2A50 aluminum alloy forging is a high-strength, high-corrosion-resistant aluminum alloy forging material with good mechanical properties and machinability, and is widely used in the aerospace field.

Why choose Chalco's 2A50 aerospace aluminum forgings?

Quality could full meet world wide aviation standard

GJB 2351-2004

HB 5204-96

Production and management comply with international aviation quality system certification

AS9100

OHSAS 18001

ISO14001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

Specs of 2A50 aluminum forgings

| FORGING | TYPE | MAX. WEIGHT | MAX. DIMENSION |

| Open Die Forging | Cube | ≤9T |

Length≤7000mm, Width≤2000mm, Height≤500mm |

| Disk | ≤5T | Diameter≤2500mm | |

| Ring | ≤5T |

Outer diameter of quenching parts≤2500mm, Outer diameter of non-quenching parts≤4000mm, Height≤500mm |

|

| Cylinder | ≤5T |

Outer diameter 200-800mm, Length≤2000mm; Outer diameter 801-2000mm, Length≤1500mm; |

|

| Axle | ≤8T |

Length≤7000mm, Diameter≤800mm |

|

| Backward Extrusion | Forged Pipe |

Outer diameter≤830mm, Inner diameter≤650mm, Length≤1800mm |

|

| Closed Die Forging | Common Closed Die Forgings | - | PVA≤3.0㎡(Diameter≤1950mm) |

| Complex Closed Die Forgings | - | PVA≤1.5㎡(Diameter≤1400mm) |

Chemical composition of 2A50 aluminum alloy

| Element | Weight percentage |

| Si | 0.70-1.20 |

| Fe | 0.70 |

| Cu | 1.8-2.60 |

| Mn | 0.40-0.80 |

| Mg | 0.40-0.80 |

| Ni | 0.10 |

| Zn | 0.30 |

| Al | Remainder |

Mechanical property of 2A50 aluminum forgings

| Standard | GJB 2351 | HN 5204 | |||

| Type | Free forgings | Die forgings | Free forgings | Die forgings | |

| Temper | T6 | T6 | T6 | T6 | |

| L | Rm/MPa | 365 | 380 | 365 | 380 |

| Rp0.2/MPa | - | 275 | - | 275 | |

| A5% | 8.0 | 10.0 | 9.0 | 11.00 | |

| LT | Rm/MPa | 345 | 365 | 345 | 365 |

| Rp0.2/MPa | - | 245 | - | 245 | |

| A5% | 6.0 | 7.0 | 6.0 | 7.0 | |

| ST | Rm | 335 | 345 | 335 | 345 |

| A5% | 4.0 | 5.0 | 4.0 | 5.0 | |

| HBS | 95 | 100 | 95 | 100 | |

Features of 2A50 aluminum forgings

High strength: 2A50 aluminum alloy has high strength, especially in the heat treatment state, its tensile strength can reach 550~610 MPa.

Good plasticity: 2A50 aluminum alloy forgings have good plasticity, good formability and extrudability, and can be processed by various processing techniques.

Good welding performance: 2A50 aluminum alloy forgings have good welding performance and can be used in various welding methods such as TIG, MIG and resistance welding.

Good corrosion resistance: 2A50 aluminum alloy forgings have good corrosion resistance, especially for seawater and chloride corrosion.

Good thermal stability: 2A50 aluminum alloy has good thermal stability and can maintain good mechanical properties and stability at high temperatures for a long time

Uses of 2A50 aluminum forgings

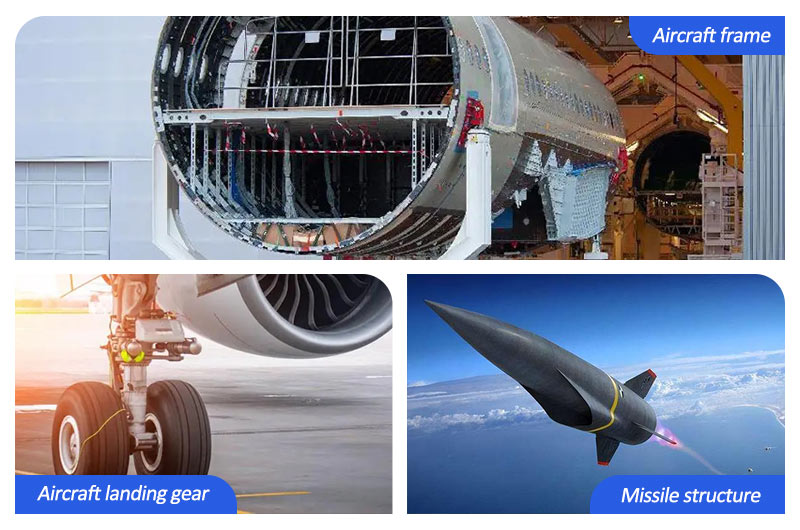

Aircraft structural parts: 2A50 aluminum alloy forgings can be used to manufacture structural parts such as front beam die forgings, landing gear, aircraft bulkheads, joints, brackets and rocker arms of transport aircraft, with light weight, high strength, excellent formability and reliability, etc. features.

Spacecraft structural parts: 2A50 aluminum alloy forgings can be used to manufacture spacecraft propellers, chassis, load platforms, guidance instruments and other structural parts, with high strength, low density, good weldability and corrosion resistance.

Missile components: 2A50 aluminum alloy forgings can be used to manufacture structural parts, shells, missile engines and other components of missiles, with light weight, high strength, excellent formability and corrosion resistance.

What precautions should be taken when purchasing 2A50 aluminum forgings?

When purchasing 2A50 aluminum alloy forgings, you need to pay attention to the following points:

Material certification: confirm that the purchased 2A50 aluminum alloy forgings meet the relevant national and industry standards and requirements, and require suppliers to provide relevant documents such as material certification and inspection reports.

Specifications and dimensions: Confirm whether the specifications and dimensions of the purchased 2A50 aluminum alloy forgings meet your needs, and ask the supplier to provide detailed dimensions and shape drawings.

Surface quality: Confirm whether the surface of the purchased 2A50 aluminum alloy forging is flat, smooth, free of cracks, bubbles and other defects, and require the supplier to provide a surface inspection report.

Production process: Confirm whether the production process of the purchased 2A50 aluminum alloy forging meets the requirements, and require the supplier to provide the production process and process inspection report.

Supplier reputation: choose a reputable and experienced supplier for purchase, and require the supplier to provide credit certificates and recommendation letters from relevant customers.

In short, when purchasing 2A50 aluminum alloy forgings, it is necessary to carefully check the details and relevant information to ensure that the purchased forgings meet the quality requirements and use requirements. At the same time, it is also very important to choose a reliable supplier.