The 2219 aluminum bar is a high-strength alloy that combines excellent machinability with superior mechanical properties.

Capable of withstanding temperatures from -240°C to 320°C, the 2219 aluminum bar offers good weldability and outstanding fracture toughness. In the T8 temper, it also provides resistance to stress corrosion cracking. These features make it ideal for demanding aerospace applications, especially in high-temperature structural components such as space boosters and fuel tanks.

Specifications: AMS 4162, ASTM B221, ASTM B211

Chalco 2219 aluminum bar types

AA2219 T8511 extruded aluminum round bar

Diameter: Φ5-420mm

Length: 1000-6000mm

2219-T8511 extruded aluminum round bar is manufactured through precision extrusion processes. Known for its high strength, excellent weldability, and thermal stability, it is widely used in aerospace applications, including structural components exposed to elevated temperatures such as fuel tanks and booster systems.

Custom Alu bar

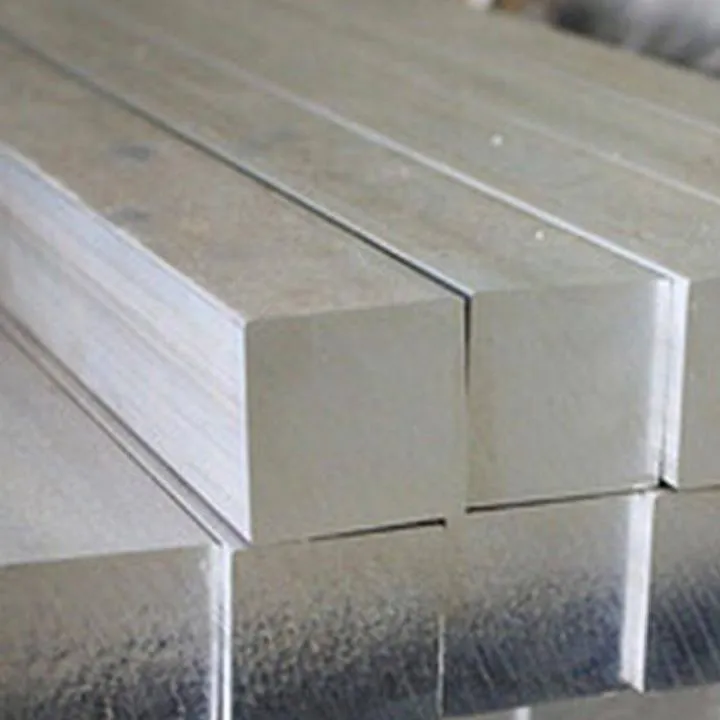

EN AW-2219 T8511 extruded aluminum square bar

Diameter: 5-200mm

Length: 1000-6000mm

2219-T8511 extruded aluminum square bars feature a square cross-section produced through the extrusion of EN AW-2219 aluminum. They offer high strength, excellent weldability, and good fracture toughness, especially in high-temperature environments. These properties make them suitable for aerospace structures, precision engineering, and other applications requiring both strength and thermal stability. Get A Quote Today

A92219 T8511 extruded aluminum flat bar

Diameter: 2-100mm

Length: 1000-6000mm

ASME SB B221 AL 2219 T8511 Flat Bar is produced through precision extrusion processes and features a flat rectangular cross-section. With its high strength, excellent weldability, and performance at elevated temperatures, it is widely used in aerospace structures, cryogenic tanks, and other high-performance engineering applications. Free samples

2219 T8511 extruded aluminum hexagonal bar

Diameter: 5-200mm

Length: 1000-6000mm

2219 extruded aluminum hexagonal bar is formed using advanced extrusion processes and features a hexagonal cross-sectional shape. Known for its high strength, excellent weldability, and thermal stability, it is well-suited for demanding applications in aerospace, precision components, and high-temperature structural assemblies. Purchase Now

2219 T8511 aerospace aluminum round bar

Diameter: Φ100-350mm

Length: 1000-6000mm

UNS A92219 T8511 aerospace aluminum round bars are high-strength aluminum bars engineered for aerospace applications, offering excellent performance at elevated temperatures. They are certified to meet stringent aerospace standards such as AMS 4162, UNS A92219, and QQ-A-200/31. Get A Quote Today

AA92219 aluminum forged round bar

Diameter: Φ100-650mm

Length: 1000-6000mm

AMS 4162 AA2219-T8511 Forged Round Bars are produced using precision forging processes, where metal blanks are shaped under high pressure to refine their internal structure. 2219 forged aluminum bars offer excellent strength, dimensional stability, and outstanding fatigue resistance, making them ideal for aerospace components, high-performance engineering, and critical mechanical applications. Welcome to contact

2219 aluminium cast round bar

Diameter: Φ124-1350mm

Length: 1000-6000mm

AlCu6Mn 2219 aluminium cast round bar is primarily used for subsequent extrusion billets, with a maximum diameter of up to 1350mm. Free samples

Our 2219 aluminum bars are among our key products. If the 2219 series aluminum rods mentioned above do not fully meet your project requirements, we also offer other rods from the 2000 series, such as 2024 aluminum bars and 2017 aluminum bars. Please feel free to contact us if needed.

Product introduction of 2219 aluminum rod bar

| Alloy | 2219 |

| Equivalent names | A92219, AlCu6Mn, EN AW-2219, DIN 3.1325, AMS 4162 |

| 2219 aluminum bar temper | O, T6, T8, T851, T8511 |

| 2219 aluminum bar types | Square, Round, Hex, Flat in Black & Bright Finish |

| 2219 aluminum bar length | 1-6m, Random, Fix & Cut Length or as per clients’ requirement |

| 2219 aluminum bar surface | Bright, Polish & Black |

| 2219 aluminum bar quality | Click to view detailed appearance quality requirements |

| 2219 aluminum bar packaging | Click to view detailed packaging requirements |

| 2219 aluminum bar standards | EN 573, EN 755, ASTM B221, AMS 4162, AMS QQ-A-200/31 |

If you want more information about the product, please contact us for specific inquiries. Insert a call-to-action button.Quick Quote

Chemical composition of 2219 aluminum bar

| Element | Composition % |

| Cu | 5.8-6.8 |

| Fe | 0.3 |

| Mg | 0.02 |

| Mn | 0.2-0.4 |

| Si | 0.2 |

| Ti | 0.02-0.10 |

| V | 0.05-0.15 |

| Zn | 0.1 |

| Zr | 0.1-0.25 |

| Each | 0.05 |

| Total | 0.15 |

| Al | Remainder |

2219 aluminum belongs to the Al-Cu series of heat-treatable aluminum alloys. With a high copper content (Cu: 5.8–6.8%), it offers excellent strength and good performance at elevated temperatures. 2219 aluminum is widely used in aerospace applications due to its superior mechanical properties and weldability, and it is often selected for structural components requiring high strength and thermal stability.

Physical properties of 2219 t8511 aluminum bar

| Property | Value |

| Density | 2.84 g/cm³ |

| Melting Point | 543 - 643 °C |

| Thermal Conductivity | 120 W/m-K |

| Modulus of Elasticity | 73.1 GPa |

| Electrical Resistivity | 0.00000570 ohm-cm |

Mechanical properties of 2219 t8511 aluminum bar

| Material | Temper | Direction | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation in 2" (%) |

| AMS 4162 2219 aluminum bar | T8511 | L | 58 | 42 | 6 |

| AMS 4162 2219 aluminum bar | T8511 | LT | 56 | 39 | 4 |

Characteristics of 2219 aluminum bar

- EN AW-2219 aluminum bar is a high-strength alloy primarily alloyed with copper, offering excellent performance in applications requiring superior strength and thermal stability, especially in aerospace and structural components.

- 2219 aluminum bar provides good weldability, particularly by arc welding methods. It retains its mechanical properties well in welded areas, making it ideal for fuel tanks, aerospace frames, and other welded structures.

- 2219 aluminum bar maintains good strength at elevated temperatures, making it suitable for high-temperature environments such as rocket components and cryogenic tanks.

- While 2219 aluminum bar has moderate corrosion resistance, it may require surface treatment or protective coatings in corrosive environments for long-term performance.

- 2219 aluminum bar offers fair machinability. Due to its higher copper content, proper tooling and cutting conditions are recommended to achieve optimal results during turning, milling, or drilling operations.

Applications of 2219 aluminum bar

2219 aluminum bar is widely used in high-performance engineering fields due to its excellent strength, thermal stability, and good weldability. Below are common application areas of 2219 aluminum bar.

Aerospace

2219 aluminum bar is extensively used in aerospace applications, including rocket motor cases, fuel tanks, structural frames, and high-temperature components, due to its superior strength and performance at elevated temperatures.

Structural applications

Thanks to its high strength and good weldability, 2219 aluminum bar is suitable for structural applications where strength and thermal resistance are required, such as support frames and load-bearing components in critical systems.

Cryogenic tanks

The thermal stability and weld integrity of 2219 aluminum make it ideal for cryogenic applications, including storage and transport tanks for liquid gases in aerospace and energy industries.

Defense and military

2219 aluminum bar is used in defense systems, such as missile structures and armored components, where strength, durability, and reliability under extreme conditions are crucial.

High-performance automotive

In high-performance and racing vehicles, 2219 aluminum bar is selected for engine components, suspension parts, and other critical elements that require a high strength-to-weight ratio and thermal stability.

Industrial machinery

2219 aluminum bar is also used in precision industrial machinery and equipment, particularly in parts exposed to heat or requiring high mechanical strength, such as robotic arms, fixtures, and heat-exposed mechanical assemblies.

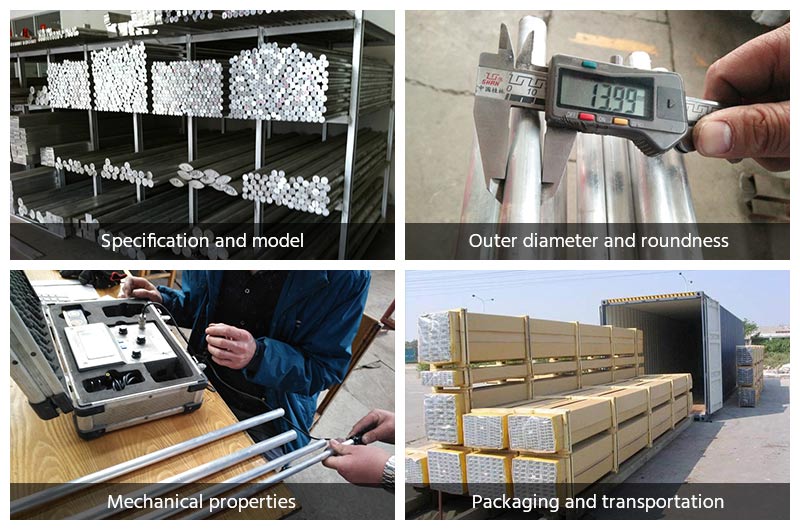

2219 aluminum bar supplier

Chalco is a large modern aluminum processing enterprise that combines research, processing, and manufacturing. It possesses equipment such as 12, 500-ton horizontal extruders, 2800mm hot rolling mills, cold rolling mills, and 6, 000-ton stretch straighteners.

Additionally, Chalco has multiple imported cutting machines, fully automatic feeding saws, large vertical automatic feeders, and other processing equipment, allowing material processing according to various industry requirements and fulfilling different processing needs.

Services like ultrasonic testing of aluminum bars, sawing, milling, facing, thin-film laser engraving, etc., are also provided. All products are certified by CE and ISO9001, and they can be customized to meet different standards, such as Japanese, European, American, etc. For more details, please email us to discuss. Chalco looks forward to cooperating with you!

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Recommended Related Products for 2219 Aluminum Rods

Stock list of Chalco 2219 aluminum round bars

Inventory information is being updated in real-time, with hot selling inventory lengths of 3m, 6m and other sizes available for cutting.

Welcome to click on the button to obtain the latest inventory information and lowest quotation....Get A Quote

2219 T8511 Aluminum Round Bar Stock List

| Description | Diameter/mm | Description | Diameter/mm |

| 2219 T8511 aluminum round bar | φ15 | 2219 T8511 aluminum round bar | φ165 |

| 2219 T8511 aluminum round bar | φ20 | 2219 T8511 aluminum round bar | φ170 |

| 2219 T8511 aluminum round bar | φ25 | 2219 T8511 aluminum round bar | φ175 |

| 2219 T8511 aluminum round bar | φ30 | 2219 T8511 aluminum round bar | φ180 |

| 2219 T8511 aluminum round bar | φ35 | 2219 T8511 aluminum round bar | φ185 |

| 2219 T8511 aluminum round bar | φ40 | 2219 T8511 aluminum round bar | φ190 |

| 2219 T8511 aluminum round bar | φ45 | 2219 T8511 aluminum round bar | φ195 |

| 2219 T8511 aluminum round bar | φ50 | 2219 T8511 aluminum round bar | φ200 |

| 2219 T8511 aluminum round bar | φ55 | 2219 T8511 aluminum round bar | φ210 |

| 2219 T8511 aluminum round bar | φ60 | 2219 T8511 aluminum round bar | φ220 |

| 2219 T8511 aluminum round bar | φ65 | 2219 T8511 aluminum round bar | φ230 |

| 2219 T8511 aluminum round bar | φ70 | 2219 T8511 aluminum round bar | φ240 |

| 2219 T8511 aluminum round bar | φ75 | 2219 T8511 aluminum round bar | φ250 |

| 2219 T8511 aluminum round bar | φ80 | 2219 T8511 aluminum round bar | φ260 |

| 2219 T8511 aluminum round bar | φ85 | 2219 T8511 aluminum round bar | φ270 |

| 2219 T8511 aluminum round bar | φ90 | 2219 T8511 aluminum round bar | φ280 |

| 2219 T8511 aluminum round bar | φ95 | 2219 T8511 aluminum round bar | φ290 |

| 2219 T8511 aluminum round bar | φ100 | 2219 T8511 aluminum round bar | φ300 |

| 2219 T8511 aluminum round bar | φ105 | 2219 T8511 aluminum round bar | φ310 |

| 2219 T8511 aluminum round bar | φ110 | 2219 T8511 aluminum round bar | φ320 |

| 2219 T8511 aluminum round bar | φ115 | 2219 T8511 aluminum round bar | φ330 |

| 2219 T8511 aluminum round bar | φ120 | 2219 T8511 aluminum round bar | φ340 |

| 2219 T8511 aluminum round bar | φ125 | 2219 T8511 aluminum round bar | φ350 |

| 2219 T8511 aluminum round bar | φ130 | 2219 T8511 aluminum round bar | φ360 |

| 2219 T8511 aluminum round bar | φ135 | 2219 T8511 aluminum round bar | φ370 |

| 2219 T8511 aluminum round bar | φ140 | 2219 T8511 aluminum round bar | φ380 |

| 2219 T8511 aluminum round bar | φ145 | 2219 T8511 aluminum round bar | φ390 |

| 2219 T8511 aluminum round bar | φ150 | 2219 T8511 aluminum round bar | φ400 |

| 2219 T8511 aluminum round bar | φ155 | 2219 T8511 aluminum round bar | φ410 |

| 2219 T8511 aluminum round bar | φ160 | 2219 T8511 aluminum round bar | φ420 |

2219 T6 Aluminum Round Bar Stock List

The 2219-T6 aluminum bar indicates that the rod has undergone solution heat treatment, stretching and straightening (with a permanent strain of approximately 0.5% to 2%), and artificial aging treatment, significantly enhancing its mechanical properties and dimensional stability.

However, for aluminum rods with slightly larger diameters, ordinary stretching machines cannot handle them. Therefore, many suppliers replace 2219-T6511 aluminum rods with 2219-T6 aluminum rods in their supply.

Chalco owns a 12, 500-ton horizontal extrusion machine and a 6, 000-ton stretching and straightening machine, capable of stretching aluminum rods with a maximum diameter of 350mm. We supply you with genuine 2219-T6511 aluminum rods.Quick Quote

| Description | Diameter/mm | Description | Diameter/mm |

| 2219 T6 aluminum round bar | φ20 | 2219 T6 aluminum round bar | φ140 |

| 2219 T6 aluminum round bar | φ25 | 2219 T6 aluminum round bar | φ160 |

| 2219 T6 aluminum round bar | φ30 | 2219 T6 aluminum round bar | φ170 |

| 2219 T6 aluminum round bar | φ45 | 2219 T6 aluminum round bar | φ180 |

| 2219 T6 aluminum round bar | φ50 | 2219 T6 aluminum round bar | φ190 |

| 2219 T6 aluminum round bar | φ60 | 2219 T6 aluminum round bar | φ210 |

| 2219 T6 aluminum round bar | φ80 | 2219 T6 aluminum round bar | φ220 |

| 2219 T6 aluminum round bar | φ90 | 2219 T6 aluminum round bar | φ240 |

| 2219 T6 aluminum round bar | φ95 | 2219 T6 aluminum round bar | φ260 |

| 2219 T6 aluminum round bar | φ100 | 2219 T6 aluminum round bar | φ270 |

| 2219 T6 aluminum round bar | φ110 | 2219 T6 aluminum round bar | φ280 |

| 2219 T6 aluminum round bar | φ120 | 2219 T6 aluminum round bar | φ290 |

| 2219 T6 aluminum round bar | φ130 | 2219 T6 aluminum round bar | φ330 |

| 2219 T6 aluminum round bar | φ135 | 2219 T6 aluminum round bar | φ350 |

Comparison between 2219 aluminum alloy and 2024 aluminum alloy

2219 aluminum and 2024 aluminum are both high-strength alloys in the Al-Cu (2xxx series), widely used in aerospace and high-performance applications. While they share similar base elements, they differ in temperature performance, weldability, and corrosion resistance, making them suitable for distinct engineering scenarios.

Similarities

- High strength: Both 2024 and 2219 offer excellent strength and fatigue resistance, making them ideal for aerospace structures, aircraft skins, and load-bearing components.

- Heat-treatable: These alloys can be strengthened through heat treatment processes such as solution heat treatment and artificial aging to achieve high mechanical performance.

- Machinability: Both alloys provide good machinability in heat-treated conditions and are compatible with conventional machining methods like milling, drilling, and turning.

Differences

- Weldability: 2219 has excellent weldability with high resistance to cracking in welded areas, making it suitable for applications such as rocket fuel tanks and pressure vessels. In contrast, 2024 has poor weldability and is generally avoided for welded structures.

- Temperature performance: 2219 aluminum maintains better strength and stability at elevated temperatures, suitable for components exposed to high thermal loads. 2024, while strong at room temperature, loses strength in elevated-temperature environments.

- Corrosion resistance: 2219 generally has slightly better corrosion resistance than 2024, although both may require surface treatments or protective coatings in corrosive environments.

- Applications: 2024 is often used in aircraft fuselage skins, structural frames, and wing tension members. 2219 is preferred in aerospace fuel systems, high-temperature components, and cryogenic tanks where weld integrity and thermal stability are critical.

- Composition: 2024 contains higher magnesium (1.2%–1.8%) and manganese (0.3%–0.9%), enhancing strength and fatigue resistance, while 2219 has a higher copper content (5.8%–6.8%) and trace elements like titanium and vanadium to improve thermal properties and weldability.

In conclusion, 2024 and 2219 aluminum alloys serve different engineering needs. 2024 is best for applications requiring high strength and fatigue resistance at room temperature, while 2219 is more suitable for high-temperature and welded aerospace structures. Choosing between them depends on the specific mechanical, thermal, and fabrication requirements of your project.

At Chalco, we supply both 2219 aluminum bars and 2024 aluminum bars. Contact us to get detailed stock availability, technical data, or assistance in choosing the right alloy for your application.

How Chalco Solves the Coarse Grain Ring Issue in 2219 Aluminum Bar Rods?

- Optimizing Ingot Casting Parameters: Chalco adopts precise control over cooling rates and casting temperatures during DC casting of 2219 aluminum to minimize thermal gradients and suppress the formation of surface coarse grains.

- Homogenization Annealing: A multi-stage homogenization treatment is applied to promote uniform diffusion of copper and other alloying elements, reducing segregation and promoting fine, uniform grain structures.

- Grain Refinement with Master Alloys: The addition of grain-refining elements such as titanium, zirconium, or vanadium during melt treatment helps to inhibit coarse grain formation and ensure a finer microstructure.

- Controlled Extrusion Process: During extrusion, Chalco controls extrusion temperature, speed, and billet preheating to ensure stable deformation conditions and uniform recrystallization, avoiding coarse grain rings near the surface.

- Post-Extrusion Heat Treatment: Precise quenching and aging schedules tailored for 2219-T8511 temper refine grains and eliminate coarse peripheral grain zones that might form during thermal cycling.

- Advanced Quality Monitoring: Metallographic inspection, ultrasonic testing, and grain size analysis are routinely performed to detect early-stage coarse grain formation, allowing for timely process adjustments and ensuring consistent quality.

Production Process of 2219 Aluminum Bars

Process for casting 2219 aluminum bars

- Melting: the raw aluminum alloy material is melted at high temperatures, transforming it into liquid aluminum alloy.

- Casting: the molten aluminum alloy is poured into pre-made molds, and after cooling and solidification, it takes the initial shape of aluminum bars.

- Sawing: the solidified aluminum bars are cut using saws to remove any undesired parts, leaving the desired length of aluminum bar blanks.

- Homogenization: the aluminum bars undergo a heat treatment process to achieve a uniform internal structure, reducing internal stresses.

- Cooling and Cleaning of Bars: The homogenized aluminum bars are cooled and cleaned, preparing them for subsequent processing.

- Aluminum Bars Storage: The processed aluminum bars are stored for future use.

Process for extruding 2219 aluminum bars

- Pre-Extrusion preparation: the aluminum alloy material is prepared for the extrusion process, which includes heating it to the appropriate temperature.

- Extrusion: the heated aluminum alloy is forced through a specially shaped die to produce aluminum bars with the desired cross-sectional shape.

- Stretching and straightening: the extruded aluminum bars are stretched and straightened to improve their mechanical properties and alignment.

- Cutting finished products: the stretched bars are cut into the desired lengths using cutting equipment, creating finished aluminum bars.

- Framing and edge trimming: the finished aluminum bars are framed and their edges are trimmed to meet the required specifications.

Guidelines for purchasing 2219 aluminum bar from Chalco Aluminum

Before purchasing 2219 aluminum bars from China Aluminum, please confirm the sizes and quantities you need. Then, contact our customer service team, and we will provide you with the highest quality products and the most competitive market prices.

2219 aluminum bar price

2219 aluminum bar price: (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact China Aluminum for price inquiries, as well as the processing fee per ton for various specifications of aluminum bars. The processing fees for different sizes of 2219 aluminum bars may vary significantly, and we will provide you with the most favorable quotation.Quick Quote

2219-T6 Aluminum Bar, 2219-T8511 Aluminum Bar, and 2219-T851 Aluminum Bar are the most commonly ordered conditions.

Calculation of 2219 aluminum bar weight

Weight of aluminum round bar: πR² * h × 0.0000027 (3.1415 * square of the radius of the aluminum bar * length of the aluminum bar * density, radius length in millimeters). Insert link to aluminum round bar weight calculator.

Calculation of Aluminum Square Bar Weight = A-side * B-side * 0.0027 * h (length of the aluminum bar) Where A-side and B-side are the dimensions of the square bar's sides, and h is the length of the aluminum bar in millimeters.

Appearance quality of 2219 aluminum bar

- The surface of 2219 round, square, or hexagonal bars should be free from cracks, bubbles, or corrosive spots.

- The thickness of 2219 round, square, or hexagonal bars must not exceed the allowable deviation range.

- The surface of 2219 round, square, or hexagonal bars should be free from deep scratches, abrasions, dents, or straightening marks that exceed the deviation range.

Packaging of 2219 aluminum bar

- Plastic or kraft paper packaging with moisture desiccants.

- Mounted on wooden pallets, reinforced with steel straps, and provided with fumigation certificates.

- Packaging can be tailored to other customer requirements.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote