6013 aluminum plate delivers aerospace-grade strength—12 % higher yield than Alclad 2024—yet keepsthe excellent corrosion resistance, weldability and machinability designers expect from 6061.

Supplied in T4 for easy deep-draw or stretch forming and then naturally aged to T6 without costly heat-treat cycles,it offers a rare mix of high strength-to-weight ratio, fatigue resistance, and clean surface finish ideal forhigh-stress parts, structural panels and precision fixtures.

6013 Aluminum Plate Sheet Specifications

- AMS 4347

- AMS4216

- ASTM B209

- EN 573-3

- EN 485-2

- Rolling: Precision rolling to reduce and unify material thickness into rings or ring segments per your specifications.

- Blanchard Grinding: Large-area surface grinding of plates to meet exact flatness and finish requirements.

- Circular Saw Cutting: High-precision ring or circle cutting from plate stock using circular saws.

- Bending: Controlled bending of material in various sizes and lengths to your exact shape requirements.

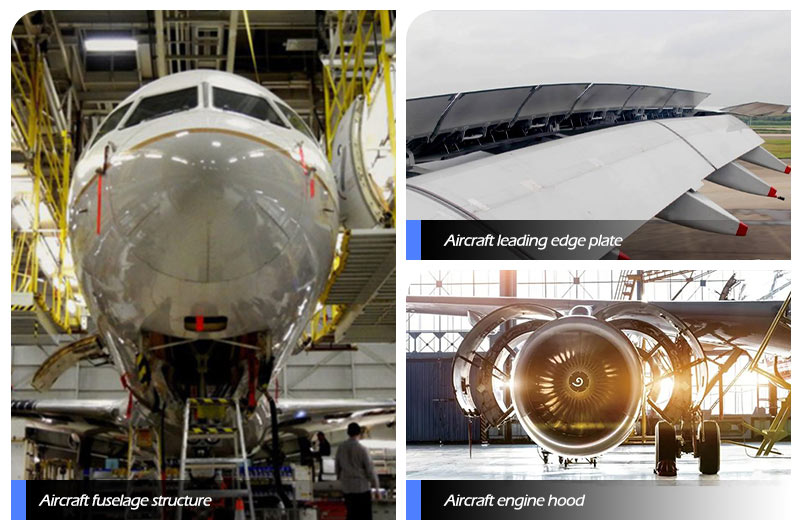

- Fuselage skin panels

- Engine cowlings

- Leading and trailing edge components

- Rotary wing parts (e.g., blade fittings)

- Structural support members

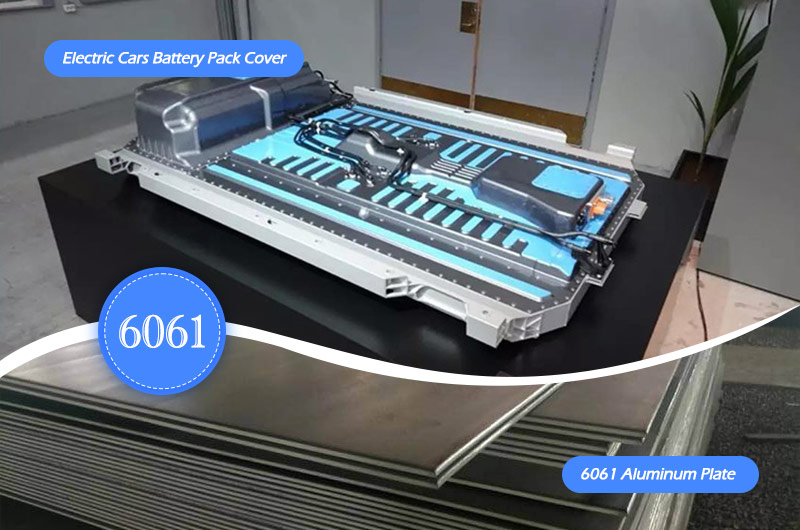

- Body panels and doors

- Engine covers and hoods

- Bicycle frames, wheel rims, handlebars

- Brake system housings (ABS components)

- Hydraulic valve bodies and housings

- Precision machined parts (gears, splines, rollers)

- High-tolerance tooling components (molds, cutters)

- Mechanical fittings and fixtures

- Small caliber ammunition casings

- ABS braking system components

- Formability: Equivalent to 2024-O, offering superior stretch-forming characteristics.

- Natural Aging Sensitivity: Grain growth under 2–13% strain is highly responsive to natural aging before solution heat treatment.

- Stable Formability: Retains excellent formability after months at room temperature—no refrigeration needed, unlike 2024-W.

- Post-forming Aging: Can be naturally aged to peak strength without additional solution treatment, minimizing part distortion.

- Strength & Toughness: Yield strength, fracture toughness, and fatigue resistance comparable to 2024-T3 plates.

- Corrosion Resistance: Superior corrosion performance compared to 2024-T3.

- Strength-to-Weight: Lower density than 2024-T3, delivering an improved strength-to-weight ratio.

- Factory-direct pricing powered by China’s low electricity and raw material costs

- Competitive processing fees thanks to automated in-house equipment

- Flexible MOQ and fast delivery – from small samples to large bulk orders

- DDP (Delivered Duty Paid) options to simplify your import process

- Global logistics support covering North/South America, Europe, Middle East, and Asia

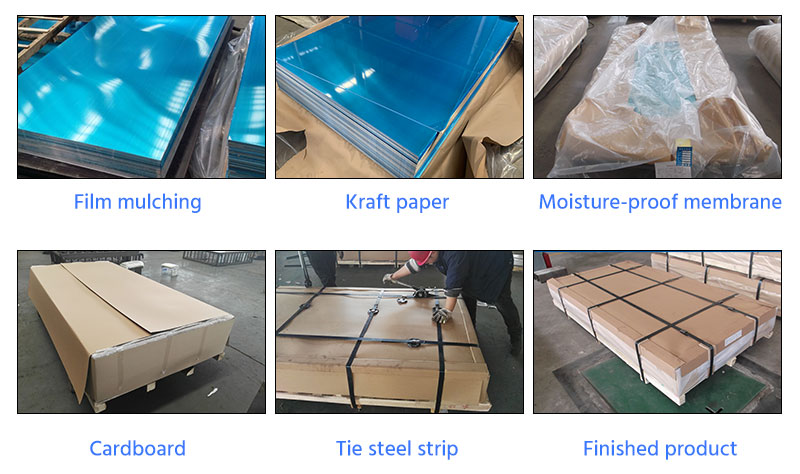

- Apply interleaving paper or film to protect the aluminum sheet.

- Wrap with plastic or kraft paper (ensuring each package has a moisture-absorbing desiccant).

- Add protective corners or edge protection materials to prevent damage.

- Reinforce with wooden pallets and secure with steel straps to prevent collisions during transportation.

- For export, package the products in wooden boxes and pallets marked with fumigation signs.

- Packaging can be customized according to additional requirements from the customer.

We hold ISO 9001:2015, AS9100D and ISO 14001:2015 certifications, are RoHS compliant, and our 6013 aluminum sheet and plate meet Chinese GB/T 3880 standards.

With in-stock supply, flexible minimum order quantities, and global DDP shipping, we help you get the exact size and spec you need—on time and with full traceability—so your project moves forward with confidence.

The stock sizes of 6013 aluminum sheet

Quoted tolerances guaranteed. Precision cutting accuracy up to -0/+0.03 in, and high-tolerance cutting accuracy up to -0/+0.06 in.

Chalco provides size cutting services for 6013 Aluminum Sheet. Contact us for prompt delivery.

Instant Quote| Description | Temper | Thickness (in) | Width (in) | Length (in) | Specification |

| 6013 T4 Aluminum Sheet 0.032" × 24" × 48" | T4 | 0.032" | 24" | 48" | AMS 4347 |

| 6013 T4 Aluminum Sheet 0.032" × 48" × 144" | T4 | 0.032" | 48" | 144" | AMS 4347 |

| 6013 T6 Aluminum Sheet 0.032" × 24" × 48" | T6 | 0.032" | 24" | 48" | AMS 4216 |

| 6013 T4 Aluminum Sheet 0.040" × 48" × 48" | T4 | 0.040" | 48" | 48" | AMS 4347 / ASQR-01 |

| 6013 T6 Aluminum Sheet 0.050" × 48" × 144" | T6 | 0.050" | 48" | 144" | AMS 4216 |

| 6013 T4 Aluminum Sheet 0.063" × 48" × 144" | T4 | 0.063" | 48" | 144" | AMS 4347 / ASQR-01 |

| 6013 T4 Aluminum Sheet 0.071" × 24" × 48" | T4 | 0.071" | 24" | 48" | AMS 4347 |

| 6013 T4 Aluminum Sheet 0.071" × 48" × 144" | T4 | 0.071" | 48" | 144" | AMS 4347 |

| 6013 T6 Aluminum Sheet 0.071" × 48" × 144" | T6 | 0.071" | 48" | 144" | AMS 4216 |

| 6013 T4 Aluminum Sheet 0.080" × 48" × 144" | T4 | 0.080" | 48" | 144" | AMS 4347 |

| 6013 T4 Aluminum Sheet 0.100" × 48" × 144" | T4 | 0.100" | 48" | 144" | AMS 4347 |

| 6013 T4 Aluminum Sheet 0.125" × 48" × 48" | T4 | 0.125" | 48" | 48" | AMS 4347 / ASQR-01 |

| 6013 T651 Aluminum Plate 0.500" × 8" × 8" | T651 | 0.500" | 8" | 8" | ASTM B209 |

| 6013 T651 Aluminum Plate 0.500" × 12" × 12" | T651 | 0.500" | 12" | 12" | ASTM B209 |

| 6013 T651 Aluminum Plate 0.500" × 18" × 18" | T651 | 0.500" | 18" | 18" | ASTM B209 |

| 6013 T651 Aluminum Plate 0.500" × 24" × 24" | T651 | 0.500" | 24" | 24" | ASTM B209 |

| 6013 T651 Aluminum Plate 0.750" × 8" × 8" | T651 | 0.750" | 8" | 8" | ASTM B209 |

| 6013 T651 Aluminum Plate 0.750" × 12" × 12" | T651 | 0.750" | 12" | 12" | ASTM B209 |

| 6013 T651 Aluminum Plate 0.750" × 18" × 18" | T651 | 0.750" | 18" | 18" | ASTM B209 |

| 6013 T651 Aluminum Plate 0.750" × 24" × 24" | T651 | 0.750" | 24" | 24" | ASTM B209 |

| 6013 T651 Aluminum Plate 1.000" × 8" × 8" | T651 | 1.000" | 8" | 8" | ASTM B209 |

| 6013 T651 Aluminum Plate 1.000" × 12" × 12" | T651 | 1.000" | 12" | 12" | ASTM B209 |

| 6013 T651 Aluminum Plate 1.000" × 18" × 18" | T651 | 1.000" | 18" | 18" | ASTM B209 |

| 6013 T651 Aluminum Plate 1.000" × 24" × 24" | T651 | 1.000" | 24" | 24" | ASTM B209 |

| 6013 T651 Aluminum Plate 2.000" × 8" × 8" | T651 | 2.000" | 8" | 8" | ASTM B209 |

| 6013 T651 Aluminum Plate 2.000" × 12" × 12" | T651 | 2.000" | 12" | 12" | ASTM B209 |

| 6013 T651 Aluminum Plate 2.000" × 18" × 18" | T651 | 2.000" | 18" | 18" | ASTM B209 |

| 6013 T651 Aluminum Plate 2.000" × 24" × 24" | T651 | 2.000" | 24" | 24" | ASTM B209 |

Can't find the size you need? please

Instant QuoteValue-added services & delivery conditions

Value-added services

If you need any of these custom services, please fill out our Special Request Form to discuss details with our sales team.

Delivery conditions

6013 aluminum plate is typically supplied in T4 temper according to AMS 4347, with T6 temper also available. We stock 6013-T4 plates in thicknesses from 0.032" to 0.125" and can cut to your exact dimensions in-house using our dedicated slitting and shearing equipment.

Because these tempers deliver peak properties without additional heat treatment or annealing, you benefit from lower material and processing costs—delivered on time and ready for your production line.

Typical mechanical properties of 6013 aluminum alloy

Compared to other aerospace-grade materials, this alloy offers superior stretch-forming characteristics.

With 6013 aluminum plate, stress corrosion cracking and exfoliation are virtually eliminated, and the product also delivers excellent compressive strength. Its low density, excellent formability, and corrosion resistance make it a highly popular choice.

Instant Quote| Temper | T4 | T6 | T651 |

| Elastic Modulus | 69 GPa | 69 GPa | 69 GPa |

| Elongation at Break | 22 % | 9.1 % | 3.4 % |

| Fatigue Strength | 98 MPa | 140 MPa | 110 MPa |

| Shear Strength | 190 MPa | 240 MPa | 240 MPa |

| Yield Strength | 170 MPa | 350 MPa | 359 MPa |

| Maximum Service Temperature | 160 °C | 160 °C | 160 °C |

| Specific Heat Capacity | 900 J/kg·K | 900 J/kg·K | 900 J/kg·K |

| Thermal Conductivity | 150 W/m·K | 150 W/m·K | 150 W/m·K |

| Thermal Expansion | 23 µm/m·K | 23 µm/m·K | 23 µm/m·K |

Note: Tensile strength in T6 reaches ≈ 379 MPa (55 ksi) and in T651 ≥ 379 MPa (55 ksi), with elongation ≥ 5% in thicker sections.

These values are typical characteristics and may not meet your needs. If you have special needs, please

Instant QuoteChemical composition of 6013 aluminum alloy (weight %)

| Si (Silicon) | 0.6 – 1.0 % |

| Fe (Iron) | ≤ 0.50 % |

| Cu (Copper) | 0.6 – 1.1 % |

| Mn (Manganese) | 0.20 – 0.80 % |

| Mg (Magnesium) | 0.8 – 1.2 % |

| Cr (Chromium) | ≤ 0.10 % |

| Zn (Zinc) | ≤ 0.25 % |

| Ti (Titanium) | ≤ 0.10 % |

| Other (each) | ≤ 0.05 % |

| Other (total) | ≤ 0.15 % |

| Al (Aluminum) | Balance |

Applications of 6013 aluminum plate sheet

Aerospace & MRO

In T4 temper, 6013's excellent formability allows deep drawing and stretch forming. After forming, natural aging to T6 delivers peak strength—12 % higher yield than Alclad 2024—making it ideal for both OEM and MRO applications.

Automotive & transportation

6013 combines higher strength than standard 6xxx alloys with superior weldability, supporting lightweight, high-stress automotive and bicycle applications.

Industrial & defense

Its mix of fatigue resistance, corrosion resistance, and machinability makes 6013 suitable for demanding industrial and defense uses.

Comparison of 6013-T4 and 6013-T6 alloy tempers

6013-T4

6013-T6

Looking for 6013 aluminum sheet plate at the best price?

If you're searching for 6013 aluminum sheet plate price or 6013 aluminum sheet plate forsale, you're likely comparing suppliers to get the best value—without compromising on quality or leadtime. At Chalco, we help global buyers minimize total cost by offering:

All our 6013 aluminum plates meet international standards like AMS 4347 and ASTMB209, ensuring both performance and compliance. Whether you need sheets for aerospace brackets,automotive panels, or thermal enclosures, we deliver cost-effective solutions—on time, worldwide.

Request a quote now and see how much you can save with Chalco.

Packaging for 6013 aluminum sheet

Feel to leave your requirements below, and we will respond to you as quickly as possible.

Instant Quote

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customizedproducts. Precise quotation will be provided within 24 hours.

Get a quotePopular products related to 6013 aluminum plate

6013-body-sheet

6013-plate

6013-3c-sheet

6061-aluminum-plate

6061-aluminum-flat-bar

6061-aluminum-tube

FAQ – 6013 aluminum sheet plate

What is 6013 aluminum plate used for?

Automotive body panels, door frames and pedals; aerospace interior parts and brackets; heat sinks and electronicenclosures; precision machinery parts, molds and fixtures.

How does 6013 aluminum plate differ from 7075 aluminum?

6013 is a 6XXX (Si–Mg) heat-treatable alloy; 7075 is a 7XXX (Zn–Mg–Cu) high-strength alloy. 7075-T6 offers ~520 MPaUTS vs. ~310 MPa for 6013-T6. 6013 machines and forms more easily, while 7075 is harder to machine and morecrack-prone. 6013 also has slightly better corrosion resistance.

The strength of 6013 Aluminum Sheet is comparable to that of 7075 AluminumSheet, but 6013 Aluminum Sheet is more corrosion-resistant and weldable.

What is the composition of 6013 aluminum plate?

Si 0.40–0.80 % | Fe ≤ 0.70 % | Cu 0.15–0.40 % | Mg 0.80–1.20 % | Mn 0.15–0.40 % | Zn ≤ 0.20 % | Ti ≤ 0.15 % | Albalance

What are the properties of 6013-T4 aluminum plate?

Tensile strength ~265 MPa; yield strength ~145 MPa; elongation ~12 %; hardness ~80 HB.

6013 aluminum sheet VS 2024 aluminum sheet

The yield strength of 6013 Aluminum Sheet is 12% higher than that of 2024 Aluminum Sheet.

6013 aluminum sheet VS 6061 aluminum sheet

6013 aluminum sheet possesses the same corrosion resistance, weldability, and workability as 6061 Aluminum Sheet, but with higher strength.