Aluminum profiles, also known as aluminum extrusions, are products formed through the aluminum extrusion process, where aluminum alloy material is pushed through a die to create specific cross-sectional shapes. This process gives aluminum excellent strength, lightweight properties, and high design flexibility, making it widely used in construction, industry, electronics, and transportation.

As a professional aluminum supplier and manufacturer, Chalco offers a wide range of high-quality aluminum profile products, including standard aluminum profiles, special aluminum profiles, and custom aluminum extrusions tailored to unique design or technical requirements.

Standard aluminum profiles

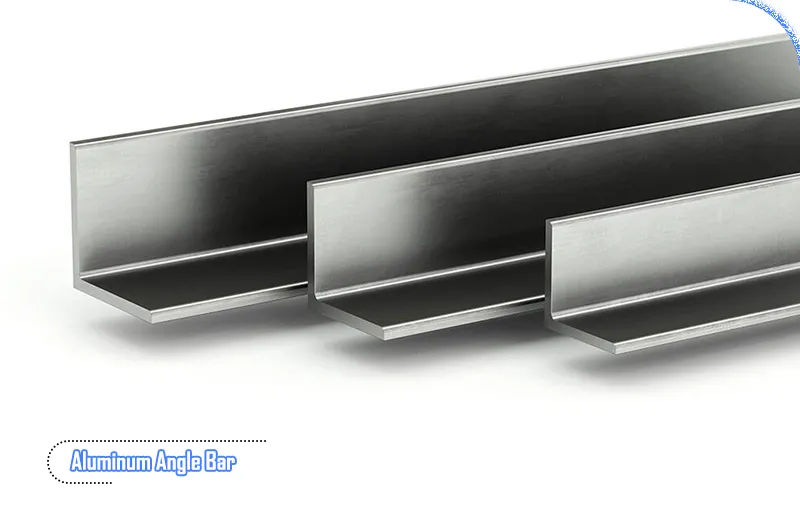

Standard aluminum profiles refer to commonly used extruded aluminum shapes that follow industry or national specifications. These profiles include extruded aluminum round tubes, square and rectangular tubes, angle bars, U-channels, and T-slot profiles widely used in construction, framing systems, and general industrial applications.

Aluminum extruded bar

Extruded aluminum bars are solid aluminum products formed by forcing heated aluminum alloy through a die using the aluminum extrusion process. It typically comes in round, square, or hexagonal cross-sections and is known for its strength, machinability, and dimensional stability. Extruded aluminum bars are widely used in aerospace, automotive, construction, and general engineering applications.

Chalco can supply various cross-section types of extruded aluminum bars include:- Extruded aluminum round bar

The maximum diameter of extruded aluminum round bar is 600mm. It is commonly used for shafts, pins, spacers, and precision-machined components.

Extruded aluminum flat bars are commonly used in the electrical power industry for conductors and busbars.

Extruded aluminum square bars are used for connectors, structural framing, and machined components in industrial and architectural fields.

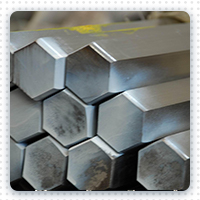

- Extruded aluminum hexagonal bar

Extruded aluminum hexagonal bars are typically used for fasteners, fittings, and parts requiring multi-sided profiles.

- Extruded aluminum half round bar

Extruded aluminum half round bars feature a semi-circular cross section, ideal for decorative trims, edge protection, and finishing applications.

2024 aluminum bar

2014 aluminum bar

2017 aluminum bar

2618 aluminum bar

2219 aluminum bar

5052 aluminum bar

5083 aluminum bar

6061 aluminum bar

6063 aluminum bar

6082 aluminum bar

7075 aluminum bar

7050 aluminum bar

Aluminum extruded tube

Aluminum extruded tube refers to aluminum or aluminum alloy tubes formed by extrusion process. It is characterized by seamless extrusion technology, complete tubular cross-section and uniform wall thickness. This type of tube combines the lightweight and corrosion-resistant properties of aluminum with the high-precision geometry given by the extrusion process.

Chalco can provide extruded aluminum tube sections including:

Extruded aluminum round tubes are ideal for structural and transportation applications where lightweight and corrosion resistance are critical.

Extruded aluminum square tubes are widely used in frameworks, enclosures, and furniture due to their clean lines and high strength.

Extruded aluminum hexagonal tubes offer multi-faceted geometry, making them suitable for mechanical, aesthetic, and custom-profile designs.

Extruded oval aluminum tubes feature an aerodynamic profile, often used in decoration, automotive trim, and bicycle frame construction.

6061 aluminum tube

7075 aluminum tube

2024 aluminum tube

5052 aluminum tube

5083 aluminum tube

5086 aluminum tube

6082 aluminum tube

6063 aluminum tube

7005 aluminum tube

Aluminum angle

Alloy: 6061 6063 6082 7075 2024 7050

Type: Equal/unequal aluminum angle

Temper: T6 T651 T52 T3

Surface: Anodizing, powder coating, polishing,

Contact us nowAluminum angle is an L-shaped extruded product widely used in structural and architectural applications. It offers excellent strength-to-weight ratio, corrosion resistance, and is easy to cut, weld, and machine. Commonly used for framing, brackets, reinforcements, and supports.

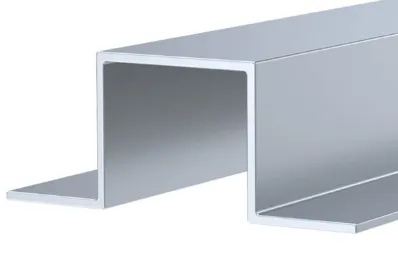

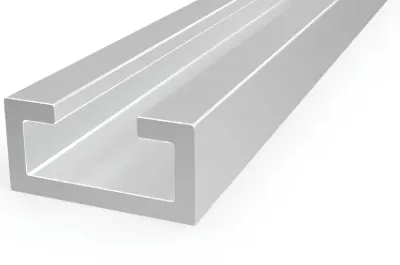

Aluminum channel extrusions

Aluminum channel is an extruded profile available in various shapes such as U, C, H, F, and J, commonly used for structural framing, edge protection, and trim. It is lightweight, corrosion-resistant, and easy to fabricate, making it ideal for both industrial and architectural applications.

Aluminum U Channel

Aluminum Hat Channel

Aluminum H Channel

Aluminum F Channel

Aluminum C Channel

Aluminum J Channel

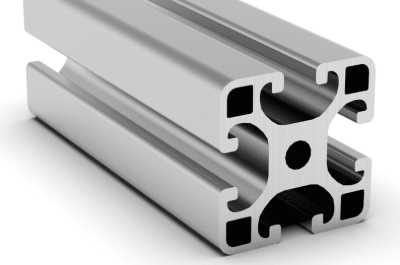

T slot aluminium extrusion

Alloy: 6063, 6061

Temper: T5, T6

Common Size: 20×20mm, 30×30mm, 40×40mm, 45×45mm, 60×60mm

Contact us nowT slot aluminium extrusion is a modular framing system with a T-shaped groove that allows easy assembly using connectors and fasteners. Made primarily from 6063 or 6061 alloys, it offers excellent strength, corrosion resistance, and flexibility for building machine frames, workstations, and automation equipment.

4040 4080 Aluminum Extrusion

3030 3060 Aluminum Extrusion

2020 2040 Aluminum Extrusion

45 Series Aluminum Extrusion

15 Series Aluminum Extrusion

10 Series Aluminum Extrusion

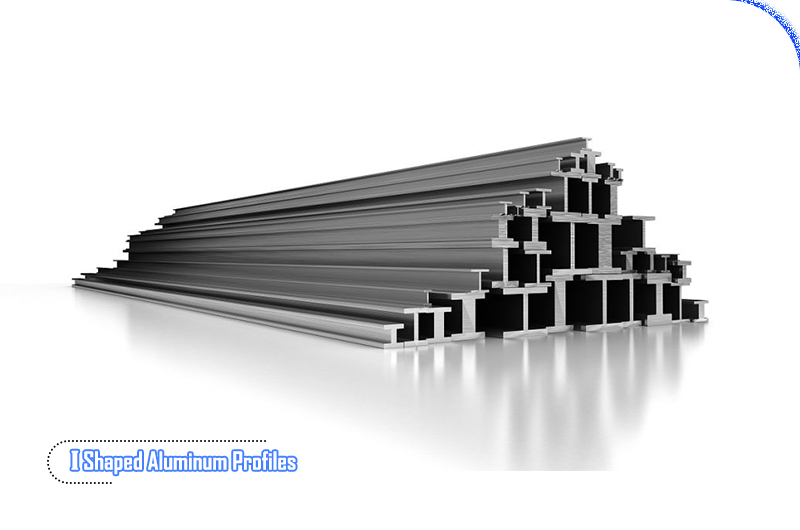

Aluminum i beam

An Aluminum i beam is an extruded profile with an "I"-shaped cross-section, designed for structural support, framing, and load-bearing applications. It combines lightweight properties with high strength and corrosion resistance, making it ideal for construction, transport, marine, and industrial automation. The most commonly used alloy is 6061-T6 due to its excellent machinability and strength.

| Product size | Common Alloy | Typical Dimensions (inches) |

| 6061 t6 aluminum i beam | 6061-T6 | 4×2, 6×3, 8×4, 12×6 |

| 6061 beam / 6061 aluminum beam | 6061-T6 | 3", 4", 6", 8", 12" |

| 8 inch aluminum i beam | 6061-T6 | 8×4, 8×6 |

| 8 aluminum i beam | 6061-T6 | 8" wide beam (height varies) |

| 6x6 aluminum i beam | 6061-T6 | 6×6 |

| 6 inch aluminum i beam | 6061-T6 | 6×3, 6×4, 6×6 |

| 6 aluminum i beam | 6061-T6 | 6" width, common heights 3"–6" |

| 4 inch aluminum i beam | 6061-T6 | 4×2, 4×3 |

| 4 extruded aluminum beams | 6061-T6 | Typically 4" wide I-beams |

| 4 aluminum i beam | 6061-T6 | 4" width I-beam |

| 3 inch aluminum i beam | 6061-T6 | 3×2, 3×3 |

| 3 aluminum i beam | 6061-T6 | 3" width beam |

| 2x6 aluminum beam | 6061-T6 | 2" width × 6" height |

| 24 aluminum beam | 6061-T6 | 24 ft length beam, 6"–8" wide typical |

| 12 foot aluminum i beam | 6061-T6 | 12 ft length (size varies) |

| 12 aluminum i beam | 6061-T6 | 12" width beam |

| 20 aluminum i beam | 6061-T6 | 20" width large I-beam |

| 150 x 50 aluminium beam | 6061-T6 / EN AW 6061 | 150 mm × 50 mm |

| 2020 extruded aluminum beam | 6063-T5 | 20mm × 20mm T-slot or light beam |

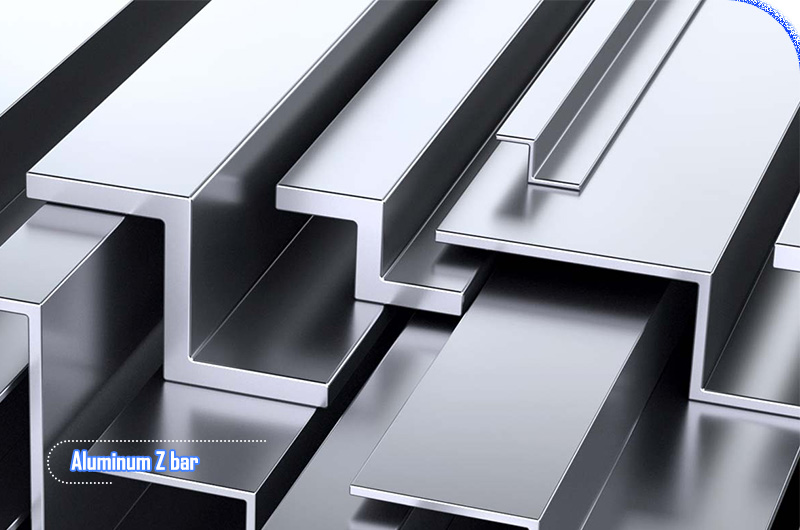

Aluminum z bar

Aluminum Z bar is an extruded profile with a Z-shaped cross-section, commonly used for trim, edging, support brackets, and structural transitions. It offers corrosion resistance, light weight, and easy fabrication, making it suitable for architectural, industrial, and marine applications.

Aluminum Z bars are available in a variety of standard sizes to suit different structural and trim applications. Common dimensions include 1/8 inch, 1/4 inch, 3/4 inch, and 2 inch aluminum Z bars, providing flexibility for both light-duty edging and heavy-duty reinforcement needs. These size options ensure compatibility with framing, paneling, and transition installations across construction and industrial projects.

Special aluminum profile

- Special aluminum profiles have relatively complex shapes, mainly used in the construction and furniture industry, automobile industry and transportation industry, such as:

- Aluminum curve profiles

- Aluminum glazing extrusions

- Aluminum picture frames

- Extruded aluminum handles

- Handrail extrusions

- Aluminum drainers and water deflectors

- Aluminum trim profiles for motor vehicles

- Corner elements with special cross-sections

Chalco Aluminum profile application field

Extruded aluminum profiles are transformed from aluminum alloys to the products with defined cross section through extrusion process, which has a wide range of applications. Our aluminum profiles are mainly used in advertising, industry, construction, rail vehicles, mounting and other traditional fields.

And with the demand of the global market for environment-friendly and new energy materials, our products are also gradually spreading in light-weight cars, aluminum furniture, LED and some other emerging markets.

Advertising aluminum profile

Aluminum alloy advertising frame profile refers to the aluminum sign frame, advertising signboard, display panel, light box frame, advertising frame, etc. It is suitable for outdoor, subway, elevator, corridor, aisle and advertisements on many places. Because the open aluminum alloy advertising frame is erected in the outdoor field, the main material of the outdoor advertising frame is aluminum alloy profiles with high-quality.

| Alloy | 6060, 6061, 6063, 6082, 6005, 6463, 7075, etc. |

| Temper | T4 T5 T6 |

| Specifications | common specifications can be found in our drawings |

| Bottom width | generally 20-400mm |

Height is 20-600mm, and the thickness is 0.4-3.5mm or customized according to customer requirements.

Length is within 6 meters, and the special size can be customized according to customer requirements.

Color: brushed gold, brushed silver, brushed wine red, brushed black, brushed light purple gold, brushed bronze, brushed rose gold, brushed champagne, brushed crystal bronze, electrophoretic black, matte black, white sand, gray sand, black sand grain, crystal electrophoretic champagne, crystal electrophoretic rose gold, porcelain electrophoretic apple gold, porcelain electrophoretic apple silver, porcelain electrophoretic champagne, brown, red, yellow pear, deep walnut, ebony, etc.

General industrial aluminum profiles

General industrial aluminum profiles are mainly used for industrial production and manufacturing, such as automatic mechanical equipment and the skeleton of the cover. And each company can customize the model according to their own mechanical equipment, such as assembly line conveyor belt, elevator, dispensing machine, testing equipment, shelves, etc. It is widely used in electronic machinery industry and clean room.

| Alloy | 1050, 2011, 4040, 6061, 6063 |

| Film standard | anodic oxidation is7-23 μ; powder spraying is 60-120 μ; electrophoretic membrane is 12-25 μ |

| Service life | 12-15 years for outdoor anodizing, 18-20 years for outdoor powder coating |

| Length | 5.8M or customized |

| Thickness | 0.4mm-20mm or customized |

| Color | silver, champagne, bronze, gold, black, sand coating, anodized acid and alkali or customized. |

Architectural aluminum profiles

Construction field is one of the main application fields of aluminum profiles. Compared with traditional construction steel, aluminum alloy has many advantages, such as convenient transportation, easy processing to different shapes, easy coloring and fashionable appearance, corrosion resistance, keeping the exterior surface of buildings in a new state for a long time. It is mainly used in the field of aluminum window frames and curtain walls.

| Alloy | 6063, 6061, 6005, 6005A, 6082 etc. |

| Temper | T1, T2, T3, T4, T5, T6, T7, T8, T9, T10 |

| Surface treatment | anodizing (different colors), sandblasting, powder coating, wood grain, PVDF coating |

Door and window aluminum profiles

System doors and windows are one of the application fields of architectural aluminum profiles, which are systematically designed, manufactured and installed. Compared with traditional doors and windows, system doors and windows integrate a series of performance requirements such as water tightness, air tightness, wind pressure resistance, heat insulation, sound insulation etc., and play the role of green energy conservation and consumption reduction.

| Alloy | 6061, 6063 |

| Temper | T5, T6 |

| Surface treatment | polishing, anodizing, powder coating, electrophoresis, wood grain |

| Coating standard | anodic oxidation is 7~23 μ; powder coating is 60~120 μ; electrophoresis is 12-25 μ |

| Length | 5.8M/5.85M/6M/6.4M or customized |

| Color | silver, champagne, bronze, gold, black, powder coated white, analok, hanalok and custom colors. |

Aluminum handle profile

Aluminum handle is widely used in various home decoration. For example, wardrobe, cabinet, window, gate, courtyard, folding door, etc. Customized aluminum profiles provide personalized functions for various products, and further improve the durability.

| Alloy | 6063, 6061 |

| Temper | T5 T6 |

| Type of aluminum handle | straight aluminum handle, curved aluminum handle, C-shaped handle, combined handle |

| Deep processing | CNC processing, powder spraying, anodizing, electrophoresis, etc. |

| Surface treatment | wood grain, powder coating, anodizing, polishing |

| Color | white, silver, champagne, bronze, gold, black, wood grain, sand coating, anodized acid and alkali or customized |

Solar aluminum profile

Aluminum alloy profiles can usually be used for solar battery frames. The aluminum profiles used for solar battery frames are mostly 6000 series Mg-Si alloys, which are the most popular extrusion alloys. It has the characteristics of good strength, good extrudability, good corrosion resistance, good machinability, good weldability, good formability, heat treatment, etc.

| Alloy | 6063, 6060, 6061, 6005 |

| Temper | T4, T5, T6 |

| Surface treatment | polishing, anodizing, powder coating, wood finishing, polishing |

| Color | silver, black, white, red, blue and other colors are available |

| Length | as required |

| Thickness | above 0.8mm |

Lightweight automobile aluminum profiles

Aluminum alloy has the characteristics of light weight and excellent quality, and its density is about 30% of that of steel. The use of aluminum alloy can effectively reduce the weight of vehicles, and the strength and other indicators can meet the requirements. In recent years, the trend of using aluminum alloy to replace steel in the automotive field has become increasingly obvious, in order to achieve lightweight, energy-saving and environment-friendly effects.

| Alloy | 6060/6061/6063/6082, etc |

| Temper | T3-T8 |

| Surface treatment | anodic oxidation |

| Polished aluminum profile | mechanical polishing |

| Shape or size | according to customer requirements |

LED light aluminum profile

High quality anodized aluminum LED light bar profiles are the best choice for LED light bar projects. Aluminum profiles provide housing and protection for LED light strips. As radiators, they significantly improve the thermal management of LED light bars. These specially designed LED light bar aluminum profiles can be perfectly installed in the grooves of cabinets, ceilings, stairs, walls and floors.

| Alloy | 6000 series |

| Temper | T3, T4, T5, T6, T7, T8 |

| Internal width | 8mm, 10mm, 12mm, 20mm, 30mm, ≥ 100mm |

| Length | 1m, 2m, 2.5m, 3m, etc. |

| Shape | U-shaped, angular or round aluminum profiles, flanges, etc. |

| Anodic oxide layer | the anodic oxide layer shall reach 8-13 microns |

| Paint layer | 60-80 microns. The thicker the layer, the better the corrosion resistance |

| Color | anodized silver, painted white and black are the three primary colors of LED aluminum profiles |

Radiator aluminum profile

The aluminum profile of radiator has the characteristics of beautiful appearance, light weight, good heat dissipation performance and good energy-saving effect. The surface of the processed aluminum profile radiator is anodized to increase the corrosion resistance and wear resistance of aluminum. At present, the commonly used radiator aluminum profiles include: electronic, electrical, computer radiator aluminum profiles, and power semiconductor radiator profiles.

| Alloy | 6061, 6063, 6063B, 6060, 6005, 6N01 |

| Shape | square, round, flat, angular, T-shaped, etc |

| Surface treatment | drilling, tapping, punching, wire drawing, sand blasting, milling, polishing, cutting, anodizing |

| Anodizing color | silver, red, champagne, black, blue, bronze, etc. |

Others

In addition to the above common fields, aluminum alloy profiles are also widely used in furniture, cabinets, mounting, alloy rails and other fields.

Cupboard and wardrobe aluminum profiles

Aluminum kitchenware has strong corrosion resistance and can be easily cleaned with any household cleaner without causing any damage to furniture. These characteristics make aluminum kitchen cabinet the first choice for kitchen furniture.

Instant Quote

Framed aluminum profile

Framed aluminum profiles are aluminum alloy picture frames used for mounting various exhibitions or decorative paintings, etc. It is light in weight, not easy to bend, and easy to clean. Framed aluminum profiles can be used for decoration in shopping malls, homes and other places, as well as outdoor advertising for wedding celebrations, newspaper columns and other occasions.

Aluminum furniture profiles

Aluminum is one of the best choice foe furniture because of its portability, durability and aesthetics. The outstanding advantage of cast aluminum furniture is that cast aluminum will not rust, so it can be used in any weather conditions.

Pipe and rail aluminum alloy profiles

We provide aluminum tubes (aluminum square tubes, aluminum round tubes), aluminum curtain rods, guide rails, and rails. Because of their high durability, excellent quality and other characteristics, they are in great demand in the market. It can be used for furniture parts, buildings, auto parts, etc.

Instant Quote

Chalco Aluminum profile production capacity

Chalco can extrude special section aluminum alloy profiles according to customer requirements and drawings.

Our existing equipment has the capabilities of extrusion, rolling, quenching, straightening, sizing, anodizing, etc. The processing length can reach 6m, and the minimum wall thickness can reach 0.6MM.

Chalco aluminum profile has 2200, 1800, 1350 (2 machines), 1100, 900, 600, 550 ton capacity machines with PLC control system. According to customers' requirements for different processes, the extruded profiles are sent to anodizing, powder spraying or mechanical operation units. It has 8 extrusion lines. The total production capacity is 25.000 tons per year.

The alloy that can be produced include 1060, 2A12, 2014, 2014A, 2017A, 2024, 3003, 5083, 5A02, 5A05, 5754, 5052, 6005A, 6060, 6061, 6063A, 6082, 7075, etc. Temper includes H112, O, T3, T4, T5, T6, etc. In order to minimize the damage of products during storage and transportation, the finished products are tightly packed, such as national standard paper packaging, single plastic bag or single cotton+shrink film, outer packaging tape or waterproof paper.

Chalco Aluminum profile processing technology

Aluminum profile extrusion die production

Chalco has the professional technical teams to design molds. We possess CAD CAM and CEA programs, and high-speed machines controlled by CNC. The laboratory that produces extrusion dies conducts microstructure research and testing, and starts production after receiving the test results. On average, 1500 moulds can be produced every year.

Production and processing of aluminum profiles

The processing of aluminum profiles mainly includes cutting, stamping, tapping and surface treatment. In addition to these basic processing technologies and methods, the processing of aluminum profile frame products also requires customized cutting, punching, tapping and surface treatment according to the drawings. Chalco has a number of punching machines, chamfering machines and other mechanical processing equipment, which can meet the processing needs of aluminum products.

Chalco Aluminum profile surface treatment technology

Aluminum surface treatment is on the one hand to improve corrosion resistance, and on the other hand to meet the appearance requirements. Chalco offers a variety of processes for aluminum surface treatment. We will carry out different surface treatment (anodizing, spraying, brushing, electrophoresis, etc.) according to customer requirements.

Chalco has two different types of anodizing production lines, including black anodizing, silver anodizing, gold anodizing, champagne anodizing, bronze anodizing, titanium anodizing, and copper anodizing. If you have any other requirements, we can also customize anodizing according to the requirements.

Anodizing of aluminum profiles

Aluminum profiles are anodized in different colors, and the surface is matt and glossy. In order to meet customers' different decorative appearance requirements, different processes, such as mechanical polishing or satin treatment, will be carried out before anodizing.

Type E6 anodizing is also carried out in the facility. The anodizing facilities work with the highest technology under the Qualanod standard and are checked by professional engineers 24 hours to ensure the highest standard of production and reduce production failures.

Instant QuoteMarket prospect of aluminum profiles

Aluminum alloy building profile products have the advantages of high strength, light weight, corrosion resistance, good decoration, rich colors, long service life, etc. Generally, the surface of a good product can remain shiny and does not change color within 20 years.

As the world pays more and more attention to energy conservation and environmental protection, aluminum profiles have a huge market in transportation, household appliances, electronic and mechanical equipment and other fields due to their light weight, low price and recyclability.

In recent years, the global new energy and environmental protection industry grew rapidly. Due to the advantages of good heat conduction and light weight, aluminum profiles will be widely used in solar energy, LED and other industries.