6061 aluminum is a versatile heat-treatable alloy composed primarily of silicon and magnesium, offering a balanced combination of strength, corrosion resistance, and excellent machinability. It retains many of the superior qualities of pure aluminum while providing enhanced performance for structural and precision applications.

Widely used in aerospace, marine, transportation, and general engineering industries, 6061 aluminum round bars are ideal for aircraft components, yacht frames, truck structures, bicycle parts, and CNC-machined elements.

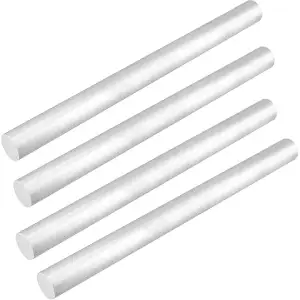

Brief introduction of Chalco 6061 aluminum round bar

Equivalent name: A96061; AW-AlMg1SiCu; EN AW-6061; AlMgSiCu; AlMg1SiCu; HE20; AA6061; 3.3211

Temper Options: T6, T651, T6511 (Most commonly supplied tempers for machining and structural applications)

Diameter Range: 10 mm – 390 mm (Metric) / 1/8” – 16” (Inch)

Standard Lengths: 2.8 m, 3 m, 3.5 m, 4 m (Custom cut-to-length available)

Processing Methods: Extruded, Cold Finished, Precision Cut, Chamfered

Industry Standards: ASTM B221, ASTM B211, AMS-QQ-A-200/8, AMS 4117, AMS 4128

Surface Finish Options: Mill Finish (Standard), Polished (Optional), Anodized (Optional)...

Product types of Chalco 6061 aluminum round bar

Chalco offers a wide range of 6061 aluminum round bar types to meet the diverse needs of structural, mechanical, and precision machining applications. Each bar type is engineered for optimal performance in its intended use, with various processing methods and surface options available.

6061 aluminum Extruded Round Bar

6061 aluminum Extruded Round BarProduced through direct extrusion, these bars are ideal for structural components where dimensional tolerance is less critical.

Applications: Load-bearing parts, frames, marine hardware.

Available in mill finish with standard tempers T6 and T6511. 6061 Aluminum Cold Finished Round Bar

6061 Aluminum Cold Finished Round BarEnhanced dimensional accuracy and surface finish make cold finished bars suitable for CNC turning and high-speed automatic lathes.

Applications: Shafts, bushings, pins, connectors.

Offered in T6, T651, and T6511, with optional polishing. 6061 Aluminum Chamfered Round Bar

6061 Aluminum Chamfered Round BarMachined with precision chamfered ends, these bars reduce feeding resistance and improve efficiency in centerless grinding and screw machining.

Applications: Screw machine blanks, sliding parts, tool holders.

Ready for immediate use with consistent end finish. 6061 Aluminum Polished Round Bar

6061 Aluminum Polished Round BarSurface-polished bars provide enhanced visual quality and are suitable for applications with aesthetic or post-anodizing requirements.

Applications: Decorative parts, display hardware, visible components.

Available upon request with optional anodizing support. 6061 Aluminum Cut-to-Length Round Bar

6061 Aluminum Cut-to-Length Round BarChalco provides custom-length cutting services to match your production needs, minimizing material waste and lead time.

Applications: Prototyping, short-run machining, batch manufacturing.

Free cutting available for selected stock sizes.

Not sure which type suits your application best? Contact Chalco's aluminum experts for tailored product selection and machining advice.

Instant QuotePurchasing of Chalco 6061 aluminum round bar

- Relying on Chalco production line and its subsidiaries, source procurement, lowest price guarantee.

- Chalco has the largest inventory and can allocate its subsidiary's inventory products at any time, seven-day delivery guarantee;

- The quality of large and small batches is the same, and be provided at the lowest price. Extra discount for large quantity order.

- Customized sizes can be provided.

6061 aluminum round bar stock (Round-metric size)

Inventory information is being updated in real-time, with hot selling inventory lengths of 2.8m, 3m, 3.5m, 4m, and other sizes available for cutting.

Welcome to click on the button to obtain the latest inventory information and lowest quotation....

Instant Quote| Product | Diameter mm | Product | Diameter mm |

| 6061-T651 round bar | φ10 | 6061-T651 round bar | φ12 |

| 6061-T6 round bar | φ16 | 6061-T651 round bar | φ18 |

| 6061-T6 6061-T651 | φ20 | 6061-T6 6061-T651 round bar | φ25 |

| 6061-T6 6061-T651 6061-T6511 round bar | φ30 | 6061-T6 round bar | φ32 |

| 6061-T651 6061-T6511 round bar | φ35 | 6061-T6 | φ38 |

| 6061-T6 6061-T6511 round bar | φ40 | 6061-T6511 round bar | φ45 |

| 6061-T6 6061-T651 6061-T6511 round bar | φ50 | 6061-T6 6061-T651 6061-T6511 round bar | φ55 |

| 6061-T6 6061-T6511 round bar | φ60 | 6061-T6511 round bar | φ65 |

| 6061-T6 6061-T6511 round bar | φ70 | 6061-T6 6061-T6511 round bar | φ75 |

| 6061-T6511 round bar | φ80 | 6061-T6511 round bar | φ85 |

| 6061-T6511 round bar | φ90 | 6061-T6511 round bar | φ95 |

| 6061-T6 6061-T6511 round bar | φ100 | 6061-T6 6061-T651 6061-T6511 round bar | φ105 |

| 6061-T651 6061-T6511 round bar | φ110 | 6061-T651 6061-T6511 round bar | φ115 |

| 6061-T6 6061-T6511 round bar | φ120 | 6061-T6511 round bar | φ125 |

| 6061-T6511 round bar | φ130 | 6061-T6 6061-T651 6061-T6511 round bar | φ135 |

| 6061-T6511 round bar | φ140 | 6061-T6 6061-T6511 round bar | φ145 |

| 6061-T6511 round bar | φ150 | 6061-T6 round bar | φ155 |

| 6061-T6511 round bar | φ155 | 6061-T6511 round bar | φ160 |

| 6061-T6511 round bar | φ165 | 6061-T6511 round bar | φ170 |

| 6061-T6511 round bar | φ175 | 6061-T6 6061-T6511 round bar | φ180 |

| 6061-T6 6061-T6511 round bar | φ190 | 6061-T6511 round bar | φ200 |

| 6061-T6511 round bar | φ215 | 6061-T6 6061-T6511 round bar | φ220 |

| 6061-T6 6061-T6511 round bar | φ230 | 6061-T6511 round bar | φ240 |

| 6061-T6511 round bar | φ250 | 6061-T6 round bar | φ260 |

| 6061-T6511 round bar | φ290 | 6061-T6 round bar | φ310 |

| 6061-T6 round bar | φ320 | 6061-T6 round bar | φ340 |

| 6061-T6511 round bar | φ390 |

Hot selling size list of Chalco 6061 aluminum round bars

Chalco can produce and process more popular products of 6061 aluminum round bars, with regular lengths of 6 feet and 12 feet, and other lengths can be customized for cutting.

The product has a large circulation volume, please contact for consultation if needed. Click to check Chalco[round bar extrusion mold capacity table].

| Product | Diameter: inch | Contact | |

| 6061 T6 CF | 1/8 | 0.125 | Instant Quote |

| 6061 T6 CF 6061 T6511 EXD | 3/16 | 0.3125 | Instant Quote |

| 6061 T6 CF 6061 T651 CF 6061 T6511 EXD | 1/4 | 0.250 | Instant Quote |

| 6061 T6 CF 6061 T6511 EXD | 3/8 | 0.375 | Instant Quote |

| 6061 T6 CF 6061 T6511 EXD | 7/16 | 0.4375 | Instant Quote |

| 6061 T6511 | 1/2 | 0.500 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 5/8 | 0.625 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 3/4 | 0.750 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 7/8 | 0.875 | Instant Quote |

| 6061 T6 CF 6061 T6511 EXD | 1 | 1.000 | Instant Quote |

| 6061 T6511 EXD | 1 1/8 | 1.125 | Instant Quote |

| 6061 T6 CF 6061 T6511 EXD | 1 1/4 | 1.250 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 1 3/8 | 1.375 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 1 1/2 | 1.500 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 1 5/8 | 1.625 | Instant Quote |

| 6061 T651 CF | 1 3/4 | 1.750 | Instant Quote |

| 6061 T6511 EXD | 1 7/8 | 1.875 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 2 | 2.000 | Instant Quote |

| 6061 T6511 EXD | 2 1/8 | 2.125 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 2 1/4 | 2.250 | Instant Quote |

| 6061 T6511 EXD | 2 3/8 | 2.375 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 2 1/2 | 2.500 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 2 5/8 | 2.625 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 2 3/4 | 2.750 | Instant Quote |

| 6061 T6511 EXD | 2 7/8 | 2.875 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 3 | 3.000 | Instant Quote |

| 6061 T6511 EXD | 3 1/8 | 3.125 | Instant Quote |

| 6061 T6511 EXD | 3 1/4 | 3.250 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 3 1/2 | 3.500 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 3 3/4 | 3.750 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 4 | 4.000 | Instant Quote |

| 6061 T6511 EXD | 4 1/4 | 4.250 | Instant Quote |

| 6061 T6511 EXD | 4 1/2 | 4.500 | Instant Quote |

| 6061 T6511 EXD | 4 3/4 | 4.750 | Instant Quote |

| 6061 T6 CF 6061 T6511 EXD | 5 | 5.000 | Instant Quote |

| 6061 T6 CF 6061 T651 CF 6061 T6511 EXD | 5 1/2 | 5.500 | Instant Quote |

| 6061 T651 CF 6061 T6511 EXD | 6 | 6.000 | Instant Quote |

| 6061 T6511 EXD | 6 1/4 | 6.250 | Instant Quote |

| 6061 T6511 EXD | 6 21/2 | 6.500 | Instant Quote |

| 6061 T6511 EXD | 7 | 7.000 | Instant Quote |

| 6061 T6511 EXD | 7 1/2 | 7.500 | Instant Quote |

| 6061 T6511 EXD | 8 | 8.000 | Instant Quote |

| 6061 T6 EXD | 9 | 9.000 | Instant Quote |

| 6061 T6 EXD | 10 | 10.000 | Instant Quote |

| 6061 T6 EXD | 11 | 11.000 | Instant Quote |

| 6061 T6 EXD | 12 | 12.000 | Instant Quote |

| 6061 T6 EXD | 13 | 13.000 | Instant Quote |

| 6061 T6 EXD | 16 | 16.000 | Instant Quote |

Weight calculation of 6061 aluminum round bar

Calculation of weight of aluminum round bar: π R 2 * h × 0.0000027 (3.1415 * square of aluminum rod radius * aluminum rod length * density, radius length in mm).

If the length is short, the cutting loss will increase.

The length and diameter of the incision should have a tolerance of 1-3mm. The length and diameter of the incision should have a tolerance of 1-3mm.

Need to estimate the weight of your order? Use our 6061 aluminum round bar weight calculator to quickly calculate the theoretical weight based on your desired diameter and length.

Note: Actual weight may vary slightly due to cutting loss and dimensional tolerance (±1–3 mm).

Chalco's production capabilities for 6061 aluminum round bar

At Chalco, our production of 6061 aluminum round bars is backed by a fully integrated manufacturing system—from alloy melting and extrusion to precision finishing and custom packaging. We combine large-scale capacity with tight quality control to support both high-volume orders and specialized machining requirements.

- High-precision extrusion lines for a wide diameter range (10 mm to 390 mm), with tight control of mechanical properties and grain structure.

- Advanced cold finishing lines, including drawing, straightening, and chamfering equipment for high-tolerance and surface-quality requirements.

- Custom cutting and chamfering services, supporting CNC machining centers and automatic lathes with optimized feeding dimensions.

- Polishing and pre-anodizing preparation, available for architectural or decorative applications.

- Digital mold inventory and rapid die change system, enabling short lead times for both standard and non-standard sizes.

- Full compliance with ASTM, AMS, and ISO standards

- Chemical composition and mechanical property verification for each batch

- Dimensional inspection, ultrasonic testing (upon request), and surface quality checks

From raw material to finished bar, every step is controlled for consistency, reliability, and traceability—meeting the exacting needs of aerospace, automotive, and precision engineering clients. Contact our team to discuss your technical requirements or request a fast quote for your preferred size and temper.

Instant QuotePerformance parameter table of 6061 aluminum round bar

| Density (pounds per cubic inch) | 0.098 |

| Specific gravity | 2.7 |

| Melting point (Fahrenheit) | 1090 |

| Ultimate tensile strength psi | 45, 000 |

| Yield strength psi | 40, 000 |

| Brinell hardness | 95 |

| Rockwell hardness | B60 |

Looking for more details on 6061 aluminum properties and applications? Or curious why T6 is the most popular temper for 6061 aluminum? Visit our 6061 aluminum material overview and 6061 T6 analysis for comprehensive alloy data, and explore a full range of related products including round bars, plates, sheets, and custom profiles.

Advantage of 6061 aluminum round bar

- 6061 aluminum bar is lightweight and its high-strength is close to steel; easy to drill, machine, and saw.

- The main alloy components of 6061 aluminum are magnesium and silicon, which are corrosion resistant, moisture resistant, stress resistant, and crack resistant.

- This alloy is easy to anodize and has good formability, machinability, and weldability.

Chalco 6061 aluminum rod related recommendations

6061 aerospace aluminum bar

6061 Aluminum extrusion

6061 aluminum forged bar

6061 aluminum forged block

6061 aluminum sheet coil

6061 aluminum plate

6061 aluminum busbar

2024 aluminum bar

7075 aluminum bar

Further reading knowladge about 6061 aluminum bar

- 6061 vs 7075 aluminum

7075 aluminum rod offers significantly higher strength compared to 6061, making it preferable for applications where strength is paramount.

- 6061 vs 5052 aluminum

6061 aluminum alloy is typically used for structural applications, while 5052 aluminum alloy is more suitable for applications requiring corrosion resistance, such as marine environments.

- 6061 vs 6063 aluminum

Aluminum 6061 has a lower melting point, higher yield strength, lower thermal conductivity, and poor corrosion resistance. Aluminum 6063 has a higher melting point, lower yield strength, higher thermal conductivity, and better corrosion resistance.

In addition to the comparisons above, Chalco also supplies a full range of aluminum bar alloys to meet diverse application needs. Whether you require enhanced corrosion resistance, ultra-high strength, or aerospace-grade fatigue performance, we have the right solution for you.

5052 aluminum bar – Excellent corrosion resistance, ideal for marine and chemical applications

5A06 aluminum bar – Superior toughness and weldability, suitable for shipbuilding and pressure vessels

7075 aluminum bar – Ultra-high strength for aerospace and tooling components

2024 aluminum bar – High fatigue resistance, used in aerospace structural parts

2618 aluminum bar – Excellent high-temperature strength and creep resistance, used in aerospace engine parts, racing pistons, and military components

2011 aluminum bar – Exceptional machinability, ideal for high-speed automatic lathes

2017 aluminum bar – Good strength and fatigue resistance, often used in aerospace fittings and transportation

6110 aluminum bar – Balanced mechanical properties and corrosion resistance, recommended for industrial structural components

Click to explore each product page or contact our sales team for real-time stock availability and personalized alloy recommendations.

Instant QuoteChalco 6061 aluminum round bar extrusion capacity

| D(mm) | Line Density (Kg/m) | Extrusion Tonnage(T) | Alloy |

| 4.76 | 0.049 | 500 | Universal |

| 6 | 0.076 | 500 | Universal |

| 6.35 | 0.086 | 500 | Universal |

| 7.94 | 0.133 | 500 | Universal |

| 8 | 0.136 | 500 | Universal |

| 8.1 | 0.515 | 500 | Universal |

| 8.10 | 0.139 | 500 | Universal |

| 9.53 | 0.192 | 500 | Universal |

| 9.60 | 0.139 | 500 | Universal |

| 10 | 0.212 | 500 | Universal |

| 10.5 | 0.234 | 500 | Universal |

| 10.7 | 0.243 | 500 | Universal |

| 11.11 | 0.261 | 500 | Universal |

| 12 | 0.305 | 660 | Universal |

| 12.70 | 0.341 | 660 | Universal |

| 13.49 | 0.386 | 660 | Universal |

| 13.60 | 0.392 | 660 | Universal |

| 14 | 0.416 | 660 | Universal |

| 14.29 | 0.432 | 660 | Universal |

| 15 | 0.477 | 660 | Universal |

| 15.09 | 0.483 | 660 | Universal |

| 15.88 | 0.534 | 880 | Universal |

| 15.88 | 0.534 | 660 | Universal |

| 16 | 0.543 | 660 | Universal |

| 16.46 | 0.575 | 660 | Universal |

| 17.48 | 0.648 | 880 | Universal |

| 18 | 0.687 | 660 | Universal |

| 18.16 | 0.699 | 880 | Universal |

| 19.05 | 0.781 | 880 | Universal |

| 19.685 | 0.822 | 880 | Universal |

| 20 | 0.848 | 880 | Universal |

| 20.64 | 0.903 | 880 | Universal |

| 22 | 1.026 | 880 | Universal |

| 22.23 | 1.046 | 880 | Universal |

| 23.81 | 1.201 | 1250 | Universal |

| 25 | 1.325 | 1250 | Universal |

| 25.40 | 1.367 | 1250 | Universal |

| 25.40 | 1.373 | 1250 | Universal |

| 25.65 | 1.394 | 1250 | Universal |

| 26.99 | 1.544 | 1250 | Universal |

| 28.00 | 1.663 | 2000 | Universal |

| 28.58 | 1.731 | 1250 | Universal |

| 30.00 | 1.909 | 2000 | Universal |

| 30 | 1.909 | 1250 | Universal |

| 30.16 | 1.930 | 1250 | Universal |

| 31.75 | 2.136 | 1250 | Universal |

| 32 | 2.171 | 1250 | Universal |

| 33.34 | 2.356 | 1250 | Universal |

| 34.93 | 2.586 | 2000 | Universal |

| 35.00 | 2.598 | 1250 | Universal |

| 36.00 | 2.748 | 1800 | Universal |

| 36.51 | 2.827 | 1250 | Universal |

| 38 | 3.062 | 1250 | Universal |

| 38.10 | 3.076 | 2000 | Universal |

| 39.69 | 3.337 | 1250 | Universal |

| 40.00 | 3.393 | 2000 | Universal |

| 40 | 3.393 | 1250 | Universal |

| 41.28 | 3.612 | 2000 | Universal |

| 42 | 3.741 | 1800 | Universal |

| 42.86 | 3.894 | 2000 | Universal |

| 44.00 | 4.105 | 1250 | Universal |

| 44.45 | 4.188 | 1250 | Universal |

| 45 | 4.294 | 1250 | Universal |

| 46 | 4.487 | 3150 | Universal |

| 46.04 | 4.492 | 2000 | Universal |

| 47.63 | 4.807 | 2000 | Universal |

| 48 | 4.886 | 3150 | Universal |

| 49.21 | 5.136 | 2000 | Universal |

| 50 | 5.301 | 3150 | Universal |

| 50.80 | 5.470 | 2000 | Universal |

| 51.59 | 5.643 | 2000 | Universal |

| 52 | 5.734 | 3150 | Universal |

| 52.39 | 5.817 | 2000 | Universal |

| 53.98 | 6.175 | 2000 | Universal |

| 55 | 6.415 | 3600 | Universal |

| 55.60 | 6.544 | 2000 | Universal |

| 57.15 | 6.923 | 2000 | Universal |

| 58.74 | 7.313 | 3600 | Universal |

| 59 | 7.382 | 3600 | Universal |

| 60 | 7.634 | 3600 | Universal |

| 60.33 | 7.714 | 3600 | Universal |

| 61.91 | 8.128 | 3600 | Universal |

| 62 | 8.151 | 3150 | Universal |

| 63.50 | 8.548 | 3600 | Universal |

| 65 | 8.959 | 3600 | Universal |

| 66.68 | 9.423 | 3600 | Universal |

| 69.85 | 10.343 | 3600 | Universal |

| 70 | 10.391 | 3600 | Universal |

| 72 | 3600 | Universal | |

| 73.03 | 11.303 | 3600 | Universal |

| 75.00 | 11.928 | 7500 | Universal |

| 75 | 11.928 | 3600 | Universal |

| 76 | 12.248 | 3600 | Universal |

| 76.20 | 12.309 | 3600 | Universal |

| 79.38 | 13.355 | 3600 | Universal |

| 80 | 13.572 | 3600 | Universal |

| 82.55 | 14.445 | 3600 | Universal |

| 85 | 15.321 | 3600 | Universal |

| 85.73 | 15.576 | 3600 | Universal |

| 88.90 | 16.752 | 3600 | Universal |

| 90 | 17.177 | 3600 | Universal |

| 91 | 17.56 | 3600 | Universal |

| 92 | 17.949 | 3600 | Universal |

| 92.08 | 17.971 | 3600 | Universal |

| 95 | 19.138 | 3600 | Universal |

| 95.25 | 19.232 | 3600 | Universal |

| 97.20 | 20.035 | 3600 | Universal |

| 100 | 21.206 | 3600 | Universal |

| 100 | 21.206 | 7500 | Universal |

| 101.60 | 21.880 | 3600 | Universal |

| 104.78 | 23.279 | 7500 | Universal |

| 107.95 | 24.711 | 7500 | Universal |

| 110 | 25.659 | 7500 | Universal |

| 110 | 25.659 | 7500 | Universal |

| 111.25 | 26.186 | 7500 | Universal |

| 114.3 | 27.704 | 7500 | Universal |

| 115 | 28.045 | 7500 | Universal |

| 117.475 | 29.265 | 7500 | Universal |

| 120 | 30.536 | 7500 | Universal |

| 120.65 | 30.868 | 7500 | Universal |

| 125 | 33.134 | 7500 | Universal |

| 127 | 34.203 | 7500 | Universal |

| 130 | 35.838 | 7500 | Universal |

| 130.175 | 35.934 | 7500 | Universal |

| 133.35 | 37.709 | 7500 | Universal |

| 135 | 38.647 | 7500 | Universal |

| 139.7 | 41.385 | 7500 | Universal |

| 140 | 41.563 | 7500 | Universal |

| 145 | 44.585 | 7500 | Universal |

| 146.05 | 45.233 | 7500 | Universal |

| 150 | 47.713 | 7500 | Universal |

| 152.4 | 7500 | Universal | |

| 160 | 54.286 | 7500 | Universal |

| 165 | 57.733 | 7500 | Universal |

| 170 | 61.285 | 7500 | Universal |

| 175 | 64.943 | 12500 | Universal |

| 180 | 68.707 | 12500 | Universal |

| 200 | 84.823 | 12500 | Universal |

| 250 | 132.536 | 12500 | Universal |

| 260 | 143.351 | 12500 | Universal |

| 350 | 259.77 | 12500 | Universal |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote