Chalco is committed to providing you with the capacitor foil you need, when and where you need it, by rolling and manufacturing to your exact application specifications. Available in sizes from .00019" to .00040", we have a large selection of stock foils and target lead times based on your needs.

We are a leading supplier of ultra-thin industrial laser cut aluminum foil for the most demanding electronic applications.Our foils have clean cut edges for consistent unwinding with minimal breakage. With tolerances down to 0.0625 inches, our capacitor foils are the perfect match for nearly any capacitor application.Quick Quote

Why choose Chalco Capacitor Aluminum Foil 1060/1100?

Standard: ASTM B479-18, IEC 60384-1, JIS H 4120, GB/T 3618-2019 etc.

Laser Cutting Technology: Unique laser cutting foil technology with excellent high voltage performance.

Surface Cleanliness: The foil surface is clean to ensure capacitor reliability.

Straight and tight winding: The foil winding is straight and tight.

Customized service: We are committed to meeting the needs of our customers in a customized manner.

High quality consistency: High quality consistency is a key factor in achieving the desired product and production performance.

Chemical composition of capacitor aluminum foil

Our foils are rolled from 1050, 1060, 1100, 1235 alloys with a minimum aluminum content of 99%.

| Alloy | Chemical composition |

| 1050 | (Al): ≥ 99.50% |

| 1060 | (Al): ≥ 99.60% |

| 1100 | (Al): ≥ 99.00% |

| 1235 | (Al): ≥ 99.35% |

Capacitor Aluminum Foil Popular Sizes

Chalco is committed to providing you with the capacitor foil you need, when and where you need it, by rolling and manufacturing to your exact application specifications.

| Thickness (inches) | Thickness(mm) |

| 0.00019 | 0.0048 |

| 0.00020 | 0.0051 |

| 0.00025 | 0.0064 |

| 0.00030 | 0.0076 |

| 0.00035 | 0.0089 |

| 0.00040 | 0.0102 |

Features of capacitor aluminum foil

High conductivity: Aluminum is an excellent conductive material, and aluminum foil for capacitors has good conductivity and can quickly conduct charges.

Lightweight: Aluminum is a relatively lightweight metal, and capacitor aluminum foil has a low density, which helps reduce the overall weight of the capacitor.

High mechanical strength: Capacitor aluminum foil usually has high mechanical strength and tensile strength, can withstand large forces and stresses, and has good physical strength and durability.

Good machinability: Aluminum has good plasticity and machinability, capacitor aluminum foil can be easily cut, formed and connected to meet the needs of capacitors of various shapes and sizes.

Corrosion resistance: Capacitor aluminum foil usually has a certain corrosion resistance, can operate stably for a long time under certain environmental conditions, and is not easily affected by oxidation, corrosion or chemical reactions.

High surface area: Capacitor aluminum foil often forms tiny holes and nanostructures with high surface area through special treatment, such as corrosion, so as to increase the effective surface area and increase the capacitance of the capacitor.

Low cost: Aluminum is a widely used and common metal material, and the relatively low cost of capacitor aluminum foil makes the production cost of capacitors relatively low.

The main application of capacitor aluminum foil

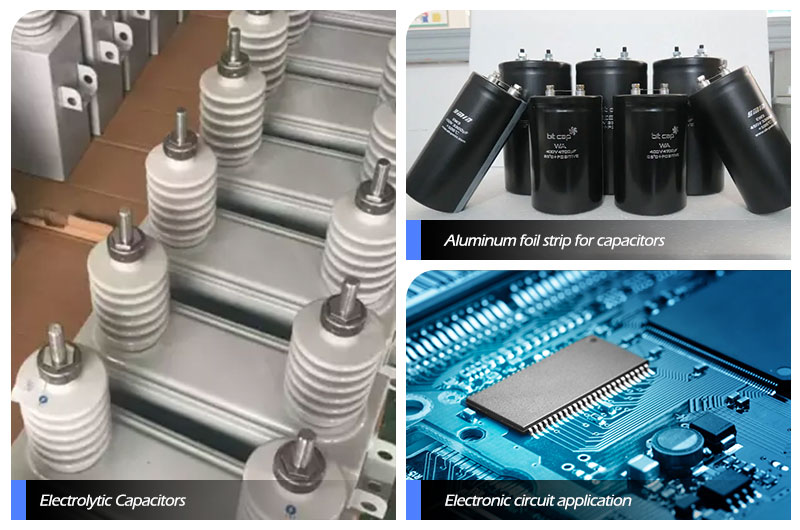

Electrolytic capacitors: Capacitor aluminum foil is one of the key components of electrolytic capacitors. Electrolytic capacitors use aluminum foil as the positive and negative electrodes to store charge through the action of the electrolyte. Capacitor aluminum foil has high conductivity and large surface area, which can provide greater capacitance and store energy.

Aluminum foil strip for capacitors: Aluminum foil for capacitors can also be used as a raw material for manufacturing aluminum foil strips for capacitors. These aluminum foil strips are specially processed including corrosion and surface treatment to increase their capacitance and electrical properties. These aluminum foil strips are used to manufacture various types of capacitors such as film capacitors, aluminum electrolytic capacitors, etc.

Electronic circuit application: Capacitor aluminum foil can also be used in coupling capacitors and filter capacitors in electronic circuits. These capacitors are used to control the frequency and voltage of the signal, smooth the power signal, reduce noise interference, etc. As one of the electrodes of the capacitor, aluminum foil can meet the needs of fast charging and discharging in the circuit.

Power electronics application: In the field of power electronics, capacitor aluminum foil is used to manufacture high-power capacitors, such as power electrolytic capacitors, pulse capacitors, etc. These capacitors are used in applications such as energy storage, filtering, power balancing, and pulse discharge.

Precautions for the use of capacitor aluminum foil

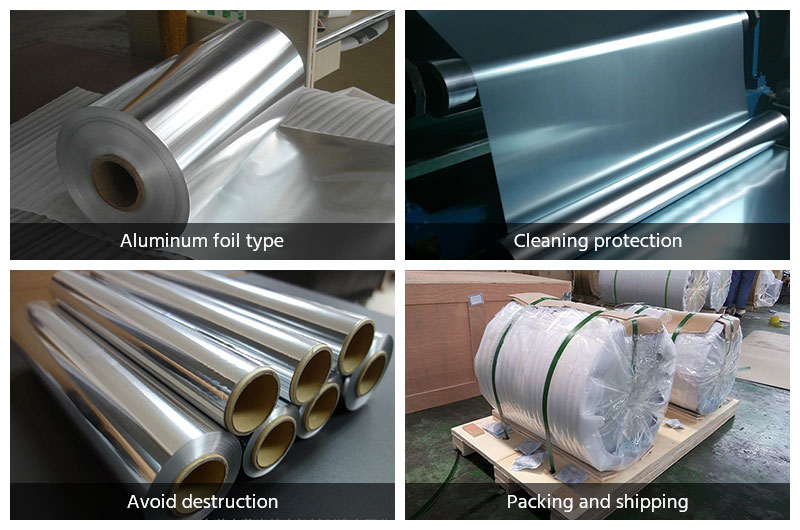

Select the appropriate aluminum foil type: According to the specific capacitor application requirements, select the appropriate capacitor aluminum foil type and alloy grade. Consider capacitance, voltage requirements, operating temperature range, and other special requirements to select the appropriate aluminum foil material.

Avoid Damage: When handling and disposing of capacitor foil, avoid anything that could cause physical damage such as tearing, bending or scratching. These damages can affect the performance and reliability of the capacitor.

Watch out for electrostatic discharge: Electrostatic discharge can cause damage to capacitor foil, so care should be taken to prevent static buildup and discharge when handling foil. Take appropriate antistatic measures, such as wearing antistatic gloves, using antistatic tools and working environment, etc.

Cleaning and Protection: When handling capacitor foil, maintain a clean working environment free from dirt, moisture or other substances that may cause corrosion. If storage capacitor foil is required, it can be stored in a moisture-proof bag or airtight container to prevent corrosion and contamination.

Be aware of temperature limits: Capacitor foil has a certain operating temperature range, beyond which its performance and stability may be affected. Make sure to use capacitor foil within the specified operating temperature range and avoid extreme high or low temperature conditions.

Follow manufacturer's guidelines: When using capacitor foil, follow the manufacturer's guidelines and recommendations. Know the product's characteristics, conditions of use and limitations, and follow the instructions provided by the manufacturer for its operation and use.