An aluminum heat exchanger typically combines aluminum tubes that carry the coolant and aluminum fins that dissipate heat.

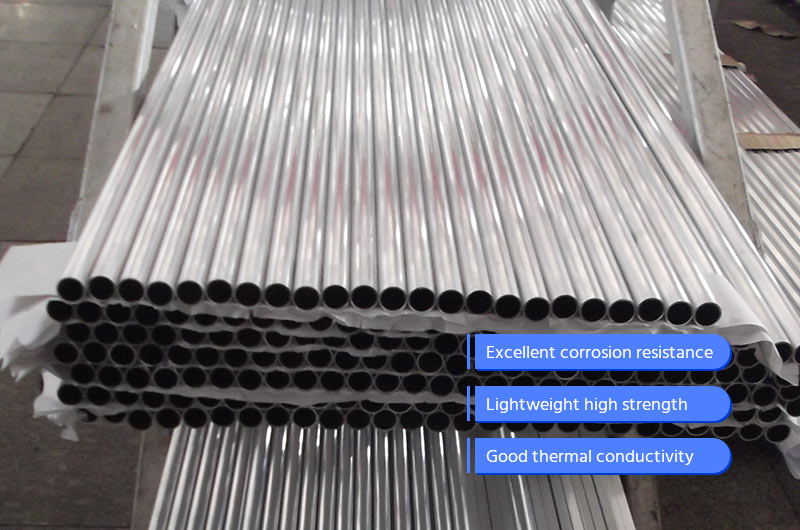

Aluminum tubes for heat exchangers are generally extruded or cold drawn from alloys such as 1050, 1100, 3003, 5083, 6061, and 6063.

The alloy selection depends on the application, operating conditions, and required properties such as strength, corrosion resistance, and thermal conductivity.

What aluminum tube products are available for heat exchangers?

Standards

- ASTM B234: Cold-drawn seamless aluminum alloy tubes for condensers, evaporators, and heat exchangers.

- ASTM B210: Seamless cold-drawn aluminum and aluminum-alloy tubes (straight lengths and LWC coils).

- ASTM B241: Seamless and seamless-extruded aluminum and aluminum-alloy pipe and tube for pressure service.

Compliance & validation: Declare conformity to ASTM B234/B210/B241 and provide MTCs, leak/flare/burst tests and full traceability (EN 10204 3.1/3.2).

Specifications & capability

Support large sizes and custom sizes; full range of MPE flat tubes / inner-grooved round tubes / smooth tubes / welded tubes / bends & coils; optional pre-flux coating, zinc spraying, 7072 sacrificial layer, anodizing/organic coatings for corrosion protection; compatible with CAB and vacuum brazing processes.

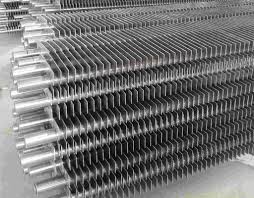

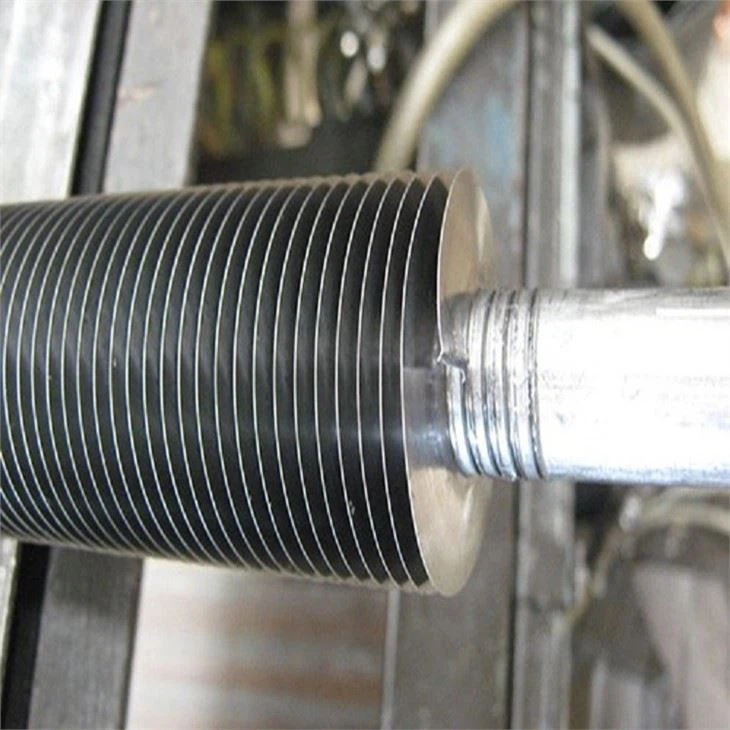

Aluminium finned tube for heat exchanger

The aluminum finned tube process is a labor-intensive process. It adopts the form of a base tube covered with an aluminum tube. (The base tube can be carbon steel or stainless steel) is extruded by a machine to form fins. The base of the fins is closely attached to the outer wall of the tube. Together, the length is from 0.5 meters to 6 meters.

It meets the demand for the length of the steel-aluminum finned tube, thus solving the trouble of re-cutting caused by improper length during use.

The specifications of aluminium finned tube for heat exchanger

- Fin material alloy: 1050, 1060, 1070, 1100, 5052, 6063

- Fin pitch: Min. 1.5mm

- Fins per pitch(Density) : 4-12

- Fin segments: 12, 16, 24 fins or as per your design

- Fin height: Max. 16.5mm

- Fin thickness: 0.4mm average

- Base tube OD: Max 2”(50.8mm)

All sizes of aluminum finned tubes

Looking for complete size charts and specifications of aluminum finned tubes? Click here to view detailed dimensions and product data from Chalco Aluminum.

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

| 5/8 | 3/8, 1/2 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 1 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 1/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, |

| 1 1/2 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 3/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10 |

| 2 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10 |

Classification of aluminum finned tubes

High frequency welded finned tube

Square-finned tube

Needle tube

Laser welded finned tubes

Inlaid finned tube

DR extruded high finned tube

Low-finned tube

Threaded tube

Wave joint tube

can create specific finned tubes for your needs like intergral turbulator finned tubes or double tube construction finned tubes.

The performance characteristics of aluminium finned tube for heat exchanger

Aluminum finned tubes have the characteristics of tight combination, small thermal resistance, good heat transfer performance, high strength, small flow loss, High corrosion resistance performance, not easy to deform in long-term cold and hot conditions, and long working life.

The application of aluminium finned tube for heat exchanger

Aluminum finned tubes are mainly used in air coolers and air heaters in petrochemical, electric power, papermaking, tobacco, building heating and other industries, and air heaters in spray drying systems for vegetable eggs and starch in the food industry.

The advantages and characteristics of aluminum finned tubes in application is that aluminum finned tubes are formed in parallel with aluminum alloy plates and aluminum tubes at one time.

Instant QuoteAluminum inner-grooved tubes for heat exchanger

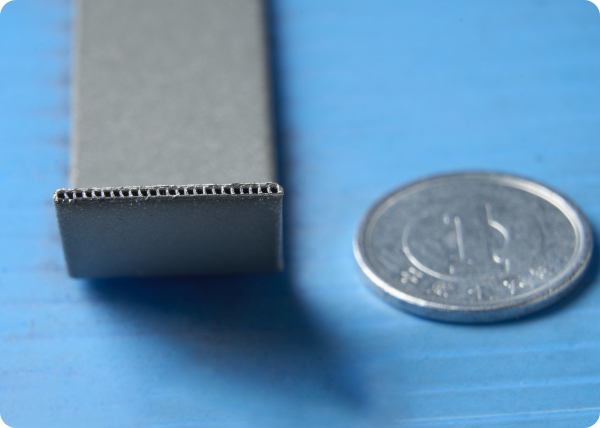

Aluminum internally grooved tubes, also known as internally-grooved tubes, are a lightweight and cost-reducing solution for air conditioning heat exchangers and are an attractive alternative to copper tubes.

Internal grooves can be straight or spiral. The height of the inner groove ranges from 0.05 to 0.3mm. The higher the groove, the better the heat transfer performance. Aluminum internally grooved tubes are widely used in heat exchangers in domestic and commercial air conditioning systems.

The specifications of aluminum inner-grooved tubes for heat exchanger

Alloy grade:

1000 series, such as 1050, 1060, 1070, 1070A, 1100, etc.

3000 series, such as 3003, AA003H, etc.

Type: Straight inner-grooved tubes, Helical inner-grooved tubes

Outer diameter: Φ5.0-Φ16 mm

Bottom wall thickness: 0.4-2.0mm

Tooth height: 0.05-0.35 mm

Addendum angle: 30-135 (degree)

Helical Angle: 0-25 (degree)

Tooth Number: 20 to 70 (tooth)

All sizes of aluminum internally grooved tubes

All dimensions (in inches) and technical specifications of aluminum internally grooved tubes are available upon request. For complete product information and detailed size charts, please visit Aluminum inner-grooved tube details .

| Tube OD | I.D | Bottom Wall Thickness (Tw) | Fin Groove Depth (Hf) | Total Wall Thickness (Tw) | Apex Angle (°) | Helix Angle (°) | Number of Teeth |

| 5.00 | 4.30 | 0.20 | 0.15 | 0.35 | 40 | 18 | 40 |

| 7.00 | 6.34 | 0.23 | 0.10 | 0.33 | 40 | 15 | 65 |

| 7.08 | 6.06 | 0.25 | 0.18 | 0.43 | 40 | 18 | 50 |

| 7.94 | 7.08 | 0.25 | 0.18 | 0.43 | 40 | 18 | 50 |

| 9.52 | 8.72 | 0.28 | 0.12 | 0.40 | 53 | 15 | 65 |

| 12.70 | 11.50 | 0.35 | 0.25 | 0.60 | 53 | 18 | 70 |

| 14.00 | 12.82 | 0.37 | 0.22 | 0.59 | 52 | 16 | 75 |

| 15.87 | 14.37 | 0.40 | 0.30 | 0.70 | 25 | 15 | 68 |

| 16.00 | 14.70 | 0.40 | 0.25 | 0.65 | 10 | 1 | 110 |

The performance characteristics of aluminum inner-grooved tubes for heat exchanger

- High heat transfer efficiency

- Low material cost

- Easy to form and bend

- Light weight

- Strong corrosion resistance

- High recycling value

- High precision

- High surface quality

The application range of aluminum inner-grooved tubes for heat exchanger

The Aluminum inner-grooved tubes for heat exchanger are mainly used in household air conditioners, freezers, refrigerators, automotive air conditioner tubes, automotive solar energy, etc.

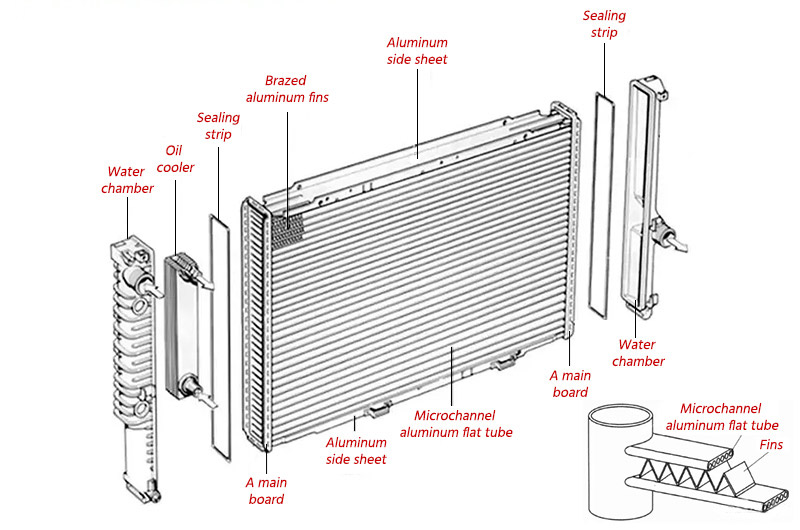

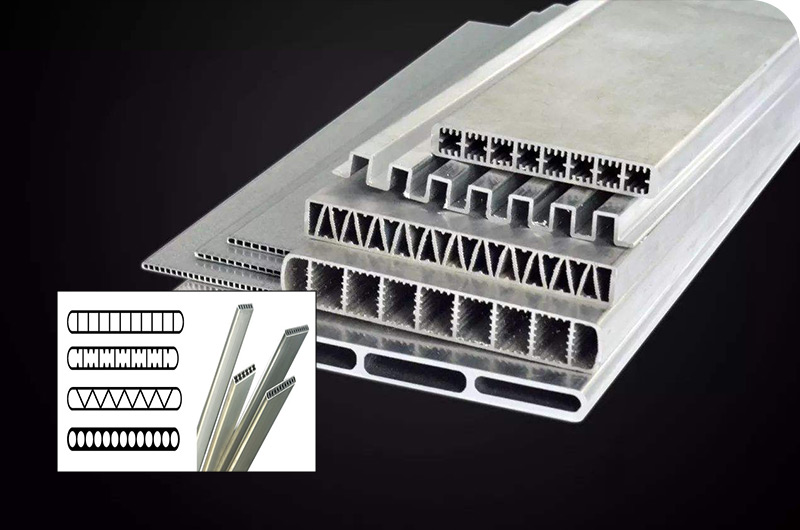

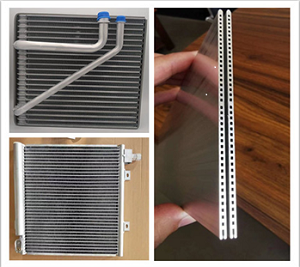

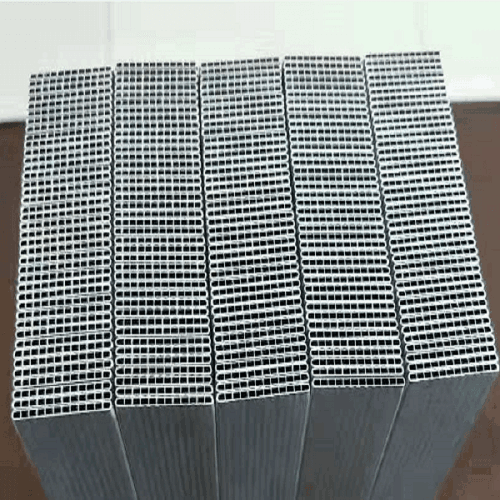

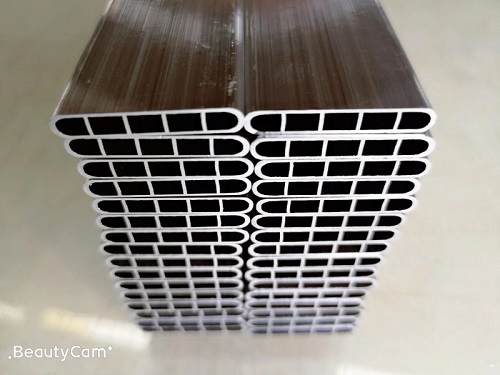

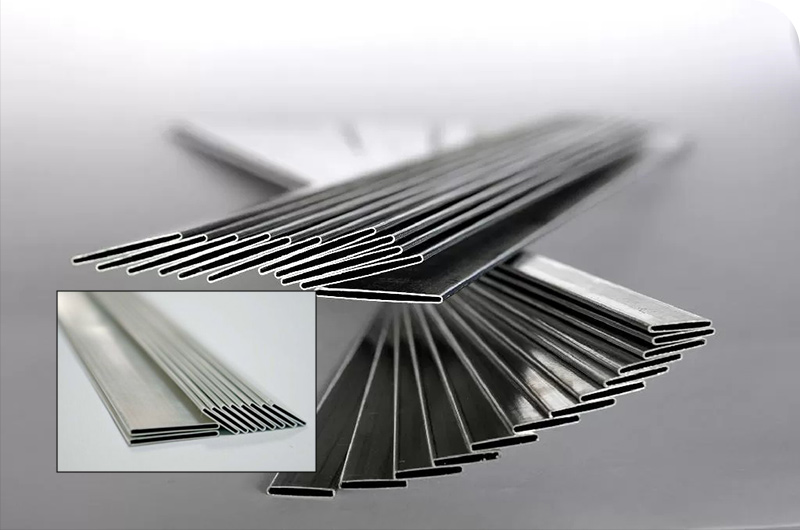

Instant QuoteMicro-channel aluminum tubes for heat exchangers

This flat rectangular extruded tube, also known as a multi-port extruded tube, is made of multiple channels. These channels help increase heat transfer through a higher surface area/volume ratio

Microchannel tubes are available in a variety of sizes and alloys to ensure optimal performance for the required application. They can be delivered coated, ready for assembly and oven brazing.

The specification of micro-channel aluminum tubes for heat exchangers

Alloy grade:

1000 series: 1050, 1060, 1070, 1100

3000 series: 3003, 3102

Temper: H112 etc.

Width: 6–40 mm Height: 0.8–8.0 mm

Wall thickness: ≥ 0.12 mm

Number of ports: 2–35

Coating options: Pre-flux coating, NOCOLOK® Si flux coating, zinc coating

Zinc coating weight: 5–15 g/㎡

Flux coating weight: 8–25 g/㎡

Free samples: Yes, we can provide free samples.

What kinds of aluminum micro-channel tubes do we offer?

- Aluminium Micro-channel Tube

- Aluminium Multi-Port Tube

- Parallel Flow Aluminium Flat Tube

- Zinc-coated Aluminum Tube

- Pre-Flux Coated Aluminium Tube

- Si Flux Coated Aluminum Tube

- Large Multi-channel Tube(width range 50-200mm)

- Double Row Joint Multi-channel Flat Tube

Aluminum Extrusion Micro Channel tube

Aluminum Micro Channel Oil-Cooling Tube

Aluminum Microchannel Condenser Tube

High Performance Harmonica Aluminum Tube

Micro channel aluminum flat tube

Extremely Small Micro Channel Tube

If you need ultra-wide aluminum micro-channel tubes, we also supply customized sizes and profiles. Please click to view detailed information at Ultra-wide aluminum micro-channel tube .

The performance characteristics of micro-channel tube for heat exchangers

- Good thermal conductivity

- Low material cost

- Light weight

- High corrosion resistance

- High precision

- High surface finish

The application range of micro-channel aluminum tubes for heat exchangers

- Refrigerators

- Air conditioners

- Condensers

- Freezers

- Evaporators

- Gas ovens

- Car radiators

- Heat exchanger

- HVAC and R systems

- Infrared detectors

- Microelectronics

- Power and process industries

- Aerospace

- Bioengineering

- Powerful laser mirrors

For automotive applications, we also offer dedicated aluminum micro-channel tubes designed for vehicle cooling systems. Please click to learn more at automotive aluminum micro-channel tubes .

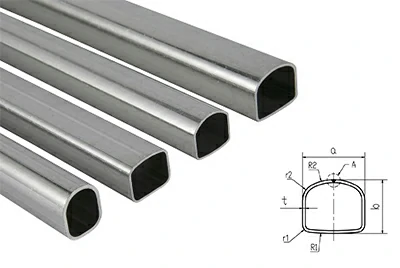

Heat exchanger welded aluminum tube (HFW tube)

High-frequency welded (HFW) aluminum tubes are efficient and cost-effective solutions for heat exchangers, replacing seamless and brazed tubes in HVAC and EV cooling systems.

Key advantages:

- Fast production: up to 150 m/min, ideal for mass supply

- Flexible size: φ8–300 mm, wall 0.3–6 mm

- 40–60 % lower cost than seamless tubes

- Support round, D-shaped, oval, flat, and multi-cavity designs

Applications: HVAC, EV battery cooling, condensers, intercoolers, solar and oil coolers.

Typical alloys: 3003, 3105, 4343/3003, 4045/3003, 7072/3003.

For complete size charts and drawings, visit:

High-Frequency Welded Aluminum Tube

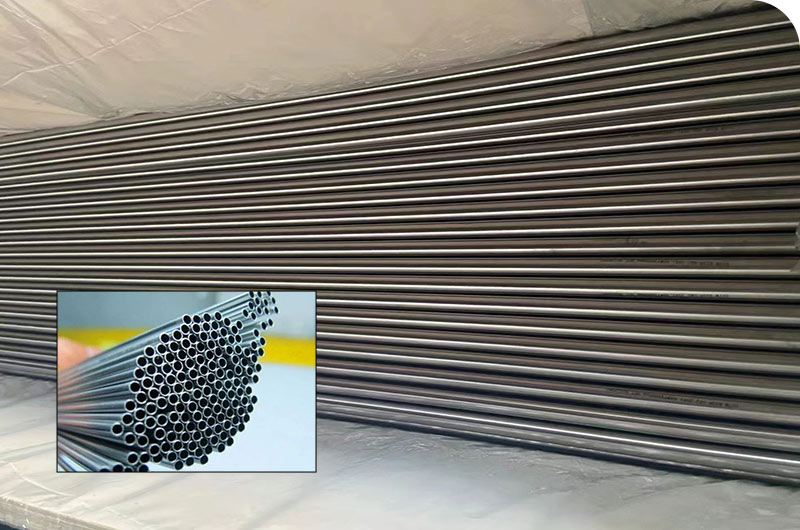

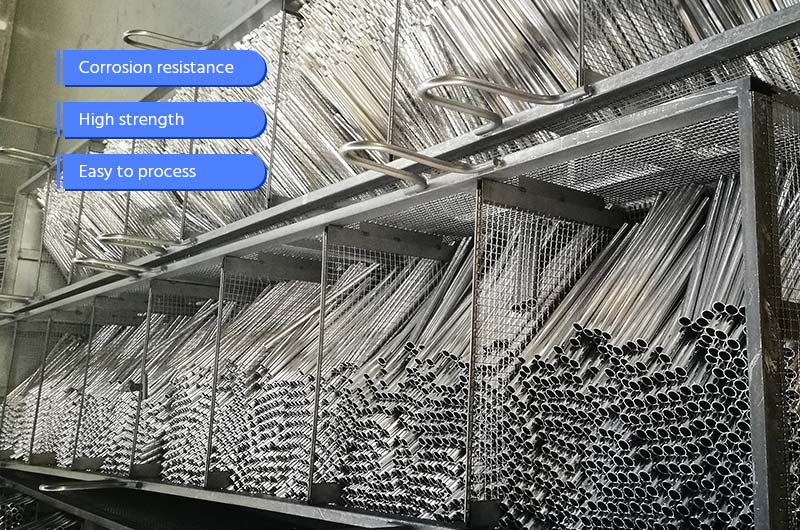

Precision drawn aluminum tubes for heat exchangers

High-precision drawn aluminum tubes, also known as aluminum cold-drawn tubes, are widely used in heat exchangers. These include aluminum round tubes, internal threaded tubes, seamless collector tubes, Cold drawn aluminum tubes, seamless tubes, etc.

The main alloys for drawn aluminum tubes, capillary tubes, peanut tubes, etc., are 1070, 3003/3103, and 6063.

The specification of precision drawn aluminum tubes for heat exchangers

Alloy grade:

3000 series, such as 3003, 3103

5000 series, such as 5052, 5049, 5086

6000 series, such as 6063, 6061

Temper: O, H12, H14, H18, H34, H112, T4, T6, T83, etc.

Round tube outer diameter: 4mm-90mm

Round tube wall thickness: 0.3mm-5mm

Popular precision drawn aluminum tubes

For more detailed specifications and product information, please visit Cold Drawn Aluminum Tube .

cold-drawn-aluminum-tube

2024-aluminu-tube

3003-seamless-tube

5052-aluminum-tube

6061-aluminum-tube

7075-aluminum-tube

All in-stock products are available for retail. After confirming the order, customs clearance and shipment can be completed within one week.

As an original manufacturer, we carry out large-scale one-stop production. The price of aluminum pipes of the same quality is 10% lower than the market price.

The performance characteristics of precision drawn aluminum tubes for heat exchangers

- Light weight

- Good thermal conductivity and electrical conductivity

- Good corrosion resistance

- Good forming and bending performance

- Compliance with ROHS standards

- High recycling value

- Small deviation range

- High surface quality

- TS 16949 certification

The application range of aluminum precision drawn tubes for heat exchanger

Automotive air conditioners, civil air conditioners (condensers, evaporators, heat exchangers).

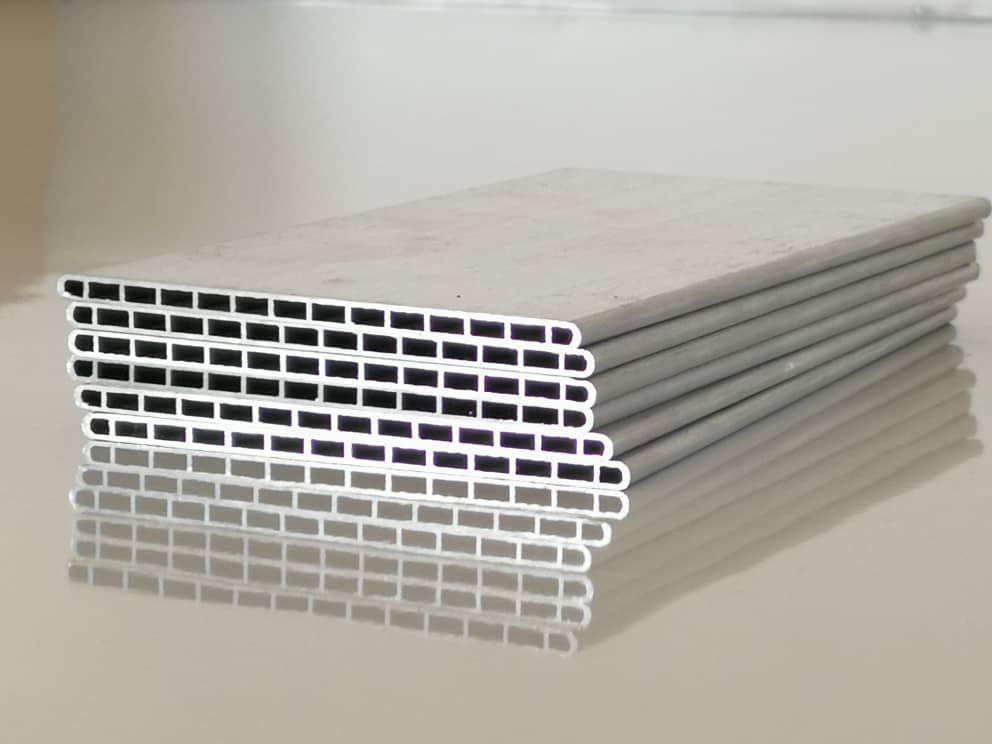

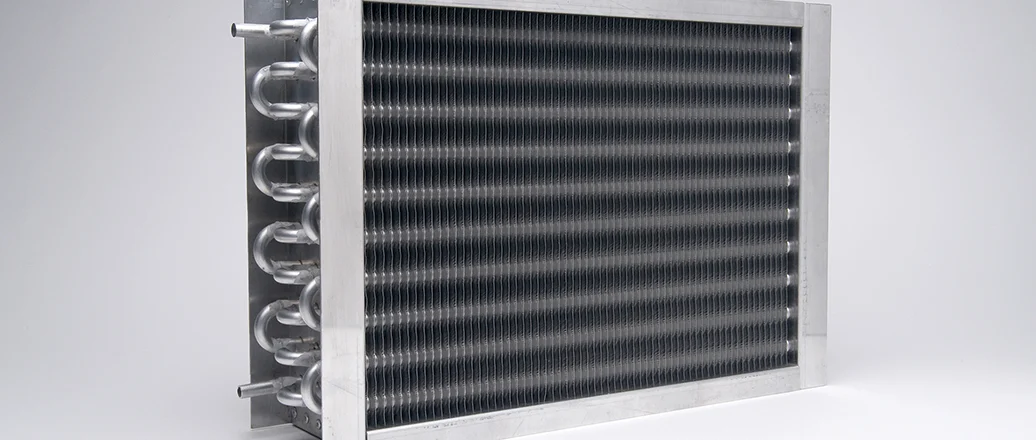

Instant QuoteAluminum flat tube for heat exchangers

Aluminum brazed heat exchangers are widely used in automotive air conditioning systems. Typically, such heat exchangers are made from flat tubes with multiple independent channels in cross-section, forming a serpentine or parallel flow geometry.

In these heat exchangers, multiple louvered corrugated fins are inserted into the gaps between flat tubes. Due to their high performance, some companies are beginning to use extruded brazed aluminum heat exchangers in heating, ventilation and air conditioning applications.

Instant QuoteThe specifications of aluminum flat tube for heat exchangers

Brazing layer: 4343, 4045

Core layer: 7072 anti-corrosion

Forming: high frequency welding

Temper: H14

Composite rate: 10±2

Specifications: according to customer requirements

The performance characteristics of aluminum flat tube for heat exchangers

- Light weight

- Easy to weld

- Good corrosion resistance

- Good pressure resistance

- Compliance with ROHS standards

- High recycling value

- Small deviation range

- High surface quality

The usage of aluminum flat tube for heat exchangers

Radiator aluminium flat tubes are mainly used in parallel flow condensers, automotive water tanks, and new energy vehicles.

Instant QuoteCustomized aluminum tubing solutions for heat exchangers

Chalco offers customized aluminum tubes for heat exchangers — from large-size and thin-wall designs to micro and capillary tubes — showcasing our full capability in precision forming, extrusion, and bending to meet diverse industrial and HVAC applications.

Corrosion protection & surface treatment

Chalco offers a range of surface protection solutions to enhance the durability and reliability of aluminum heat exchanger components. These include zinc spraying, pre-flux coating, anodizing, and organic surface treatments, each designed to improve corrosion resistance and brazing performance.

Zinc spraying provides sacrificial protection for harsh environments such as coastal or industrial areas, extending the service life of condensers and radiators.

Pre-flux coating ensures stable brazing quality in CAB processes, reducing oxide formation and improving joint strength.

Anodizing and special coatings offer additional chemical resistance and enhanced appearance for automotive, HVAC, and electronic cooling applications.

Quality & performance testing

Chalco performs comprehensive quality and reliability tests to ensure every aluminum tube and heat exchanger component meets international standards and project specifications. Our testing covers both mechanical integrity and leak-proof performance to guarantee safe, long-term operation under pressure and thermal cycling.

Key procedures include:

- Hydrostatic pressure test: verifies tube and joint strength under rated and burst pressure conditions.

- Air or helium leak test: detects micro-leaks to ensure 100% sealing performance in condensers, evaporators, and cooling plates.

- Dimensional and surface inspection: checks wall thickness, ovality, curvature, and surface finish to maintain precision tolerance.

- Corrosion and salt spray tests: simulate real-world environments for durability verification.

Each batch is supplied with complete EN 10204 3.1/3.2 inspection certificates, ensuring traceability and compliance with ASTM, EN, and ISO standards.

Brazing materials for heat exchangers

Chalco provides high-performance aluminum brazing materials designed for advanced heat exchanger systems. Our products support vacuum brazing, Nocolok brazing, and controlled atmosphere brazing (CAB), ensuring excellent thermal conductivity, corrosion resistance, and stable joint quality.

We offer custom multilayer aluminum brazing foils and clad strips (such as 4343/3003/7072 and 4045/3102 combinations), widely used for radiator fins, condenser headers, evaporator plates, and EV battery cooling modules.

Chalco's brazing materials are available in sheet, strip, and coil form, with thickness from 0.05–3.0 mm and width up to 1500 mm, offering durable performance and cost-efficient production for automotive, HVAC, industrial, and energy applications.

For detailed specifications and applications, please visit:

Why choose chalco?

We have more than 30 years of experience in supplying aluminum brazing composite materials for heat exchangers, intercoolers, air-conditioning condensers and evaporators, and aluminum tubes for various heat exchangers. Now we have become a world famous enterprise in the market of rolled aluminum and aluminum tubes for heat exchangers.

We have a complete set of domestic advanced R&D, testing and analysis instruments for aluminum brazing composite materials and aluminum tubes for various heat exchangers. These provide guarantee for the efficiency of new product research and development, and accelerate the transformation of scientific and technological achievements.

In addition, our R&D&innovation and verification capabilities can help enhance the competitiveness of customers by saving time and costs for new product development and marketing.

We have passed the IATF16949 certification required by the automotive industry, the AS9100 certification required by the aviation industry, and the DNV BV LR ABS RINA CCS certification required by the shipbuilding industry.

The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.

Instant QuoteFrequently asked questions

What is the best material for a heat exchanger tube?

The best material depends on the working environment and fluid type. Aluminum is ideal for applications requiring lightweight design, high thermal conductivity, and corrosion resistance, especially in automotive and HVAC systems. For high-pressure or corrosive media, titanium and stainless steel may be used.

What is the best pipe for a heat exchanger?

The optimal pipe is one that balances heat transfer efficiency, strength, and corrosion resistance. Micro-channel, inner-grooved, and HFW aluminum tubes are widely recognized for compact design, high surface area, and efficient cooling performance.

Is aluminum tubing used for boiler heat exchangers?

Yes. Aluminum tubing is used in condensing boilers and low-pressure systems because it offers excellent heat transfer and resistance to thermal fatigue. However, for high-pressure steam boilers, stainless steel or copper alloys are typically preferred.

What grade of aluminum is used in heat exchangers?

Common grades include 3003, 3102, 6061, 6063, and 7072. These alloys provide a balance of thermal conductivity, corrosion protection, and formability, making them suitable for condensers, evaporators, intercoolers, and battery cooling systems.