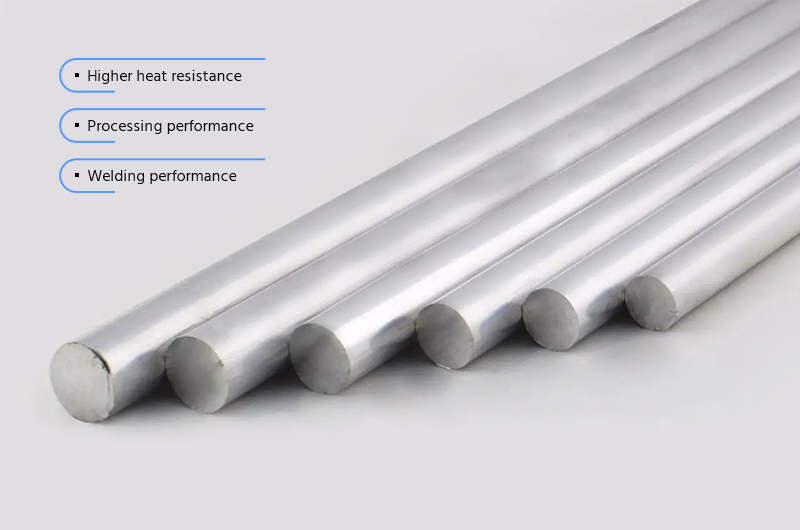

At the forefront of high-performance aluminum alloys, our 2011 and patented 2011B aluminum bars offer unparalleled machinability and precision for a wide range of industrial applications. While 2011 aluminum is renowned for its exceptional free-machining properties, our exclusive 2011B alloy takes innovation a step further by combining superior machinability with eco-friendly, RoHS-compliant characteristics. Designed to meet the demanding needs of CNC machining, connectors, and precision components, these alloys provide both efficiency and environmental responsibility — making them the ideal choice for manufacturers targeting global markets.

Product overview of Chalco 2011 & 2011B aluminum bar

Purcahse equivalent name: AlCu6BiPb, FC1, A92011, CB60, 3.1655, AlCuBiPb

Tempers: T3, T6; For detailed technical specifications, please refer to the [Technical Specifications section]

Standard diameter range: 3mm to 300mm (customizable); Click to [Size table]

Length: Standard 6 meters, custom cut-to-length available; Click to [Size table]

Specification: AMS-QQ-A-225/3 ASTM B211 UNS A92011 and RoHS environmental directive requirements to ensure product quality is stable and environmentally compliant.

Surface treatments: Bright finish, sandblasting, anodizing, deburring of cut edges, and more

Additional services: Custom cut-to-length, OEM marking, custom packaging, and special processing services

In-depth introduction and comparison of 2011 & 2011B aluminum

2011 aluminum bar

High-strength, free-cutting aluminum alloy widely used in precision machining, offering excellent mechanical properties and cutting performance. Ideal for electronic connectors, automotive parts, aviation accessories, and applications requiring high efficiency and accuracy.

2011B aluminum bar

2011B aluminum rod is our patented upgraded alloy, maintaining 2011's excellent machinability while meeting RoHS environmental standards. It offers improved processing stability and guaranteed quality, making it ideal for international markets, especially the EU.

- Excellent machinability

- Higher lead (Pb) content (0.2–0.6%)

- Not compliant with environmental standards

- Used for CNC machining, connectors, fasteners

- Very good machinability with eco benefits

- Significantly reduced lead, RoHS compliant

- ully compliant with RoHS, ELV, WEEE

- Same applications plus eco-sensitive industries

The 2011 and 2011B aluminum bars are known for their excellent machinability and are widely used in high-precision machining. To meet the needs of complex part processing, we offer a variety of easy-to-machine aluminum bars. For more detailed information and to find the perfect solution for your projects, please click [Easy-Cutting Aluminum Bars Introduction] or contact our sales team today.

Instant QuoteHot selling products of Chalco 2011 & 2011B aluminum rod bar products

- 2011 CF aluminum bar rod

Cold finished condition with high dimensional accuracy and smooth surface, suitable for high-precision machining.

- 2011B aluminum bar rod

Combines the advantages of all 2011 tempers, meets RoHS environmental standards, offers improved machinability and greater processing stability, perfect for export and high-end customers.

- 2011 2011B extruded aluminum bar rod

Available in various cross-sectional shapes, suitable for manufacturing complex structural parts, with excellent surface quality and customizable specifications.

- 2011 2011B T3 aluminum bar rod

Solution heat treated and naturally aged, offering moderate hardness, ideal for general machining and light-load parts.

- 2011 2011B T6 aluminum bar rod

Solution heat treated and artificially aged, with higher hardness and strength, suitable for structural parts requiring high strength.

- 2011 2011B T8 aluminum bar rod

Solution heat treated, artificially aged, and cold worked for enhanced mechanical properties, ideal for parts with very high processing requirements.

Explore our hot-selling Chalco 2011 & 2011B aluminum rods and bars — contact us now for quotes and customized solutions!

Instant QuoteStock peoducts and size table of 2011 2011B aluminum bar rod

- Relying on Chalco production line and its subsidiaries, source procurement, lowest price guarantee.

- Chalco has the largest inventory and can allocate its subsidiary's inventory products at any time, seven-day delivery guarantee;

- The quality of large and small batches is the same, and be provided at the lowest price.

- 2011 aluminum round bar

- 2011 aluminum square bar

- 2011 aluminum flat bar

- 2011 aluminum hex bar

| 2011 CF aluminum bar rod (round square hex) | ||

| Product Description | Diameter/Size (inch) | Diameter/Size (mm) |

| ASTM B211 CF 2011 aluminum round bar | 1 | 25.4 |

| ASTM B211 CF 2011 aluminum round bar | 1 1/2 | 38.1 |

| ASTM B211 CF 2011 aluminum round bar | 1 1/4 | 31.75 |

| ASTM B211 CF 2011 aluminum round bar | 1 1/8 | 28.575 |

| ASTM B211 CF 2011 aluminum round bar | 1 3/4 | 44.45 |

| ASTM B211 CF 2011 aluminum round bar | 1 3/8 | 34.925 |

| ASTM B211 CF 2011 aluminum round bar | 1 5/8 | 41.275 |

| ASTM B211 CF 2011 aluminum round bar | 1 7/8 | 47.625 |

| ASTM B211 CF 2011 aluminum round bar | 1/2 | 12.7 |

| ASTM B211 CF 2011 aluminum round bar | 1/4 | 6.35 |

| ASTM B211 CF 2011 aluminum round bar | 1/8 | 3.175 |

| ASTM B211 CF 2011 aluminum round bar | 2 | 50.8 |

| ASTM B211 CF 2011 aluminum round bar | 2 1/2 | 63.5 |

| ASTM B211 CF 2011 aluminum round bar | 2 1/4 | 57.15 |

| ASTM B211 CF 2011 aluminum round bar | 2 3/4 | 69.85 |

| ASTM B211 CF 2011 aluminum round bar | 3 | 76.2 |

| ASTM B211 CF 2011 aluminum round bar | 3/4 | 19.05 |

| ASTM B211 CF 2011 aluminum round bar | 3/8 | 9.525 |

| ASTM B211 CF 2011 aluminum round bar | 5/8 | 15.875 |

| ASTM B211 CF 2011 aluminum round bar | 7/8 | 22.225 |

| ASTM B211 CF 2011 aluminum square bar | 1/4 | 6.35 |

| ASTM B211 CF 2011 aluminum square bar | 3/8 | 9.525 |

| ASTM B211 CF 2011 aluminum square bar | 1/2 | 12.7 |

| ASTM B211 CF 2011 aluminum square bar | 5/8 | 15.875 |

| ASTM B211 CF 2011 aluminum square bar | 3/4 | 19.05 |

| ASTM B211 CF 2011 aluminum square bar | 1 | 25.4 |

| ASTM B211 CF 2011 aluminum square bar | 1 1/4 | 31.75 |

| ASTM B211 CF 2011 aluminum square bar | 1 1/2 | 38.1 |

| ASTM B211 CF 2011 aluminum hex bar | 1/4 | 6.35 |

| ASTM B211 CF 2011 aluminum hex bar | 5/16 | 7.9375 |

| ASTM B211 CF 2011 aluminum hex bar | 3/8 | 9.525 |

| ASTM B211 CF 2011 aluminum hex bar | 1/2 | 12.7 |

| ASTM B211 CF 2011 aluminum hex bar | 9/16 | 14.2875 |

| ASTM B211 CF 2011 aluminum hex bar | 5/8 | 15.875 |

| ASTM B211 CF 2011 aluminum hex bar | 3/4 | 19.05 |

| ASTM B211 CF 2011 aluminum hex bar | 7/8 | 22.225 |

| ASTM B211 CF 2011 aluminum hex bar | 1 | 25.4 |

| ASTM B211 CF 2011 aluminum hex bar | 1 1/8 | 28.575 |

| ASTM B211 CF 2011 aluminum hex bar | 1 1/4 | 31.75 |

| Easy-to-Machine 2011 Aluminum Bars | |||||

| Thick. | Thick. Tolerance | Wd. | Heat | Temperature | Straightness |

| Treatment | Range, °F | Tolerance | |||

| 1/4" | -0.002" to 0.002" | 1/4" | Hardened | -320° to 300° | 0.025" per ft. |

| 3/8" | -0.002" to 0.002" | 3/8" | Hardened | -320° to 300° | 0.025" per ft. |

| 1/2" | -0.002" to 0.002" | 1/2" | Hardened | -320° to 300° | 0.025" per ft. |

| 5/8" | -0.003" to 0.003" | 5/8" | Hardened | -320° to 300° | 0.025" per ft. |

| 3/4" | -0.003" to 0.003" | 3/4" | Hardened | -320° to 300° | 0.025" per ft. |

| 1" | -0.003" to 0.003" | 1" | Hardened | -320° to 300° | 0.025" per ft. |

| 1 1/4" | -0.003" to 0.003" | 1 1/4" | Hardened | -320° to 300° | 0.025" per ft. |

| 1 1/2" | -0.003" to 0.003" | 1 1/2" | Hardened | -320° to 300° | 0.025" per ft. |

| Easy-to-Machine 2011 Aluminum Rods | |||

| Dia. | Dia. Tolerance | Heat | Max. |

| Treatment | Temperature, °F | ||

| 1/4" | -0.002" to 0.002" | Hardened | 212° |

| 3/8" | -0.002" to 0.002" | Hardened | 212° |

| 1/2" | -0.002" to 0.002" | Hardened | 212° |

| 5/8" | -0.002" to 0.002" | Hardened | 212° |

| 3/4" | -0.002" to 0.002" | Hardened | 212° |

| 7/8" | -0.002" to 0.002" | Hardened | 212° |

| 1" | -0.002" to 0.002" | Hardened | 212° |

| 1 1/8" | -0.003" to 0.003" | Hardened | 212° |

| 1 1/4" | -0.003" to 0.003" | Hardened | 212° |

| 1 3/8" | -0.003" to 0.003" | Hardened | 212° |

| 1 1/2" | -0.003" to 0.003" | Hardened | 212° |

| 1 5/8" | -0.004" to 0.004" | Hardened | 212° |

| 1 3/4" | -0.004" to 0.004" | Hardened | 212° |

| 1 7/8" | -0.004" to 0.004" | Hardened | 212° |

| 2" | -0.004" to 0.004" | Hardened | 212° |

| 2 1/4" | -0.006" to 0.006" | Hardened | 212° |

| 2 1/2" | -0.006" to 0.006" | Hardened | 212° |

| 2 3/4" | -0.006" to 0.006" | Hardened | 212° |

| 3" | -0.006" to 0.006" | Hardened | 212° |

| Tight-Tolerance Easy-to-Machine 2011 Aluminum Rods | ||||

| Dia. | Dia. Tolerance | Heat | Max. | Straightness |

| Treatment | Temperature, °F | Tolerance | ||

| 1/8" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| 1/4" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| 3/8" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| 1/2" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| 5/8" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| 3/4" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| 1" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| 1 1/2" | -0.0005" to 0" | Hardened | 212° | 0.005" per ft. |

| Easy-to-Machine 2011 Aluminum Hex Bars | |||

| Wd. | Wd. Tolerance | Heat | Max. |

| Treatment | Temperature, °F | ||

| 1/4" | -0.003" to 0.003" | Hardened | 212° |

| 5/16" | -0.003" to 0.003" | Hardened | 212° |

| 3/8" | -0.003" to 0.003" | Hardened | 212° |

| 1/2" | -0.003" to 0.003" | Hardened | 212° |

| 9/16" | -0.003" to 0.003" | Hardened | 212° |

| 5/8" | -0.003" to 0.003" | Hardened | 212° |

| 3/4" | -0.003" to 0.003" | Hardened | 212° |

| 7/8" | -0.003" to 0.003" | Hardened | 212° |

| 1" | -0.003" to 0.003" | Hardened | 212° |

| 1 1/8" | -0.003" to 0.003" | Hardened | 212° |

| 1 1/4" | -0.003" to 0.003" | Hardened | 212° |

Advantages of Chalco 2011 aluminum bar

- One of the most commonly used aluminum alloys for free-cutting, producing easily removable fine chips during high-speed machining.

- Exhibits excellent machining characteristics, capable of producing complex and fine parts, widely used in the manufacturing of components requiring extensive machining.

- Relatively poor corrosion resistance; Chalco can provide anodizing treatment to offer additional surface protection.

- As an alloy of aluminum with copper and other elements, it enhances strength and durability. In certain situations, it can replace unprocessed brass without the need for tool modifications.

- Can be extruded, drawn, or forged into rods, tubes, or other shapes, serving various purposes.

- Suitable for multiple engineering fields due to its corrosion resistance, lightweight, and high strength, such as aerospace, chemical engineering, and construction machinery manufacturing.

Chalco 2011 and 2011B aluminum parameter table

Our Chalco 2011 and 2011B aluminum products deliver excellent performance and reliability. Explore the detailed parameters below to see how they can meet your specific needs—contact us for expert advice and tailored solutions!

Instant Quote| Chemical composition of 2011 aluminum alloy | ||

| Element | 2011 | 2011B Pb Free |

| Si | 0.4 | 0.4 |

| Fe | 0.7 | 0.7 |

| Cu | 5.0-6.0 | 4.0-7.0 |

| - | - | - |

| Mg | - | - |

| Cr | - | - |

| Ni | - | - |

| Zn | 0.3 | 0.3 |

| Bi | 0.20-0.6 | 0.05-3.0 |

| Pb | 0.20-0.6 | |

| Sn | 0.05-1.5 | |

| Al | Remainder | Remainder |

| Physical property of 2011 2011B aluminum bar rod | ||||

| Alloy | Temper | Tension strength Rp0.2/MPa | Yield strength Rm/MPa | Elongation A50mm/% |

| 2011 | T1 | ≥3 | ≥227 | ≥24.7 |

| T3 | ≥393 | ≥340 | ≥14.8 | |

| T8 | ≥426 | ≥346 | ≥12.7 | |

| 2011B | T3 | ≥310 | ≥260 | ≥10 |

| T6 | ≥310 | ≥230 | ≥8 | |

| T8 | ≥370 | ≥275 | ≥10 | |

| Cold finish 2011 aluminum bar tolerance table | ||||||

| Rounds | Squares, Hexagons, Octagons | |||||

| Tolerance – in. plus and minus except as noted | DISTANCE ACROSS FLATS | |||||

| SPECIFIED DIAMETER INCHES | Allowable Deviation from Specified Diameter | SPECIFIED DISTANCE ACROSS FLATS (in.) | Tolerance – in. plus and minus | |||

| Cold Finished Rod | Rolled Rod | Allowable Deviation from Distance Specified Across Flats | ||||

| Plus | Minus | Cold Finished Bar | Rolled Bar | |||

| 0.125 – 0.500 | 0.0015 | – | – | 0.125 – 0.500 | 0.002 | – |

| 0.501 – 1.000 | 0.002 | – | – | 0.501 – 1.000 | . 0025 | – |

| 1.001 – 1.500 | 0.0025 | – | – | 1.001 – 1.500 | 0.003 | – |

| 1.501 – 2.000 | 0.004 | 0.006 | 0.006 | 1.501 – 2.000 | 0.005 | 0.016 |

| 2.001 – 3.000 | 0.006 | 0.008 | 0.008 | 2.001 – 3.000 | 0.008 | 0.02 |

| 3.001 – 3.499 | 0.008 | 0.012 | 0.012 | 3.001 – 4.000 | – | 0.02 |

| 3.500 – 5.000 | 0.012 | 0.031 | 0.016 | |||

| 5.001 – 8.000 | – | 0.062 | 0.031 | |||

| Extruded 2011 aluminum bar tolerance table | |||||

| Rounds | Squares & Flats | Hexagons | |||

| Size | Tolerance | Thickness or Width In. | Tolerance | Size | Tolerance |

| .438 – 1.000″ | +/- .003″ | Under .125″ | +/- .006 | .438 – .938″ | +/- .005″ |

| 1.001 – 1.500″ | +/- .004″ | .125″ – .249” | +/- .007 | .939 – 1.499″ | +/- .006″ |

| 1.501 – 2.00″ | +/- .005″ | .250″ – .499″ | +/- .008 | 1.500 – 1.874″ | +/- .007″ |

| 2.001 – 3.00″ | +/- .007″ | .500″ – .749″ | +/- .009 | 1.875 – 2.00″ | +/- .008” |

| 3.001 – 3.999″ | +/- .012″ | .750″ – .999″ | +/- .010 | 2.001 – 3.250″ | +/- .012″ |

| 4.00 – 5.00″ | +/- .0017″ | 1.0″ – 1.49″ | +/- .012 | ||

| 5.01 – 7.500″ | +/- .022″ | 1.5″ – 1.99″ | +/- .014 | ||

| 7.501 – 8.00″ | +/- .030″ | 2.0″ – 3.99″ | +/- .024 | ||

| 4.0″ -7.99″ | +/- .034 | ||||

| 8.0″ – 9.99″ | +/- .054 | ||||

Application field of Chalco 2011 2011B aluminum bar

Chalco's 2011 and patented 2011B aluminum bars excel in delivering high-performance solutions across a wide range of precision industries. Leveraging 2011's proven machinability and 2011B's enhanced processing stability and RoHS-compliant eco-friendly formula, these alloys are perfect for producing complex, high-precision components with stringent quality demands.

Typical applications include:

- High-speed automatic screw machine parts requiring exceptional cutting efficiency

- Precision gears and machine components with tight dimensional tolerances

- Automotive fuel system parts and connectors that meet rigorous environmental standards

- Industrial and electronic connectors demanding superior conductivity and durability

- Aerospace and defense components where both strength and reliability are critical

- Consumer electronics and camera parts benefiting from improved surface finish and stability

Whether for mass production or specialized custom orders, Chalco 2011 and 2011B bars offer unparalleled performance, reduced machining costs, and sustainable benefits—ideal for industries striving for both excellence and environmental responsibility.

Instant Quote

Chalco Aluminum - 5 tips for machining 2011 aluminum

1. Selecting the right cutting tools is crucial for processing aluminum alloy round bars; high-speed steel (HSS) or carbide tools are recommended for optimal results. However, carbide tools, while more durable with a better finish, are also more expensive.

2. Using recommended feed rates and speeds for 2011 aluminum is essential for optimal cutting performance. Running the tool too slowly may lead to built-up edges and chip welding, while running too fast can result in excessive tool wear and poor surface finish.

3. Maintaining proper cutting conditions is critical for efficient machining of aluminum alloy round bars. A rigid setup, avoidance of vibration and chatter, and ensuring appropriate tool overhang are necessary for stability during cutting.

4. Avoiding work hardening is important; excessive pressure on the workpiece can lead to work hardening, making the material harder and more difficult to machine. Avoid applying too much pressure during the machining process.

5. Clean the workpiece before machining, removing dirt, oil, or debris that may affect cutting performance, ensuring a smooth machining process.

Chalco other hot selling aluminum bar products

2024 aluminum bar

2017 aluminum bar

2618 aluminum bar

7075 aluminum bar

7050 aluminum bar

6061 aluminum bar

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote