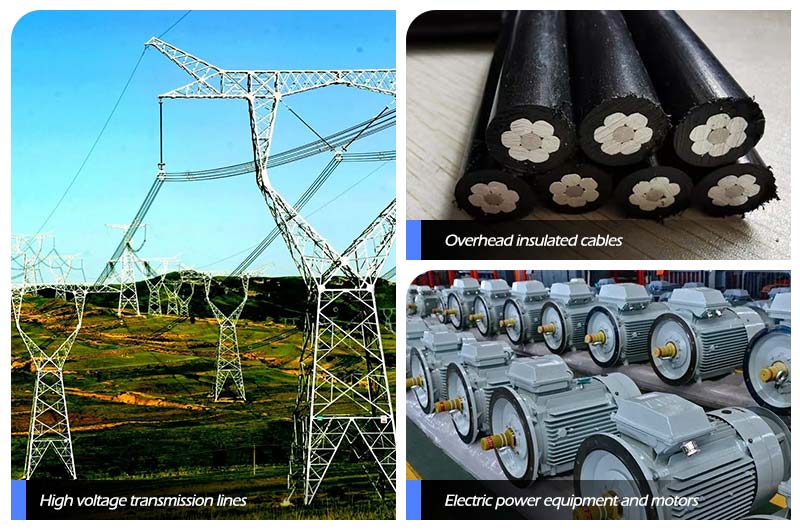

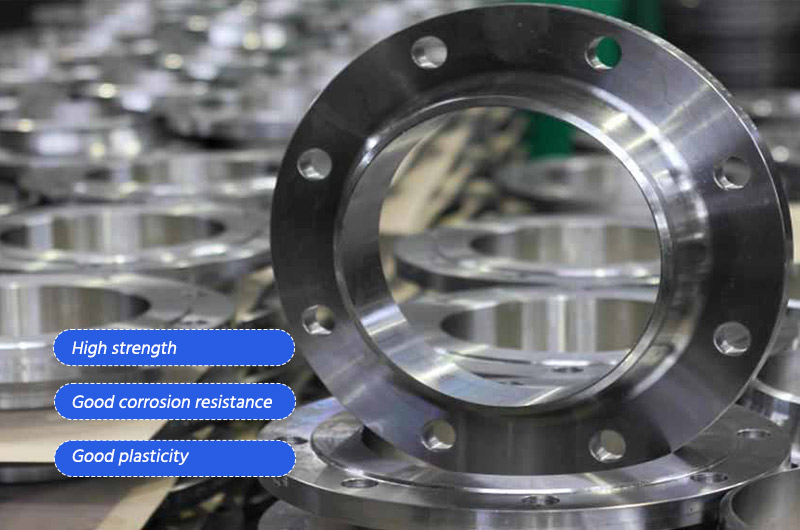

6061 aluminum rods are high-strength, corrosion-resistant, and highly machinable, making them an ideal choice for aerospace, automotive, marine, construction, and electrical applications. These rods offer excellent tensile strength, durability, and weldability, ensuring optimal performance in demanding environments.

At Chalco, we provide a full range of 6061 aluminum rods, covering various sizes, shapes, and tempers, ensuring customized solutions for every project. Contact us today to get the best quality 6061 aluminum rods at competitive prices!

Instant QuoteTechnical specifications of Chalco 6061 aluminum bar

- 6061 aluminum bar temper: 6061-T4, 6061-T6, 6061-T651, 6061-T6511, 6061-O

- 6061 aluminum bar shape aviliable: round bar, square bar, flat bar, hexagonal bar

- 6061 aluminum round bar diamerter range: 4mm to 300mm [View details]

- 6061 aluminum flat bar size: A side from 3mm to 70mm; B side from 10mm to 150mm [View details]

- 6061 aluminum square bar size range: 6-50mm [View details]

- 6061 aluminum hex bar size range: across flat 12-65mm; Length 100-2500mm [View details]

- 6061 aluminum bar extrusion capacity: click the [6061 aluminum bar extrusion modle table] to know Extrusion Capacity

- Surface treatment: anodizing, electrophoretic coating, powder coating, etc.

- Specification: ASTM B211, AMS 4115, AMS 4116, AMS 4117, AMS 4128, AMS-QQ-A-225/8 and ASTM B221, AMS4150, AMS 4160, AMS 4161, AMS-QQ-A-200/8

Temper choosing of 6061 aluminum bar

When selecting 6061 aluminum rods, choosing the right temper is crucial, for example, T6 offers high strength, while T4 provides better machinability. Understanding and selecting the appropriate temper ensures project success and optimal performance.

For any questions regarding the characteristics or applications of different alloy tempers, please contact Chalco for consultation.

Instant Quote- 6061 T6 aluminum bar

Best for structural strength, machining, marine applications.

- 6061 T651 aluminum bar

Similar to T6 but with better stress-relief properties.

- 6061-T6511 aluminum rod

Ideal for extruded bars, precision machining.

- 6061 T4 aluminunm bar

Good for forming, bending, and moderate strength needs.

- 6061 O aluminum bar

Fully annealed, best for deep drawing, cold working.

Chalco 6061 Aluminum bar rod products | Advanced Manufacturing & CNC-Ready & Precision Engineered

6061 aluminum bars from Chalco are engineered for precision machining, structural strength, and visual excellence. Below are our featured high-performance bars, followed by core general-purpose types.

CNC Chamfered 6061 Aluminum Bars for Swiss-Type Machines

CNC Chamfered 6061 Aluminum Bars for Swiss-Type MachinesIdeal for: High-speed automatic lathes, Swiss-type CNC turning; Pre-chamfered 6061 bars with clean ends and tight length control, ideal for automated feeding in Swiss-type and CNC multi-axis machines. Reduces prep time, enhances part consistency, and minimizes tool wear in mass production.

Ready-to-load Tight tolerances Burr-free Excellent machinability Precision Cold Drawn 6061 Aluminum Bars

Precision Cold Drawn 6061 Aluminum BarsIdeal for: Aerospace parts, connectors, structural components; High-precision cold drawn bars with ±0.05 mm dimensional tolerance and increased tensile strength. Excellent straightness and finish make them suitable for high-precision machining and post-treatment (e.g., anodizing, plating).

High strength Excellent straightness Tight dimensional control Bright/Polished 6061 Aluminum Bars

Bright/Polished 6061 Aluminum BarsIIdeal for: Appearance-critical parts, decorative or cleanroom assemblies; Polished bars with minimal surface defects and high reflectivity, suitable for components requiring visual appeal or smooth anodized surfaces.

High gloss Defect-free surface Good for anodizing Short Bar / Cut-to-Length 6061 Aluminum Bar for CNC Feeders

Short Bar / Cut-to-Length 6061 Aluminum Bar for CNC FeedersIdeal for: CNC automation environments, bar feeders, robotic loaders; Fixed-length 6061 bars with smooth, burr-free ends, specifically tailored for automatic loading systems in CNC production lines.

Fixed length (1.2m, 1.5m, etc.) Clean ends Minimal waste

Extruded 6061 Aluminum Bar

High-pressure extrusion ensures uniform structure and strong mechanical properties.

Hot-Rolled 6061 Aluminum Bar

Designed for heavy-load applications, providing toughness and durability.

Forged 6061 Aluminum Bar

Refined grain structure for superior strength and fatigue resistance.

6061 Aluminum Bar – Popular Shapes & Stock Availability

Chalco offers a comprehensive range of 6061 aluminum bars, available in various shapes and sizes to meet diverse industrial needs. With a well-stocked inventory and customizable dimensions, we ensure quick delivery and reliable supply. Whether you need round, square, flat, hexagonal, or large-diameter bars, our extensive stock and precision processing capabilities guarantee the right solution for your project.

6061 aluminum large diameter bar rod

Diameter can reach Φ1350mm

Chalco 6061 large diameter aluminum bar can reach Φ1350mm, commonly used diameter is Φ600-700mm. Various industries such as aerospace, defense, and casting markets require the large cross-section circular aluminum alloys for key projects.

6061 aluminum round bar rod

Stock diameter: 5-420mm; length: 100-6000mm

Chalco 6061 aluminum round bars are available in a variety of sizes in stock, including full sizes and custom cut lengths. Welcome to contact.

Click to check the detailed information and stock list of [6061 aluminum round bar]

| Product | Diameter(mm) | Product | Diameter(inch) |

| 6061-T651 round bar | φ10 | 6061 T6 CF | 1/8 (0.125) |

| 6061-T651 round bar | φ12 | 6061 T6511 EXD | 3/16 (0.3125) |

| 6061-T6 round bar | φ16 | 6061 T6 CF 6061 T6511 EXD | 1/4 (0.250) |

| 6061-T651 round bar | φ18 | 6061 T6511 EXD | 3/8 (0.375) |

| 6061-T6 6061-T651 | φ20 | 6061 T6511 EXD | 7/16 (0.4375) |

| 6061-T6 6061-T6511 | φ25 | 6061 T6511 | 1/2 (0.500) |

| 6061-T6511 round bar | φ30 | 6061 T6511 EXD | 5/8 (0.625) |

| 6061-T6511 round bar | φ35 | 6061 T6511 EXD | 3/4 (0.750) |

| 6061-T6 6061-T6511 | φ40 | 6061 T6511 EXD | 7/8 (0.875) |

| 6061-T6511 round bar | φ45 | 6061 T6 CF 6061 T6511 EXD | 1 (1.000) |

| 6061-T6511 round bar | φ50 | 6061 T6511 EXD | 1 1/8 (1.125) |

| 6061-T6511 round bar | φ55 | 6061 T6511 EXD | 1 1/4 (1.250) |

| 6061-T6511 round bar | φ60 | 6061 T6511 EXD | 1 3/8 (1.375) |

| 6061-T6511 round bar | φ65 | 6061 T6511 EXD | 1 1/2 (1.500) |

| 6061-T6511 round bar | φ70 | 6061 T6511 EXD | 1 5/8 (1.625) |

| 6061-T6511 round bar | φ75 | 6061 T6511 EXD | 1 3/4 (1.750) |

| 6061-T6511 round bar | φ80 | 6061 T6511 EXD | 1 7/8 (1.875) |

| 6061-T6511 round bar | φ85 | 6061 T6511 EXD | 2 (2.000) |

| 6061-T6511 round bar | φ90 | 6061 T6511 EXD | 2 1/8 (2.125) |

| 6061-T6511 round bar | φ95 | 6061 T6511 EXD | 2 1/4 (2.250) |

| 6061-T6511 round bar | φ100 | 6061 T6511 EXD | 2 3/8 (2.375) |

| 6061-T6511 round bar | φ105 | 6061 T6511 EXD | 2 1/2 (2.500) |

| 6061-T6511 round bar | φ110 | 6061 T6511 EXD | 2 5/8 (2.625) |

| 6061-T6511 round bar | φ115 | 6061 T6511 EXD | 2 3/4 (2.750) |

| 6061-T6511 round bar | φ120 | 6061 T6511 EXD | 2 7/8 (2.875) |

| 6061-T6511 round bar | φ125 | 6061 T6511 EXD | 3 (3.000) |

| 6061-T6511 round bar | φ130 | 6061 T6511 EXD | 3 1/8 (3.125) |

| 6061-T6511 round bar | φ135 | 6061 T6511 EXD | 3 1/4 (3.250) |

| 6061-T6511 round bar | φ140 | 6061 T6511 EXD | 3 1/2 (3.500) |

| 6061-T6511 round bar | φ145 | 6061 T6511 EXD | 3 3/4 (3.750) |

| 6061-T6511 round bar | φ150 | 6061 T6511 EXD | 4 (4.000) |

| 6061-T6511 round bar | φ155 | 6061 T6511 EXD | 4 1/4 (4.250) |

| 6061-T6511 round bar | φ160 | 6061 T6511 EXD | 4 1/2 (4.500) |

| 6061-T6511 round bar | φ165 | 6061 T6511 EXD | 4 3/4 (4.750) |

| 6061-T6511 round bar | φ170 | 6061 T6511 EXD | 5 (5.000) |

| 6061-T6511 round bar | φ175 | 6061 T6511 EXD | 5 1/2 (5.500) |

| 6061-T6511 round bar | φ180 | 6061 T6511 EXD | 6 (6.000) |

| 6061-T6511 round bar | φ190 | 6061 T6511 EXD | 6 1/4 (6.250) |

| 6061-T6511 round bar | φ200 | 6061 T6511 EXD | 6 1/2 (6.500) |

| 6061-T6511 round bar | φ215 | 6061 T6511 EXD | 7 (7.000) |

| 6061-T6511 round bar | φ220 | 6061 T6511 EXD | 7 1/2 (7.500) |

| 6061-T6511 round bar | φ230 | 6061 T6511 EXD | 8 (8.000) |

| 6061-T6511 round bar | φ240 | 6061 T6511 EXD | 9 (9.000) |

| 6061-T6511 round bar | φ250 | 6061 T6511 EXD | 10 (10.000) |

| 6061-T6511 round bar | φ260 | 6061 T6511 EXD | 11 (11.000) |

| 6061-T6511 round bar | φ290 | 6061 T6511 EXD | 12 (12.000) |

| 6061-T6511 round bar | φ310 | 6061 T6511 EXD | 13 (13.000) |

| 6061-T6511 round bar | φ320 | 6061 T6511 EXD | 16 (16.000) |

| 6061-T6511 round bar | φ340 |

6061 aluminum flat/rectangular bar rod

Stock height: 6-50mm; thickness * Width: (3-1)*(10*130)mm; length: 100-2500mm

6061 aluminum square bars offer high strength, corrosion resistance, and versatility, ideal for aerospace and structural applications.

Click to check the detailed information and stock list of [6061 aluminum flat bar]

| Product Description | Metric Dimensions (mm) | Imperial Dimensions (in) |

| Aluminum Flat Bar 6061-T6-Extruded | 10x5 | 3/8 x 1/4 |

| Aluminum Flat Bar 6061-T6-Extruded | 12x6 | 1/2 x 1/4 |

| Aluminum Flat Bar 6061-T6-Extruded | 14x7 | 9/16 x 5/16 |

| Aluminum Flat Bar 6061-T6-Extruded | 15x8 | 5/8 x 5/16 |

| Aluminum Flat Bar 6061-T6-Extruded | 16x10 | 5/8 x 3/8 |

| Aluminum Flat Bar 6061-T6-Extruded | 18x12 | 3/4 x 1/2 |

| Aluminum Flat Bar 6061-T6-Extruded | 20x15 | 7/8 x 5/8 |

| Aluminum Flat Bar 6061-T6-Extruded | 25x20 | 1 x 3/4 |

| Aluminum Flat Bar 6061-T6-Extruded | 30x25 | 1 1/4 x 1 |

| Aluminum Flat Bar 6061-T6-Extruded | 35x30 | 1 3/8 x 1 1/8 |

| Aluminum Flat Bar 6061-T6-Extruded | 40x35 | 1 1/2 x 1 3/8 |

| Aluminum Flat Bar 6061-T6-Extruded | 45x40 | 1 3/4 x 1 1/2 |

| Aluminum Flat Bar 6061-T6-Extruded | 50x45 | 2 x 1 3/4 |

| Aluminum Flat Bar 6061-T6-Extruded | 55x50 | 2 1/4 x 2 |

| Aluminum Flat Bar 6061-T6-Extruded | 60x55 | 2 1/2 x 2 1/8 |

| Aluminum Flat Bar 6061-T6-Extruded | 65x60 | 2 1/2 x 2 1/4 |

| Aluminum Flat Bar 6061-T6-Extruded | 70x65 | 2 3/4 x 2 1/2 |

6061 aluminum square bar rod

Stock height: 6-50mm; thickness * Width: (3-1)*(10*130)mm; length: 100-2500mm

6061 aluminum square bars offer high strength, corrosion resistance, and versatility, ideal for aerospace and structural applications.

Click to check the detailed information and stock list of [6061 aluminum square bar]

.

| Product Description | Metric Dimensions (mm) | Imperial Dimensions (in) |

| Aluminum Square Bar 6061-T6-Extruded | 10x10 | 0.39x0.39 |

| Aluminum Square Bar 6061-T6-Extruded | 12x12 | 0.47x0.47 |

| Aluminum Square Bar 6061-T6-Extruded | 14x14 | 0.55x0.55 |

| Aluminum Square Bar 6061-T6-Extruded | 15x15 | 0.59x0.59 |

| Aluminum Square Bar 6061-T6-Extruded | 16x16 | 0.63x0.63 |

| Aluminum Square Bar 6061-T6-Extruded | 18x18 | 0.71x0.71 |

| Aluminum Square Bar 6061-T6-Extruded | 20x20 | 0.79x0.79 |

| Aluminum Square Bar 6061-T6-Extruded | 25x25 | 0.98x0.98 |

| Aluminum Square Bar 6061-T6-Extruded | 30x30 | 1.18x1.18 |

| Aluminum Square Bar 6061-T6-Extruded | 35x35 | 1.38x1.38 |

| Aluminum Square Bar 6061-T6-Extruded | 40x40 | 1.57x1.57 |

| Aluminum Square Bar 6061-T6-Extruded | 45x45 | 1.77x1.77 |

| Aluminum Square Bar 6061-T6-Extruded | 50x50 | 1.97x1.97 |

| Aluminum Square Bar 6061-T6-Extruded | 55x55 | 2.17x2.17 |

| Aluminum Square Bar 6061-T6-Extruded | 60x60 | 2.36x2.36 |

| Aluminum Square Bar 6061-T6-Extruded | 65x65 | 2.56x2.56 |

| Aluminum Square Bar 6061-T6-Extruded | 70x70 | 2.76x2.76 |

| Aluminum Square Bar 6061-T6-Extruded | 75x75 | 2.95x2.95 |

| Aluminum Square Bar 6061-T6-Extruded | 80x80 | 3.15x3.15 |

| Aluminum Square Bar 6061-T6-Extruded | 85x85 | 3.35x3.35 |

| Aluminum Square Bar 6061-T6-Extruded | 90x90 | 3.54x3.54 |

| Aluminum Square Bar 6061-T6-Extruded | 95x95 | 3.74x3.74 |

| Aluminum Square Bar 6061-T6-Extruded | 100x100 | 3.94x3.94 |

| Aluminum Square Bar 6061-T6-Extruded | 105x105 | 4.13x4.13 |

| Aluminum Square Bar 6061-T6-Extruded | 110x110 | 4.33x4.33 |

| Aluminum Square Bar 6061-T6-Extruded | 115x115 | 4.53x4.53 |

| Aluminum Square Bar 6061-T6-Extruded | 120x120 | 4.72x4.72 |

| Aluminum Square Bar 6061-T6-Extruded | 125x125 | 4.92x4.92 |

| Aluminum Square Bar 6061-T6-Extruded | 130x130 | 5.12x5.12 |

| Aluminum Square Bar 6061-T6-Extruded | 135x135 | 5.31x5.31 |

| Aluminum Square Bar 6061-T6-Extruded | 140x140 | 5.51x5.51 |

| Aluminum Square Bar 6061-T6-Extruded | 145x145 | 5.71x5.71 |

| Aluminum Square Bar 6061-T6-Extruded | 150x150 | 5.91x5.91 |

| Aluminum Square Bar 6061-T6-Extruded | 160x160 | 6.3x6.3 |

| Aluminum Square Bar 6061-T6-Extruded | 170x170 | 6.69x6.69 |

| Aluminum Square Bar 6061-T6-Extruded | 180x180 | 7.09x7.09 |

| Aluminum Square Bar 6061-T6-Extruded | 190x190 | 7.48x7.48 |

| Aluminum Square Bar 6061-T6-Extruded | 200x200 | 7.87x7.87 |

6061 aluminum hexagonal bar rod

Stock across flat: 12-65mm; Length: 100-2500mm

6061 T6/T651 aluminum hexagonal standard screw stock is commonly used for items with hexagonal and turned sections, such as screws, fasteners, and connectors.

Click to check the detailed information and stock list of [6061 aluminum hexagonal bar]

| Product 1 | Width (inches) | Product 2 | Width (inches) |

| Aluminum Hex Bar 6061-T6-Extruded | 0.25" | Aluminum Hex Bar 6061-T6-Extruded | 0.375" |

| Aluminum Hex Bar 6061-T6511-Extruded | 0.4375" | Aluminum Hex Bar 6061-T6-Extruded | 0.472" |

| Aluminum Hex Bar 6061-T6511-Extruded | 0.5" | Aluminum Hex Bar 6061-T6-Extruded | 0.551" |

| Aluminum Hex Bar 6061-T6511-Extruded | 0.5625" | Aluminum Hex Bar 6061-T6-Extruded | 0.63" |

| Aluminum Hex Bar 6061-T6-Extruded | 0.669" | Aluminum Hex Bar 6061-T6-Extruded | 0.748" |

| Aluminum Hex Bar 6061-T6511-Extruded | 0.75" | Aluminum Hex Bar 6061-T6-Extruded | 0.787" |

| Aluminum Hex Bar 6061-T6-Extruded | 0.866" | Aluminum Hex Bar 6061-T6-Extruded | 0.945" |

| Aluminum Hex Bar 6061-T6-Extruded | 0.984" | Aluminum Hex Bar 6061-T6-Extruded | 1" |

| Aluminum Hex Bar 6061-T6-Extruded | 1.024" | Aluminum Hex Bar 6061-T6-Extruded | 1.063" |

| Aluminum Hex Bar 6061-T6-Extruded | 1.102" | Aluminum Hex Bar 6061-T6-Extruded | 1.125" |

| Aluminum Hex Bar 6061-T6-Extruded | 1.181" | Aluminum Hex Bar 6061-T6-Extruded | 1.25" |

| Aluminum Hex Bar 6061-T6-Extruded | 1.26" | Aluminum Hex Bar 6061-T6-Extruded | 1.339" |

| Aluminum Hex Bar 6061-T6-Extruded | 1.417" | Aluminum Hex Bar 6061-T6-Extruded | 1.496" |

| Aluminum Hex Bar 6061-T6-Extruded | 1.575" | Aluminum Hex Bar 6061-T6-Extruded | 1.625" |

| Aluminum Hex Bar 6061-T6-Extruded | 1.75" | Aluminum Hex Bar 6061-T6-Extruded | 1.8125" |

| Aluminum Hex Bar 6061-T6-Extruded | 2" | Aluminum Hex Bar 6061-T6-Extruded | 2.25" |

| Aluminum Hex Bar 6061-T6-Extruded | 2.5" | Aluminum Hex Bar 6061-T6-Extruded | 2" |

Why Chalco is the preferred supplier of 6061 aluminum bars

When choosing 2024 aluminum bars, main attention will be given to the tensile strength, elongation, surface quality, and dimensional accuracy. Chalco's advanced production capabilities and strict quality controls effectively address these concerns, making it the preferred supplier across various industries.

Instant QuoteStrong tensile strength

- Use high-quality raw materials.

- Implement precise alloying and heat treatment processes.

- Conduct regular tensile strength tests.

Flexible elongation

- Optimize alloy composition and heat treatment to balance strength and ductility.

- Ensure uniform cooling and annealing processes.

- Regularly test elongation properties.

Controlled grain coarsening

- Use controlled cooling rates to prevent coarse grain formation.

- Apply proper homogenization treatment to refine the grain structure.

- Monitor and control processing temperatures.

Pristine surface quality

- Use clean, well-maintained molds and dies.

- Implement rigorous cleaning processes to remove impurities.

- Apply protective coatings and use precision cutting tools.

Accurate dimensional accuracy

- Utilize high-precision extrusion and drawing equipment.

- Implement strict quality control measures at each production stage.

- Use advanced measurement tools for regular inspections.

Reliable internal quality

- Conduct non-destructive testing (NDT) such as ultrasonic or X-ray inspection.

- Ensure proper alloy mixing and degassing to prevent internal defects.

- Apply proper homogenization and heat treatment processes.

Straight precision

- Use advanced straightening machines and techniques.

- Regularly inspect and adjust straightening equipment.

- Ensure uniform cooling and annealing processes to reduce warping.

Selection tips of 6061 aluminum bar for differnet industries

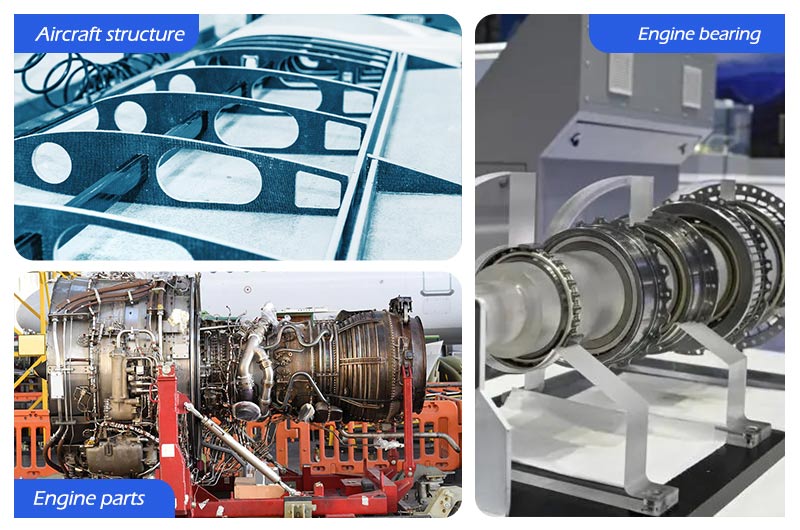

6061 aluminum bar rod for aerospace field

High strength aluminum, and cooperated with Airbus, Boeing, Collins Aerospace and other famous aviation enterprise.

Contact us now

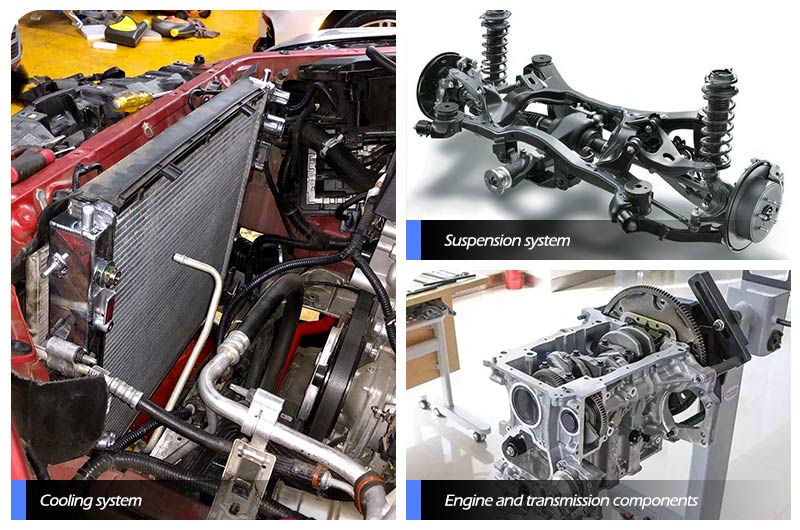

6061 aluminum bar rod for auto field

Serving Tesla, Ford, Shanghai Automobile, Weilai Automobile, BAIC New Energy, Changan Automobile and other famous new energy automobile manufacturers such as BAIC and Weilai.

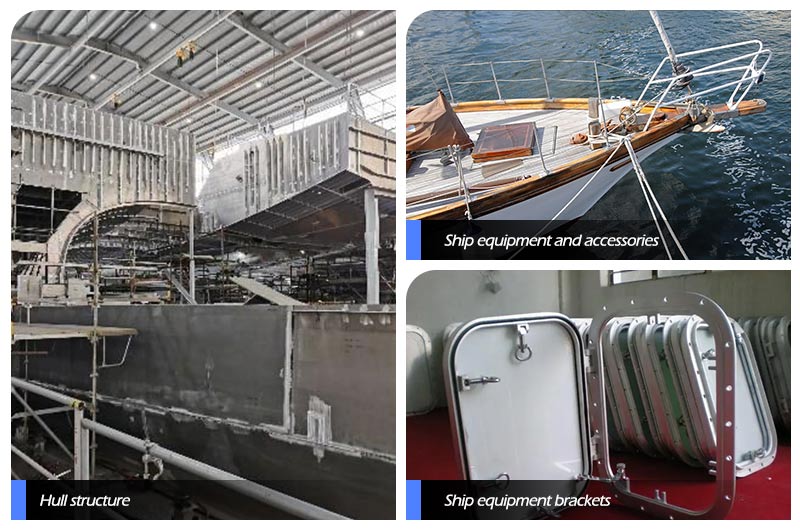

Contact us now6061 bar round for marine field

Chalco 6061 Aluminum bar has served many well-known shipyards, has DNV, NK, CCS, ABS, BV, LR, KR and other marine aluminum certifications

Contact us now

The products have been widely exported to Hitachi, ABB, Siemens, Legrand, Toshiba etc. companies, and enjoy good reputation from them.

Contact us nowMechanical properties of 6061 aluminum bar rod

| 6061-T6 | 6061-T651 | 6061-T6511 | 6061-O | 6061-T4 | |

| Ultimate tensile strength | 310 MPa or 42,000 KSI | 310 MPa or 45,000 KSI | 290 MPa or 45,000 KSI | 18,000 KSI | 35,000 KSI |

| Yield strength | 270 MPa or 39,000 KSI | 145 MPa or 21,000 KSI | 270 MPa or 40,000 KSI | 8,000 KSI | 21,000 KSI |

| Brinell | 95 | 65 | 95 | 30 | 65 |

| Elongation % | 25% | 25-30% | 22-25% |

6061 aluminum chemical composition

| Element | Composition (%) |

| Al | Balance |

| Cr | 0.04 - 0.35 |

| Cu | 0.15 - 0.4 |

| Fe | 0 - 0.7 |

| Mg | 0.8 - 1.2 |

| Mn | 0.15 max |

| Si | 0.4 - 0.8 |

| Ti | 0.15 max |

| Zn | 0.25 max |

| Other | 0.15 max |

| Remainder Each | 0.05 max |

Performance characteristics of 6061 aluminum bar

6061 aluminum rod is the representative product of 6000 series aluminum rod. The main components of 6000 series aluminum rods include magnesium and silicon. Therefore, it has the characteristics of both 4000 series and 5000 series.

- The strength of 6061 aluminum bar is close to that of steel, but its weight is much lighter. It is a strong and durable alloy. It is easy to drill, machine and saw.

- The main alloy components of 6061 aluminum are magnesium and silicon, so it has strong corrosion resistance, moisture resistance, stress resistance and crack resistance. This means that this material type is easy to form and weld.

- This alloy can be easily anodized and has good molding and finishing properties.

- The machinability is good under the hard T4 and T6 conditions. It is obviously not easy to machine in the annealing and tempering state.

- It is easy to cold work and shape under annealing conditions. Stamping, bending, spinning and drawing can be easily completed using standard methods.

- 6061 has good machinability and good weldability. All commonly used welding techniques can be used for welding. Generally, after welding, the properties near the weld are the same as 6061-O, and the strength loss is about 80%. The material can be reheated to restore the T4 or T6 temper of the whole workpiece. After welding, the material will naturally age and recover some strength.

Unveiling Chalco's commitment to produce high-quality 6061 aluminum bars

| Process | Advantages of Chalco casting process |

| Melting | Advanced equipment ensures rapid, uniform melting with pure, impurity-free alloy. |

| Casting | High-precision molds and automated casting ensure perfect initial shapes. |

| Sawing | Efficient, precise cutting for accurate dimensions. |

| Homogenization | Advanced heat treatment achieves uniform internal structure, reducing stress. |

| Cooling & Cleaning | Automated systems ensure clean, uncontaminated aluminum bars. |

| Storage | High-standard facilities maintain optimal conditions and excellent performance. |

| Process | Advantages of Chalco extruded process |

| Pre-extrusion Heating | Professional heating equipment ensures optimal extrusion temperature. |

| Extrusion | High-pressure extrusion with precision molds produces accurate profiles. |

| Stretching & Straightening | Advanced equipment enhances mechanical properties and uniformity. |

| Cutting to Length | High-precision cutting for consistent product lengths. |

| Framing & Trimming | Professional processes ensure smooth edges and strict specifications. |

| Process | Advantages of Chalco cold drawn process |

| Material Preparation | Selection of high-quality aluminum alloy material ensures excellent starting quality. |

| Heating | Precise heating to optimal temperatures for improved ductility and workability. |

| Cold Drawing | Advanced drawing equipment achieves precise dimensions, smooth surfaces, and improved strength. |

| Annealing | Controlled annealing reduces internal stress and enhances material properties. |

| Straightening | Precision straightening ensures uniformity and alignment of the aluminum bars. |

| Cutting | High-precision cutting equipment ensures consistent and accurate lengths. |

| Cleaning | Automated cleaning systems remove impurities and ensure clean surfaces. |

Chalco 6061 aluminum bar related products recommendation

6061 aerospace aluminum bar

6061 aerospace forging

6061 aerospace extrusion

6061 auto profile

6061 auto forging

6061 aluminum busbar

6061 marine round bar

6061 marine square bar

6061 marine hexagon bar

Knowledge center of 6061 aluminum bar

Comparison of 6061 and 6063

Similarities: both alloys contain silicon and magnesium and both are widely used in building profiles, structural components, and mechanical parts.

Differences:

- Strength: 6061 has higher tensile strength, making it suitable for applications requiring higher strength; 6063 has lower strength and is preferred for applications needing excellent extrusion properties and surface finish.

- Extrudability: 6063 performs better in extrusion processing, making it suitable for complex profiles and thin-walled sections; 6061 has lower extrudability.

Comparison of 6061 and 5052

Similarities: both alloys have good corrosion resistance, making them suitable for various environments. Both alloys can be welded and machined.

Differences:

- Strength: 6061 has higher strength compared to 5052, suitable for high-strength structural components; 5052 has lower strength but better formability and corrosion resistance.

- Formability: 5052 offers better formability, making it suitable for complex shapes; 6061 is better suited for high-strength structural components.

Comparison of 6061 and 7075

Similarities: both alloys belong to the aluminum alloy series and are widely used in aerospace and military applications. Both have good corrosion resistance, suitable for harsh environments.

Differences:

- Strength: 7075 has significantly higher strength compared to 6061, making it suitable for high-strength applications such as aerospace structural parts; 6061 is used for components requiring medium strength.

- Workability: 6061 is easier to heat-treat and machine, suitable for complex structures; 7075, while stronger and harder, has poorer workability.

Purchase instructions of Chalco 6061 aluminum bar

Please ensure the size and quantity before purchasing Chalco 6061 aluminum bars. Then contact our customer service personnel, we will provide you with the best quality products and the most competitive quotations in the market.

Production process of 6061 aluminum bar

It begins with solution heat treatment at 990°F and water quenching, followed by precipitation hardening at 320°F for 18 hours and subsequent air cooling at 350°F for 8 hours. Hot forging is performed within the temperature range of 900°F to 750°F, and hot working can be carried out between 700°F and 500°F. Cold working is most suitable in the O temper condition. Annealing is done at 775°F for 2 to 3 hours, with controlled cooling to 500°F and air cooling. The aging process, leading to the T6 temper, entails heat treatment at 350°F for 8 hours. Tempering is not applicable to this process.Dimensions and weights of 6061 aluminum bar

Calculation of the weight of the aluminum round rod: πR2*h×0.0000027 (3.1415*the square of the radius of the aluminum rod*the length of the aluminum rod*density, the unit of the radius length is mm).

Calculation of the weight of the aluminum square rod: side A*side B*0.0027*h (side length*side length*density*aluminum rod length), the unit is mm.

If the length is short, the cutting loss shall be increased.

The length and width of the cut shall have a tolerance of 1-3mm.

Price of 6061 aluminum bar

6061 aluminum rod price: (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact Chalco aluminum to inquire about the price, and how much is the processing fee per ton for the relevant type of aluminum square rod. The processing fee for 6061 aluminum rods of different sizes is quite different, and we will provide you with the best quotation.

6061-T6, 6061-T651, 6061-T6511 are the most ordered tempers by customers.

How to find a reliable supplier or factory for 6061 aluminum rod

- Chalco is one of the leading suppliers of 6061 T4/T6/T651/T6511 aluminum bar. It has a large number of inventories and provides professional aluminum bar alloy 6061 T4/T6/T651/T651 processing services. The inventory, processing and supply range of aluminum round bar alloy 6061T6/T651/T6511 is 3/4 inch (19.05 mm) to 8 inch(203.2 mm).

- Chalco 6061 T6/T651/T6511 aluminum bar includes aerospace QQ-A-Grades and AMS-Grades, which can be ordered according to your specific requirements by selecting inch or metric diameters.

- Chalco processing plant has the ability to process 6061 aluminum bar alloy 6061 T4/T6/T651/T6511 etc. and can process and produce aluminum bars of various shapes, which can be cut into certain sizes and delivered in a short delivery time to meet your delivery requirements.

Chalco's 6061 extrusion modle table

| A(mm) | B(mm) | Line Density (Kg/m) | Extrusion Tonnage | Alloy | Radius Angle |

| 6.35 | 6.35 | 0.109 | 500T | 6061-T6511 | |

| 6.35 | 6.35 | 0.109 | 500T | 6061-T6511 | Yes |

| 6.35 | 6.35 | 2.592 | 2000T | Universal | |

| 7.95 | 7.95 | 0.17 | 500T | 6061-T6 | R0.38 |

| 7.95 | 7.95 | 0.171 | 500T | 6061-T6511 | |

| 7.95 | 7.95 | 3.266 | 1250T | Universal | |

| 8 | 8 | 0.171 | 500T | Universal | |

| 9.525 | 9.525 | 4.32 | 2000T | Universal | |

| 10 | 10 | 0.89 | 880T | Universal | |

| 12 | 12 | 15.39 | 9000T | Universal | |

| 12.7 | 12.7 | 0.435 | 6061-T6511 | ||

| 12.7 | 12.7 | 0.272 | 550T | Universal | |

| 15 | 15 | 10.452 | 3600T | Universal | |

| 15.875 | 15.875 | 8.1 | 3600T | Universal | |

| 15.88 | 15.88 | 0.68 | 880T | 6061-T6511 | |

| 17.46 | 17.46 | 0.823 | 6061-T6511 | ||

| 17.46 | 17.46 | 8.492 | 3600T | Universal | |

| 18 | 18 | 0.823 | 880T | Universal | |

| 19.05 | 19.05 | 0.978 | 6061-T6511 | ||

| 19.05 | 19.05 | 7.29 | 3150T | Universal | |

| 20 | 20 | 15.677 | 3600T | Universal | |

| 20.64 | 20.64 | 10.8 | 3600T | Universal | |

| 22.2 | 22.2 | 1.334 | 1250T | 6061-T6511 | |

| 22.225 | 22.225 | 1.15 | 1250T | Universal | |

| 25 | 25 | 3.047 | 2000T | Universal | |

| 25.4 | 25.4 | 10.463 | 3600T | Universal | |

| 27 | 27 | 20.903 | 3600T | Universal | |

| 30 | 30 | 22.769 | 7500T | Universal | |

| 31.75 | 31.75 | 2.722 | 2000T | 6061-T6 | |

| 31.75 | 31.75 | 44.946 | 7500T | Universal | |

| 35 | 35 | 1.652 | 1250T | Universal | |

| 38.1 | 38.1 | 3.919 | 3150T | 6061-T6 | |

| 38.1 | 38.1 | 37.8 | 7500T | Universal | |

| 40 | 40 | 2.916 | 2000T | Universal | |

| 44.45 | 44.45 | 5.335 | 2000T | 6061-T6511 | |

| 44.45 | 44.45 | 9.299 | 3600T | Universal | |

| 45 | 45 | 24.387 | 7500T | Universal | |

| 50 | 50 | 6.75 | 3600T | 6061-T6 | |

| 50 | 50 | 5.468 | 2000T | Universal | |

| 50 | 50 | 6.75 | 2000T | Universal | |

| 50.8 | 50.8 | 6.968 | 3150T | 6061-T6511 | |

| 50.8 | 50.8 | 3.318 | 2000T | Universal | |

| 55 | 55 | 34.839 | 7500T | Universal | |

| 57.15 | 57.15 | 8.819 | 3600T | 6061-T6511 | |

| 57.15 | 57.15 | 8.168 | 3600T | Universal | |

| 60 | 60 | 15.677 | 3600T | Universal | |

| 63.5 | 63.5 | 10.887 | 3600T | 6061-T6 | |

| 63.5 | 63.5 | 12.96 | 3600T | Universal | |

| 65 | 65 | 26.129 | 7500T | Universal | |

| 69.85 | 69.85 | 13.173 | 3600T | 6061-T6511 | |

| 69.85 | 69.85 | 11.408 | 3600T | Universal | |

| 70 | 70 | 13.173 | 3600T | Universal | |

| 76.2 | 76.2 | 15.677 | 3600T | 6061-T6511 | |

| 76.2 | 76.2 | 20.25 | 3600T | Universal | |

| 80 | 80 | 41.806 | 7500T | Universal | |

| 85 | 85 | 22.14 | 7500T | Universal | |

| 88 | 88 | 20.909 | 7500T | 6061-T651 | |

| 88.9 | 88.9 | 19.508 | 3600T | Universal | |

| 90 | 90 | 24.387 | 7500T | Universal | |

| 95.25 | 95.25 | 24.496 | 7500T | 6061-T6511 | |

| 95.25 | 95.25 | 21.87 | 3600T | Universal | |

| 100 | 100 | 24.496 | 7500T | Universal | |

| 101.6 | 101.6 | 27.871 | 7500T | 6061-T6511 | |

| 101.6 | 101.6 | 27 | 7500T | Universal | |

| 110 | 110 | 29.4 | 7500T | Universal | |

| 114.3 | 114.3 | 35.272 | 12500T | 6061-T6511 | 1 |

| 120 | 120 | 32.67 | 7500T | Universal | |

| 127 | 127 | 43.548 | 7500T | 6061-T6511 | |

| 130 | 130 | 38.88 | 7500T | Universal |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote