Chalco offers high-performance aluminum alloy thick plates. T6 extruded thick plates can reach up to 400mm in thickness, and T651 stretched thick plates can reach up to 260mm. They are widely applied across various sectors of the national economy, especially in tool and mold manufacturing and aerospace industries. Welcome contact

Chalco's production capacity for aluminum thick plate

Chalco has an advanced 1+4 hot rolling production line, combining the hot roughing mill and hot finishing mill to produce high-quality aluminum alloy plates.

Hot Roughing Mill: Used for reciprocating rolling of heated ingots to achieve the required thickness.

Hot Finishing Mill: Performs continuous rolling to control the final thickness and ensure uniform performance.

These two machines work together to produce aluminum plates with high surface quality, precise thickness, and excellent uniformity.

| Equipment Type | Maximum Rolling Force | Product Specifications | Features |

| Hot Roughing Mill | 8000 kN |

Thickness: 12~250mm Width: 1020~4350mm Length: 1500~38000mm |

Used for reciprocating rolling of heated ingots, equipped with cleaning devices, three-stage emulsion spraying system, and IMS thickness gauge, producing aluminum alloy plates with high surface quality and thickness precision. |

| Hot Finishing Mill | 60000 kN |

Thickness: 2.0~12mm Width: 1000~3100mm |

Equipped with 4 finishing mills and 1 coiler, capable of continuous rolling of rough-rolled intermediate plates to final thickness, featuring tension meters, SmartCrown roll shape, cleaning devices, and automated equipment, producing aluminum alloy strips with high surface quality, excellent shape, and uniform performance. |

Chalco's extensive ready stock for aluminum plate

- Thickness: 12-250mm; usually stretched to 15-170mm; stretching thickness range is broader, allowing for producing thicker strethed plate (T651 temper)

- Hot selling thicknesses: 1/4 inch, 1/2 inch, 1 inch, 3/8 inch, 3/16 inch, 3/4 inch, 1/8 inch, 5/8 inch, 8 inch, 12 inch; 6mm, 8mm, 10mm, 20mm, 25mm

- Width: 1020-4350mm; (4.5m hot rolling mill offers a wider processing range)

| Popular size of 6-12 mm plate | Popular size of 12-260mm plate | ≥260mm ultra thick plate |

|

Width: 2000-2600 Length: 2000-24000 |

Width: 1000-3800 Length: 2000-38000 |

Ultra-thick plates are typically customized, with their width and length adjustable according to specific project requirements. |

| Thickness/mm | Size/mm | ||||||

| 8 | 10 | 12 | 14 | 15 | 16 | 18 |

1250x2500 1500x3000 1520x3020 1525x3660 2000x4000 2400x4000 |

| 20 | 22 | 25 | 28 | 30 | 35 | 40 | |

| 45 | 50 | 55 | 60 | 65 | 70 | 75 | |

| 80 | 85 | 90 | 95 | 100 | 110 | 120 | |

| 130 | 140 | 150 | 160 | 170 | 180 | 190 | |

| 200 | 210 | 220 | 230 | 240 | 250 | 260 | |

Click to view [detailed stock size reference]

Chalco aluminum plate product introduction

Typical alloy: 6061, 6082, 2024, 7075, 7050, 5083, 5052, 3003 etc. Click to [purchase by alloy grade] [check performance reference table]

Temper: T6 T651

Industries Served: Molds and Tools; Aerospace; Military Industry; Vehicle Manufacturing; Vacuum chamber; Shipbuilding; Construction; Storage Tanks;

Click to[Custom aluminum plates based on industry requirements]

Surface treatment: Mill finish, oxidation, embossing, anodizing, etc.

Aluminum cast plate

Thickness: up to 1100mm

Features: High Strength, Excellent Flatness, Good Corrosion Resistance, Machinability.

Chalco's cast plates are known for fine grains, dense structure, stress-free processing, and high dimensional stability.

Contact us now

Aluminum Cast Plate is a high-strength aluminum product made through a casting process. This type of plate offers excellent dimensional stability and is known for its uniform thickness, making it ideal for precision machining applications.

| Thickness/mm | |||

| 100 | 150 | 200 | 250 |

| 300 | 350 | 400 | 450 |

| 500 | 550 | 600 | Can be customized |

- Manufacturing: Commonly used as tooling plates and in machining setups.

- Aerospace: Used in components that require lightweight yet strong materials.

- Transportation: Ideal for parts in automotive and railway industries.

Aluminum forged plates

Thickness: 12 inches (300 mm) or more, depending on the specific alloy and manufacturer.

Features: High Strength, Improved Fatigue Resistance, Good Machinability, Dimensional Stability.

Produced through high-temperature forging, ensuring excellent mechanical properties.

Contact us now

Aluminum Forged Plate is produced through a forging process that enhances its mechanical properties and strength. These plates are commonly used in demanding applications due to their excellent performance characteristics. Suitable for manufacturing high-strength structural components and critical parts.

| Thickness/mm | Size/mm | ||||||

| 250 | 260 | 270 | 280 | 290 | 300 | 310 |

1520*2500 1520*3020 |

| 320 | 330 | 340 | 350 | 370 | 380 | 390 | |

| 400 | 410 | 420 | 430 | 440 | 450 | 460 | |

| 470 | 480 | 490 | 500 | 510 | 520 | 530 | |

| 540 | 550 | 560 | 570 | 580 | 590 | 600 | |

- Aerospace: Used in critical components like wing structures, fuselage parts, and landing gear due to their high strength-to-weight ratio.

- Marine: Commonly found in shipbuilding for structural components that require durability.

- Automotive: Used in high-performance vehicles for parts that must withstand extreme conditions.

- Heavy Machinery: Suitable for components in industrial equipment and machinery that require high load-bearing capacity.

Aluminum hot rolled plates

Thickness: doesn't exceed 180 mm, with widths up to 5400 mm

Commonly, widths for thick plates are under 3500 mm. Current trends favor practical dimensions over maximum size due to advancements in aluminum alloy welding technology.

Contact us now

Aluminum Rolled Plate is produced by passing aluminum alloy through rollers to achieve the desired thickness and surface finish. This manufacturing process is widely used for creating flat sheets and plates.

| Alloy | Temper | Dimension(mm) | Executive Standard | ||

| Thickness | Width | Length | |||

| Series 1, 3, 8 | O, F, H111, H112, H12, H14, H16, H18, H19, H22, H24, H26 |

4.1~12.0 12.1~20 21~200 |

500~1500 | 500~4000 |

ASTM B209 ASME SB-209 EN 485 YS/T91 GB/T3880 |

| 1000~2650 | 2000~10000 | ||||

| 1000~3800 | 2000~20000 | ||||

| Series 5 | O, F, H111, H112, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H116, H321 |

4.1~12.0 12.1~20 21~200 |

1000~2650 1000~3800 |

2000~20000 |

ASTMB209 ASME SB-209 EN485 ASTMB928M GB/T3880 GJB1541 GJB2662 |

| Series 2, 6, 7 | O, F, H111, H112, T3, T4, T6, T7 | 4.0 ~12.0 |

1000~1500 1000~2650 |

2000~10000 |

ASTM B209 ASME SB-209 EN 485 GB/T3880 GJB1541 GB/T167 GJB2053 GJB2662 |

|

12~20 21~200 |

1000~3800 | 2000~20000 | |||

| T351, T451, T651, T851, T7451, T74, T87 | 5.0~12.0 | 1000~2650 | 2000~10000 | GJB1741 | |

| 12~20 | 1000~3800 | 2000~20000 | |||

Aluminum extruded plates

Thickness: reach 400 mm.

Features: Uniform Thickness, Versatility, Good Strength-to-Weight Ratio, Easily Machinable.

Contact us now

Aluminum Extruded Plate is created through the extrusion process, where aluminum alloy is forced through a shaped die to produce plates with uniform thickness and specific profiles. Chalco's extruded plates are known for high strength, corrosion resistance, and good machinability. Widely used in automotive, aerospace, construction, electronics, and marine.

- Aerospace: Used for aircraft components, including skin panels and structural elements.

- Automotive: Commonly found in vehicle body parts and chassis components.

- Construction: Utilized in building frames, windows, and architectural elements.

- Marine: Employed in boat manufacturing for hulls and structural supports.

Large, high-strength quenched plate

Using the largest stretching machine (with a correction capacity of 5600 tons) to homogenize residual stress (minimizing machining strain after cutting).

Contact us now

Quenched materials demonstrate outstanding quality through production technologies developed for manufacturing aircraft materials for companies like Boeing; alloys can be selected based on different applications. Surface protective films can be applied.

- The 2000 series offers excellent heat resistance, suitable for structural components exposed to heat.

- The 6000 series is suitable for structural components and products requiring thermal conductivity.

- The 7000 series provides strength comparable to steel, ideal for products needing exceptional machinability.

- Marine: Employed in boat manufacturing for hulls and structural supports.

Aluminum stretching plates

Thickness: maximum thickness of up to 260mm.

Chalco offers hot-selling alloys like 6061, 7075 in T651 condition for stress-relieved stretched thick plates and the aluminum plates are stress-free after stretching.

Contact us now

Aluminum Stretching Plate is produced through a stretching process that enhances its mechanical properties and surface quality. This process involves stretching the aluminum sheet to improve strength and reduce residual stresses.

Aluminum tread checkered plate

Thick aluminum tread checkered plates are typically between 6-8mm thick. They are commonly used in applications requiring higher strength and wear resistance. These areas demand materials with superior load-bearing capacity and durability.

Contact us now

Aluminum porous foam plate

Thickness: typically has a thickness range of 10 mm to 100 mm

It is a lightweight, open-cell material designed for applications requiring sound absorption and thermal insulation.

Contact us now

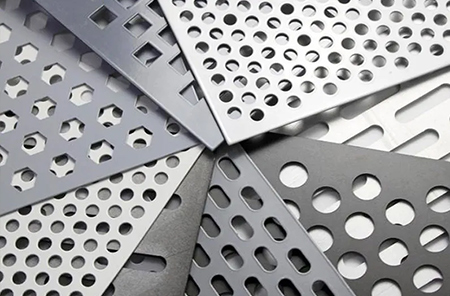

Aluminum perforated plate

Thickness: generally around 10mm.

The plate allows for various applications while maintaining strength and durability.

Contact us now

Chalco's aluminum plate hot selling aluminum alloy series

In principle, any wrought aluminum alloy can be used to produce thick plates or heavy gauge plate, but in practice, there are fewer than 20 alloys used. Here are some of Chalco's hot-selling alloy products. You can visit our homepage to view our complete inventory of aluminum alloy thick plates or contact us through the website for further inquiries. We are committed to providing you with the products you need.

| Typical Alloy | Standard | Product Specifications (mm) | Purpose |

| 2024-T351 | AMS 4037 | 12.67-101.6 × 1020-4350 × 1500-38000 | Aircraft main structural components, lower wing skins, frames |

| 7075-T651 | AMS 4045 | 12.67-101.6 × 1020-4350 × 1500-38000 | Aircraft central wing structural components, etc. |

| 7050-T7451 | AMS 4050 | 12-127 × 1020-4350 × 1500-38000 | Aircraft thick interface structural components |

| 7055-T7751 | AMS 4206 | 12.7-38.1 × 1020-4350 × 1500-38000 | Aircraft upper wing structures, horizontal tail, wing beams, and stringers |

| 6061-T651 | ASTM B209 | 12250 × 1020-4350 × 1500-38000 | Aircraft components, camera parts, couplings, ship fittings, hardware, electronic products |

| 7075-T651, 2A12-T351 | GB/T 29503 | 12-250 × 1020-4350 × 1500-38000 | Civil engineering thick plates, molds, tooling, instruments |

| 6082-T651 | GB/T 29503 | 12-250 × 1020-4350 × 1500-38000 | Mechanical parts, tools, heavy vehicles, railway structures, ships, etc. |

| 5754-0, 5754-F, 5083-0 | ASTM B209, EN485, ASTM B928/B928M | 12-250 × 1020-4350 × 1500-38000 | Containers, pressure vessels, road and rail vehicles, ships, offshore platforms, etc. |

6061 aluminum plate Quick Quote

6061 aluminum thick plate is a widely used heat-treatable alloy known for its excellent machinability and weldability. This thick plate is commonly found in aerospace, shipbuilding, automotive components, mold manufacturing, and architectural structures. It is characterized by high strength, good corrosion resistance, and a wide range of applications.

6082 aluminum plate Quick Quote

A medium-strength alloy prized for its weldability, corrosion resistance, excellent machinability, and cutting and grinding capabilities. Used in aerospace, transportation, mold manufacturing, and mechanical equipment industries, it's also crucial in shipbuilding, bridge construction, and automotive manufacturing.

7075 aluminum plate Quick Quote

The pinnacle member of the 7000 series, offering strength comparable to steel. In T651 temper, it exhibits good fatigue strength and machinability, serving as a substitute for 2000 series alloys. Widely used in the aerospace industry for aircraft and missile components, it also finds application as mold material, particularly in the plastics industry.

7050 aluminum plate Quick Quote

Ideal for aerospace applications, it maintains high strength in thick sections with low sensitivity to quenching. Known for excellent resistance to stress corrosion cracking and fracture toughness, thick plates are used in fuselage frames, primary load-bearing structures, and wing skins, typically ranging from 50.8 to 152.40 millimeters (2 to 6 inches) in thickness.

2024 aluminum plate Quick Quote

Made from aluminum-copper alloy, 2024 is renowned as one of the strongest aluminum alloys, known for its excellent fatigue resistance. 2024 aluminum alloy thick plates are primarily used in the aircraft industry, truck wheels, mechanical components, and fastener manufacturing.

2219 aluminum plate Quick Quote

It is a high-strength aluminum alloy with good weldability and corrosion resistance, commonly used in the aerospace and maritime industries. Thick plates are used to manufacture aerospace components, high-pressure vessels, ship structural parts, and hydraulic systems that operate under high temperature and pressure conditions.

5083 aluminum plate Quick Quote

5083 aluminum thick plate can be hardened by cold working. Due to its excellent resistance to comprehensive corrosion, it is commonly used in marine applications and maintains good performance at extremely low temperatures. Due to its high strength coefficient, 5083 aluminum alloy thick plate has been widely used in vehicle armor plates.

5052 aluminum plate Quick Quote

It has good machinability, moderate static strength, high fatigue strength, good weldability and excellent corrosion resistance, and performs well in marine atmospheres. Thick plates are used for interior and exterior body panels in food processing equipment, ship hulls, pressure vessels, construction and the automotive industry.

3003 aluminum plate Quick Quote

Lightweight and moderately strong, suitable for making stamping parts. Excellent weldability, machinability and corrosion resistance, suitable for finishing reactions such as lamination or anodizing. Thick plates are often used in truck beds, buildings, pressure vessels, etc.

Chalco aluminum plate service areas

Aluminum alloy thick plates have a wide range of applications. Chalco aluminum alloy thick plates mainly serve the fields of tooling manufacturing, aerospace, automobiles, ships and ships, and chemical industry.Quick Quote

- Aluminum plates (generally ≤15 mm) for welded containers in the petrochemical industry are mostly 1000 series and 3000 series alloys;

- Aluminum plates for the aerospace industry are mainly 2000 series and 7000 series alloys;

- Plates for shipbuilding and transportation industries are often 5000 series and 6000 series alloys;

- The tooling industry mostly uses 2000, 5000, 6000, and 7000 series alloys;

- The oxygen production industry also uses 4000 series alloys.

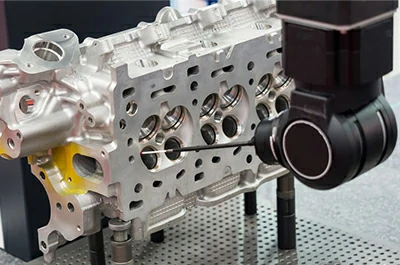

Aluminum cast plate for tool & mold

Cast extra-thick plate or block, especially 7075 aluminum alloy, offer cost savings of at least 35% compared to steel molds when used for making plastic molds and machining tools.

Thick plate for aerospace and military

Typical alloys: 2024, 6061, 7050, 7075, 7475

45% of aluminum thick plates are used in aerospace, armored vehicles, tanks, and weapons, alloys like 2024, 7075, 7050, 7055, 2219; armored vehicles and tanks use 5083.

Thick aluminum plate for automobiles

Thick aluminum plates are favored in specialized vehicles such as money transporters, automatic dump trucks, and tank trucks. Dump trucks typically use 5083 for side panels (9-10mm thick) and bottom plates (12-18mm).

Thick aluminum plate for marine

Typical alloys: 5086, 5083, 6061

5000 series alloys are widely used for ship and warship. These plates typically range from 6mm to over 100mm thick, although quantities are limited. Widths generally span from 1000mm to 5000mm, or 3000mm.

Aluminum plate for chemical container

Typical alloys: 5083

Aluminum alloys are ideal for LNG and liquid oxygen containers, mostly in 5000 series. Above-ground natural gas storage tanks use 5083 (6-70mm thick), and underground tank covers 5083 (5-10mm thick).

Chalco-high quality aluminum thick plate manufacturer and supplier

- Chalco has advanced aluminum alloy thick plate production technology, and is constantly innovating in machine introduction and production technology. It has 10 production lines of casting and rolling, 1+2 hot rolling production lines, 6 production lines of 2450mm\2050mm\1650mm\1450mm cold rolling, 2 production lines of 1850mm continuous rolling, 1 quenching furnace and 1 tension pre-stretching machine. In terms of rolling speed and rolling width, we also have presses, double-sided milling, cutting machines, coilers, grinders, lathes, casting wells, annealing furnaces, smelting furnaces, etc. It can independently complete the production and supply of aluminum alloy thick plates.

- Chalco aluminum alloy thick plates are available in two types: Mill Finish and Polished Surface. The surface of the aluminum plate is coated with film and marked, and desiccant is placed in the packaging. The outer packaging includes kraft paper, plastic paper, and cardboard, which are then fixed to the wooden pallet with steel belts, and corner cardboard is placed under the steel belt at each corner to protect the plate.

- Chalco's quality assurance system has obtained ISO 9001:2008 certificate. The properties, chemical composition and tolerance of aluminum are monitored using computerized chemical analyzers and other mechanical properties through the most advanced quality control equipment and technology in accordance with AA standard specifications.

- We provide sample testing before mass production and product quality testing before production delivery. Strictly control product quality at every stage to ensure the interests of every customer are protected.

Qulity control of Chalco aluminum thick plate-Strict and diverse quality inspections

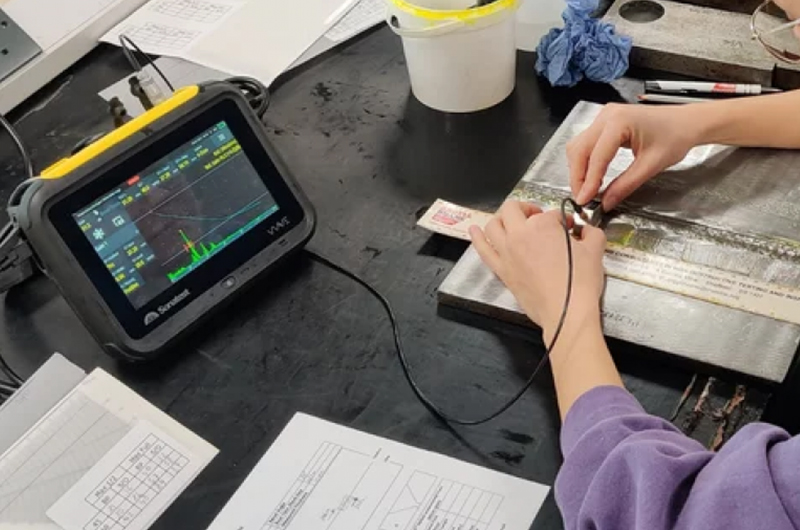

- Ultrasonic testing: Using ultrasonic technology to deeply detect internal defects to ensure the consistency and integrity of the material.

- Metallographic Microscope Inspection: Use high-powered microscopes to analyze the microstructure of the material and evaluate the manufacturing quality of the aluminum plate.

- Radiographic testing: Radiographic imaging is used to detect internal defects and ensure the integrity of the product without damage.

- Ultrasonic Thickness Gauge Inspection: Accurately measure the thickness of aluminum plates to ensure that they meet customer specifications.

- Chemical analysis instrument inspection: Detailed analysis of the chemical composition of the material to ensure compliance with industry standards and customer requirements.

Chalco aluminum alloy detailed performance reference table

| Chemical conponents | |||||||||

| Alloy | 6061 | 6082 | 7075 | 7050 | 2024 | 2219 | 5083 | 5052 | 3003 |

| Si | 0.40-0.8 | 0.7-1.3 | 0.4 | 0.2 | 0.5 | 0.2 | 0.4 | 0.25 | 0.6 |

| Fe | 0.7 | 0.5 | 0.5 | 0.3 | 0.5 | 0.3 | 0.4 | 0.4 | 0.7 |

| Cu | 0.15-0.40 | 0.1 | 1.2-2.0 | 1.50-2.60 | 3.8-4.9 | 5.8-6.8 | 0.1 | 0.1 | 0.05-0.20 |

| Mn | 0.15 | 0.40-1.0 | 0.3 | 0.15 | 0.30-0.9 | 0.20-0.40 | 0.40-1.0 | 0.1 | 1.0-1.5 |

| Mg | 0.6-1.2 | 0.6-1.2 | 2.1-2.9 | 1.80-2.60 | 1.2-1.8 | 0.02 | 4.0-4.9 | 2.2-2.8 | - |

| Cr | 0.04-0.35 | 0.25 | 0.18-0.28 | 0.1 | 0.1 | - | 0.05-0.25 | 0.15-0.35 | - |

| Zn | 0.25 | 0.2 | 5.1-6.1 | 5.70-7.60 | 0.25 | 0.1 | 0.25 | 0.1 | 0.1 |

| Ti | 0.15 | 0.1 | 0.2 | 0.06 | 0.15 | 0.02-0.10 | 0.15 | - | - |

| Al | Re | Re | Re | Re | Re | Re | Re | Re | Re |

| Mechanical property | |||||||

| Alloy | Temper | Thickness | Direction | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A/A50 (%) | Bending Radius |

| Not less than | |||||||

| 6061 | T651 | >6.3~12.5 | LT | 290 | 240 | 10 | |

| >12.5~25 | LT | 290 | 240 | 8 | |||

| >25~50 | LT | 290 | 240 | 7 | |||

| >50~100 | LT | 290 | 240 | 5 | |||

| >100~150 | LT | 275 | 240 | E | |||

| >150~250 | LT | 265 | 230 | 4 | |||

| 7075 | T651 | >12-25 | LT | 540 | 470 | 6 | |

| >25~50 | LT | 530 | 460 | 5 | |||

| >50~60 | LT | 525 | 440 | 4 | |||

| >60~80 | LT | 495 | 420 | 4 | |||

| >80~90 | LT | 490 | 400 | 4 | |||

| >90~100 | LT | 460 | 370 | 2 | |||

| >100~120 | LT | 410 | 300 | 2 | |||

| >120~150 | LT | 360 | 260 | 2 | |||

| >150~200 | LT | 360 | 240 | 2 | |||

| >200~250 | LT | 360 | 220 | 1 | |||

| 2A12 2024 | T351 | >12.5~40 | LT | 430 | 290 | 11 | |

| >40~80 | LT | 420 | 290 | 8 | |||

| >80~100 | LT | 400 | 285 | 7 | |||

| >10~120 | LT | 380 | 270 | 5 | |||

| >120~150 | LT | 360 | 250 | 5 | |||

| 6082 | T651 | >12.5~60 | LT | 295 | 240 | 8 | |

| >60~100 | LT | 295 | 240 | 7 | |||

| >100~150 | LT | 275 | 240 | 6 | |||

| >150~175 | LT | 275 | 230 | 4 | |||

| >175~200 | LT | 260 | 220 | 2 | |||

| 5754 | O | 12.5~100 | L | 190~240 | 80 | 17 | |

| F | >12.5~100 | L | 190 | ||||

| >100~150 | L | 180 | |||||

| 5083 | O | >12.5~50 | L | 270~345 | 115 | 15 | |

| >50~80 | L | 270~345 | 115 | 14 | |||

| >80~120 | L | 260 | 110 | 12 | |||

| >120~200 | L | 255 | 105 | 12 | |||

| >200~250 | L | 250 | 95 | 10 | |||

| 2017A | T451 | ≥6~12.5 | 390 | 260 | 13 | ||

| 6082 | T651 | ≥6~12.5 | 300 | 255 | 9 | ||

| 7075 | 7075-T651 | ≥6~12.5 | 540 | 460 | 8 | ||

| 5052 | H112 | ≥6~12.5 | 190 | 80 | 7 | ||

| 5083 | H111 | ≥6~12.5 | 270~345 | 115 | 16 | ||

| H116/H321 | ≥3~6 | 305 | 215 | 10 | 2.5t | ||

| >6~12.5 | 305 | 215 | 12 | 4.0t | |||

| 5454 | O | ≥3~6 | 215~285 | 85 | 19 | 1.0t | |

| >6~12 | 215-285 | 85 | 19 | 2.0t | |||

| 5182 | O | ≥3~6 | 280 | 125 | 26 | 1.0t | |

| >6~12 | 280 | 125 | 26 | 2.0t | |||

| H111 | ≥3~6 | 280 | 125 | 24 | 1.0t | ||

| >6~12 | 280 | 125 | 24 | 2.0t | |||

| 5083 | O/H111 | ≥3~6 | 290~370 | 145 | 17 | 1.5t | |

| >6~12 | 290~370 | 145 | 17 | 4.0t | |||

Chalco aluminum plate stock size reference table

| Product Name | Thickness mm | Width mm | Length mm |

| 6061-T651-10 | 10 | 1500 | 3000 |

| 6061-T651-10 | 10 | 1497 | 3410 |

| 6061-T651-14 | 14 | 2000 | 4000 |

| 6061-T651-15 | 15 | 2400 | 4000 |

| 6061-T651-16 | 16 | 2400 | 4000 |

| 6061-T651-20 | 20 | 1525 | 3085 |

| 6061-T651-22 | 22 | 2400 | 4000 |

| 6061-T651-25 | 25 | 1615 | 3345 |

| 6061-T651-28 | 28 | 2400 | 4000 |

| 6061-T651-40 | 40 | 1520 | 3020 |

| 6061-T651-65 | 65 | 2400 | 4000 |

| 6061-T651-70 | 70 | 2215 | 2215 |

| 6061-T651-75 | 75 | 2400 | 4000 |

| 6061-T651-80 | 80 | 2240 | 2335 |

| 6061-T651-85 | 85 | 2400 | 4000 |

| 6061-T651-90 | 90 | 2400 | 4000 |

| 6061-T651-100 | 100 | 1465 | 2542 |

| 6061-T651-105 | 105 | 2400 | 4000 |

| 6061-T651-135 | 135 | 2400 | 4000 |

| 6061-T651-145 | 145 | 2000 | 3000 |

| 6061-T651-150 | 150 | 2000 | 3000 |

| 6061-T651-150 | 150 | 2300 | 3000 |

| 6061-T651-155 | 155 | 2000 | 3000 |

| 6061-T651-165 | 165 | 2000 | 3000 |

| 6061-T651-175 | 175 | 2000 | 3000 |

| 6061-T651-180 | 180 | 2000 | 3000 |

| 6061-T651-210 | 210 | 2000 | 3000 |

| 6061-T651-250 | 250 | 2000 | 3000 |

| 6061-T651-260 | 260 | 2000 | 4000 |

| 7075-T651-10 | 10 | 2000 | 4000 |

| 7075-T651-10 | 10 | 1500 | 3000 |

| 7075-T651-10 | 10 | 1525 | 3660 |

| 7075-T651-12 | 12 | 1525 | 3660 |

| 7075-T651-12 | 12 | 2000 | 4000 |

| 7075-T651-12 | 12 | 1500 | 3000 |

| 7075-T651-14 | 14 | 1500 | 3000 |

| 7075-T651-14 | 14 | 2000 | 4000 |

| 7075-T651-14 | 14 | 2000 | 4020 |

| 7075-T651-15 | 15 | 1525 | 3660 |

| 7075-T651-15 | 15 | 2000 | 4000 |

| 7075-T651-15 | 15 | 1500 | 3000 |

| 7075-T651-16 | 16 | 1500 | 3000 |

| 7075-T651-16 | 16 | 2000 | 4000 |

| 7075-T651-16 | 16 | 1305 | 3241 |

| 7075-T651-16 | 16 | 1525 | 3660 |

| 7075-T651-18 | 18 | 1525 | 3660 |

| 7075-T651-18 | 18 | 2000 | 4000 |

| 7075-T651-18 | 18 | 1500 | 3000 |

| 7075-T651-20 | 20 | 2000 | 4000 |

| 7075-T651-22 | 22 | 1500 | 3000 |

| 7075-T651-22 | 22 | 2000 | 4000 |

| 7075-T651-22 | 22 | 1525 | 3660 |

| 7075-T651-25 | 25 | 2000 | 4000 |

| 7075-T651-28 | 28 | 2000 | 4000 |

| 7075-T651-28 | 28 | 1500 | 3000 |

| 7075-T651-28 | 28 | 1600 | 3200 |

| 7075-T651-30 | 30 | 1525 | 3660 |

| 7075-T651-30 | 30 | 2000 | 4000 |

| 7075-T651-30 | 30 | 1800 | 4000 |

| 7075-T651-30 | 30 | 1500 | 3000 |

| 7075-T651-32 | 32 | 2000 | 4000 |

| 7075-T651-32 | 32 | 1500 | 3000 |

| 7075-T651-32 | 32 | 1525 | 3660 |

| 7075-T651-35 | 35 | 2000 | 4000 |

| 7075-T651-40 | 40 | 2000 | 4000 |

| 7075-T651-45 | 45 | 2000 | 4000 |

| 7075-T651-45 | 45 | 1500 | 3000 |

| 7075-T651-45 | 45 | 1525 | 3660 |

| 7075-T651-50 | 50 | 2000 | 4000 |

| 7075-T651-55 | 55 | 1500 | 3000 |

| 7075-T651-55 | 55 | 2000 | 4000 |

| 7075-T651-60 | 60 | 2000 | 4000 |

| 7075-T651-60 | 60 | 1500 | 3000 |

| 7075-T651-60 | 60 | 1525 | 3660 |

| 7075-T651-70 | 70 | 2000 | 4000 |

| 7075-T651-70 | 70 | 1500 | 3000 |

| 7075-T651-75 | 75 | 1500 | 3000 |

| 7075-T651-75 | 75 | 2000 | 4000 |

| 7075-T651-75 | 75 | 1800 | 4000 |

| 7075-T651-80 | 80 | 1500 | 3000 |

| 7075-T651-80 | 80 | 2000 | 4000 |

| 7075-T651-85 | 85 | 1500 | 3000 |

| 7075-T651-85 | 85 | 2000 | 4000 |

| 7075-T651-90 | 90 | 1500 | 3000 |

| 7075-T651-90 | 90 | 2000 | 4000 |

| 7075-T651-95 | 95 | 2000 | 4000 |

| 7075-T651-95 | 95 | 1500 | 3000 |

| 7075-T651-100 | 100 | 2000 | 4000 |

| 7075-T651-100 | 100 | 1500 | 3000 |

| 7075-T651-105 | 105 | 1500 | 3000 |

| 7075-T651-105 | 105 | 2000 | 4000 |

| 7075-T651-110 | 110 | 1500 | 3000 |

| 7075-T651-110 | 110 | 2000 | 4000 |

| 7075-T651-115 | 115 | 1500 | 3000 |

| 7075-T651-115 | 115 | 2000 | 4000 |

| 7075-T651-120 | 120 | 1500 | 3000 |

| 7075-T651-120 | 120 | 2000 | 4000 |

| 7075-T651-125 | 125 | 1500 | 3000 |

| 7075-T651-125 | 125 | 2000 | 4000 |

| 7075-T651-130 | 130 | 1500 | 3000 |

| 7075-T651-130 | 130 | 2000 | 4000 |

| 7075-T651-135 | 135 | 2000 | 4000 |

| 7075-T651-135 | 135 | 1500 | 3000 |

| 7075-T651-140 | 140 | 1500 | 3000 |

| 7075-T651-140 | 140 | 2000 | 4000 |

| 7075-T651-160 | 160 | 1500 | 3000 |

| 7075-T651-170 | 170 | 1500 | 3000 |

| 7075-T651-180 | 180 | 1500 | 3000 |

| 7075-T651-200 | 200 | 1500 | 3000 |

| 7075-T651-210 | 210 | 1500 | 3000 |

| 7075-T651-220 | 220 | 1500 | 3000 |

| 7075-T651-230 | 230 | 1500 | 3000 |

| 7075-T651-240 | 240 | 1500 | 3000 |

| 7075-T651-250 | 250 | 1500 | 3000 |

| 2024-H112 | 8 | 1500 | 3000 |

| 2024-H112 | 8 | 1500 | 2865 |

| 2024-H112 | 10 | 1520 | 4000 |

| 2024-H112 | 10 | 1500 | 3000 |

| 2024-H112 | 15 | 1520 | 4000 |

| 2024-H112 | 20 | 1520 | 4000 |

| 2024-H112 | 20 | 1520 | 3835 |

| 2024-H112 | 25 | 1520 | 4000 |

| 2024-H112 | 30 | 1520 | 4000 |

| 2024-H112 | 35 | 1520 | 4000 |

| 2024-H112 | 40 | 1520 | 4000 |

| 2024-H112 | 45 | 1520 | 4000 |

| 2024-H112 | 45 | 1520 | 3830 |

| 2024-H112 | 50 | 1520 | 4000 |

| 2024-H112 | 55 | 1520 | 4000 |

| 2024-H112 | 60 | 1520 | 4000 |

| 2024-H112 | 65 | 1520 | 4000 |

| 2024-H112 | 70 | 1520 | 4000 |

| 2024-H112 | 75 | 1520 | 4000 |

| 2024-H112 | 80 | 1520 | 4000 |

| 2024-H112 | 90 | 1520 | 4000 |

| 2024 -T4 aluminum plate | 12 | 120 | 135 |

| 2024 -T4 aluminum plate | 14 | 90 | 120 |

| 2024 -T4 aluminum plate | 18 | 242 | 285 |

| 2024 -T4 aluminum plate | 18 | 160 | 160 |

| 2024 -T4 aluminum plate | 18 | 140 | 165 |

| 2024 -T4 aluminum plate | 18 | 80 | 1210 |

| 2024 -T4 aluminum plate | 18 | 70 | 630 |

| 2024 -T4 aluminum plate | 18 | 60 | 140 |

| 2024 -T4 aluminum plate | 18 | 50 | 140 |

| 2024 -T4 aluminum plate | 20 | 69 | 80 |

| 2024 -T4 aluminum plate | 20 | 48 | 240 |

| 2024 -T4 aluminum plate | 20 | 40 | 310 |

| 2024 -T4 aluminum plate | 20 | 38 | 310 |

| 2024 -T4 aluminum plate | 22 | 60 | 648 |

| 2024 -T4 aluminum plate | 25 | 110 | 559 |

| 2024 -T4 aluminum plate | 25 | 99 | 120 |

| 2024 -T4 aluminum plate | 25 | 90 | 315 |

| 2024 -T4 aluminum plate | 25 | 54 | 375 |

| 2024 -T4 aluminum plate | 30 | 155 | 265 |

| 2024 -T4 aluminum plate | 30 | 83 | 170 |

| 2024 -T4 aluminum plate | 30 | 70 | 310 |

| 2024 -T4 aluminum plate | 30 | 60 | 90 |

| 2024 -T4 aluminum plate | 40 | 105 | 130 |

| 2024 -T4 aluminum plate | 50 | 200 | 367 |

| 2024 -T4 aluminum plate | 50 | 198 | 1125 |

| 2024 -T4 aluminum plate | 50 | 138 | 180 |

| 2024 -T4 aluminum plate | 50 | 114 | 180 |

| 2024 -T4 aluminum plate | 50 | 110 | 180 |

| 2024 -T4 aluminum plate | 50 | 110 | 254 |

| 2024 -T4 aluminum plate | 50 | 70 | 105 |

| 2024 -T4 aluminum plate | 55 | 60 | 280 |

| 2024 -T4 aluminum plate | 55 | 58 | 264 |

| 2024 -T4 aluminum plate | 55 | 57 | 190 |

| 2024 -T4 aluminum plate | 60 | 140 | 250 |

| 2024 -T4 aluminum plate | 60 | 90 | 135 |

| 2024 -T4 aluminum plate | 60 | 75 | 85 |

| 2024 -T4 aluminum plate | 60 | 75 | 117 |

| 2024 -T4 aluminum plate | 60 | 72 | 210 |

| 2024 -T4 aluminum plate | 60 | 68 | 220 |

| 2024 -T4 aluminum plate | 65 | 310 | 380 |

| 2024 -T4 aluminum plate | 65 | 170 | 410 |

| 2024 -T4 aluminum plate | 65 | 155 | 265 |

| 2024 -T4 aluminum plate | 65 | 145 | 269 |

| 2024 -T4 aluminum plate | 65 | 128 | 287 |

| 2024 -T4 aluminum plate | 65 | 127 | 140 |

| 2024 -T4 aluminum plate | 65 | 127 | 135 |

| 2024 -T4 aluminum plate | 65 | 110 | 118 |

| 2024 -T4 aluminum plate | 65 | 110 | 270 |

| 2024 -T4 aluminum plate | 75 | 205 | 223 |

| 2024 -T4 aluminum plate | 75 | 147 | 290 |

| 2024 -T4 aluminum plate | 80 | 340 | 2210 |

| 2024 -T4 aluminum plate | 80 | 340 | 3000 |

| 2024 -T4 aluminum plate | 80 | 195 | 325 |

| 2024 -T4 aluminum plate | 80 | 180 | 200 |

| 2024 -T4 aluminum plate | 80 | 145 | 155 |

| 2024 -T4 aluminum plate | 80 | 135 | 345 |

| 2024 -T4 aluminum plate | 80 | 128 | 1335 |

| 2024 -T4 aluminum plate | 80 | 110 | 250 |

| 2024 -T4 aluminum plate | 80 | 100 | 520 |

| 2024 -T4 aluminum plate | 80 | 98 | 197 |

| 2024 -T4 aluminum plate | 80 | 97 | 510 |

| 2024 -T4 aluminum plate | 80 | 89 | 130 |

| 2024 -T4 aluminum plate | 80 | 78 | 1520 |

| 2024 -T4 aluminum plate | 85 | 80 | 710 |

| 2024 -T4 aluminum plate | 90 | 280 | 460 |

| 2024 -T4 aluminum plate | 90 | 195 | 255 |

| 2024 -T4 aluminum plate | 90 | 160 | 468 |

| 2024 -T4 aluminum plate | 90 | 147 | 160 |

| 2024 -T4 aluminum plate | 90 | 125 | 150 |

| 2024 -T4 aluminum plate | 90 | 120 | 140 |

| 2024 -T4 aluminum plate | 90 | 79 | 1503 |

| 2024 -T4 aluminum plate | 90 | 79 | 1000 |

| 2024 -T4 aluminum plate | 90 | 79 | 340 |

| 2024 -T4 aluminum plate | 100 | 200 | 288 |

| 2024 -T4 aluminum plate | 100 | 180 | 200 |

| 2024 -T4 aluminum plate | 100 | 120 | 177 |

| 2024 -T4 aluminum plate | 100 | 110 | 1200 |

| 2024 -T4 aluminum plate | 100 | 108 | 108 |

| 2024 -T4 aluminum plate | 100 | 100 | 155 |

| 2024 -T4 aluminum plate | 110 | 210 | 1327 |

| 2024 -T4 aluminum plate | 110 | 168 | 1215 |

| 2024 -T4 aluminum plate | 110 | 168 | 2338 |

| 2024 -T4 aluminum plate | 110 | 168 | 3990 |

| 2024 -T4 aluminum plate | 120 | 120 | 3000 |

| 2024 -T4 aluminum plate | 120 | 105 | 240 |

| 2024 -T4 aluminum plate | 140 | 285 | 285 |

| 2024 -T4 aluminum plate | 140 | 275 | 285 |