In the aerospace industry, AMS 4006/4008 ALUMINIUM ALLOY 3003 SHEETS PLATES produced according to A93003, AMS 4006, AMS 4008, QQ-A-250/2 etc standards are widely used and are often used to make various parts and structural parts.Welcome contact

Chalco's certification in aerospace field

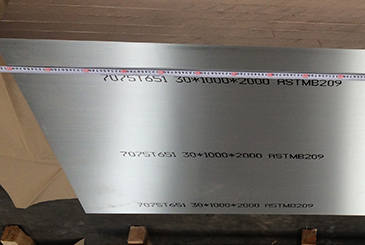

Product specification: A93003, AMS 4006, AMS 4008, QQ-A-250/2, ASTM B 209 etc.

Chalco accreditation: AS9100, OHSAS 18001, ISO14001, ISO9001, NADCAP HT, NADCAP NDT, IATP16949

The certifications specifications of Chalco has provided a strong guarantee for the quality of aerospace materials produced by our company.

The specification introduction of 3003 aircraft aluminum sheet plate

| Hot selling temper | O, H12, H14, H18, H22, H24, H28, H112 | |

| Equivalent name | AW-AlCu4Mg1, 3.0517, A93003, AlCu4Mg, AlCuMg2, ASTM B209 | |

| 3003 aluminum sheets | Thickness:0.01”-0.24”(0.2mm-6mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 aluminum plate | Thickness:0.32”-9.84”(8mm-250mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 Ultra wide aluminum sheet | Thickness:0.01”-0.24”(0.2mm-6mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 color coated aluminum sheet plate | Thickness:0.01”-0.24”(0.2mm-6mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 aluminum diamond plate | Thickness:0.05”0.32”(1.2-8mm) | Width:35.4”-72.83”(900mm-1850mm) |

| Surface treatment | Mill finish, Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

| Lamination type | Blue film, transparent film, black and white film, paper (film thickness: 50 microns, 80 microns) | |

For the detailed stock, please check the size reference list and other size can send email to inquire. [size reference list]

The hot selling products of Chalco 3003 aluminum plate

Aluminium 3003 AMS 4006 3003-T0 sheets plates

AMS 4006 3003-T0 has excellent plasticity, it can be cold-formed, such as stretching, bending, etc., usually used to make parts such as wings and bulwarks.

Contact us now

AMS 4008 aluminium 3003 H14 sheets plates

High strength and hardness, has a certain corrosion resistance, can meet some components with medium strength and corrosion resistance requirements.

Contact us now3003 H24 aerospace aluminum sheet plate

High strength and hardness, can meet the needs of high-speed forming processes, such as stretching, stamping and other processes, and can also maintain stable performance.

Contact us now

3003 H12/H16/H18 aviation aluminum sheet plate

High strength and toughness, it is suitable for some aerospace parts that require high strength and rigidity.

Contact us nowThe chemical composition of 3003 aerospace-grade aluminum plate

| 3003 Alloy % | |

| Si | 0.6 |

| Fe | 0.7 |

| Cu | 0.05-0.20 |

| Mn | 1.0-1.5 |

| Mg | - |

| Cr | - |

| Ni | - |

| Zn | 0.10 |

| Ti | - |

| Al | Remainder |

The mechanical properties of 3003 aircraft aluminum sheet

| Material | Condition | Tensile strength (ksi min) | Yield strength (ksi min) | Elongation % in 2'' 0.064 Sheet |

| Alloy 3003-0 Sheet 0.064'' thick | 3003-0 | 14-19 | 5 | 25 |

| Alloy 3003-H12 Sheet 0.064'' thick | 3003-H12 | 17-23 | 12 | 6 |

| Alloy 3003-H14 Sheet 0.064'' thick | 3003-H14 | 20-26 | 17 | 5 |

| 3003-H16 Sheet 0.064'' thick | 3003-H16 | 24-30 | 21 | 4 |

| 3003- Sheet 0.064'' thick | 3003-H18 | 27 min | 24 | 4 |

Other hot selling aluminum plates in Chalco

2219 aerospace aluminum plate

2024 aerospace aluminum plate

2014 aerospace aluminum plate

2618 aerospace aluminum plate

7050 aerospace aluminum plate

7055 aerospace aluminum plate

7075 aerospace aluminum plate

5086 aerospace aluminum plate

6061 aerospace aluminum plate

Advantages of Chalco aluminium alloy 3003/3003A aviation aluminum plate

Lightweight and high strength: the 3003 aviation aluminum plate is light in weight, much lighter than traditional steel, copper and other metal materials, and has higher strength and rigidity at the same time.

Strong corrosion resistance: the surface of 3003 aviation aluminum sheet plate is smooth, has excellent corrosion resistance, and can be used in complex environments for a long time.

Good weldability: the 3003 aircraft aluminum sheet plate can be processed by various welding processes, and can be welded with other metal materials to be processed into various complex parts.

High plasticity: 3003 aerospace-grade aluminum plate has high plasticity and deformation ability, and can be processed into various shapes of plates by stretching, bending, etc.

Good heat resistance: the 3003 aircraft aluminum sheet has good heat resistance and can be used for a long time in a high temperature environment.

High recyclability: 3003 alloy metal aluminum sheet plate can be recycled and reused, which helps to save resources and protect the environment.

The concrete application of 3003 aircraft aluminum sheet plate

Aircraft skin: the aircraft skin is a metal plate covering the outside of the aircraft, which plays the role of protecting the internal structure of the aircraft, enhancing the strength of the fuselage and reducing wind resistance. 3003 aluminum sheet is often used to make aircraft skins because of its good formability and weldability.

Oxygen cylinders: airplanes need to carry oxygen for passengers and crew to breathe, and oxygen cylinders are an important part of storing oxygen. 3003 aluminum plate is often used to make oxygen cylinders because of its excellent corrosion resistance and reliable sealing performance.

Interior panels: aircraft interior panels refer to various decorative panels installed inside the aircraft, including ceilings, seats, instrument panels, etc. 3003 aluminum sheet is often used to make aircraft interior panels because of its good surface properties and processing properties.

Tire cover: the aircraft needs to use tires during takeoff and landing, and the tire cover is an important part to protect the tire. 3003 aluminum plate is often used to make tire covers because of its high strength and good corrosion resistance.

Key points for purchasing 3003 aviation aluminum sheet

Specifications and dimensions: according to the specific use requirements and application scenarios, select the appropriate specifications and dimensions of the plate to ensure that it can meet the needs.

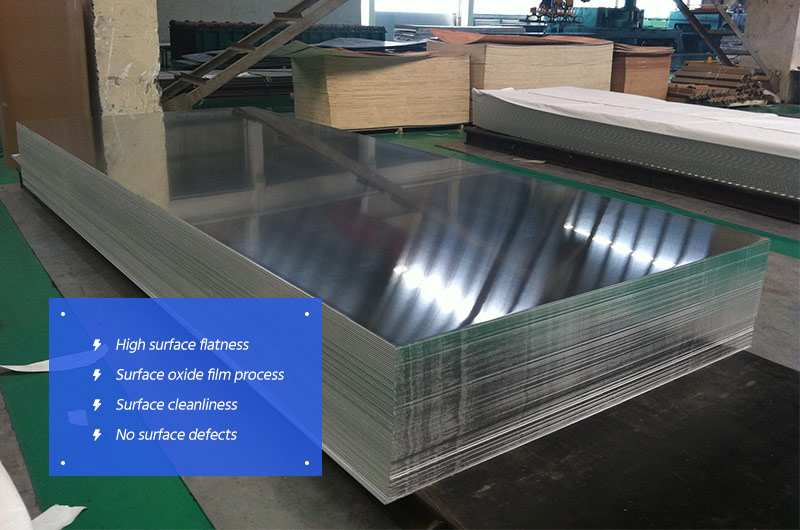

Surface quality: Chalco Aluminum ensures that the surface of the 3003 aviation aluminum plate is smooth and flat, without obvious scratches, dents and other defects.

Chemical composition and performance: Chalco Aluminum ensures that the chemical composition of the EN AW-3003 ALUMINIUM SHEETS PLATES meets the standards, and the performance meets the requirements, such as hardness, strength, corrosion resistance, etc.

Production process and quality certification: Chalco Aluminum is produced in strict accordance with A93003, AMS 4006, AMS 4008, QQ-A-250/2 and other standards to ensure that QQ-A-250/2 3003 ALUMINIUM ALLOY SHEET PLATE meet international standards and industry requirements.

Supplier reputation and service level: Chalco Aluminum is a supplier with a good reputation and good service record, which can ensure you to get high-quality products and timely after-sales service.

Price: considering the cost of 3003 alloy metal aluminum sheet plate, Chalco Aluminum is moderately priced and widely favored by aviation parts manufacturers.

Packaging and shipping: Chalco Aluminum has fully considered the packaging and shipping methods of aluminum sheets to ensure that they will not be damaged during transportation.

Why choose Chalco 3003 aviation aluminum sheet plate?

- Chalco Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

- We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements.

- The R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

- The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.

Chalco hot selling 3003 aluminum plate stock size

| Description | Temper | Thickness/in | Width*Length/in |

| 0.016(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.016 | 48x96 |

| 0.02(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.02 | 48x96 |

| 0.025(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.025 | 48x120 |

| 0.032(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.032 | 48x120 |

| 0.032(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.032 | 48x144 |

| 0.04(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.04 | 48x120 |

| 0.04(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.04 | 48x144 |

| 0.05(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 60x120 | H14 | 0.05 | 60x120 |

| 0.05(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 60x144 | H14 | 0.05 | 60x144 |

| 0.063(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.063 | 48x96 |

| 0.063(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.063 | 48x120 |

| 0.063(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.063 | 48x144 |

| 0.08(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.08 | 48x96 |

| 0.08(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.08 | 48x144 |

| 0.09(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.09 | 48x96 |

| 0.1(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.1 | 48x120 |

| 0.1(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.1 | 48x144 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.125 | 48x96 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.125 | 48x120 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.125 | 48x144 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 36x120 | H14 | 0.125 | 36x120 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 60x144 | H14 | 0.125 | 60x144 |

| 0.19(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x144 | H14 | 0.19 | 48x144 |

| 0.25(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x120 | H14 | 0.25 | 48x120 |

| 0.25(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x144 | H14 | 0.25 | 48x144 |

| 0.32(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x120 | H14 | 0.32 | 48x120 |

| 0.32(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x144 | H14 | 0.32 | 48x144 |

| 0.375(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x120 | H14 | 0.375 | 48x120 |

| 0.04(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.04 | 48x144 |

| 0.09(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.09 | 48x144 |

| 0.05(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.05 | 48x144 |

| 0.63(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.63 | 48x144 |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote