Chalco 3A21 aerospace aluminum plate conforms to ASTM B209M-14, ASTM B632/B632M-18, AMS 4028F, AMS 4029K, EN 485-2:2016, EN 485-4:2016, GB/T 3880.2-2018 standard. It is mainly used for aircraft, satellite, missile and other spacecraft structure manufacturing, as well as spacecraft parts manufacturing.

Chalco - high quality 3A21 aerospace aluminum sheet plate supplier

Aviation standard

ASTM B209M-14; ASTM B632/B632M-18; AMS 4028F; AMS 4029K; EN 485-2:2016; EN 485-4:2016; GB/T 3880.2-2018

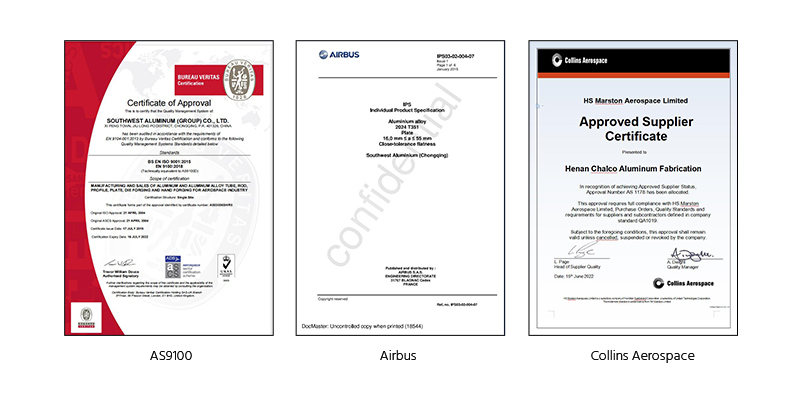

International aviation quality system certification

ISO 9001; AS9100; EN 9100; DNV

Specification of Chalco 3A21 aerospace aluminum sheet plate

| Temper | O, T3, T4, T6, H111, H112, H113 |

| Thickness | 0.5mm-6mm: usually used to manufacture the shell, interior and structural parts of aerospace vehicles |

| 6mm or above: mainly used for manufacturing large structural parts and engine parts | |

| Width | 20mm-2600mm |

| Length | 500-16000mm There is no fixed standard for the length. It can be cut into aluminum plates of different lengths according to customer requirements. |

| Packing | Export standard wooden pallet. |

| Inventory | The inventory is complete. Please check our inventory table or contact us for detailed requirements. |

| Performance parameter table | Click here to check the specific[Performance parameter table] |

Chalco hot selling 3A21 aerospace aluminum plate products and applications

Chalco's hot-selling 3A21 aerospace aluminum plates are mainly in O, T3, T4, T6, H111, H112, H116 and other alloy tempers.

3A21-O aerospace aluminum sheet plateQuick Quote

- The O temper refers to the aluminum alloy material without overheating treatment. It is easy to process and form, and has good plasticity.

- Good surface quality and corrosion resistance: it is often used to manufacture the shell and cover of aircraft, rocket and other aerospace equipment to protect the internal equipment and system from the impact of the external environment.

- High plasticity, easy to form and process: commonly used for manufacturing internal components, such as partitions, supporting structures, etc.

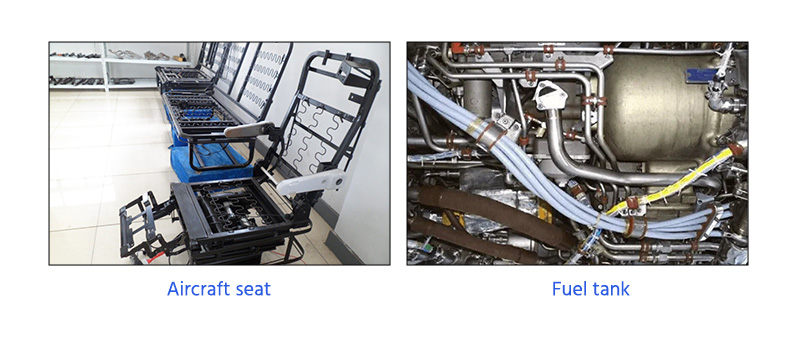

- Good corrosion resistance and sealing performance: used to manufacture containers such as fuel tanks and hydraulic oil tanks.

- The surface of the plate is high in flatness and consistent in color: it is often used to manufacture aircraft seats and interior panels to increase passenger comfort and beauty.

- Good thermal conductivity: used for manufacturing electronic equipment shell, radiator and other components to ensure the normal operation of the equipment.

3A21-T3 aerospace aluminum sheet plate Quick Quote

T3 temper refers to 3A21 aluminum alloy after aging treatment. The aluminum alloy in this temper has high strength and hardness, but still maintains certain plasticity and formability.

- High strength and rigidity: it is often used to manufacture aircraft wings, wingtips, tail fins and other components to ensure the stability and safety of aircraft during flight.

- Excellent strength and hardness: it is often used to manufacture the body shell and chassis of aircraft, rocket and other aerospace equipment to enhance the structural strength of the entire equipment.

- High strength and toughness: commonly used to manufacture key components of flight control system, such as joystick, cockpit door, etc., to ensure the accuracy and reliability of equipment.

- High heat resistance and corrosion resistance: it is often used to manufacture engine hood, thrust vector nozzle and other components to ensure normal engine operation and effective conversion of jet thrust.

T4 temper refers to 3A21 aluminum alloy temper obtained by natural aging or artificial aging. The aluminum alloy in this temper has high strength and hardness, but poor plasticity and formability.

- High strength and hardness: it can be used as the material of shell plate, bracket, bracket, keel and other structural components.

- Good heat resistance: mainly used for manufacturing blades and other high-temperature parts.

- Good strength and rigidity: used to manufacture aircraft airfoils and control panels, etc., which can withstand large pressure and tension.

- Good corrosion resistance and mechanical properties: used for manufacturing various aerospace equipment, such as radar antenna, electronic equipment shell, etc.

T6 temper refers to the temper of 3A21 aluminum alloy obtained by twice heat treatment and aging treatment. The aluminum alloy in this temper has the highest strength and hardness, but its plasticity and formability are poor.

- Excellent strength, toughness and corrosion resistance, and light weight: used for the fuselage, wing, tail and other structural parts of the aircraft, which can effectively reduce the total weight of the aircraft and improve the fuel efficiency of the aircraft.

- High strength, rigidity and fatigue resistance, as well as good thermal expansion and corrosion resistance: used for structural parts of spacecraft, such as shells, missile launchers, etc. Suitable for use in harsh space environment.

3A21-H111 is thetemper obtained by annealing after cold working, with good machinability and corrosion resistance. It is often used to manufacture aircraft structural components such as shells, partitions, assembly plates, etc.

3A21-H112 aerospace aluminum sheet plate Quick Quote3A21-H112 is the temper obtained by annealing after deformation processing, with high strength and hardness, while still maintaining good machinability and corrosion resistance. It is often used in places where the strength requirements of aircraft structural components are high, such as leading edge, web, frame, etc.

3A21-H116 aerospace aluminum sheet plateQuick Quote3A21-H116 is the temper obtained after water quenching and cooling and then tensile processing, with high strength and hardness, while maintaining good machinability and corrosion resistance. It is often used for aircraft structural components requiring high strength and toughness, such as wings, landing gear, etc.

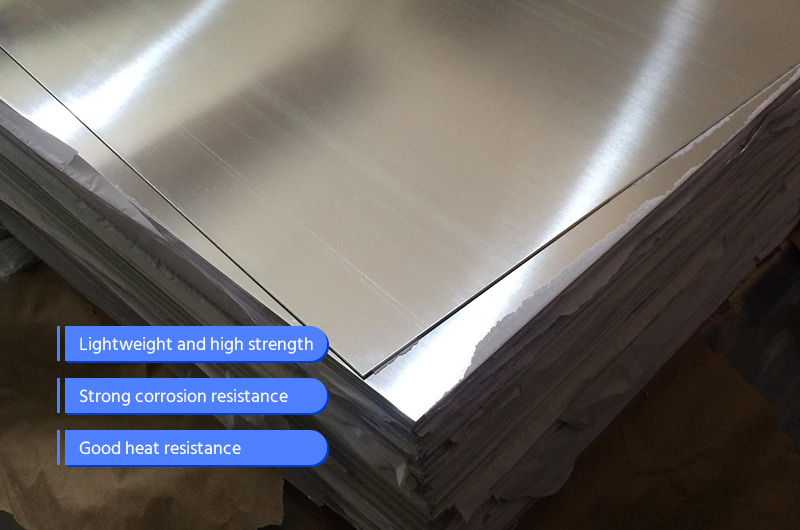

Performance advantages of Chalco 3A21 aerospace aluminum sheet plate

- Chalco's 3A21 aerospace aluminum sheet plate offers lightweight strength, enhancing aerospace vehicle efficiency and load capacity.

- It provides good machinability, weldability, and corrosion resistance, ensuring stable performance in adverse environments.

- Easy processing, including cutting and bending, and high-temperature resistance make it suitable for aerospace parts manufacturing.

Chemical components of Chalco 3A21 aerospace aluminum sheet plate

| Component | Content |

| Si | 0.6 |

| Fe | 0.7 |

| Cu | 0.05-0.5 |

| Mn | 1.0-1.6 |

| Mg | 0.05 |

| Cr | 0.10 |

| Ni | - |

| Zn | 0.10 |

| Ti | - |

| Zr | - |

| Al | Reminder |

Mechanical and physical properties of Chalco 3A21 aerospace aluminum sheet plate

| Mechanical and physical properties | |

| Density | 2.73g/cm3 |

| Melting point | About 600°C |

| Thermal expansion | 23.2×10-6/K |

| Thermal conductivity | 138 W/m·K |

| Electrical resistivity | 0.032Ω·mm2/m |

| Tensile strength | 185-230 MPa |

| Yield strength | 120-180 MPa |

| Elongation | 10%-20% |

| Hardness | 45-70 HRB |

| Fracture toughness | 13-17 MPa·m¹/₂ |

Chalco other hot selling aerospace aluminum plate products

2219 aerospace aluminum plate

2024 aerospace aluminum plate

2014 aerospace aluminum plate

7075 aerospace aluminum plate

7055 aerospace aluminum plate

7050 aerospace aluminum plate

3003 aerospace aluminum plate

5083 aerospace aluminum plate

6061 aerospace aluminum plate

Points for purchasing Chalco 3A21 aerospace aluminum sheet plate

Production capacity of 3A21 aerospace aluminum plateQuick Quote

- As a professional 3A21 aerospace aluminum sheet plate supplier, Chalco has always put product quality and production capacity in the first place.

- Chalco 3A21 aerospace aluminum sheet plate is produced in strict accordance with international standards.

- Chalco adopts advanced production equipment and technology, and strictly controls every link from raw material procurement to production processing, quality testing, etc. to ensure stable and reliable product quality.

Delivery capacity of Chalco 3A21 aerospace aluminum sheet plateQuick Quote

- Chalco's large production workshop and professional production team is well-regarded by customers.

- Chalco has abundant inventory and mass production capabilities to meet customer demands.

- Chalco offers fast delivery services to ensure minimal disruption to customer production plans.

- Plate thickness, size, and surface treatment options are customizable to meet specific requirements.

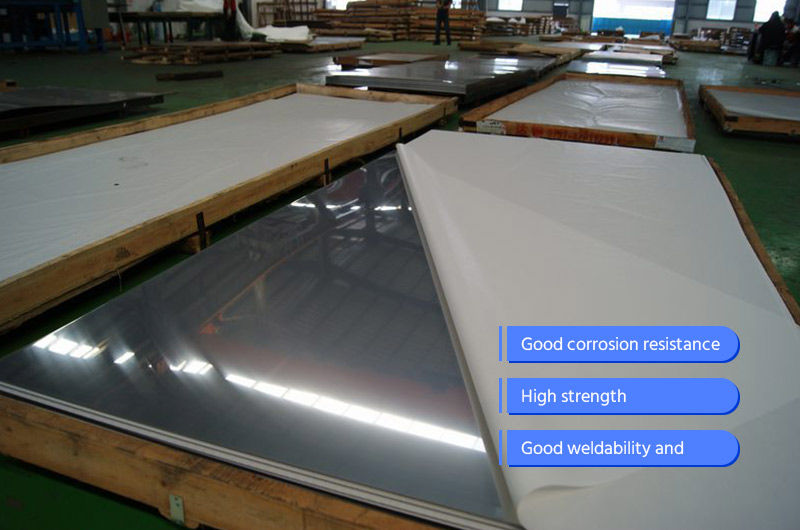

Characteristics of Chalco 3A21 aerospace aluminum sheet plateQuick Quote

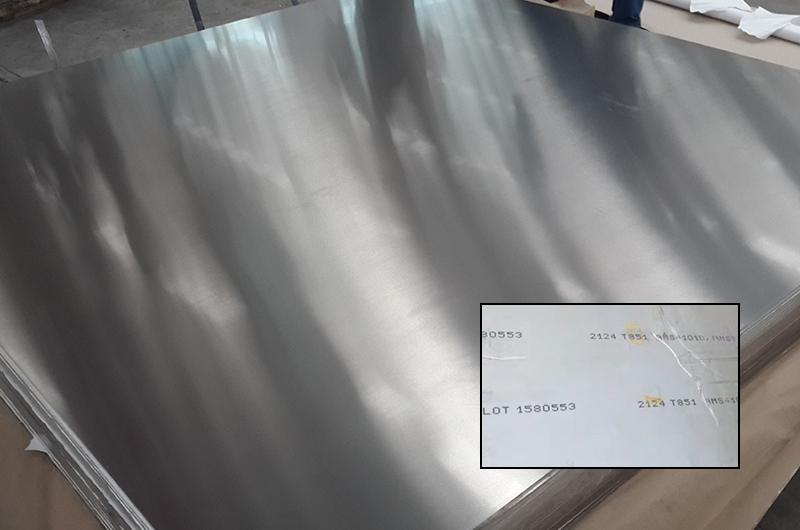

- High surface flatness: the surface of Chalco 3A21 aluminum sheet plate for aerospace should be flat and smooth, without obvious defects such as dents, ripples, wrinkles, etc.

- Surface oxide film process: Chalco 3A21 aluminum sheet plate used for aerospace shall form uniform, dense and solid oxide film on the surface. The thickness of oxide film shall comply with relevant standards.

- Surface cleanliness: the 3A21 aluminum sheet plate used in aerospace is clean and free of oil, dust, foreign matters and other impurities.

- No surface defects: Chinalco 3A21 aerospace aluminum sheet plate is free of cracks, bubbles, inclusions, water marks, scratches and other obvious defects.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote