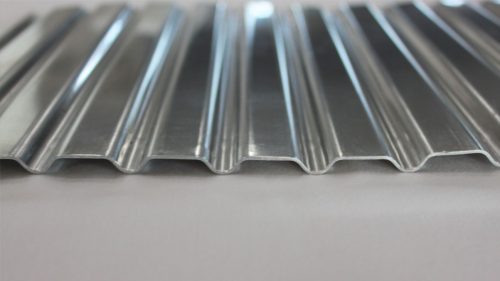

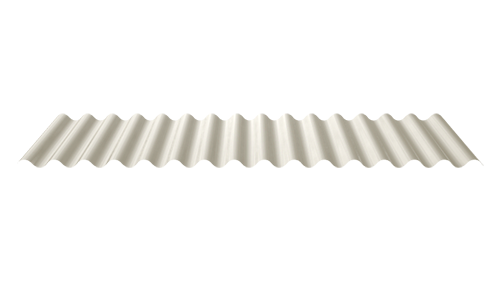

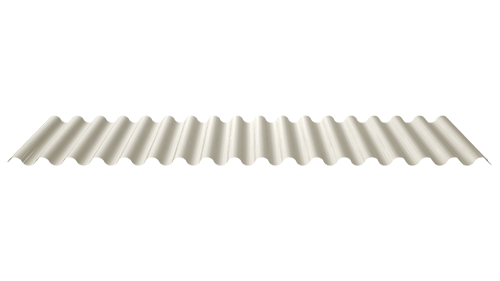

Corrugated aluminum is a panel that has a wavy and rounded appearance. It is used in roofing, fencing and siding applications.Corrugated aluminum siding and roofing panels are lightweight and corrosion-resistant. Aluminum is a better choice than metal in climates with high rainfall or in coastal areas.Quick Quote

Why choose Chalco

Chalco is strictly controlled, with good weldability, strong corrosion resistance, bending resistance and compression resistance. The surface is smooth and clean when cut, and the surface treatment can present a rich choice of colors and textures.

Chalco is the source manufacturer of aluminum corrugated sheets with complete equipment and various specifications. Can be measured according to the required standard, customized cutting.We can fabricate, bend, shape, cut, shear, tear materials into any shape, size.Quick Quote

Chalco has a complete management system, accurate dimensions, and production standards comply with GB/T 3880-2005, B209-2020, JC/T 1074-2012, ASTM A1196-2020, ISO 9001, CE, SGS.

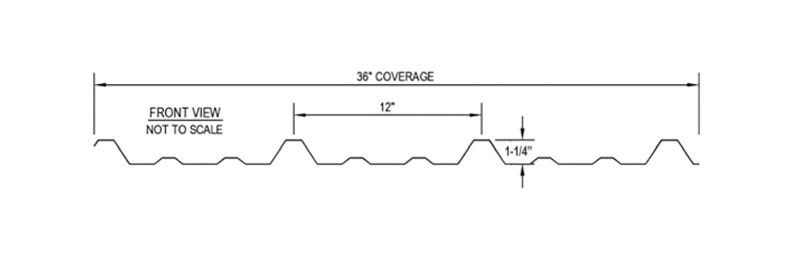

Roof Aluminum Corrugated Metal Specifications

| Alloy | 1050 1060 1100 3003 5005 5052 6061 6063 |

| Temper | O, H12, H22, H14, H24, H16, H26, H18, H32 |

| Thickness | 0.2-6.0mm |

| Width | 200-2650mm |

| Length | 1-10mm |

| Wave height | 17-18 mm |

| Coating | Galvanized, color coated |

| Standard | GB/T 3880-2005, B209-2020, JC/T 1074-2012, ASTM A1196-2020, ISO 9001, CE, SGS |

| Remark | Specifications can be customized |

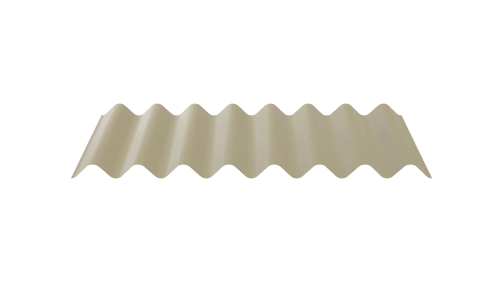

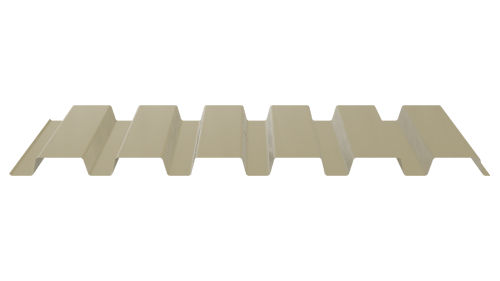

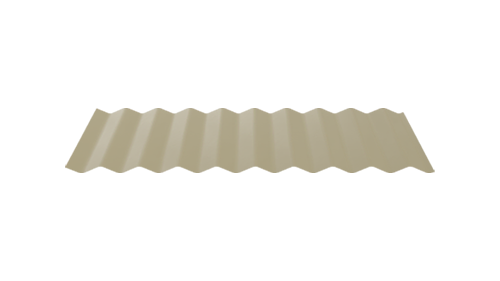

Popular aluminum corrugated panels

metal surface

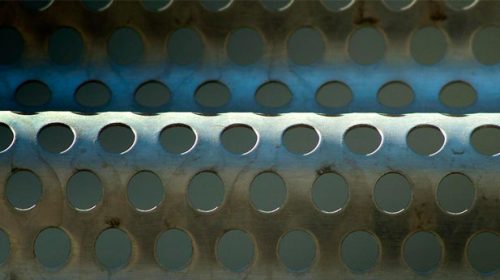

PERFORATED METAL

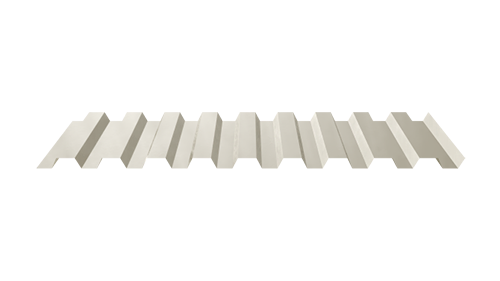

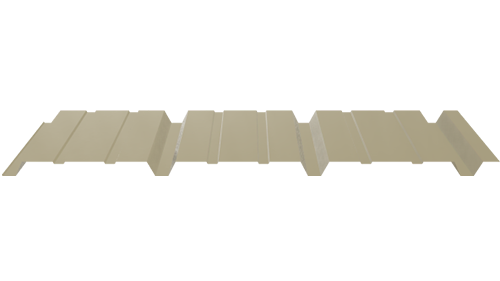

4″ BOX RIB

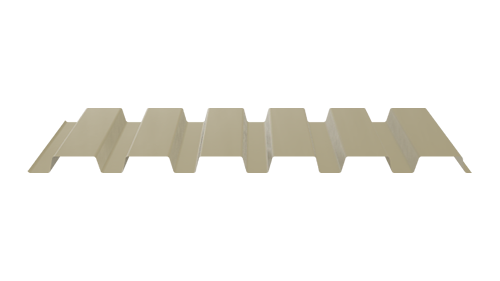

6″ BOX RIB

8″ BOX RIB

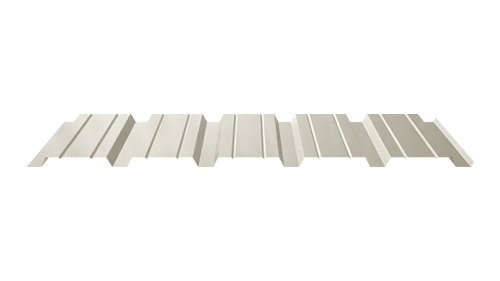

R-PANEL

HARVEST PANEL

2.67″ X 3/4″

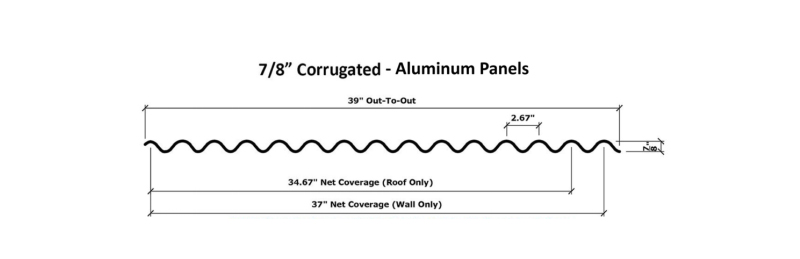

2.67″ X 7/8″

3″ X 1″

B-DECK

2.67″ X 1/2″

Roof Aluminum Corrugated Metal colors are available in two color charts

Standard Colors: These colors are in stock and available for quick delivery. There is no minimum order quantity.

Special order colors: Please allow 3-4 weeks for delivery.Quick Quote

Charcoal Gray

Dark Bronze

Matte Black

Regal White

Almond

Aluminum – Mill Finish

Roof Aluminum Corrugated Metal Popular Sizes

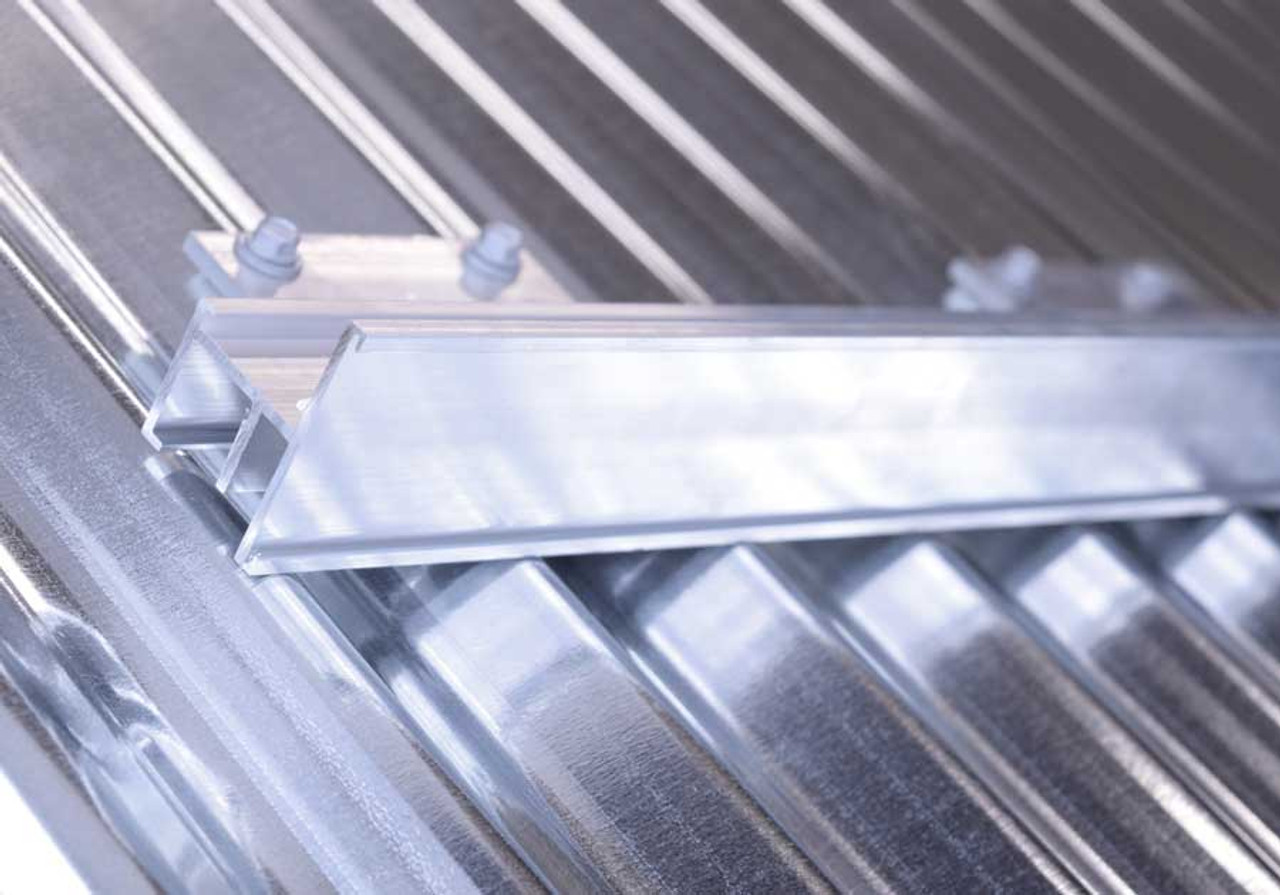

Corrugated aluminum siding and roofing are both exposed fastener panel systems, meaning that each fastener is visible on the panel's surface.Quick Quote

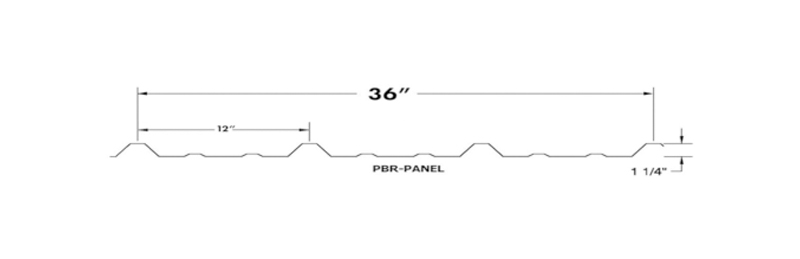

PBR panel aluminum roofing

PBR panel is short for purlin bearing R panel, meaning that the panels have a larger overlap. This creates a better connection and greater weather-tightness.

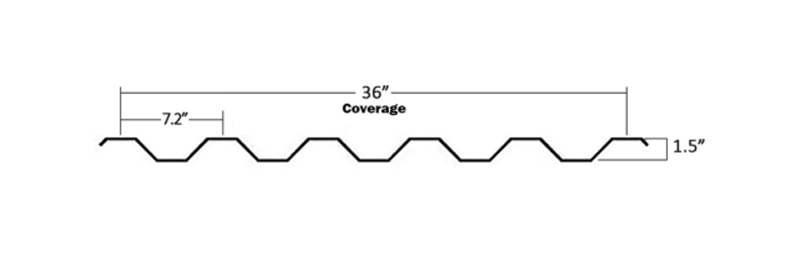

7.2 panel

The 7.2-inch on center spacing between ribs is aesthetically pleasing and offers symmetrical balance to architectural projects.

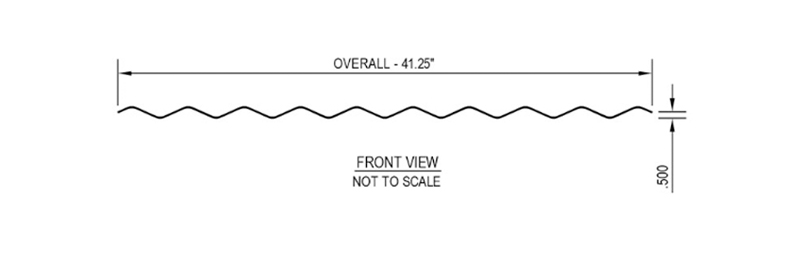

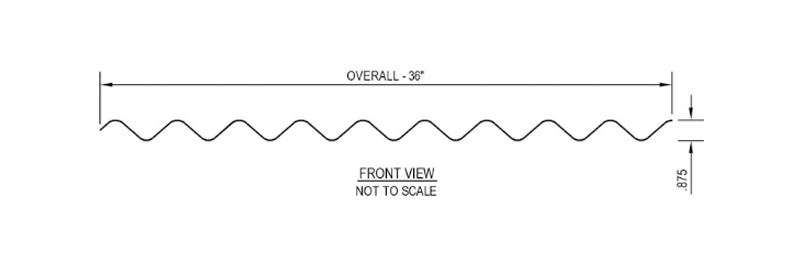

2.67" x 1/2" corrugated

The 2.67" x 1/2" corrugated meets the necessary requirements of durability, economy, and appearance.

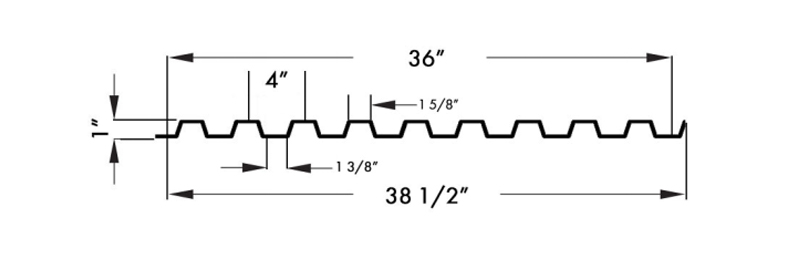

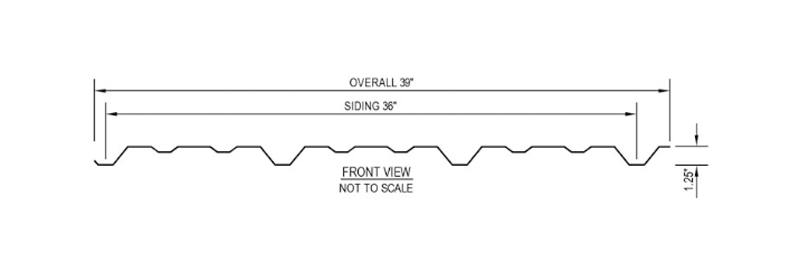

4" box rib

The 4" Rib is an industry standard siding product. The linear rib spacing is aesthetically pleasing.

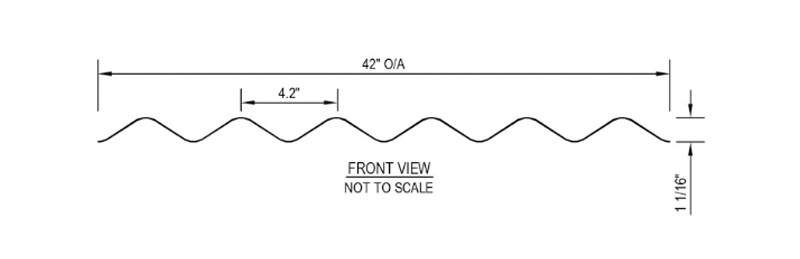

4.2" corrugated panels

As you know, 4.2" pitch panels used to be produced in an asbestos panel and today much of this panel still exists in the industry.

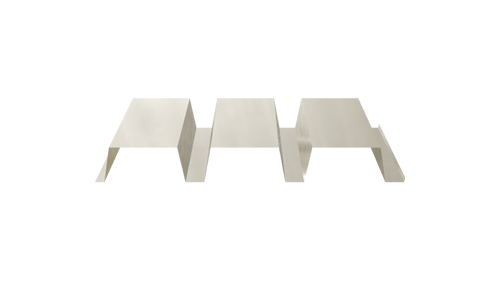

V beam

V-Beam offers superior strength and spanning capability and is used for both siding and roofing applications.

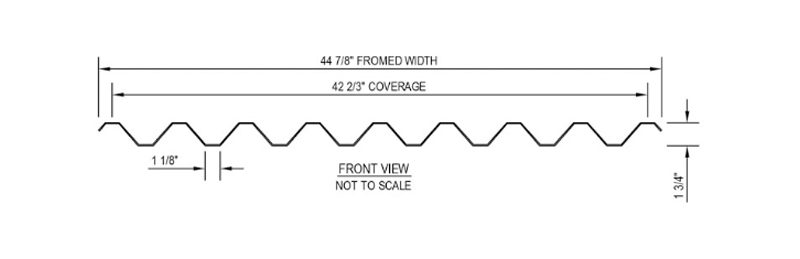

2.7" x 7/8" corrugated panels

The 2.67" x 7/8" Corrugated Panel is a siding product that also has limited applications as a roofing product.

Vertarib panels

Vertarib recessed channel siding panels are available in various stainless steel gauges. Using recessed fasteners, it is a good industrial siding choice for a smooth, flat wall.

12" rib (R Panel)

The 12" Rib Panel is a high strength, deep, wide panel. The R Panel is ideal for roofing and siding applications due to its extreme durability and aesthetically pleasing appearance.

Roof Aluminum Corrugated Metal Common Alloys and Applications

1050 1060 1100 aluminum corrugated sheets

1050 1060 1100 aluminum corrugated sheets are used in a wide range of applications including roof covering, wall decoration, ceiling, partition wall, cabinet surface and furniture making etc.

Because the 1050 1060 1100 aluminum corrugated sheets is made of pure aluminum, it can meet most of the needs if it is used in a general environment, but it is recommended to use 3003 3004 aluminum corrugated sheet in an environment with high acid, alkali and high strength.

3003 3004 aluminum corrugated sheet

3003 3004 aluminum corrugated sheet have excellent corrosion resistance due to the manganese alloy elements, and the strength is about 10% higher than that of 1100 aluminum corrugated sheets, and the formability, weldability will be better.

3003 3004 aluminum corrugated sheets are commonly used in the following applications: building roofs, walls, trim, vehicle shells, containers and containers.

5005 5052 aluminum corrugated sheet

5005 5052 aluminum corrugated sheet has good performance in corrosion resistance, welding, material forming, cold working, anodizing, and has medium strength.

It is suitable for various stamping, bending and other sheet metal processing, and can be oxidized and colored into various bright and bright colors.

Typical applications: ship decoration, curtain wall panels, aluminum furniture, decoration, door head.

6061 6063 aluminum corrugated sheet

6061 6063 aluminum corrugated sheet has excellent weldability, extrudability and electroplating , as well as good corrosion resistance, toughness, and medium strength. Capable of processing complex aluminum corrugated panels.

Application: curtain wall, interior decoration, fence, protective cover.

Corrugated aluminum plate price

The main disadvantage of corrugated aluminum is the price tag. Aluminum costs 20-30% more than corrugated metal.

Roof Aluminum Corrugated Metal How to quote

If you don't see what you want or what's listed doesn't match your current project, please call or email and we can quote exactly what you need.

Of course, if you only need raw materials for aluminum corrugated sheets, we also provide corresponding alloy aluminum sheets.Quick Quote

Aluminum and metal roofs are both popular options, but they each have their own pros and cons

The advantages of aluminum roofs are strong corrosion resistance, light weight, and fast heat dissipation, but the disadvantages are high cost and prone to dents.

The advantages of metal roofs are low cost and high durability, but the disadvantages are poor corrosion resistance, heavy weight, and slow heat dissipation.Quick Quote

Here are some other factors to consider when choosing a roof:

- Climate: If you live in a coastal area, then aluminum roofing is a better choice.

- Budget: If you are on a budget, then metal roofing is a better option.

- Aesthetics: Both aluminum and metal roofs are available in a variety of colors and finishes, so you can choose the option that best suits the look of your home.

- Durability: If you’re worried about dents, a metal roof is a better choice.

- Energy Efficiency: If you want to lower your energy bills, then aluminum roofing is a better choice.