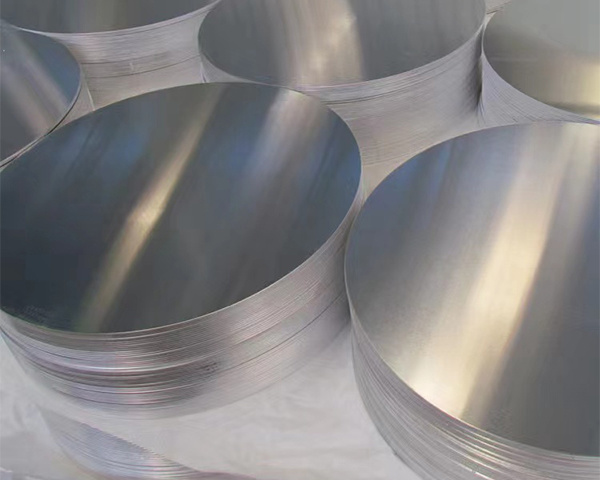

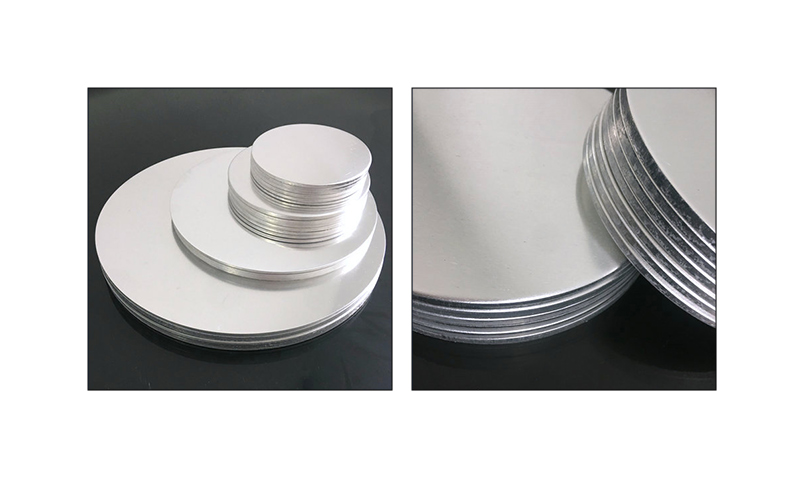

Aluminum circle discs – High-quality, in-stock, and ready to ship. Ideal for deep drawing, spinning, cookware, andlighting.

Thickness 0.3–4mm, diameter 3.94–38.5". Smooth surface, no oil or scratches. Custom sizes and alloys (1060, 1070,3003, 5052) available.

Specification of Chalco aluminum circle discs

Our aluminum circles meet global material standards to ensure stable quality and performance for deep drawing,spinning, and anodizing applications.

- ASTM B209

- AMS-QQ-A-250/11

- EN 485

- GB/T 3880

Our aluminum circles comply with international standards and multiple application certifications, including LFGB andFDA for cookware, RoHS and CE for lighting, and ISO 7599 for anodized signage.

We provide full Mill Test Certificates (MTC) and compliance documentation, welcome factory audits, and offer freesamples for your testing and approval.

Instant QuotePopular aluminum circle discs available from Chalco

As one of the top aluminum circle aluminum discs suppliers, Chalco offers a wide range of high-quality productssourced from overseas stock or made to order.

| Parameter | Description |

| Alloys | 6061, 1050, 1060, 1070, 1100, 3002, 3003, 3004, 5052A, 5052, 5754 |

| Tempers | O, H12, H14, H16, H18 |

| Thickness | Metric: Metric: 0.30–12.0 mmImperial: 0.012"–0.472" (Typical: 0.020"–0.250") |

| Surface Finish | Mill Finish, Bright, Anodizing Quality, PE/PVC Coating, Non-stick Coating |

| Production Method | Direct Casting + Hot RollingContinuous Cast & Roll (10"–60") |

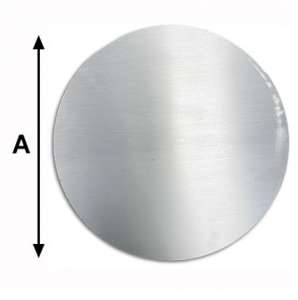

Aluminum Circle Plate

10" - 60" diameter.

Aluminum plate circles are band saw cut circles, they are cut oversized to allow to machine clean up.

Contact us now

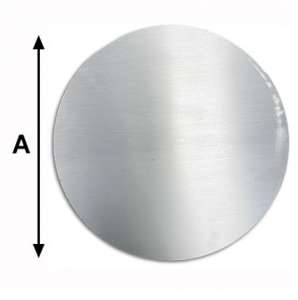

Aluminum Circle Blanks

Aluminum circle blanks are ideal for cookware, lighting, and spinning applications with high purity,smooth surface, and excellent deep drawing performance.

Contact us nowAluminum Disk

Aluminum disk offers smooth surface, accurate dimensions, and excellent formability, perfect forcookware, lighting, and industrial manufacturing needs.

Contact us now

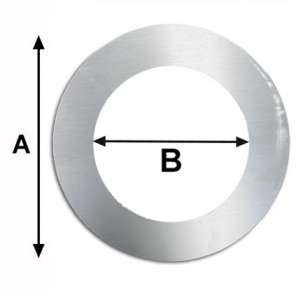

Aluminum Ring

Aluminum ring features precise dimensions and smooth edges, ideal for gaskets, flanges, cookware bases,and industrial components.

Contact us nowAluminum Ovals Plate

Aluminum oval plates offer excellent durability and precision, ideal for automotive, cookware, anddecorative applications.

Contact us now

Aluminum Discs With Center Holes

Aluminum discs with center holes are precision-engineered for applications like lighting, cookware, andindustrial parts that require a ready-to-use mounting point.

Contact us nowWe custom-manufacture aluminum cutting plates in various shapes such as triangles, hexagons, and squares according tocustomer requirements.

1/4" Thick - Aluminum Round Plate

1/2" thick - Aluminum Circle Plate

1/2" thick - Aluminum Ring Plate

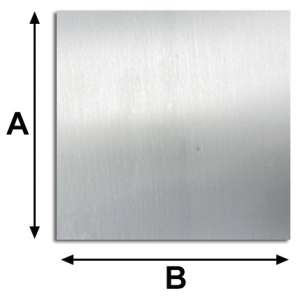

1/2" thick - Aluminum Square Plate

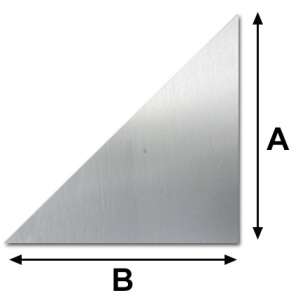

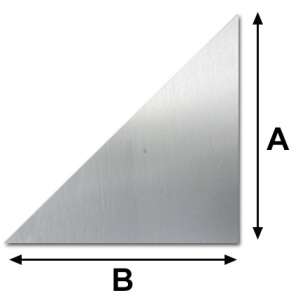

1/8" thick - Aluminum Gusset Plate

1/4" thick - Aluminum Gusset Plate

Explore the versatility of Chalco aluminum circles, offering custom services to meet your specific needs in size andsurface treatment.

Aluminum circles are ideal for cookware, automotive parts, and lighting fixtures. Optional coatings improvedurability and environmental resistance, making them suitable for indoor and outdoor use.

Chalco's stock of aluminum circle disc

We offer custom aluminum circles in decimal and fractional inch sizes, including 0.250" (1/4"), 0.375" (3/8"), 0.500"(1/", 0.750" (3/4"), 1.000" (1"), 1.500" (1 1/2"), 2.000" (2"), and 3.000" (3").

Instant Quote| Description | Alloy | Thickness (in) | Thickness (in) | Diameter (in) |

| .250 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .250 in | 1/4 in | 12.000 in |

| .250 in Thick 3.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .250 in | 1/4 in | 3.000 in |

| .250 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .250 in | 1/4 in | 6.000 in |

| .250 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .250 in | 1/4 in | 8.000 in |

| .250 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .250 in | 1/4 in | 2.000 in |

| .250 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .250 in | 1/4 in | 10.000 in |

| .250 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .250 in | 1/4 in | 4.000 in |

| .375 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .375 in | 3/8 in | 12.000 in |

| .375 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .375 in | 3/8 in | 8.000 in |

| .375 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .375 in | 3/8 in | 6.000 in |

| .375 in Thick 3.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .375 in | 3/8 in | 3.000 in |

| .375 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .375 in | 3/8 in | 4.000 in |

| .375 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .375 in | 3/8 in | 2.000 in |

| .375 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .375 in | 3/8 in | 10.000 in |

| .500 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .500 in | 1/2 in | 2.000 in |

| .500 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .500 in | 1/2 in | 4.000 in |

| .500 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .500 in | 1/2 in | 12.000 in |

| .500 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .500 in | 1/2 in | 6.000 in |

| .500 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .500 in | 1/2 in | 10.000 in |

| .500 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .500 in | 1/2 in | 8.000 in |

| .500 in Thick 3.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .500 in | 1/2 in | 3.000 in |

| .750 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .750 in | 3/4 in | 4.000 in |

| .750 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .750 in | 3/4 in | 6.000 in |

| .750 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .750 in | 3/4 in | 10.000 in |

| .750 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .750 in | 3/4 in | 8.000 in |

| .750 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .750 in | 3/4 in | 2.000 in |

| .750 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .750 in | 3/4 in | 12.000 in |

| .750 in Thick 3.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | .750 in | 3/4 in | 3.000 in |

| 1.000 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.000 in | 1 in | 10.000 in |

| 1.000 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.000 in | 1 in | 6.000 in |

| 1.000 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.000 in | 1 in | 6.000 in |

| 1.000 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.000 in | 1 in | 8.000 in |

| 1.000 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.000 in | 1 in | 12.000 in |

| 1.000 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.000 in | 1 in | 2.000 in |

| 1.000 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.000 in | 1 in | 4.000 in |

| 1.500 in Thick 3.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.500 in | 1 1/2 in | 3.000 in |

| 1.500 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.500 in | 1 1/2 in | 4.000 in |

| 1.500 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.500 in | 1 1/2 in | 2.000 in |

| 1.500 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.500 in | 1 1/2 in | 12.000 in |

| 1.500 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.500 in | 1 1/2 in | 6.000 in |

| 1.500 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.500 in | 1 1/2 in | 8.000 in |

| 1.500 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 1.500 in | 1 1/2 in | 10.000 in |

| 2.000 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 2.000 in | 2 in | 10.000 in |

| 2.000 in Thick 3.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 2.000 in | 2 in | 3.000 in |

| 2.000 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 2.000 in | 2 in | 6.000 in |

| 2.000 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 2.000 in | 2 in | 2.000 in |

| 2.000 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 2.000 in | 2 in | 8.000 in |

| 2.000 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 2.000 in | 2 in | 12.000 in |

| 2.000 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 2.000 in | 2 in | 4.000 in |

| 3.000 in Thick 8.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 3.000 in | 3 in | 8.000 in |

| 3.000 in Thick 6.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 3.000 in | 3 in | 6.000 in |

| 3.000 in Thick 3.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 3.000 in | 3 in | 3.000 in |

| 3.000 in Thick 2.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 3.000 in | 3 in | 2.000 in |

| 3.000 in Thick 10.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 3.000 in | 3 in | 10.000 in |

| 3.000 in Thick 12.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 3.000 in | 3 in | 12.000 in |

| 3.000 in Thick 4.000 in Dia. Aluminum Circle Discs | 1050, 1060, 3003, 5052, 5754 | 3.000 in | 3 in | 4.000 in |

Can't find the size you're looking for? Contact us for custom aluminum circle solutions tailored to your needs.

Instant QuoteApplications of aluminum circles and discs

Cookware aluminum circle disc

Common product specifications of cookware Aluminum circle disc:

- 2mm-3mm 1060 O, H12 cookware aluminum circle disc suitable for frying pan, pizza pan and electric fryingpan

- 2mm-4mm 3003 O aluminum circle disc for electric pressure cooker and rice cooker

- 0.7mm-2mm 1100 O cookware aluminum circle disc suitable for stock pots

- 3mm-5mm 1100 O aluminum disc is mainly used as the bottom of cooker and the bottom plate of stainless steelcooker

- 2mm-4mm 1100 3003 aluminum discs are used for coating cookware aluminum rings.

Lighting aluminium circle disc

Lighting aluminium circle is mainly used to produce lampshade. It can also be used for embedded lighting, high shedindustrial lighting, low shed industrial lighting, traffic light reflector and sports lighting.

Common product specifications of lighting aluminium circle disc:

- 0.5-1.5mm 1100 O aluminium circle disc: for ordinary lampshade

- 0.5-1.5mm 1100 O anodized aluminium circle disc: good deep drawing quality. After bright dipping andanodizing, the semi mirror finish can be maintained. The minimum total reflectivity is 65%

- 0.5-5mm 1100 O coated aluminium circle disc: used as coated aluminum lamp shade

Aluminum circle disc for road sign

Currently, it is mainly used to supervise traffic signs, warning traffic signs, guidance signs, etc

- Common alloy: 1100 H14

- Natural surface: chemically degreased polished finish

- Coil or sheet width: 2000 mm maximum

- Thickness: can reach 6.0mm

- Diameter: customizable

Spinning aluminium circle disc

Our high-quality rotary aluminum discs are mainly used for lighting, ventilation, satellites, paint sprayers,central vacuum devices, filter cartridges, planters, waste containers, drip pans, low-temperature tank cars, racingwheels, etc.

Aluminum slug

- Grade: 1100, 1050, 1060, 1070

- Temper: O-H112

- Diameter: 3mm-220mm

- Thickness: 0.5mm-25mm

- Surface Treatment: Polished, Mirror Polished, Brushed, Embossed, PE PVDF Coating, Teflon Coating

The aluminum slug complies with international standards such as EN 570/573, ROHS, SGS, etc. The surface treatment isuniform and smooth without burrs, edges, cracks, bark patterns, marks and oil stains.

Aluminum slugs are widely used in cosmetic packaging, capacitor housings, aerosol bottle aluminum plugs, hosealuminum blocks, auto parts, shoe polish tubes, aluminum cans, bottle caps, lighter housing aluminum heads and otherfields.

What alloys are there in aluminum circle disc?

Aluminum circle and disc of 1000 series

Alloy:1050, 1060, 1070, 1100

Features:aluminum content>99%, Excellent formability, high reflectivity, stable surface anodizing performance

Application:common cookers, extruded pot covers, aluminum pots, lamp accessories, lampshades, downlights, laminatedlamps, street lamps, signs and building materials, traffic signs, curtain walls, ceilings

1050 Aluminum Circle

1060 Aluminum Circle

1100 Aluminum Circle

Aluminum circle and disc of 3000 series

Alloy:3003, 3004, 3005

Features:high elongation, can be used for deep drawing, high grain size, smooth surface, high reflectivity

Application:high grade cookers, sticky pans, pressure cookers, lamp accessories, signs and building materials

3003 Aluminum Circle

3004 Aluminum Circle

3005 Aluminum Circle

Aluminum circle and disc of 5000 series

Alloy:5052, 5754, 5083

Features:low material density, light weight of finished products, high tensile strength and elongation, andgoodfatigue strength

Application:Non stick pan, pressure cooker, pressure vessel, pressure cooker, etc.

5052 Aluminum Circle

5754 Aluminum Circle

5083 Aluminum Circle

Aluminum circle and disc of 6000 series

Alloy: 6061, 6063, 6082, 6060

Features: good strength, excellent corrosion resistance, and high machinability

Application: ideal for automotive parts, structural components, and industrial equipment

6061 Aluminum Circle

6082 Aluminum Circle

6063 Aluminum Circle

Aluminum circle and disc of 8000 series

Alloy:8011

Features:excellent anodizing effect, stable performance and high surface quality

Application:can be made into pearl anodized cooker

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote

What are the production processes of aluminum discs?

Stamping: Aluminum coils are punched into round sheets using a punching machine anda round die,which is suitable for efficient and low-cost mass production.

Shearing: Use shearing machine to cut aluminum plate into circular sheets, which ishighly flexibleand suitable for customized production.

Laser Cutting: Using laser cutting machine to accurately cut preset graphics, withhigh precisionand good edge quality, suitable for cutting complex shapes.

Water Jet Cutting: Cutting with high-pressure water flow mixed with abrasives, noheat-affectedzone, high cutting accuracy, suitable for cutting thick aviation plates.

Milling: Use a milling machine to partially mill the aluminum plate to form acircular sheet withhigh precision.

Spinning: Fix the aluminum disc on the spinning machine and gradually form itthrough the spinningtool. It is suitable for the production of lamp reflectors, kitchen utensils, and gas cylinderbottoms.

Punching: Use a punching machine to punch out multiple small discs on the aluminumplate. It isefficient and suitable for the production of small-sized aluminum discs.

Why is the quality of our aluminum discs second to none in China?

In order to ensure the quality of aluminum circle disc, Chalco Aluminum sets up specialquality inspectionposts during the production process.

1. The surface of aluminum circle disc

The aluminum circle disc with good quality has no deformation, scratches, cracks, yellowspots, etc. And thesurface color of high-quality aluminum circle is consistent. If there is color difference, thequality isunqualified.

2. Chemical composition

The chemical composition of aluminum discs can be detected by professional spectrum analyzer. Thencompare with thestandard GB/T3880-2012 or ASTM B209. We must ensure that each chemical element is within the rangerequired by thestandard.

3. Mechanical properties

The tensile strength and mechanical properties of aluminum rounds are tested by a tensile testingmachine to ensurethat the tensile strength and elongation meet the standards. If the mechanical properties are not upto thestandard, it is easy to break during the stamping and spinning process. It will waste a lot of timeand materialcosts in production.

The tensile strength of aluminum circle disc 1050-O is generally 60Mpa to 100Mpa; Elongationis about 35%. Thetensile strength of aluminum circle disc 1050 H12 is generally about 100Mpa, and theelongation is about 10%.

4. Particle size test

Different manufacturers have different requirements for grain size. According to internationalstandards, mostfactories control the particle size above Grade II, while some large factories require the particlesize to be GradeI. This can ensure that the yield of aluminum circle disc reaches 98% or even 100% during theproduction ofkitchenware.

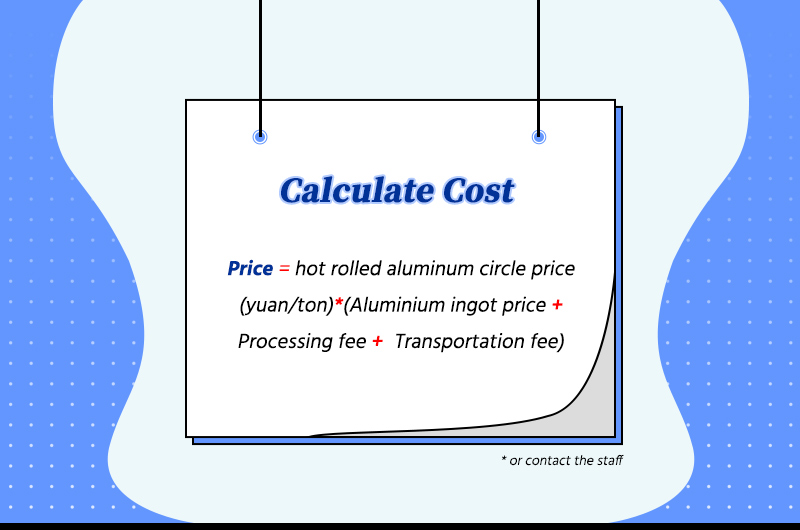

Price quotation for aluminum circle disc

Generally, the processing price of aluminum rounds varies according to different alloys andwidths.We can processaluminum rounds according to the order quantity, and the price will also decline. We look forward toyour consultation.

Price calculation method:

Hot rolled aluminum circle disc price (yuan/ton)=aluminum ingot price+processing fee+freight

Packaging and transportation of aluminum circle disc

1. Aluminum circle disc are usually packed in a crossing girder way, and the packaging shouldmeet the needsofstorage and transportation.

2. During the transportation process, a layer of neutral or weak acid material shall be wrapped onthe surface ofaluminum foil roll and then put into the packing list.

3. The lap joint shall be fixed with adhesive tape and padded with soft cushion to protect the endface of aluminumfoil roll.

4. Put desiccant in the roll and wrap it with plastic cloth. The sealing part of the outermostplastic cloth shallbe firmly stuck with adhesive tape, and the remaining parts at both ends of the plastic cloth shallbe insertedinto the pipe core.

5. Finally, put the wrapped aluminum foil roll on the cross and fix it with steel tape, and thenstick a case cardon the end face of the aluminum foil roll.

6. Pay attention to the method of transportation, and handle with care when loading and unloading.

Frequently asked questions about aluminum circles discs

How do I choose the right alloy for my application?

It depends on your process and end-use. For deep drawing cookware, 1050 or 1060 is ideal. Forcorrosion resistance andstrength, 3003 or 5052 is better. We can help you select the right grade based on your needs.

Will the aluminum disc crack during deep drawing or spinning?

No, our discs are produced with high elongation and stable grain structure, ensuring excellent deepdrawing and spinning performance without cracking.

Can I request a specific diameter, thickness, or shape?

Yes, we offer full customization — diameter, thickness, center holes, and even triangle, square, oroval shapes can be produced based on your drawings or specifications.

Are your aluminum circles safe for cookware and food contact?

Yes, our cookware-grade aluminum meets LFGB and FDA standards. Material certificates and compliancedocuments are available upon request.

I'm worried about surface defects — can I get a sample first?

Absolutely. We offer free samples so you can verify the surface quality, thickness, and suitabilitybefore placing a bulk order.

What if I can' t find my required size in your stock?

Just contact us. We provide custom cutting and mold services to meet your exact size and tolerancerequirements.

What are the advantages of using aluminum circles for cookware?

They offer excellent flatness for automated production, uniform surface for coating, and superiorheat conductivity for even cooking performance.