Aircraft extrusion offers high-performance 2024, 6061, and 7075 aerospace aluminum profiles, with over 33,000 partnumbers ready to ship.

We specialize in custom and standard extrusions for airframe structures, with fast lead times, in-house CNC, andfull design support—trusted by Boeing, Airbus, and top OEMs.

Aircraft extrusion specifications

- Certified under the AS9100 quality management system to ensure full consistency and traceability.

- Compliant with ISO 9001:2015 and AS9100:2016 Rev D standards.

- AS9120 certified to support aerospace supply chain and warehouse management.

Each batch comes with full chemical composition and mechanical property reports. All materials meet REACH and RoHSstandards. Quality records are permanently retained to ensure full traceability across the aerospace industry.

Aerospace aluminum extrusions products

Chalco understands the aerospace industry's high demands for lead time, compliance, and cost control. With in-stockinventory, fast response, and full traceability, we help reduce AOG downtime and lower material costs.

We offer not only aluminum and titanium aerospace extrusions, but also custom profiles, CNC prototypes, seatcomponents, and cargo nets—supporting everything from hand-drawn sketches to full 3D CAD models.

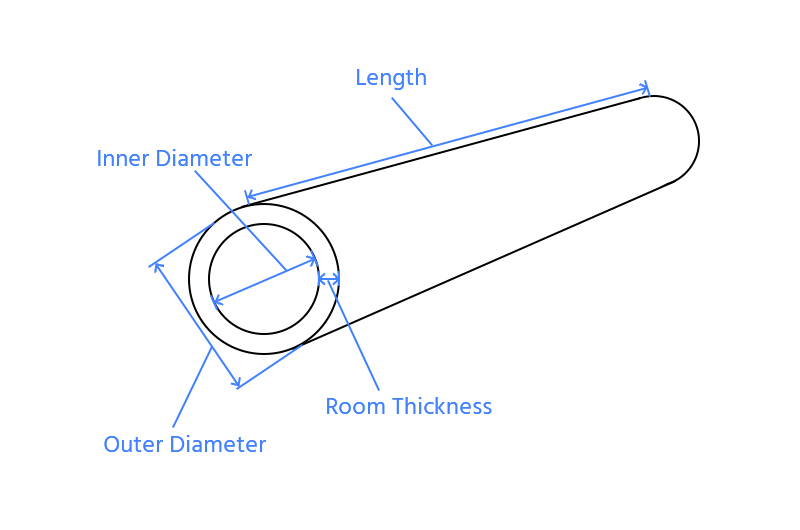

Aircraft aluminum tube pipe

As one of the reliable aircraft aluminum tubing suppliers, Chalco specializes in the development and customizationof aviation aluminum tubing for applications requiring a high strength-to-weight ratio.

We offer a wide range of standard and non-standard profiles, including square, rectangular, and complex-shapedtubes, engineered to meet the structural demands of modern aerospace and performance-driven industries.

Instant QuoteAircraft Aluminum Round Tubing

Aircraft aluminum round tubing offers high strength, lightweight properties, and excellent fatigueresistance, making it ideal for aircraft structures, supports, and hydraulic systems.

Contact us now

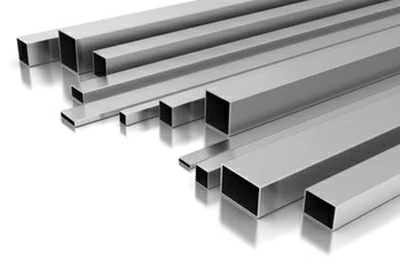

Aircraft AluminumSquare Tubing

Aircraft aluminum square tubing is strong, lightweight, and ideal for structural aerospace use.

Contact us nowAerospace-grade rectangular tubing offers excellent strength and rigidity, ideal for fuselage structuresand frame reinforcement.

Contact us now

AircraftAluminum Seamless Tubing

Aircraft aluminum seamless tubing offers high strength and a smooth, uniform structure for criticalaerospace applications.

Contact us nowAircraft Aluminum Drawn Tubing

Aircraft aluminum drawn tubing provides enhanced strength, tight tolerances, and a smooth finish forprecision aerospace components.

Contact us now

BAC1501 Boeing tubing

We offer a wide range of aircraft tubing that meets Boeing BAC1501 specifications in 2024 and 7075alloys.

Contact us nowOur inventory mainly includes extruded and drawn tubing. Drawn tubing is primarily available in 2024-T3 AMS-WW-T-700/3 and 7075-T6 AMS-WW-T-700/7.

For extruded tubing, we offer 2024-T3511 AMS-QQ-A-200/3 and 7075-T6511 AMS-QQ-A-200/11.

Browse our full aircraft aluminum tubing inventory, including round, square, rectangular, seamless, and drawnoptions in various alloys and sizes.

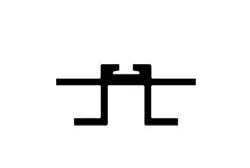

Instant QuoteAircraft extrusionstandard shapes

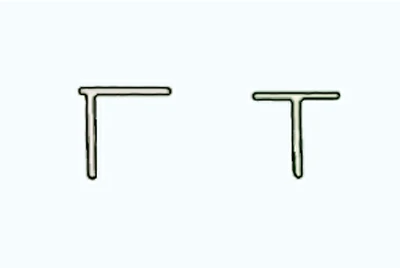

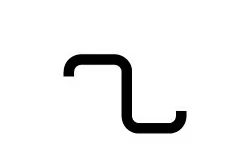

Standard aircraft extrusions are available in a variety of shapes such as angles, channels, tees, and zee profilesfor structural aerospace applications.

Aluminum Angle

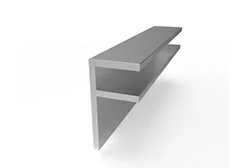

H Profil Aluminium

Aluminum Channel

Beam Aluminium

Aluminum Z Profile

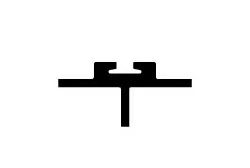

Aluminium T Profile

Aluminum C Channel

Aluminum Hat Channel

F Channel Aluminum Extrusion

Custom shapes available to meet your specific aerospace design requirements.

Interested in these shapes? Feel free to request a quote, ask questions, or learn more.

Instant QuoteBoeing (BAC) extrusions

We custom-produce Boeing (BAC) extrusions with thousands of shapes available, typically supplied in 10, 12, 20, and 24-foot lengths.

BAC1504 Angle, Bulb

BAC1515 Angle, Bulb, Misc

BAC1514 Angle, Misc

BAC1509 Channel

BAC1510 Channel, Misc

BAC1507 Double-Leg Tee

BAC1508 Double-Leg Tee, Misc

BAC1511 Filler (Solid Bar)

BAC1513 Filler, Misc

BAC1519 Forks & Fittings

BAC1520 Misc Shapes

BAC1506 Tee, Misc

Explore our range of BAC extrusions (Boeing shapes) available for custom production, and contact us for the complete size list.

Instant QuoteAND extrusions

We provide standard aerospace and aircraft extruded shapes, including Army Navy drawing extrusions, with thousands of part numbers that can be custom-produced in typical lengths of 10, 12, 20, and 24 feet — supporting your aerospace project needs.

AND10133 Equal Leg Angle

AND10134 Unequal Leg Angle

AND10135 Bulb Angle

AND10136 Tee

AND10137 Channel

AND10138 Equal Leg Zee

AND10139 Unequal Leg Zee

AND10140 H Beam

AND10141 Bulb Tee

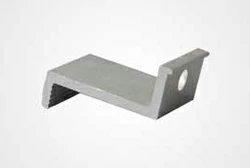

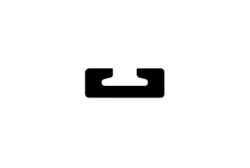

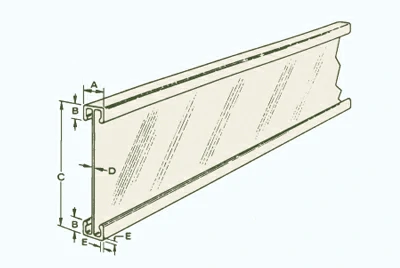

Aircraft seat trackextrusion

Chalco offers in-house CNC machining capabilities for various aircraft grades, including 2024, 6061, and 7075, withlengths up to 12 feet (approx. 3.6 meters).

All manufactured tracks come with OEM certification and full traceability. First Article Inspection (FAI) andmaterial certificates are provided in all cases.

Aircraft seat trackextrusion is a high-strength structural profile used to secure and adjust seat positionsin aircraft cabins.

Contact us now

Other shapes:

Type A

Type B

Type C

Type D

Type E

Type G

Popular aircraft component extrusions by Chalco

Chalco's best-selling aircraft components include extruded aluminum wing spars, folding screen profiles, andstringer extrusions—widely used in both commercial and military aircraft structures.

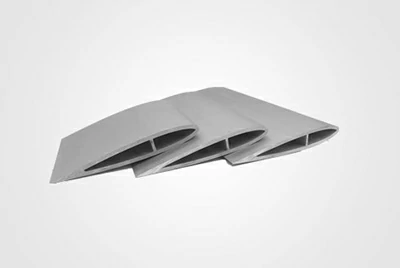

6061-T6 Aluminum Streamline Struts

All streamline struts are made from 6061-T6 extruded aluminum for excellent strength, corrosionresistance, and aerodynamic performance.

Contact us now

Extruded aluminum wing spar material

Made from 6061-T6 extruded aluminum with an ultimate tensile yield strength of 45,000 PSI and shearyield strength of 30,000 PSI.

Contact us now

Aluminum folding screen profiles for airport use

These profiles are made from 6061/6063 aluminum alloys, comply with GB/T 6892-2015 standards, feature ananodized finish, and are packaged with anti-static film and shrink wrap.

Contact us nowAircraft aluminum ribs

Aluminum alloy ribs used inside aircraft wings offer a lightweight, high-strength structure designed tosupport the skin and withstand flight loads.

Contact us now

Aircraft hinge extrusions

Aircraft hinge extrusions are used for connecting movable parts like doors and control surfaces,offering high strength, light weight, and corrosion resistance.

Contact us nowAircraft aluminum roll form stringers

Specific part numbers can be custom-produced from our range of thousands of Boeing extrusion shapes, typically supplied in 12-foot lengths.

BAC 1490 Angle 90 Degrees

BAC 1489 Angle, Acute/Obtuse

BAC 1494 Channel C-Section

BAC 1495 Channel C-Section

BAC 1500 Channel Flanged

BAC 1493 Channel U-Section

BAC 1492 Misc

BAC 1496 Misc, Channel

BAC 1517 Zee

Aircraft aluminum roll form stringers are available in 2024, 6061, and 7075 alloys (bare and clad), with tempersincluding O, T3, T4, T6, T62, T73, and T42, per AMS-QQ-A-250 standards—specific part numbers in stock, typicallength 12 feet.

Aircraft aluminum bar

Aircraft aluminum bar offers high strength and machinability, making it ideal for aerospace structuralcomponents and precision-machined parts.

Contact us now

Miniature aluminum extrusions

Miniature aluminum extrusions for aircraft are precision profiles used in tight-space structural or interiorapplications where lightweight and strength are critical.

Contact us now

Miniature aluminum extrusions for aircraft are precision profiles used in tight-space structural or interiorapplications where lightweight and strength are critical.

Aircraft extrusion alloys

-

2024 Aircraft Extrusion

High-strength copper alloy ideal for fuselage skins and structural frames.

-

2014 Aircraft Extrusion

Strong and highly machinable, perfect for heavy-load aerospace parts.

-

2219 Aircraft Extrusion

High-temp strength and weldability make it ideal for fuel systems and space structures.

-

7075 Aircraft Extrusion

Ultra-high strength, widely used in fuselage and critical stress zones.

-

7149 Aircraft Extrusion

Improved hardenability for large cross-section aircraft structures.

-

7175 Aircraft Extrusion

Excellent fatigue resistance and toughness for landing gear components.

-

7178 Aircraft Extrusion

Maximum strength and hardness for high-load structural areas.

-

6061 Aircraft Extrusion

Corrosion-resistant and versatile, used in light aircraft and support parts.

-

6063 Aircraft Extrusion

Great surface quality and formability, ideal for interior trim and panels.

Aerospace aluminum alloys and specifications overview

| Alloy | General Specification | ASTM | Latest Designation | Designer Specifications |

| 2014 | AMS4153 | B221 | AMS-QQ-A-200/2 | - |

| 2024 | AMS4152 AMS4164 AMS4165 | B221 | AMS-QQ-A-200/3 | ASNA |

| 2219 | AMS4162 AMS4163 | B221 | - | BMS7-118 DMS2077 |

| 2224 | - | - | - | BMS7-255 |

| 7050 | AMS4340 AMS4341 AMS4342 | - | - | DMS2227 |

| 7075 | AMS4154 AMS4166 AMS4167 AMS4168 AMS4169 | B221 | AMS-QQ-A-200/11 AMS-QQ-A-200/15 | ASNA |

| 7150 | AMS4345 | - | - | BMS7-257 BMS7-306 DMS2256 |

| 7175 | AMS4344 | - | - | BMS7-244 |

| 7178 | B221 | AMS-QQ-A-200/13 AMS-QQ-A-200/14 | - | - |

| 6061 | AMS4150 AMS4160 AMS4161 AMS4172 AMS4173 | B221 | AMS-QQ-A-200/8 | ASNA |

| 6063 | B221 | AMS-QQ-A-200/9 |

Mechanical properties of aerospace alloys 6061, 2024, and 7075

All properties shown in the table are taken from the QQ-A-200 specification.

| Alloy-Temper | Specification | Tensile Strength | Yield Strength | Min Elongation |

| 6061-O | AMS-QQ-A-200/8 | 18,000 psi min | 8,000 psi max | 16% |

| 6061-T6511 | AMS-QQ-A-200/8 | 38,000 psi min | 35,0000 psi min | 8% |

| 7075-O | AMS-QQ-A-200/11 | 33,000 psi min | 15,0000 psi min | 10% |

| 7075-T6511 | AMS-QQ-A-200/11 | 81,000 psi min | 72,0000 psi min | 7% |

| 7075-T73511 | AMS-QQ-A-200/11 | 69,000 psi min | 59,000 psi min | 8% |

| 2024-0 | AMS-QQ-A-200/3 | 27,000 psi min | 11,000 psi min | 12% |

| 2024-T3511 | AMS-QQ-A-200/3 | 65,000 psi min | 46,000 psi min | 10% |

| 2024-T8511 | AMS-QQ-A-200/3 | 66,000 psi min | 58,000 psi min | 5% |

Aircraft extrusion dimensional tolerances

Profile tolerance is a key factor in extrusion design, and Chalco understands aluminum processing inside and out.

For every part we produce, we carefully consider wall thickness, circumscribing circle diameter, dimensionplacement, and profile type, selecting the appropriate extrusion press to meet tolerance requirements.

Instant Quote| Dimension | Tolerance in inches | Username |

| Up Thru 0.124 | +/- 0.006 | Alloy 2000 and 7000 Series |

| 0.125 - 0.249 | +/- 0.007 | Alloy 2000 and 7000 Series |

| 0.250 - 0.499 | +/- 0.008 | Alloy 2000 and 7000 Series |

| 0.500 - 0.749 | +/- 0.009 | Alloy 2000 and 7000 Series |

| 0.750 - 0.999 | +/- 0.010 | Alloy 2000 and 7000 Series |

| 1.000 - 1.499 | +/- 0.012 | Alloy 2000 and 7000 Series |

| 1.500 - 1.999 | +/- 0.014 | Alloy 2000 and 7000 Series |

| 2.000 x 3.999 | +/- 0.024 | Alloy 2000 and 7000 Series |

| 4.000 - 5.999 | +/- 0.034 | Alloy 2000 and 7000 Series |

| Corner and Fillet Radius | ||

| Sharp Corners | +/- 0.016 | Alloy 2000 and 7000 Series |

| 0.016 - 0.187 | +/- 0.016 | Alloy 2000 and 7000 Series |

| 0.188 and over | +/- 10% | Alloy 2000 and 7000 Series |

Who are our customers?

As a specialized aircraft extrusion company, Chalco stocks over 2,000 models of 2024 and 7075 series extrusions,supporting both imperial and metric sizes in standard and non-standard shapes.

We are a recognized supplier to Spirit Aerosystems, the world's largest Tier 1 aerospace structure manufacturer, andmaintain long-term partnerships with major aerospace organizations, including:

- OEMs and airframe manufacturers: Boeing, Airbus, Lockheed Martin, Embraer, Bombardier

- Airlines and operators: Malaysia Airlines, Cargolux, Ryanair

- Advanced manufacturing companies: SpaceX, GE Aviation, Raytheon, Pratt & Whitney, Rolls-Royce, Sikorsky,Moog, Hamilton Sundstrand, Northrop Grumman

We can custom-produce Tiernay Metals parts, BAC Boeing profiles, LS Lockheed shapes, and AND drawings, with standard sizes offered for fast quotes and expedited delivery.

Contact our sales team for a complete inventory list or a custom quotation.

Instant Quote

Applications of aerospace aluminum extrusions

- Wing spars and main beams

- Keels, stringers, and longerons

- Landing gear struts

- Cockpit structural components

- Ailerons, elevators, and rudders

- Seat tracks and seat frame structures

- Interior components

- Avionics mounts and electronic housings

- Hollow beam-style rotating parts (e.g., helicopter components)

- Load-bearing fuselage and tail structures

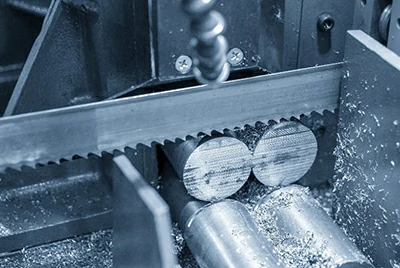

Machining services we offer

Chalco specializes not only in aerospace-grade aluminum extrusions but also in providing one-stop precisionmachining and value-added services to help reduce lead times, lower costs, and improve project efficiency.

- Standard aerospace heat treatment processes to enhance material strength and stability

- High-precision sawing, grinding, and hot forming to ensure dimensional accuracy and surface quality

- Waterjet cutting for precise, heat-free shaping of complex parts

- Trepanning for accurate circular holes in tubing and hollow components

- In-house Haas VF-9 and VF-6 vertical mills for machining large 2024 and 7075 extrusions

- CNC milling for seat tracks, stringers, reinforcements, and other structural parts

- Support for SolidWorks and Mastercam CAD modeling, with full FAI reporting available

Quality control commitment

At Chalco, we are committed to aerospace standards and have established a comprehensive quality control system toensure every aluminum extrusion meets the strict requirements of the aerospace and defense industries.

We apply advanced extrusion technology and strict process control, starting with incoming materialinspection—checking surface condition, dimensions, mechanical properties, and certifications to ensure no scratches,dents, and full traceability between heat numbers and test reports.

Throughout production, we conduct visual inspections, dimensional checks, tensile and corrosion testing, and use CNCcoordinate measuring machines (CMM) and automated inspection equipment to guarantee precision and consistency.

Our facilities are certified to both ISO 9001:2015 and AS9100:2016 Rev D, and we implement statistical processcontrol (SPC) to maintain a PPM (parts per million) defect rate well below industry averages.

From small test batches to full-scale production, Chalco is dedicated to delivering zero-defect, high-qualityaerospace-grade products you can trust.

Why choose us

- Integrated services: From design and extrusion to manufacturing and surface treatment, our experiencedengineering team customizes each profile to your needs.

- Fast delivery: Low minimum order quantities with lead times as short as 2 weeks—ideal for urgent projects.

- Full support: One-on-one technical assistance from design consultation to after-sales service ensures smoothproject execution.

- Diverse material options: Stock and custom supply of aerospace aluminum alloys such as 6061, 2024, and 7075 tomeet various strength, weight, and corrosion requirements.

- Global reach: Whether you're in North America, Europe, Asia, or the Middle East, we provide fast response andworldwide delivery.

- Cost-effective: Competitive pricing without compromising quality or service.

Contact us today for a personalized quote or to learn more about our aerospace aluminum extrusion solutions—Chalcois your trusted partner in precision and performance.

Instant QuotePackaging and shipping

Proper packaging is essential for transporting aerospace extrusions. At Chalco, we understand the risks duringtransit and use high-standard packaging methods to minimize damage and reduce return rates.

- All profiles are inspected for dimensions and appearance before storage, ensuring no scratches or dents.Certification documents and heat numbers are verified against test reports.

- For profiles ≤ 6 feet in length, we use 0.180-inch thick rigid tube packaging.

- Longer profiles are packed in 5-inch or 4×8-inch flexible cartons made of dense cardboard panels with internaldividers—designed to accommodate various shapes including square, rectangular, L, U, and triangular sections.

- Every packaging solution is engineered for impact resistance, compression strength, and surface protection toensure safe delivery.

- All orders are eligible for global shipping.

Chalco also offers other aircraft products

Aircraft aluminum sheet

In addition to extrusions, Chalco also stocks a wide range of aerospace sheets and plates.

Contact us now

Aircraft aluminum sheet is available in a wide range of thicknesses from 0.011" to 5.000", with common customerselections including 0.032", 0.063", 0.125", 0.250", and 0.500" for both structural and skin applications.

Instant Quote| Alloy | Type | Tempers | Specifications |

| 2024 | BARE | O, T3, T351 | AMS-QQ-A-250/4 |

| 2024 | CLAD | O, T3 | AMS-QQ-A-250/5 |

| 7075 | BARE | O, T6, T651, T7351 | AMS-QQ-A-250/12 |

| 7075 | CLAD | O, T6 | AMS-QQ-A-250/13 |

| 2219 | BARE | O | AMS-QQ-A-250/30 |

| 2219 | CLAD | O, T3, T31, T81 | AMS 4095, AMS 4096 |

| 7050 | - | T7451 | AMS 4050 |

| 5052 | - | H34 | AMS-QQ-A-250/8 |

| 6061 | - | O, T4, T6, T651 | AMS-QQ-A-250/11 |

Aerospace aluminum plates can be cut to size or from stocked remnants, and can also be cut in half or thirds forfaster and more cost-effective shipping.

Aerospace titanium

If you're looking for high-quality titanium tubing, bars, extrusions, sheets, and plates, Chalco is your idealchoice.

Click to view all of Chalco's aerospace titanium products.

| Alloy | Specifications |

| 6AL-4V | AMS 4911, MIL-T-9046 |

| CP1 | AMS 4901, MIL-T-9046 |

| CP2 | AMS 4900, MIL-T-9046 |

| CP3 | AMS 4902, MIL-T-9046 |

Standard sheet size is 36″ x 96″, with cut-to-size options and stock remnants also available.

Available in thicknesses from 0.016″ to 0.125″, with popular sizes including 0.025″, 0.032″, 0.040″, 0.063″, and0.090″.

Stainless steel sheet & coil

Standard sheet size is 36″ x 120″, while standard coil size is 24″ wide with customizable lengths.

| Alloy | Specifications |

| 301 1/4 HARD | AMS 5517 |

| 301 1/2 HARD | AMS 5518 |

| 302 COND A | AMS 5516 |

| 304 COND A | AMS 5513 |

| 321 COND A | AMS 5510 |

| 347 COND A | AMS 5512 |

| 15-5 PH | AMS 5862 |

| 17-7 PH | AMS 5528 |

| A – 286 COND A | AMS 5525 |

Available in thicknesses from 0.005″ to 0.125″, with popular sizes including 0.016″, 0.025″, 0.032″, 0.040″, and0.063″ commonly used for aerospace skin and structural applications.

Instant QuoteAerospace fasteners

Chalco is recognized as an expert in aluminum and titanium aerospace fasteners, offering a wide range of stockedgrades such as MS, BAC, NAS, and AN to help customers find the right solution for their aircraft.

All fasteners come with certificates of conformity and full traceability is available upon request.

Contact us now

Washers

Cherry Rivets

Bolts

Nuts

Bolts

Sheet Metal Screws

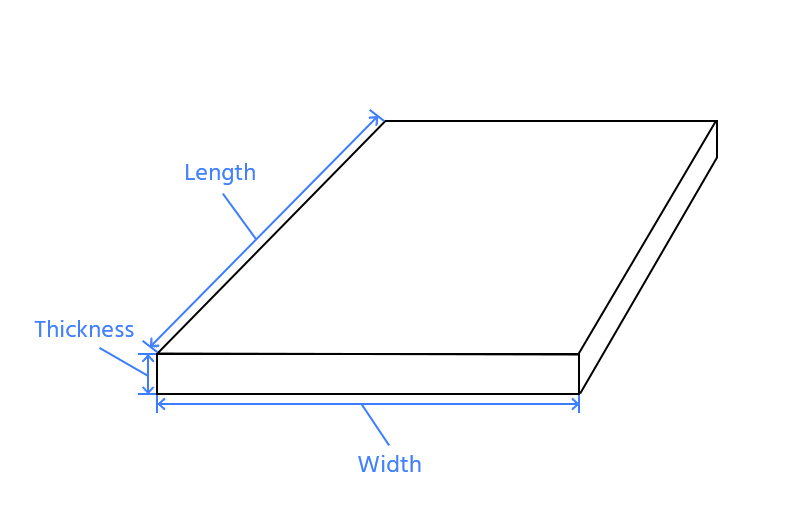

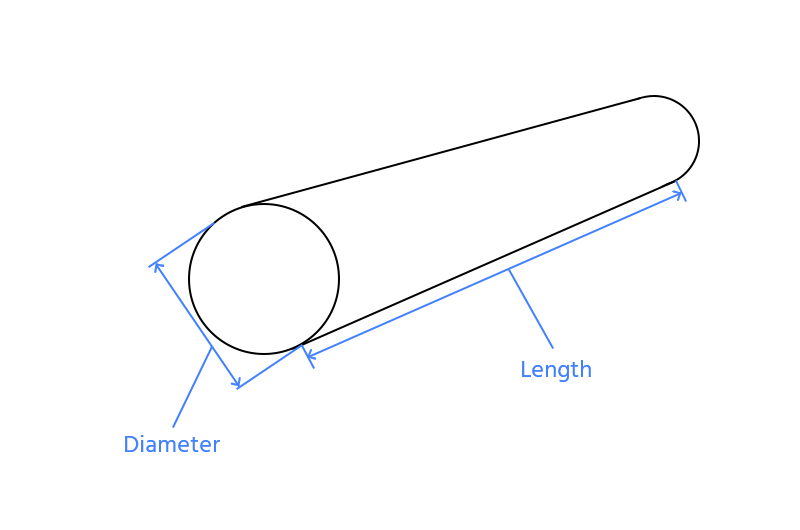

Aircraft aluminum weight calculator

Want to quickly estimate the weight of aluminum profiles?

Use our aircraft aluminum weight calculator—just enter the dimensions online to get instant results.

Click the image or text below to open the aluminum weight calculator.

Frequently asked questions

What is extrusion in the aerospace industry?

Extrusion is a metal forming process where material is pushed or drawn through a die to create a desiredcross-section. This method allows for the production of complex profile shapes.

What is the difference between extrusion and casting?

Casting is limited to low-melting-point metals like aluminum, magnesium, and copper. It has higher initial moldcosts and shorter mold life.

Extrusion, with lower startup costs, is ideal for short-run production. Unlike castings, extrusions are less limitedby size.

What is the difference between extrusion and rolling?

Extrusion allows for a wide variety of shapes, especially complex or continuous cross-sections, and offersflexibility in texture and finish customization.

Rolling produces flat sheets, either smooth or textured, and is best for uniform thickness.

What is the difference between drawing and extrusion?

Unlike extruded tubes and beams, drawn parts are pulled through a die multiple times to gradually reach the desireddimensions.

Extrusion pushes metal through a die in one pass, while drawing reduces the size with each pass until the finalshape is achieved.

How to distinguish forging from extrusion?

Forging uses high pressure to shape irregular, high-strength parts.

Extrusion pushes metal through a die to create continuous profiles with consistent cross-sections.