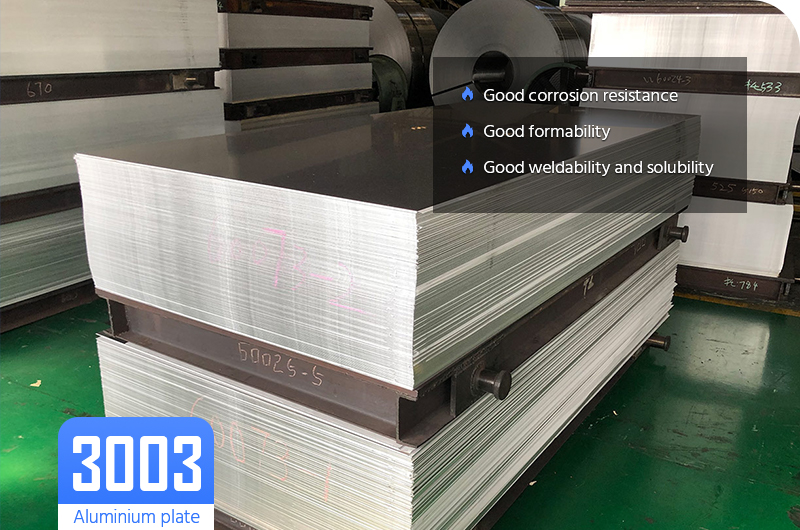

3003 Aluminum Sheet is a typical AL-Mn series alloy known for its excellent workability, weldability, and corrosion resistance. Although it can't be strengthened by heat treatment, its mechanical properties can be improved through cold working methods.

Instant QuoteFor bulk purchases, Chalco can customize according to your requirements for American or European standards. You can view the specifications and performance details for 3003 aluminum sheets.

Chalco's best-selling sizes for A93003 aluminum sheets

Chalco offers a variety of hot-selling sizes for AL3003 aluminum sheets, which can be customized or cut. The most popular are AMS 4006 in the O state and AMS 4008 in H14.

Instant Quote| Description | Temper | Thickness/in | Width*Length/in |

| 0.016(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.016 | 48x96 |

| 0.02(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.02 | 48x96 |

| 0.025(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.025 | 48x120 |

| 0.032(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.032 | 48x120 |

| 0.032(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.032 | 48x144 |

| 0.04(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.04 | 48x120 |

| 0.04(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.04 | 48x144 |

| 0.05(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 60x120 | H14 | 0.05 | 60x120 |

| 0.05(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 60x144 | H14 | 0.05 | 60x144 |

| 0.063(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.063 | 48x96 |

| 0.063(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.063 | 48x120 |

| 0.063(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.063 | 48x144 |

| 0.08(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.08 | 48x96 |

| 0.08(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.08 | 48x144 |

| 0.09(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.09 | 48x96 |

| 0.1(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.1 | 48x120 |

| 0.1(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.1 | 48x144 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x96 | H14 | 0.125 | 48x96 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x120 | H14 | 0.125 | 48x120 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 48x144 | H14 | 0.125 | 48x144 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 36x120 | H14 | 0.125 | 36x120 |

| 0.125(t) 3003 H14 Aluminum sheet AMS 4008 ASTM B209 60x144 | H14 | 0.125 | 60x144 |

| 0.19(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x144 | H14 | 0.19 | 48x144 |

| 0.25(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x120 | H14 | 0.25 | 48x120 |

| 0.25(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x144 | H14 | 0.25 | 48x144 |

| 0.32(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x120 | H14 | 0.32 | 48x120 |

| 0.32(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x144 | H14 | 0.32 | 48x144 |

| 0.375(t) 3003 H14 Aluminum plate AMS 4008 ASTM B209 48x120 | H14 | 0.375 | 48x120 |

| 0.04(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.04 | 48x144 |

| 0.09(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.09 | 48x144 |

| 0.05(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.05 | 48x144 |

| 0.63(t) 3003 O Aluminum sheet AMS4006 ASTM B209 48x144 | O | 0.63 | 48x144 |

If the popular sizes listed above don't meet your specifications, you can directly contact us for custom options or check out the specific production capabilities below.

Instant QuoteChalco 3003 aluminum sheet specifications

| Name | 3003 aluminum sheet | |

| Hot selling status | O,H22,H24,H14,H16,H26,H18,H28,H112 | |

| Equivalent name | AW-AlCu4Mg1,3.0517,A93003,AlCu4Mg,AlCuMg2,ASTM B209 | |

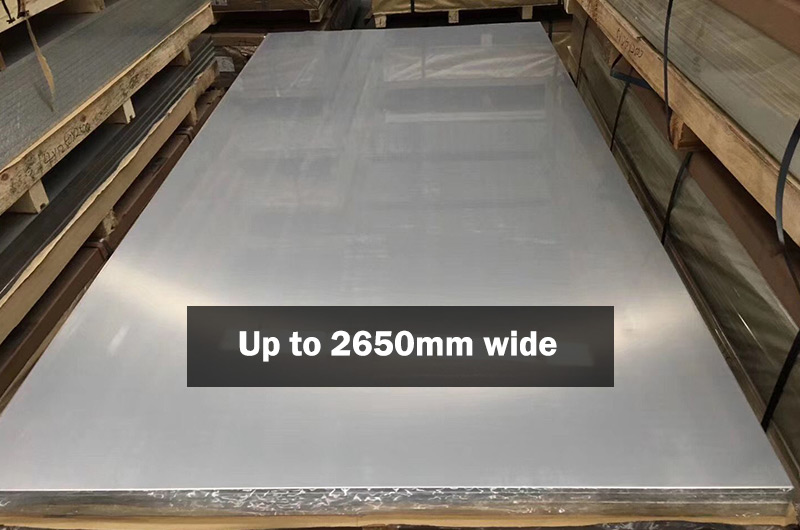

| 3003 aluminum sheets | Thickness:0.01”-0.24”(0.2mm-6mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 aluminum plate | Thickness:0.32”-9.84”(8mm-250mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 Ultra wide aluminum sheet | Thickness:0.01”-0.24”(0.2mm-6mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 white coated aluminum sheet | Thickness:0.01”-0.24”(0.2mm-6mm) | Width:35.4”-104”(900mm-2650mm) |

| 3003 aluminum diamond plate | Thickness:0.05”0.32”(1.2-8mm) | Width:35.4”-72.83”(900mm-1850mm) |

| length | Max 6m, Fix & Cut Length or Customized | |

| Surface treatment | Mill finish,Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

| Lamination type | Blue film, transparent film, black and white film, paper (film thickness: 50 microns, 80 microns) | |

| Standard | AMS 4008,ASTM B20,QQ-A-250/2,ASTM B209,AMS4006 | |

Chalco EN-AW3003 aluminum plate physical properties

| 3003-O | 3003-H14 | 3003-H22 | |

| Shear Strength | 75MPa | 96MPa | 81MPa |

| Tensile Strength | 40-110MPa | 130-160MPa | 94-140MPa |

| Elastic Modulus | 70GPa | 70GPa | 70GPa |

| Hardness Brinell | 28HB | 42HB | 37HB |

| Elongation | 28% | 8% | 8% |

Related Products of 3003 Aluminum Sheet

For scenarios requiring exterior coating, embossed anti-slip surfaces, lightweight decoration, or large-area installation, 3003 offers multiple variants that balance corrosion resistance, formability, and surface-finishing performance.

Related Products of 3003 Aluminum Sheet

For scenarios requiring exterior coating, embossed anti-slip surfaces, lightweight decoration, or large-area installation, 3003 offers multiple variants that balance corrosion resistance, formability, and surface-finishing performance.

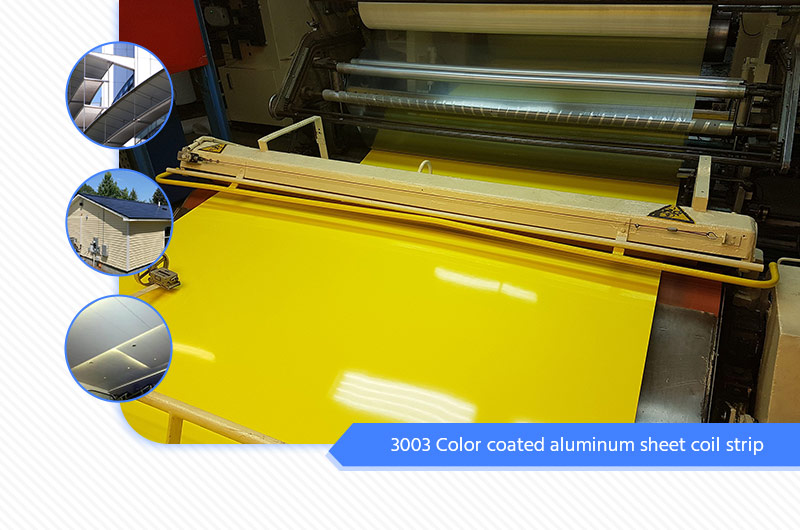

3003 Color-Coated Alu Sheet

Excellent corrosion resistance and attractive appearance; suitable for architectural decoration and home-appliance shells.

3003 Embossed Stucco Sheet

Enhanced anti-slip performance, often used for floor laying.

3003 Tread Checkered Plate

Ideal for decoration and architectural uses with a distinctive visual effect.

3003 Aluminum Diamond Plate

It is often used as aluminum anti-slip plate or aluminum floor plate.

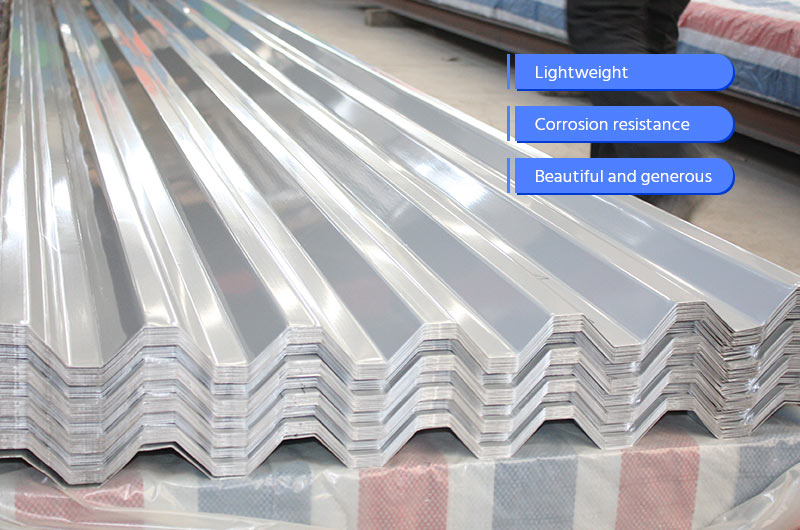

3003 Aluminum Corrugated Sheet

Commonly used for exterior walls and roofs, offering excellent weatherability.

3003 Sublimation Alu Sheet

Realistic appearance and strong formability, used in furniture, signage, and 3C applications.

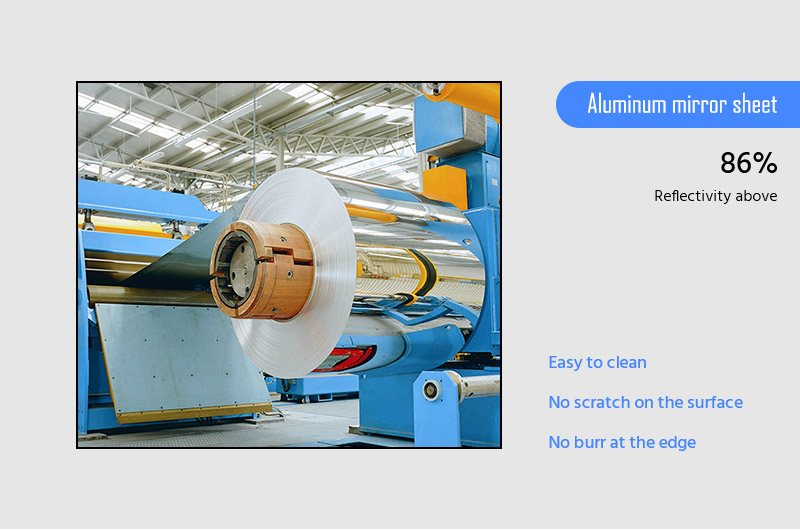

3003 Mirror Aluminum Sheet

Reflectivity up to 95%, ideal for mirror-grade decorative use.

3003 PCB Aluminum Entry Sheet

Used in electronics for drilling aluminum-based PCBs and heat-sink plates.

3003 Ultra-Wide Aluminum Plate

For applications requiring large-format aluminum sheets.

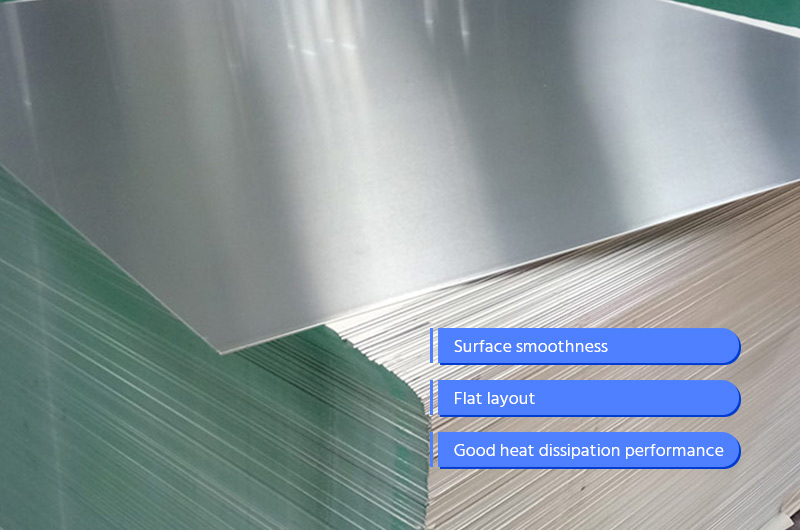

What are the characteristics of A93003 aluminum plate?

- Excellent corrosion resistance

- Outstanding malleability

- Excellent weldability

- Suitable for cold working

Typical Industry Applications of 3003 Aluminum Sheet

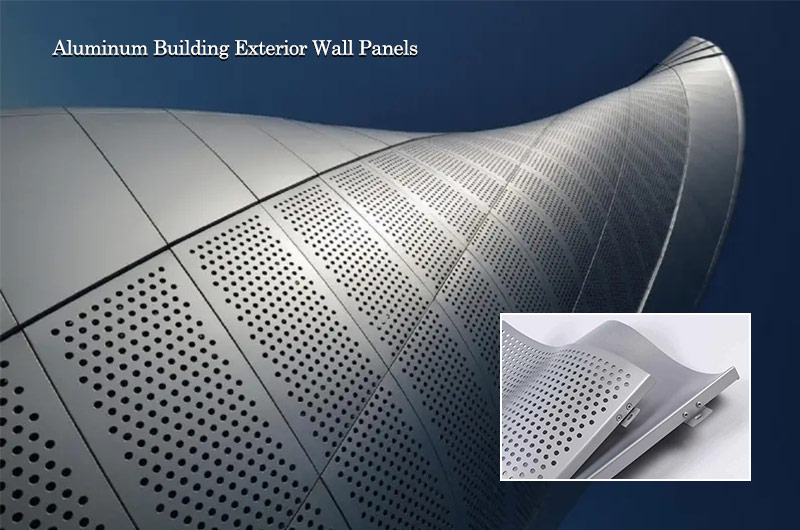

Leveraging 3003’s corrosion resistance and formability, it is suitable for curtain-wall liners, roofing/decorative sheets, as well as corrugated and embossed panels.

Contact us now

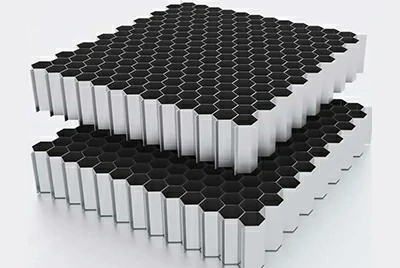

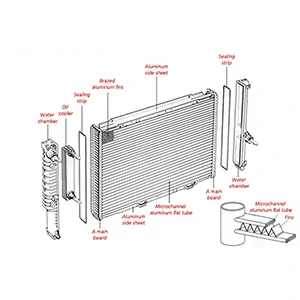

A "go-to alloy” for heat-exchange systems, 3003 is used for radiator/condensed/evaporator fins and cladded cover sheets for oil coolers. It pairs well with brazing cladding to form integrated welding solutions.

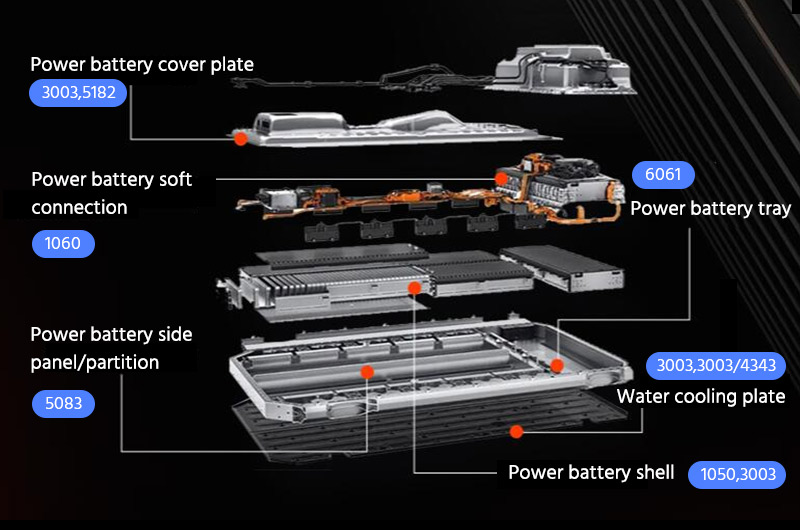

Contact us now3003 aluminum sheet is commonly used for liquid-cooling plates (water-cooling plates), battery base/cover plates, and battery enclosures.

Power Battery Liquid-Cooling Plate

Contact us now

For lightweight interior panels, carriage liners, corrugated sheets and container liners, 3003 balances formability and corrosion resistance.

Contact us nowFor sign faces requiring surface finishing and weatherability, 3003 offers excellent compatibility with coating and anodizing.

Contact us now

Processing Services for Chalco 3003 Aluminum Sheet

Surface Treatment

3003 can be anodized to enhance corrosion resistance and surface hardness. It is also suitable for mirror polishing and color coating, delivering both appearance and weatherability. For outdoor decoration or applications that require subsequent printing/signage, these finishes significantly improve the final product performance.

Deep Processing

Chalco can manufacture to drawing with sheet CNC cutting (straight/contoured), CNC precision machining (slotting, counterboring, chamfering, etc.), and circle-cutting (blanking round discs/rings). Leveraging 3003’s excellent formability and weldability helps shorten your material preparation and prototyping cycles.

What are the advantages of Chalco?

Chalco produces ASTM B209 3003 aluminum coils and sheets, reaching up to a maximum width of 2650mm and a minimum thickness of 0.2mm. The diverse range caters to different thickness and width requirements, offering highly competitive prices as a direct manufacturer. Chalco provides comprehensive supply, removing any worries associated with the procurement process. All products pass quality system certifications like ISO 9001, GJB 9001, AS9100, TS16949, and Nadcap (NonDestructive/Heat/Materials Testing) certificates. Customized labeling standards for Japanese, European, and American specifications are available upon customer request.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

What production equipment does Chalco have as a EN-AW 3003 aluminum plate supplier?

Chalco is equipped with an advanced German-made 1+4 4500mm hot rolling production line from SMS Group. The line is furnished with Siemens electrical configurations and features a German IMS curvature gauge, enabling closed-loop control for thickness and sheet shape. The hot rolling mill is equipped with hydraulic adjustment systems, CVCplus technology, work roll bending with a multi-zone cooling system, and temperature control systems. It also includes a light and heavy shear, edge trimming equipment, coiling machinery, waste transport systems, and flue gas purification systems. For cold rolling, they utilize German-made 2800mm single-stand and double-stand CVC cold rolling mills from SMS Group, offering a maximum rolling force of 20,000 kN and speeds reaching up to 1800m/min. These advanced production lines and technologies guarantee superior plate shape and surface quality, minimizing common quality issues.

What quality problems do A93003 aluminum plates generally encounter?

- Appearance Quality: Common appearance issues in aluminum alloy plates include surface unevenness, poor plate shape, scratches, black streaks, peeling, impurities, tropical stains, airway defects, adhesive roller marks, holes, corrosion, oxidation, and yellow oil spots, which can impact the usability.

- Dimensional Quality: Customers now demand higher precision in dimensions, including length, width, and thickness. Compliance with these dimensional tolerances is crucial for product acceptance. If the dimensions do not meet the specified tolerances, the product may be considered non-compliant.

- Packaging Wear: Friction between plates without interleaving paper or film can lead to static black streaks, among other surface issues.

- Transportation Wear: Rough handling during loading and unloading, causing packaging damage, or container water ingress leading to dampness and mold in the packaging.

3003 aluminum sheet vs. 5052 aluminum sheet

When selecting aluminum sheet, 3003 is widely used for its excellent formability and moderate strength. If you require stronger corrosion resistance, 5052 is an ideal choice. Compared with 3003, 5052 offers superior salt-spray resistance and performs well in harsher environments, especially in marine and chemical industries. The table below outlines the core differences for quick material selection.

| Key Attribute | 3003 Aluminum Sheet | 5052 Aluminum Sheet |

| Strength | Medium strength | Higher strength |

| Corrosion Resistance | Good | Stronger; suitable for seawater environments |

| Formability | Excellent | Good; slightly less than 3003 |

| Typical Applications | Architectural trim, signage, heat-exchange components | Marine parts, automotive exterior panels, enclosure panels |

If you need stronger corrosion resistance, 5052 aluminum sheet is the better choice.