02 T6A industrial automotive grade aluminium extrusion

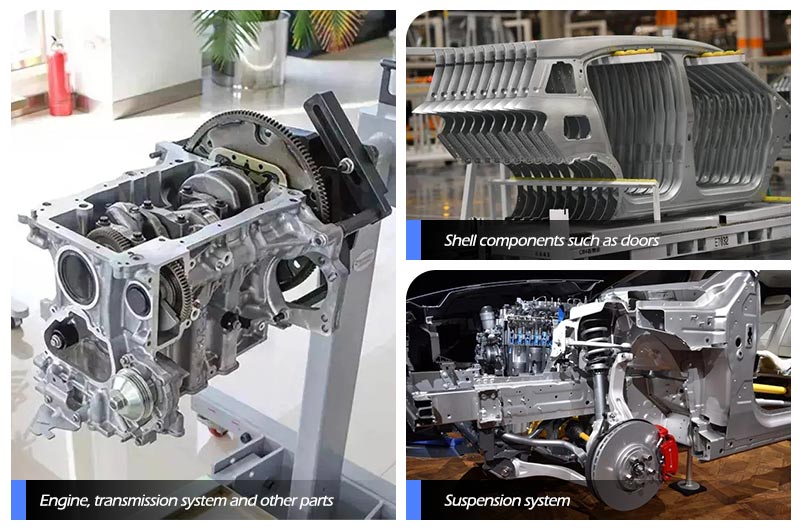

Body frame: the high strength and lightweight characteristics of 6S02 T6 aluminum profile make it an ideal material for automobile body frame. It can reduce the weight of the vehicle, improve fuel economy, and at the same time provide sufficient strength and rigidity to ensure the safety performance of the vehicle.

Shell components such as doors, windows, and roofs: 6S02 T6 aluminum profiles have good machinability, and can produce shell components such as doors, windows, and roofs in various shapes and sizes. They not only have good corrosion resistance, but also can effectively insulate sound and heat, and improve the comfort in the car.

Engine, transmission system and other parts: 6S02 T6 aluminum profile can be used to make engine, transmission system and other parts, because it has good thermal conductivity and high temperature resistance. At the same time, it can withstand greater pressure and vibration to ensure the stability and reliability of parts.

Production process of Chalco aluminum alloy 6S02 T6 (UNS A96S02 T6) extrusion

At present, the production process of aviation aluminum profiles mainly includes casting, extrusion and rolling.

Melting and casting is the method of heating the aluminum material to a liquid state and cooling it through a mold;

Extrusion is to extrude the aluminum material into profiles of various cross-sectional shapes;

Rolling is to pass the aluminum material through multiple passes of pressure. It is tapered and formed into profiles of the desired shape.

When purchasing 6S02 T6 automotive aluminum profiles, you need to pay attention to the following items

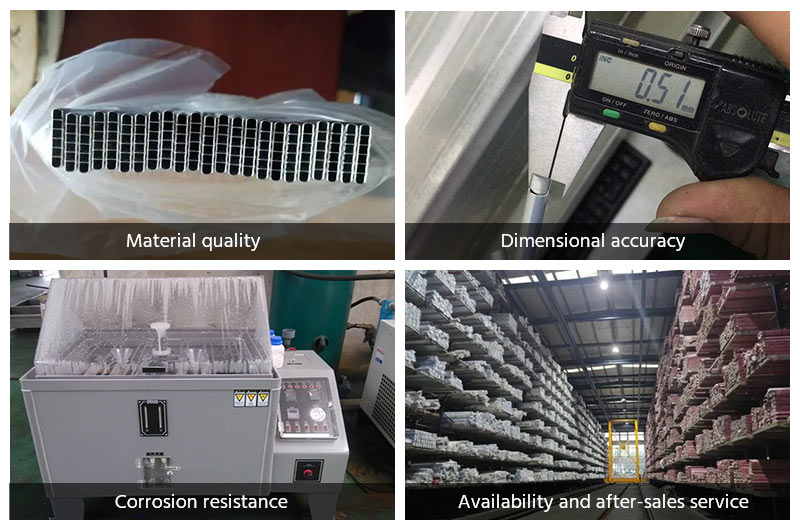

Material certification: when selecting suppliers, suppliers with qualifications and experience should be given priority, and qualified material certification certificates should be required at the same time. The material certification certificate should include information such as the chemical composition, mechanical properties, processing technology and surface treatment of the material to ensure that the purchased 6S02 T6 aluminum profiles meet the corresponding standards and requirements.

Specification and size: according to the required specific use and design requirements, select the appropriate 6S02 T6 aluminum profile specification and size. Pay attention to the performance and price differences between different specifications and sizes, and make choices and trade-offs according to actual needs.

Surface treatment: the surface treatment of 6S02 T6 aluminum profiles includes oxidation, anodic oxidation, electrophoretic coating, sandblasting and other methods. Choose the appropriate surface treatment method according to the specific requirements to improve the corrosion resistance, wear resistance and aesthetics of the 6S02 T6 aluminum profile.

Supply cycle and delivery method: when negotiating with suppliers, details such as supply cycle and delivery method need to be clarified. Ensure that the purchased 6S02 T6 aluminum profiles can be supplied in a timely manner, and at the same time require suppliers to provide reasonable transportation and delivery methods to ensure that the goods arrive at their destination safely and in time.

Price and after-sales service: price is a factor that cannot be ignored in the procurement process. The price and after-sales service of different suppliers should be evaluated and compared, and the cost-effective supplier should be selected for cooperation. At the same time, establish a good cooperative relationship with suppliers to obtain better service and support in future cooperation.