1070 aluminum sheet (AA/EN AW-1070, UNS A91070) is an industrial pure aluminum (≥99.7% Al) with excellent formability, corrosion resistance, and outstanding electrical and thermal conductivity.

It is non-heat-treatable and gains strength through cold working (O, H12, H14, H18 tempers), making it ideal for conductive, reflective and decorative applications.

Instant Quote1070 aluminum sheet plate specifications and standards

Chalco aluminum complies with ISO 209-1/2, EN 573-3 and EN 485-2/-4 standards, ensuring good ductility, formability and tensile toughness to fully meet processing requirements such as stamping and stretching.

| Standard system | Specification | Scope |

| ASTM | ASTM B209 | Aluminum and aluminum-alloy sheet and plate |

| ISO | ISO 209-1 / ISO 209-2 | Chemical composition & product forms of wrought aluminum |

| EN (Europe) | EN 573-3 | Chemical composition of wrought aluminum alloys |

| EN (Europe) | EN 485-2 / EN 485-4 | Mechanical properties and tolerances for sheet and plate |

| GB (China) | GB/T 3190 | Chemical composition of wrought aluminum and alloys |

| GB (China) | GB/T 3880.1-2012 | Aluminum and aluminum alloy plate, sheet and strip for general engineering |

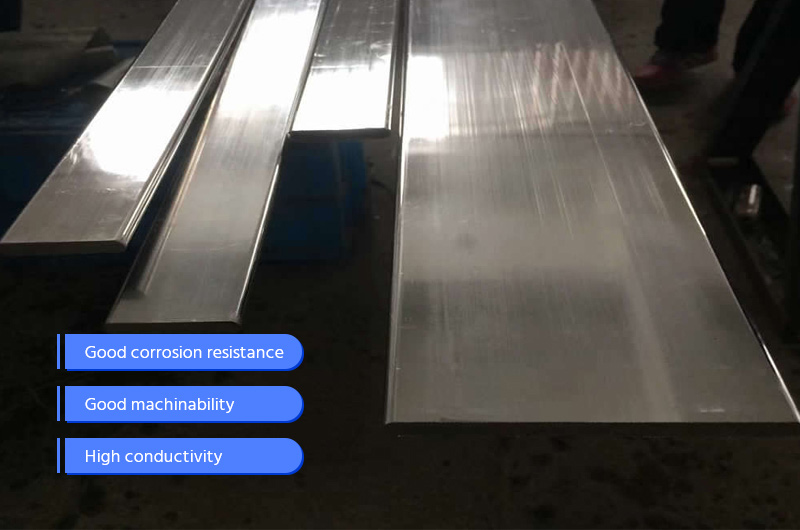

Chalco Aluminum supplies conductive busbar products in alloys such as 1050, 1060, 1070, 1100, 1350 and 6101. Our products have been widely exported to international companies including Hitachi, ABB, Siemens, Legrand and Toshiba, earning long-term trust and reputation.

Quick selection guide for 1070 aluminum sheet plate

Chalco is the leading manufacturer and supplier of 1070 aluminum plate and sheet in China, providing large-scale customized production as well as ready-to-ship stock sizes to meet both bulk and small-batch demands.

- For electrical conductivity & heat transfer – choose 1070-O or 1070-H14; use mill finish or anodized natural surface for better contact and cooling.

- For high reflectivity appearance – choose mirror-finish 1070 (or 1085) for lighting fixtures, reflectors and decorative panels.

- For deep drawing & bending – choose soft temper O or low temper H12/H14; recommended bend radius ≥ 1–2 × sheet thickness.

- For outdoor corrosion resistance – 1070 has natural corrosion resistance; anodizing or clear coating further improves durability.

Inventory sizes of 1070 H112 aluminum sheet plate

We maintain a wide range of 1070 aluminum sheet stock sizes with ready-to-ship options to meet urgent delivery needs.

For more sizes and accurate weight calculation, please use our aluminum plate weight calculator.

| Description | Thickness (mm) | Thickness (in) | Width × Length (mm) | Weight (kg/pc) |

| 1070-H112 0.5 mm thickness Aluminum Sheet | 0.5 | 0.020" | 1500 × 3000 | 6.1 |

| 1070-H112 0.8 mm thickness Aluminum Sheet | 0.8 | 0.031" | 1500 × 3000 | 9.8 |

| 1070-H112 1.0 mm thickness Aluminum Sheet | 1.0 | 0.039" | 1500 × 3000 | 12.2 |

| 1070-H112 1.2 mm thickness Aluminum Sheet | 1.2 | 0.047" | 1500 × 3000 | 14.7 |

| 1070-H112 1.5 mm thickness Aluminum Sheet | 1.5 | 0.059" | 1500 × 3000 | 18.3 |

| 1070-H112 2.0 mm thickness Aluminum Sheet | 2.0 | 0.079" | 1500 × 3000 | 24.4 |

| 1070-H112 3.0 mm thickness Aluminum Sheet | 3.0 | 0.118" | 1500 × 3000 | 36.7 |

| 1070-H112 4.0 mm thickness Aluminum Sheet | 4.0 | 0.157" | 1500 × 3000 | 48.9 |

| 1070-H112 5.0 mm thickness Aluminum Sheet | 5.0 | 0.197" | 1500 × 3000 | 61.1 |

| 1070-H112 6.0 mm thickness Aluminum Sheet | 6.0 | 0.236" | 1500 × 3000 | 73.3 |

| 1070-H112 8 mm thickness Aluminum Plate | 8 | 0.315" | 1500 × 3000 | 97.7 |

| 1070-H112 10 mm thickness Aluminum Plate | 10 | 0.394" | 1500 × 3000 | 122.2 |

| 1070-H112 20 mm thickness Aluminum Plate | 20 | 0.787" | 1500 × 3000 | 244.4 |

| 1070-H112 25 mm thickness Aluminum Plate | 25 | 0.984" | 1500 × 3000 | 305.5 |

| 1070-H112 30 mm thickness Aluminum Plate | 30 | 1.181" | 1500 × 3000 | 366.6 |

| 1070-H112 40 mm thickness Aluminum Plate | 40 | 1.575" | 1500 × 3000 | 488.8 |

| 1070-H112 45 mm thickness Aluminum Plate | 45 | 1.772" | 1500 × 3000 | 549.9 |

| 1070-H112 50 mm thickness Aluminum Plate | 50 | 1.969" | 1500 × 3000 | 611.0 |

| 1070-H112 55 mm thickness Aluminum Plate | 55 | 2.165" | 1500 × 3000 | 672.1 |

| 1070-H112 55 mm thickness Aluminum Plate | 55 | 2.165" | 700 × 2760 | 205.0 |

| 1070-H112 60 mm thickness Aluminum Plate | 60 | 2.362" | 1500 × 3000 | 733.2 |

| 1070-H112 65 mm thickness Aluminum Plate | 65 | 2.559" | 1500 × 3000 | 794.3 |

| 1070-H112 70 mm thickness Aluminum Plate | 70 | 2.756" | 1500 × 3000 | 855.4 |

Can't find the size you need? Or you need 1070 Aluminum coil, 11070 Aluminum strip or 1060 Aluminum sheet please contact us.

Instant QuoteKey advantages of 1070 aluminum sheet plate

- High electrical conductivity (61% IACS), ideal for busbars and power components

- Excellent thermal conductivity (230 W/m·K) for heat dissipation and cooling systems

- Good ductility and formability, easy for bending, stamping and welding

- Lightweight material, about one-third the weight of copper, reducing system load

- Strong corrosion resistance, suitable for outdoor and humid environments

- Available in anodized, polished or embossed finishes for durable appearance

- Cost-effective alternative to copper with reliable performance

Surface finishes of 1070 aluminum sheet plate

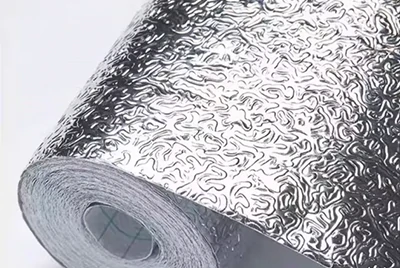

- Mill finish – standard smooth surface for general applications

- Coated surface – protective or decorative coatings available

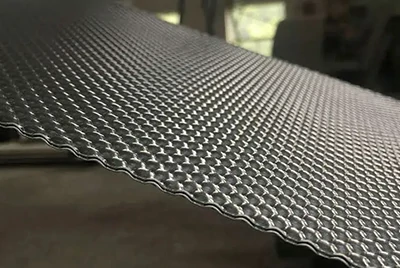

- Embossed patterns – orange peel, diamond, five-bar anti-slip designs

- Brushed finish – matte texture for decorative and architectural use

- Polished finish – bright reflective surface for lighting and reflectors

- Anodized finish – enhanced corrosion resistance and durable colors

Chemical composition of 1070 aluminum sheet plate (EN 573-3)

| Element | Si | Fe | Cu | Mn | Mg | Zr + Ti | Zn | Other (each) | Other (total) | Al |

| Max. % | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | 0.03 | 0.04 | 0.03 | 0.10 | Balance |

1070 H112 aluminum sheet plate performance

| Elastic Modulus | 68 GPa |

| Elongation at Break | 17 % |

| Fatigue Strength | 36 MPa |

| Shear Strength | 48 MPa |

| Yield Strength | 40 MPa |

| Specific Heat Capacity | 900 J/kg-K |

| Thermal Conductivity | 230 W/m-K |

| Electrical Conductivity | 61 % IACS |

These values are typical characteristics and may not meet your needs. If you have special needs, please contact us.

Instant QuoteApplications of 1070 aluminum sheet plate

- Electrical & power distribution – busbars, connector plates, grounding plates, transformer covers

- Heat dissipation & thermal management – air conditioner heat exchangers, cooling plates, thermal covers, reflective panels

- Lighting & reflection – lamp housings, reflector sheets, polished or mirror-finish aluminum coils

- Building & signage – decorative panels, curtain wall liners, advertising signboards, embossed sheets

- General sheet metal & chemical – stamped and deep-drawn parts, anti-corrosion linings for mild chemical environments

Note: In high-conductivity applications, alloys such as 1350, 1060, and 6101 are also used for busbars. However, for decorative, reflective, and thermal uses, 1070 aluminum sheet is preferred due to its high purity, excellent reflectivity, and superior formability.

Our processing services for 1070 aluminum sheet plate

- OEM customization: punching, bending, welding, cutting, anodizing and surface treatment

- Precision processing: leveling, slitting, CNC punching, laser cutting, bending and forming

- Large format capability: wide plates up to 2000 mm, thickness up to 150 mm

- Inspection support: dimensional reports, air tightness testing, ultrasonic flaw detection

- Stock supply for quick delivery + tailor-made production for special sizes

- All orders supplied with EN 10204 3.1 certificates and full traceability

Difference between 1050, 1060 and 1070 aluminum sheet plate

| Grade | 1050 aluminum sheet | 1060 aluminum sheet | 1070 aluminum sheet |

| Aluminum content | ≥ 99.5% | ≥ 99.6% | ≥ 99.7% |

| Electrical conductivity | ~ 58% IACS | ~ 59% IACS | ~ 61% IACS (highest) |

| Strength | Low | Low | Low |

| Corrosion resistance | Good | Good | Good |

| Formability | Excellent, easy to bend and weld | Excellent, slightly better mechanical balance | Excellent, very ductile |

| Main applications | Chemical equipment, food industry, decorative parts | Automotive radiators, heat exchangers, battery shells | Electrical busbars, capacitors, high conductivity parts |

| Price level | Lowest | Moderate | Slightly higher |

Packaging for 1070 H112 aluminum sheet plate

- Apply interleaving paper or film to protect the aluminum sheet.

- Wrap with plastic or kraft paper (ensuring each package has a moisture-absorbing desiccant).

- Add protective corners or edge protection materials to prevent damage.

- Reinforce with wooden pallets and secure with steel straps to prevent collisions during transportation.

- For export, package the products in wooden boxes and pallets marked with fumigation signs.

- Packaging can be customized according to additional requirements from the customer.

Feel free to leave your requirements below, and we will respond to you as quickly as possible.

Related aluminum products customers also buy

To support one-stop procurement, Chalco not only supplies 1070 aluminum sheet, but also provides a full range of related products such as 1xxx conductive aluminum plates, 5xxx corrosion-resistant sheets, 6xxx high-strength structural plates, and electrical busbars. This allows customers to complete their aluminum material sourcing in one place with guaranteed quality and fast delivery.

Instant Quote

1060 Aluminum Plate

1100 Aluminum Sheet

5052 Aluminum Sheet

5754 Aluminum Sheet

6061 Aluminum Sheet

6082 Aluminum Sheet

6063 Aluminum Busbar

1350 1370 Aluminum Busbar

1060 Aluminum Busbar

Frequently asked questions about 1070 aluminum sheet plate

What is a 1070 aluminium grade?

1070 is a high-purity aluminum alloy with ≥99.7% Al content. It offers excellent electrical and thermal conductivity, good corrosion resistance, and is widely used for busbars, capacitors, and heat dissipation components.

How do I know if my aluminum is 5052 or 6061?

5052 belongs to the 5xxx series (Al-Mg), known for excellent corrosion resistance and weldability, often used in marine and chemical equipment. 6061 is a 6xxx series (Al-Mg-Si) alloy with higher strength and machinability, widely used in aerospace and structural parts. A material test certificate (EN 10204 3.1) can confirm the grade.

What is the yield strength of 1070 aluminum?

The typical yield strength of 1070 aluminum is about 40 MPa (EN 485-2), depending on temper condition. It is lower than 5xxx and 6xxx series alloys, but sufficient for electrical and ductile applications.

What is the difference between 1100 and 6061 aluminum?

1100 is a commercially pure aluminum (99% min), excellent in corrosion resistance and formability, mainly used for chemical equipment and food industry. 6061 is a heat-treatable alloy with higher strength and hardness, preferred for aerospace, automotive and structural parts.

What is the price of 1070 aluminum sheet?

The price depends on thickness, width, length, surface finish, temper and order quantity. For the latest factory-direct price, please contact Chalco with your specifications.

How much does 1070 aluminum sheet cost?

1070 aluminum sheet cost is usually quoted per kg or per ton, and varies with alloy temper, processing, and delivery terms. Chalco offers competitive pricing with both stock sizes and custom production.