Aluminum joining covers two major technical systems—fusion welding and brazing—each selected according to structural strength, operating temperature, and application requirements. Chalco provides a complete portfolio of aluminum welding fillers and brazing materials engineered for strong joints, stable metallurgical performance, and high reliability in heat exchangers, automotive structures, battery cooling plates, HVAC systems, and general aluminum assemblies.

-

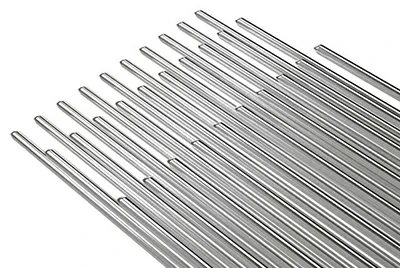

Includes: Welding wire, TIG filler rods, MIG wire, electrodes

Alloys: ER4043, ER5356, ER4943, ER4643, ER4047, ER5183

Processes: TIG / MIG / GMAW / GTAW / SMAW

Applications: automotive, structural parts, fabrication

-

Includes: Brazing sheet/coil, clad materials, brazing rods

Consumables: flux-core rod, coated rod, flux, ring preforms

Alloys: 4045, 4047, 4343, 4004, 4A13, 4A17, 4A43

Applications: heat exchangers, condensers, battery cooling, HVAC

Backed by long-term supply experience across automotive, HVAC, electronics cooling, energy systems, and general industrial manufacturing, Chalco's welding and brazing materials are trusted by leading OEMs and component producers worldwide. Explore how our materials are applied in real projects in the Applications & Solutions section.

Aluminum Welding Materials

Chalco Aluminum offers a complete welding filler system supporting MIG, TIG, and Stick (SMAW) aluminum welding across fabrication, repair, and structural applications.

Aluminum welding alloy options

Contact us now

Aluminum Welding Material Products(MIG / TIG / Stick)

Chalco provides a complete portfolio of aluminum welding consumables for MIG, TIG, furnace brazing, and repair welding. Our product range includes welding wire, filler rods, stick welding rods, flux-core rods, aluminum brazing rods, and low-temperature repair rods.

Aluminum welding wire

MIG aluminum solid welding wire

Aluminum TIG filler rod

Aluminum TIG welding rod

Aluminum stick welding rod

Flux-coated aluminum rod / electrode

Aluminum Welding Alloy Options (ER4043 / ER5356 / ER4943 / ER4643 / ER4047 / ER5183)

Chalco Aluminum offers a full portfolio of ER-series aluminum welding alloys engineered to deliver stable arc performance, strong mechanical properties, and reliable compatibility with common aluminum base materials. Through precise alloying control and strict metallurgical consistency, our welding fillers provide the strength, crack resistance, and fluidity needed for high-quality MIG, TIG, and Stick welding across structural, automotive, marine, and industrial applications.

-

ER4043 Aluminum Welding Alloy

Type: Al-Si welding alloy

Features: Excellent fluidity, low crack sensitivity

Application: 6xxx series general welding

-

ER5356 Aluminum Welding Alloy

Type: Al-Mg high-strength alloy

Features: High tensile strength, corrosion resistance

Application: Marine & structural welding

-

ER4943 Aluminum Welding Alloy

Type: Enhanced Al-Si alloy

Features: 20–30% higher weld strength

Application: Automotive & structural components

-

ER4643 Aluminum Welding Alloy

Type: Modified Al-Si-Mg alloy

Features: Improved crack resistance

Application: High-strength 6xxx alloys

-

ER4047 Aluminum Welding Alloy

Type: High-silicon alloy

Features: Leak resistance, reduced shrinkage

Application: Repair welding & precision joints

-

ER5183 Aluminum Welding Alloy

Type: Al-Mg high-strength alloy

Features: High toughness & durability

Application: Marine, offshore, cryogenic

Chalco aluminum brazing product system

Chalco provides a complete aluminum brazing product system supporting heat-exchanger production, aluminum joining, and thermal-management assemblies. Explore our full brazing material categories below. Whether you are producing automotive radiators, condensers, battery cold plates, HVAC coils, pressure-resistant heat exchangers, or custom thermal assemblies, Chalco’s engineered alloy combinations and stable manufacturing capacity ensure strong joints, consistent brazing quality, and efficient mass production.

Chalco brazing base material

High-quality base alloys are the foundation of durable, corrosion-resistant brazed assemblies. Chalco supplies a wide selection of aluminum strip, sheet, and tube materials tailored for heat exchanger cores, structural support components, and composite brazing applications. Our alloy options are engineered for excellent formability, strength, and thermal conductivity—ensuring high reliability across automotive, HVAC, and energy sectors.

-

3A11 aluminum strip and sheet

Good corrosion resistance and excellent formability, ideal for heat exchanger cores.

-

3003 aluminum strip and sheet

Versatile and durable, widely used in HVAC and automotive brazing applications.

-

6061 aluminum sheet coil

High strength and excellent corrosion resistance, ideal for versatile applications.

-

6A02 aluminum sheet and tube

Enhanced strength and corrosion resistance for structural brazed components.

-

6060 aluminum tube

Good mechanical properties and extrudability, suited for various brazing needs.

-

6082 aluminum sheet and tube

High strength and corrosion resistance, favored for demanding assemblies.

-

6951 aluminum tube and sheet

Heat-treatable alloy popular in automotive and heat exchanger manufacturing.

-

7A11 aluminum sheet and tube

Superior strength for high-performance brazed applications.

-

7072 aluminum cladding sheet and coil

Commonly used for brazing clad materials to improve corrosion resistance.

Chalco brazing layer filler metal

Chalco offers a full portfolio of aluminum-silicon based filler alloys designed for a wide range of brazing processes, including vacuum brazing, controlled atmosphere brazing (CAB/Nocolok), and localized torch or induction brazing. These alloys feature excellent flowability, precise melting ranges, and strong metallurgical compatibility with core materials, ensuring consistent joint strength and corrosion resistance.

-

4043 brazing aluminum sheet foil coil strip

Good fluidity and less susceptibility to welding hot cracks; often used in welding wires for aluminum silicon alloys.

-

4343 brazing aluminum sheet coil block bar

Outstanding brazing, corrosion resistance, excellent thermal conductivity, suitable for high temperatures.

-

4045 brazing aluminum sheet foil coil strip

Excellent welding performance and is often used as cladding layer for composite plates and composite fins.

-

4047 brazing aluminum sheet foil coil strip

Used as welding filler wire and fusion welding material; widely used in automobiles, air conditioning...

-

4004 brazing aluminum sheet foil coil strip

Used as the coating layer, often rolled together with 3003 aluminum to form composite materials.

-

4A13 brazing aluminum sheet foil coil strip

Commonly used as a hard solder for sheet and strip materials, and for the brazing layer of radiator.

-

4A17 brazing aluminum sheet foil coil strip

Good brazing performance and a lower melting point. Used for welding radiators and brazing layers.

-

4A43 brazing aluminum sheet foil coil strip

Excellent fluidity and brazing performance, commonly used as filler metal for high-strength aluminum alloy brazing.

-

4A45 brazing aluminum sheet foil coil strip

Low melting point and good wetting properties, ideal for brazing heat exchanger components and automotive parts.

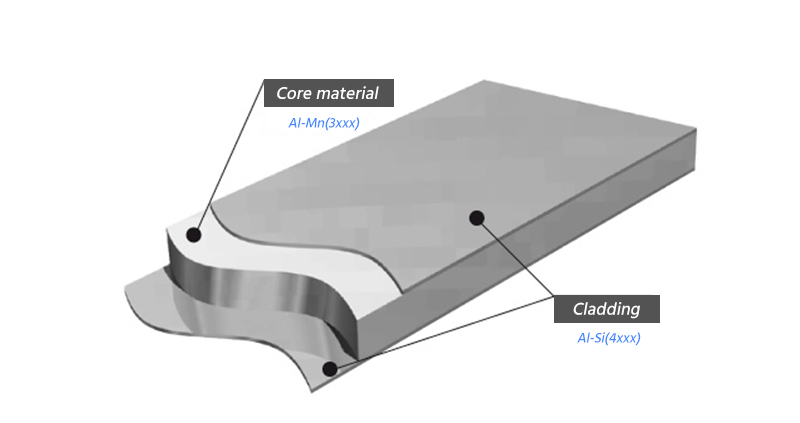

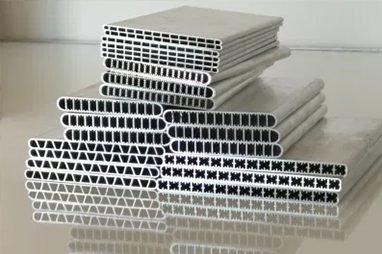

Clad brazing materials

Chalco's clad aluminum brazing materials integrate a corrosion-resistant filler layer with a high-strength core alloy, forming a reliable multi-layer composite that simplifies brazing and ensures stable, high-quality joints. These materials are widely used in heat exchangers, condensers, battery cold plates, and electronic cooling modules, supporting both large-scale production and customized engineering needs.

- Core materials are generally composed of aluminum manganese 3 series aluminum alloy, which plays the role of intensity support and heat dissipation.

- The cladding layer is composed of aluminum-silicon 4000 series alloy 4343, 4045, 4047 or other aluminum alloy, which plays a role in welding or improving the performance of the overall material.

- Thickness: 0.05mm-6mm Width: 5mm -2200mm

- 4045/3003/4045 | 4045/3003/7072 | 4045/3A11/4045 | 4045/7A11/7072 | 4045/6951/4045 | 4045/6951/7072

Clad aluminum brazing sheet

For automotive radiators, air conditioners, other heat exchangers...

Clad aluminum brazing coil strip

Suitable for automotive air conditioners, refrigerator condensers...

Clad aluminum brazing foil

Used in battery, electronic device cooling, and aerospace applications...

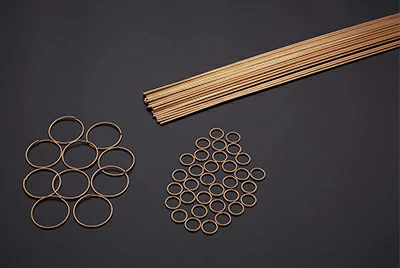

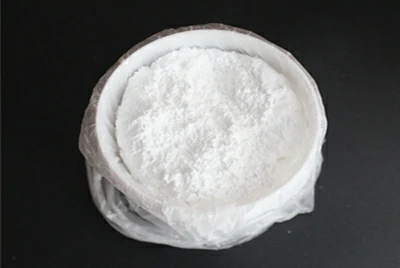

Aluminum Brazing Rods, Fluxes & Ring Preforms

Standard Aluminum Brazing Rod

Low-Temperature Aluminum Brazing Rod

Flux-Coated Aluminum Brazing Rod

Flux-Cored Aluminum Brazing Rod

Aluminum Brazing Rings & Preforms

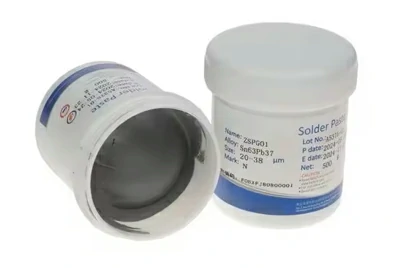

Aluminum Brazing Flux

Other Alloy Brazing Materials

In addition to aluminum-based fillers, Chalco supplies a range of non-aluminum brazing materials—including silver brazing rods, copper brazing rods, and high-activity brazing fluxes—designed for multi-metal joining in HVAC, electronics, refrigeration, and industrial assemblies.

Technical Support & Production Capability

Chalco provides full-process technical support and integrated manufacturing capability for aluminum welding and brazing materials. From alloy design to finished wire, rod, clad sheet, tube, or structural assembly, every production step is controlled in-house—ensuring stable metallurgy, consistent properties, and reliable performance across all joining processes.

Our engineering team offers professional guidance on alloy selection, wire/rod diameter customization, clad ratio design, brazing process compatibility, and joint performance optimization. Whether you are using MIG, TIG, Stick (SMAW), torch brazing, induction brazing, CAB/Nocolok, or vacuum brazing, Chalco provides tailored solutions to match your application.

With large-scale extrusion, rolling, cladding, drawing, and annealing lines, Chalco supports high-volume production of billets, sheets, tubes, foils, brazing strips, wires, and rods. Beyond materials, we also supply micro-channel tubes, HF-welded tubes, cold-plate blanks, and brazed structural components for automotive radiators, condensers, battery cooling plates, HVAC coils, and industrial heat exchangers.

For detailed specifications, melting ranges, and alloy compatibility charts, please refer to our [Technical Data and Alloy Matching Charts].

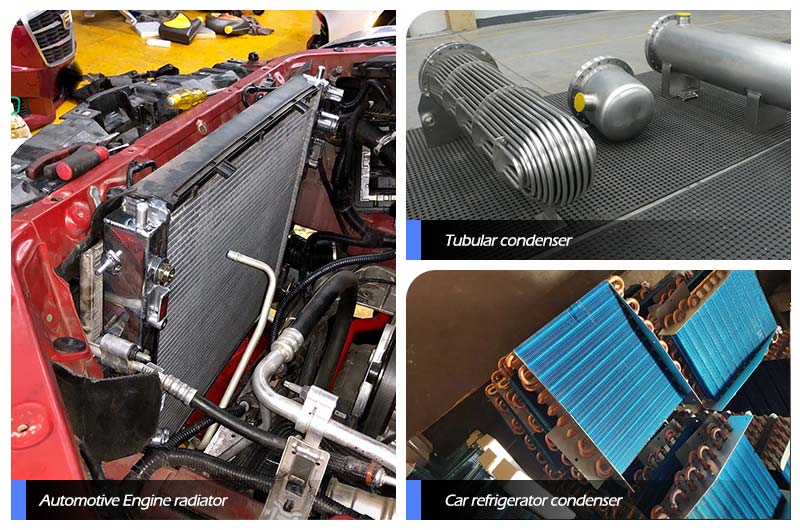

Solutions & Applications for aluminum brazing materials

Chalco's aluminum brazing materials and components are widely used in thermal management and lightweight systems across automotive, electronics, power, and industrial sectors, offering reliable performance under demanding conditions.

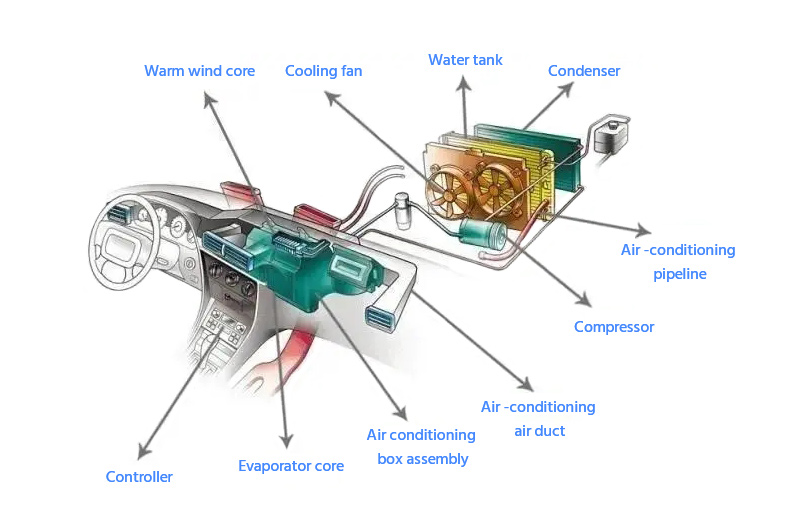

The brazing aluminum sheet foil coil strip are widely used in automotive heat exchange systems, such as engine radiators, engine oil radiator, medium refrigerator, air -conditioning condenser and evaporator etc.

Aluminum brazing material for automotive thermal managment

Automotive applications rely heavily on aluminum brazing materials for efficient heat exchange and thermal management, covering both traditional and electric vehicle systems.

Typical Components: Radiators, intercoolers, oil coolers, HVAC modules, EV battery cold plates.

Contact us now

Chalco's supplied products for this sector

Micro-channel tubes

HF welded tubes

Battery cold plate blanks

Auxiliary brazing materials

Aluminum brazing material for power electronics cooling

Reliable heat dissipation for high-performance electronics such as IGBTs and inverters requires highly consistent and thermally efficient brazed components.

Typical Components: Liquid cold plates, inverter housings, electronic heat sinks, rectifier modules.

Contact us now

Chalco's supplied products for this sector

Aluminum brazing material for industrial HVAC & chillers

Industrial cooling systems demand corrosion-resistant, durable materials for long-term performance in HVAC and refrigeration environments.

Typical Components: Plate heat exchangers, condenser tubes, chillers, HVAC evaporator cores.

Contact us now

Chalco's supplied products for this sector

Aluminum brazing material for renewable energy systems

Effective thermal control is essential in solar inverters, wind power electronics, and energy storage, where compact heat exchange is critical.

Typical Components: Heat sinks, inverter cold plates, power module housings, battery enclosures.

Contact us now

Chalco's supplied products for this sector

Aluminum brazing material for aerospace & rail transit

Aluminum brazing components support lightweight, high-efficiency thermal systems in aerospace and railway applications under strict safety standards.

Typical Components: Compact heat exchangers, electronic cooling modules, structural housings.

Contact us now

Chalco's supplied products for this sector

High-strength clad aluminum sheets

Vacuum-brazed assemblies

Aluminum welding & brazing materials for general fabrication & repair

Aluminum welding and brazing materials are widely used in workshop fabrication, equipment repair, maintenance welding, and structural assembly for general industrial applications.

Contact us now

Chalco's supplied products for this sector

Technical Data for Aluminum Welding & Brazing Materials

To support material selection, alloy matching, and process optimization, Chalco provides complete technical data for both aluminum welding fillers and brazing alloys. The tables below summarize chemical composition, melting ranges, and recommended applications to help engineers identify the most suitable filler metal for their joining process.

Aluminum Welding Alloy Technical Data

Mechanical properties and melting characteristics vary across ER-series welding alloys. The following table summarizes common grades used for MIG/TIG welding of aluminum plates, extrusions, and castings.

| Alloy | Chemical Composition | Melting Range | Typical Use |

| ER4043 | Al–5%Si | 573–625 °C | General-purpose welding; reduced cracking; good flow |

| ER5356 | Al–5%Mg | 555–635 °C | High strength; marine grade; 5xxx to 6xxx welding |

| ER5183 | Al–4.5%Mg–Mn | 535–630 °C | High-strength structural welding; cryogenic service |

| ER4943 | Al–4.5%Si–Mg | 560–620 °C | Higher strength upgrade to 4043 |

| ER4643 | Al–5%Si–Mg modified | 560–620 °C | Good fluidity with improved strength for castings |

| ER4047 | Al–12%Si | 573–582 °C | Low-melting; excellent fluidity; ideal for filling gaps |

Aluminum Brazing Alloy Technical Data

Aluminum–silicon brazing alloys are selected based on melting temperature, flow behavior, and compatibility with 3xxx and 6xxx core materials. The following data covers the main brazing filler layers used in clad sheets, wire, rings, and flux-assisted brazing.

| Alloy | Chemical Composition | Melting Range | Typical Use |

| 4043 | Al–5%Si | 573–625 °C | General brazing filler; controlled atmosphere brazing (CAB) |

| 4045 | Al–10%Si | 575–605 °C | Cladding alloy for heat-exchanger fins and sheets |

| 4047 | Al–12%Si | 573–582 °C | Low-melting brazing sheet, wires, and rings |

| 4343 | Al–7.5%Si | 577–585 °C | Most widely used clad alloy for radiators & condensers |

| 4004 | Al–9%Si–Cu | 577–613 °C | Composite sheets and fin materials for automotive HVAC |

| 4A13 | Al–11%Si–Cu | 570–600 °C | Brazing strip & foil for high-strength joints |

| 4A17 | Al–12%Si–Cu | 555–580 °C | Lower melting brazing foil for controlled flow |

Need detailed datasheets or alloy-matching recommendations? Contact our engineering team for customized welding or brazing data.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote