6008 aluminum alloy profiles have many characteristics such as high strength, light weight, corrosion resistance, good machinability, and environmental protection. They are suitable for the manufacture of various automotive structural parts and parts, mainly used in automotive structural parts, body panels, and car doors, window, roof, floor and other parts manufacturing.

Why choose Chalco 6008 automotive aluminium profile?

Chalco automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Well-known brand material certifications

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers. Some models of automotive plate material certification.

The specifications of 6008 automotive aluminum extrusion profile

| Temper | T4 T6 etc. |

| Open Profile dimensions | Min 4mm×3mm, Max.850mm×50mm. |

| Closed profiles dimension | Min.6.35mm×1mm, Max. 573mm×10mm. |

| Weight per meter | Min.0.03kg/m, Max.124kg/m |

| SECTION AREA | 0.2-90CM2 |

| WALL THICKNESS | 1-100mm |

| OUTLINE SIZE | 10-530mm |

| Profile length | Maximum 28m (standard 6000mm) |

| Surface treatment category | anodizing; Anodizing + electrophoretic painting; Powder Coating; liquid spraying |

| Extrusion Type | Dimension Range (inches) | Wall Thickness Range (inches) |

| 6008 Automotive Aluminum Extrusion Round Pipe Tube | 1-10 | 0.125-0.75 |

| 6008 Automotive Aluminium Extrusion Square Pipe Tube | 1-8 | 0.125-0.5 |

| 6008 automotive aluminum Rectangular Tube | 1×2-8×12 | 0.125-0.5 |

| 6008 automotive aluminum Angle | 1×1-8×8 | 0.125-0.5 |

| 6008 automotive aluminum T-Profile | 1×1-6×6 | 0.125-0.5 |

| 6008 automotive aluminum U-Profile | 1×0.5-6×2 | 0.125-0.5 |

The chemical composition of 6008 aluminium alloy profiles extrusions for auto

| Element | Composition % |

| Si | 0.50-0.9 |

| Fe | 0.35 |

| Cu | 0.30 |

| Mn | 0.30 |

| Mg | 0.40-0.7 |

| Cr | 0.30 |

| Zn | 0.20 |

| Ti | 0.10 |

| V | 0.05-0.20 |

| Other | 0.20 |

| Al | Remainder |

The mechanical properties of 6008 aluminium alloy profiles extrusions for automobile

| Temper | Wall thickness mm | Tension Strength /MPa | Yield Strength /MPa | Elongation/% | ||

| A | A 50mm | |||||

| T4 | ≤10 | ≥180 | ≥90 | ≥15 | ≥13 | |

| T6 | Solid Profile | ≤5 | ≥270 | ≥225 | ≥8 | ≥6 |

| >5-10 | ≥260 | ≥215 | ≥8 | ≥6 | ||

| hollow profile | ≤5 | ≥255 | ≥215 | ≥8 | ≥6 | |

| >5-10 | ≥250 | ≥210 | ≥8 | ≥6 | ||

What are the characteristics of 6008 automotive aluminum extrusion?

High strength: 6008 automotive aluminum profiles extrusions have high strength and hardness, which can meet the strength and rigidity requirements of automotive structural parts and parts.

Lightweight: compared with traditional steel materials, 6008 aluminum alloy profiles have a lower density, which can effectively reduce the overall weight of the car and improve fuel efficiency and performance.

Preservative: 6008 automotive aluminum extrusions have good corrosion resistance, which can reduce the corrosion damage of automotive structural parts and parts during use, and improve their service life and reliability.

Good machinability: 6008 aluminum alloy profiles have good machinability and formability, and can meet various shape and size requirements through various processing techniques (such as extrusion, stamping, cutting, welding, etc.).

Environmental protection: 6008 Aluminium Alloy Profiles Extrusions for Automobile have good environmental protection performance, can reduce the carbon emission and energy consumption of automobiles, and meet the requirements of modern society for environmental protection and sustainable development.

Good solderability: since the 6008 aluminum alloy profile contains an appropriate amount of magnesium and silicon elements, it has good weldability, and can achieve different joint forms and strength requirements through a variety of welding processes (such as TIG, MIG, laser welding, etc.).

Excellent surface treatment performance: since the surface of 6008 Aluminium Alloy Profiles Extrusions for Auto is smooth and flat, various surface treatment processes (such as anodizing, spraying, sandblasting, etc.) can be carried out to meet different decorative and functional requirements.

Wide adaptability: 6008 automotive aluminum extrusion can be widely used in the manufacture of automobile chassis, frame, suspension system, doors, windows, roof, body panels and other components, which can meet the needs of different models and different functional requirements.

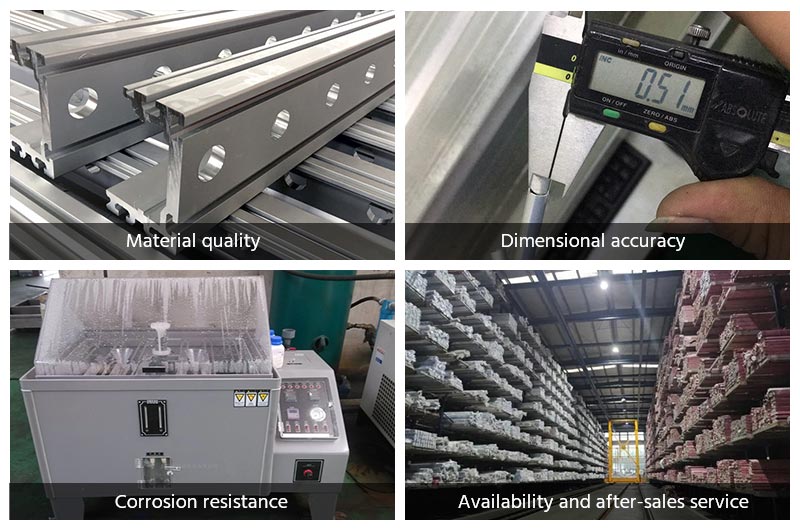

What items should be paid attention to when purchasing 6008 automotive aluminum profiles extrusions?

Model specifications: select appropriate model specifications according to needs, including shape, size, wall thickness, etc., to meet specific design and manufacturing requirements.

Material quality: 6008 automotive aluminum profiles produced by Chalco Aluminum adopt strict quality and environmental management systems to ensure that they meet ISO 9001 and ISO 14001 certification, IATF16949 certification, etc., and can meet your application needs.

Surface quality: pay attention to the surface quality of 6008 aluminum alloy profiles, including surface flatness, surface smoothness, surface oxide film quality, etc., to ensure the assembly and use performance of profiles.

Processing technology: understand the processing technology of 6008 automotive aluminum extrusion profile, including extrusion, precision cutting, forming, etc., to ensure the processing accuracy and dimensional accuracy of the profiles.

Application field: select the appropriate application field according to the needs, including the manufacture of automotive structural parts, body panels, doors, windows, roofs and other components, so as to ensure the use effect and economic benefits of the profiles.

Manufacturer's reputation: the supplier's reputation and service quality are also factors you need to consider. Chalco Aluminum is a supplier with a good reputation and perfect after-sales service to ensure your purchasing experience is pleasant and smooth.

Price: considering the cost of 6008 automotive aluminum profiles extrusions, Chalco Aluminum is moderately priced and widely favored by auto parts manufacturers.

Technical support and after-sales service: Chalco Aluminum is a supplier and material manufacturer that can provide good technical support and after-sales service to ensure that customers can get timely help and support in the process of purchasing and using.

Packaging and transportation: Chalco Aluminum has fully considered the packaging and transportation methods of automotive aluminum profiles to ensure that they will not be damaged during transportation.

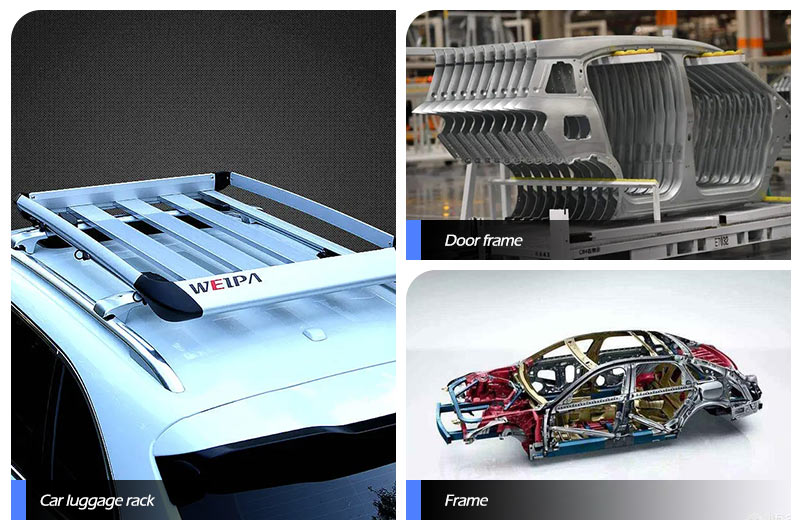

The usage of 6008 automotive aluminum extrusions

Application of 6008 T4 automotive aluminum profiles extrusions

Aluminium Alloy 6008 T4 Extrusions have good formability and good toughness, and are suitable for the manufacture of auto parts that require deep drawing or bending, such as body panels, doors, windows, roofs and other components.

Application of 6008 T6 automotive aluminum extrusion profile

6008 T6 Aluminium Alloys Profiles have high strength and hardness, and are suitable for the manufacture of automotive structural parts that require high strength and high rigidity, such as chassis supports, frames, wheels, beams and other components.

Automobile body structure: due to the high strength and excellent formability of 6008 alloy, automobile body structural parts with high torsional and bending rigidity can be manufactured. In automobile manufacturing, the use of 6008 alloy aluminum profiles to manufacture body structural parts can reduce the quality of the vehicle and improve fuel economy and driving performance.

Appearance parts of automobiles: 6008 alloy aluminum profiles can also be used to manufacture exterior parts of automobiles, such as doors, windows, roofs, tails and other parts. These parts need to have good corrosion resistance and appearance quality, and 6008 alloy aluminum profiles can meet these requirements, while also having low weight and excellent processing performance.

Automobile chassis components: 6008 alloy aluminum profiles can also be used to manufacture automobile chassis components, such as chassis supports, floor plates, luggage racks, etc. These parts need to have high strength and good corrosion resistance to cope with complex road environment and climate conditions.