3003 aluminum tube is widely used for its corrosion resistance and weldability, in food containers, kitchen utensils, decorative materials, and automotive components. Its surface can be treated for better aesthetics and durability through painting and anodizing. With high strength and ductility, it suits extrusion, welding, and cutting processes.

3000 series aluminum alloy adds Manganese (Mn), which can provide good corrosion resistance and moderate strength after appropriate surface treatment (such as anodizing). Chalco 3003 and 3A21 aluminum tube busbars can be widely used in transmission and transformation systems and wind power generation systems in harsh environments such as humidity.Welcome contact

Specification of Chalco 3003 3A21 EC aluminum tubular busbar

| Temper | H14 |

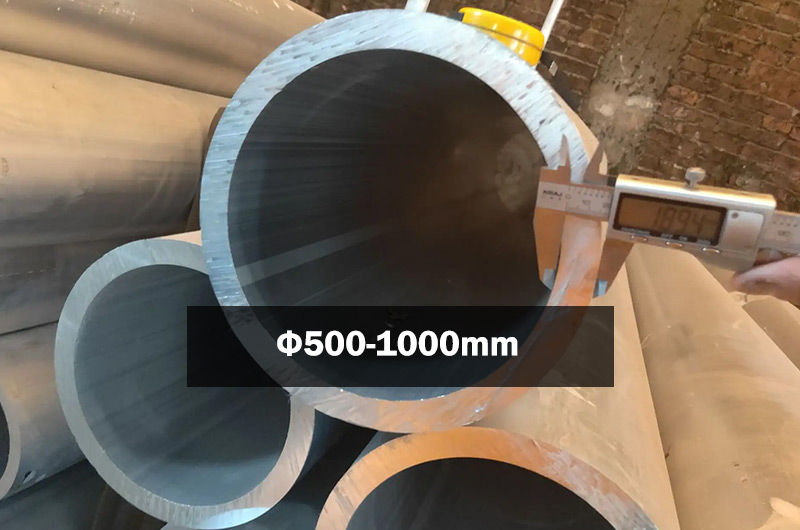

| Outer diameter | Φ60mm-Φ450mm |

| Wall thickness | 3mm-15mm |

| Length |

The length of a single bus pipe can reach 15 meters; deviation:+15~+25mm |

| Curvature | m/L<2.0mm |

| Size and Deviation | Click to view the [Size and Deviation Table] |

| Surface requirement | The surface is smooth and flat, without cracks, wrinkles, inclusions, deformation, or distortion. |

| Product requirement |

The finished pipeline is completely straight; High dimensional accuracy and high tensile strength; Not prone to discharge and corona. |

| Profiles can be provided |

Certificate of origin; Invoice and PL certified by Chamber of Commerce; Test certificate according to EN 10204 3.1; Other test reports that may be requested by the customer. |

Mechanical and Physical property of Chalco 3003 3A21 EC bus pipe tube

| Alloy | 3003 H14 | 3A21 H14 |

| Tensile strength Rm/MPa | ≥135 | ≥135 |

| Prescribed plastic extension strength Rp0.2/MPa | ≥120 | ≥120 |

| Elongation after fracture (% ) | ≥4 | ≥4 |

| Electrical conductivity(%IACS) | ≥44 | ≥41 |

| Density | - | 2.74 |

| Melting point | - | 620-640 |

| Thermal conductivity(K/℃*cm*s) | - | 0.46 |

| 20°C Temperature coefficient of electrical resistance I/℃ | - | 0.0042 |

| 20℃ Electrical Resistivity β, Ω mm2/m | - | 0.043 |

Chemical component of Chalco 3003 3A21 aluminum alloy

| Element | Composition (%) | |

| 3003 | 3A21 | |

| Si | 0.6 | 0.6 |

| Fe | 0.7 | 0.7 |

| Cu | 0.05-0.2 | 0.20 |

| Mn | 1.0-1.5 | 1.0-1.6 |

| Mg | - | 0.05 |

| Cr | - | - |

| Ni | - | - |

| Zn | 0.1 | 0.15 |

| Ca | - | - |

| V | - | - |

| Ti | - | 0.10-0.20 |

| Other | 0.15 | 0.15 |

| Min.A1 | Remainder | Remainder |

Advantage of Chalco 3003 3A21 aluminum tube pipe

Advantages of 3003 aluminum tube pipe

- It exhibits outstanding resistance to corrosion, suitable for various environmental conditions.

- It is easily weldable, suitable for various welding processes such as TIG welding, MIG welding, etc.

- The surface is easy to treat, allowing for enhancements in aesthetics and durability through processes like painting and anodizing.

- It possesses high strength and good ductility, suitable for various fabrication methods such as extrusion, welding, and cutting.

Advantages of Chalco 3003 3A21 aluminum tubular busbar

- Good conductivity;

- Good corrosion resistance, more reliable for use in humid environments or corrosive conditions;

- Compared to copper products, 3003 and 3A21 aluminum alloys have lower costs.

Cooperative field of Chalco 3003 3A21 aluminum tube pipe

3003 aluminum tube is widely used in various applications such as food container manufacturing, kitchen utensils, decorative materials, automotive components, and gas containers. Known for its excellent corrosion resistance and weldability, it can be easily treated on the surface for enhanced aesthetics and durability through processes like painting and anodizing. Its high strength and ductility make it suitable for various fabrication methods including extrusion, welding, and cutting.Quick QuoteApplication of Chalco 3003 aluminum EC tubular bus bar

- Aluminum alloy extruded pipes for high-frequency conductivity in power plants;

- Current conductors in power construction projects;

- The conductor connection between the power grid transmission conductor and the substation;

- Jumpers in transmission lines;

- High current DC ice melting device;

- Power transmission and distribution system;

- Power capacitors, battery packs, etc.

Why choose Chalco 3003 aluminum tubular pipe

Chalco aluminum conductive bus pipes are produced by using the technology of casting hollow core billet + three roll rolling + cold stretching. The products have uniform and stable mechanical and electrical properties in both length and cross-sectional directions;

Chalco conductive aluminum tube products use independently developed rare earth and heat-resistant aluminum alloy materials, which have excellent processing, welding, conductivity, and heat resistance properties;

Chalco other hot selling aluminum tube products

6061 Aluminum Tube for Bicycle

AMS 6061 Aluminum Tube

3003 Aluminum Tube

5083 Aluminum Tube

2024 Aluminum Tube

2219 Aluminum Tube

Cold Drawn Aluminum Tubing

Large Diameter Aluminum Pipe

SCH40/SCH80 Aluminum Tube

More electrical aluminum products in Chalco

- EC Grade aluminum wire rod

- Conductive aluminum busbar

- Electrical aluminum tubular bus pipe

- Aluminum plate strip foil for capacitor

- Aluminum wire for electrical application

Size and deviation table of Chalco 3003 3A21 aluminum tubular busbar

| Size table reference table | ||||

|

SCH 40 Nominal size (in.) |

Outside diameter of tube (in.) |

Wall Thickness (in.) |

Area (sq. in.) |

Weight (lb/ft) |

| 1 | 1.315 | 0.133 | 0.4939 | 0.581 |

| 1.25 | 1.66 | 0.14 | 0.6685 | 0.786 |

| 1.5 | 1.9 | 0.145 | 0.7995 | 0.94 |

| 2 | 2.375 | 0.154 | 1.075 | 1.264 |

| 2.5 | 2.875 | 0.203 | 1.704 | 2.004 |

| 3 | 3.5 | 0.216 | 2.228 | 2.621 |

| 3.5 | 4 | 0.226 | 2.68 | 3.151 |

| 4 | 4.5 | 0.237 | 3.174 | 3.733 |

| 5 | 5.563 | 0.258 | 4.3 | 5.057 |

| 6 | 6.625 | 0.28 | 5.581 | 6.564 |

| 8 | 8.625 | 0.322 | 8.399 | 9.879 |

|

SCH 80 Nominal size (in.) |

Outside diameter of tube (in.) |

Wall Thickness (in.) |

Area (sq. in.) |

Weight (lb/ft) |

| 1 | 1.315 | 0.179 | 0.6388 | 0.751 |

| 1.25 | 1.66 | 0.191 | 0.8815 | 1.037 |

| 1.5 | 1.9 | 0.2 | 1.068 | 1.256 |

| 2 | 2.375 | 0.218 | 1.477 | 1.737 |

| 2.5 | 2.875 | 0.276 | 2.254 | 2.65 |

| 3 | 3.5 | 0.3 | 3.016 | 3.547 |

| 3.5 | 4 | 0.318 | 3.678 | 4.326 |

| 4 | 4.5 | 0.337 | 4.407 | 5.183 |

| 5 | 5.563 | 0.375 | 6.112 | 7.188 |

| 6 | 6.625 | 0.432 | 8.405 | 9.884 |

| 8 | 8.625 | 0.5 | 12.763 | 15.009 |

| Wall thickness deviation | ||||||||

| Nominal wall thickness | 3-5 | >5 -8 | >8-10 | >10-12 | >12-15 | >15 -20 | ||

| Ordinary level | Average & nominal wall thickness | ±0.30 | ±0.50 | ±0.70 | ±0.9 | ±1.10 | ±1.3 | |

| Any & nominal wall thickness | H14 | ±0.40 | ±0.60 | ±0.90 | ±1.10 | ±1.3 | ±1.6 | |

| T5A, T6, T10 | ±12% of the specified wall thickness, maximum value is 1.90 | |||||||

| High precision level | Average & nominal wall thickness | ±0.15 | ±0.20 | ±0.38 | ±0.50 | ±0.70 | ±1.00 | |

| Any & nominal wall thickness | H14 | ±0.2 | ±0.3 | ±0.5 | ±0.76 | ±1.00 | ±1.4 | |

| T5A, T6, T10 | ±10% of the specified wall thickness, maximum value is 1.70 | |||||||

| Outer diameter deviation | |||

| Nominal OD | Ordinary level | ||

| Average & Nominal outer diameter | Any & Nominal outer diameter | ||

| H14 | T5A, T6, T10 | ||

| 50.00 - 80.00 | ±0.24 | ±0.30 | ±0.45 |

| > 80.00- 120.00 | ±0.35 | ±0.40 | ±0.62 |

| >120.00-150.00 | ±0.45 | ±0.50 | ±0.75 |

| >150.00 - 200.00 | ±0.65 | ±0.7 | ±1.00 |

| >200.00 - 250.00 | ±0.77 | ± | ±1.2 |

| >250.00 - 300.00 | ±0.96 | ±1 | ±1.5 |

| >300.00 - 350.00 | ±1.3 | ±1.4 | ±1.8 |

| High precision level | |||

| Nominal OD | Average & Nominal outer diameter | Any & Nominal outer diameter | |

| H14 | T5A, T6, T10 | ||

| 50.00 - 80.00 | ±0.15 | ±0.15 | ±0.3 |

| > 80.00-120.00 | ±0.20 | ±0.20 | ±0.41 |

| >120.00-150.00 | ±0.25 | ±0.25 | ±0.5 |

| >150.00-200.00 | ±0.38 | ±0.38 | ±0.76 |

| >200.00-250.00 | ±0.50 | ±0.5 | ±1.00 |

| >250.00-300.00 | ±0.64 | ±0.64 | ±1.25 |

| >300.00-350.00 | ±0.9 | ±0.9 | ±1.6 |