Compared to other modes of transportation, ships operate in uniquely harsh marine environments, which place much higher demands on the quality and performance of materials. In particular, marine aluminum must meet strict international standards to ensure outstanding structural stability and corrosion resistance, even under prolonged exposure to seawater and heavy loads.

The explanation of the following information can help you choose the best marine grade aluminum material for your next project. With the right choice, you will be able to build ocean giant ships, passenger and cargo cruises, or private speedboats, "floating" farther and more durable on the ocean! If you have any needs, you can contact us for more detailed explanations. Welcome contact

Marine grade aluminum - modern ocean miracle metal

The marine environment, due to its complexity - strong corrosiveness, humidity, and wind waves, has created high requirements for the quality, strength, and corrosion resistance of metals used in the marine environment. Compared to many other metals, pure aluminum has higher natural corrosion resistance, but in marine applications, continuous exposure to water and moisture requires additional protection.

When aluminum forms alloys with other metals such as magnesium, it produces a higher level of corrosion resistance and can withstand continuous contact with water and salt water. These specially treated aluminum alloys are called marine grade aluminum. Marine grade aluminum is very suitable for building marine vessels and structures, as well as the machinery and components used therein. Quick Quote

- Light weight, reduce the weight of the ship, improve the aspect ratio of the ship, reduce fuel consumption, and improve economy and environmental protection.

- Good corrosion resistance, no tendency for stress corrosion, peeling corrosion, and intergranular corrosion in seawater or marine environments.

- Good processing performance, easy to perform various processing operations such as cutting, punching, cold bending, rolling, etc.

- Good formability, wide availability of sheets, profiles, and plates, capable of manufacturing large, wide, and thin-walled profiles.

- Good welding performance, using automatic argon arc welding method, good forming, less cracks, and easy correction.

Nine maritime transportation major aluminum alloys that cannot be ignored

-

5052 H32 H34 aluminum alloy

5052 aluminum alloy features excellent corrosion resistance and moderate strength, making it ideal for marine tanks, side panels, and interior structures. Its good cold workability and surface finish also support decorative and functional marine applications.

-

5083 H321 H116 aluminum alloy

Known for its excellent corrosion resistance in seawater environments and high strength, 5083 aluminum alloy is widely used in ship hulls, decks, and offshore structures.

-

5086 aluminum alloy

This alloy provides strong resistance to saltwater corrosion and good weldability, making it ideal for boat hulls, superstructures, and marine components.

-

5059 aluminum alloy

Offering higher strength and improved crack resistance, 5059 aluminum alloy is used in high-performance ships, patrol boats, and military marine applications.

-

5456 aluminum alloy

With high tensile strength and excellent corrosion resistance, 5456 aluminum alloy is suited for welded marine structures such as decks and bulkheads.

-

5454 aluminum alloy

5454 aluminum alloy offers good corrosion resistance and moderate strength, commonly used in marine tanks, pressure vessels, and deck plates.

-

5754 aluminum alloy

5754 aluminum alloy is known for its good corrosion resistance, medium strength, and formability. It is commonly used in marine flooring, ship interiors, and non-structural decorative elements exposed to marine environments.

-

6061 T6 T651 T6511 aluminum alloy

6061 aluminum alloy offers a balance of strength, corrosion resistance, and machinability, making it suitable for marine masts, fittings, and custom structural components that require both strength and lightweight performance.

-

6063 aluminum alloy

6063 aluminum alloy features excellent surface finish and moderate strength, often used in marine trim, railings, and profiles. Its anodizing ability and resistance to marine corrosion make it a reliable option for aesthetic and functional parts.

Premium marine aluminum products for advanced shipbuilding

Chalco marine aluminum product range is specifically engineered to meet the demanding requirements of modern ship construction. Combining superior corrosion resistance, lightweight strength, and excellent formability, these products provide reliable solutions for critical ship components from hulls to superstructures and specialized onboard systems.

-

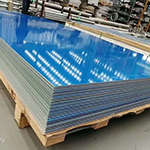

Aluminum Plates for Hull Construction

Aluminum Plates for Hull ConstructionHigh-strength, corrosion-resistant aluminum plates are the backbone of modern ship hulls. These materials withstand harsh seawater conditions and mechanical stress, making them ideal for military vessels, cargo ships, ferries, and yachts.

5083 aluminum plate 5086 aluminum plate 5454 aluminum plate -

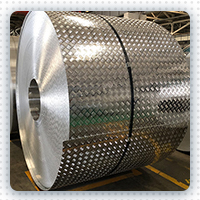

Aluminum Sheets Coil for Decks and Superstructures

Aluminum Sheets Coil for Decks and SuperstructuresMarine-grade aluminum sheets provide a lightweight yet durable solution for upper deck structures, cabins, and wall panels. They offer good surface quality for painting and coating.

-

Aluminum Profiles and Sections for Ship Railings and Frames

Aluminum Profiles and Sections for Ship Railings and FramesExtruded aluminum profiles are widely used in railing systems, window frames, ladders, and walkways on ships. Alloys like 6061 and 6063 provide strength, corrosion resistance, and excellent formability.

-

Premium Marine Aluminum Bars for Advanced Shipbuilding

Premium Marine Aluminum Bars for Advanced ShipbuildingHigh-performance aluminum bars are widely used in marine frameworks, fittings, and machinery parts, providing excellent strength-to-weight ratio and corrosion resistance to withstand challenging marine environments.

-

Aluminum Tubes and Pipes for Shipbuilding Structural Components

Aluminum Tubes and Pipes for Shipbuilding Structural ComponentsAluminum tubing is used in marine piping systems, ladders, and handrails. Corrosion resistance and weight savings are key advantages in these applications.

-

Aluminum Clad Plates for Critical Shipboard Systems

Aluminum Clad Plates for Critical Shipboard SystemsFor demanding environments such as engine rooms and chemical transport tanks, copper- or stainless-clad aluminum plates combine aluminum's light weight with the enhanced conductivity or corrosion protection of another metal.

Advanced deep-processed aluminum plates for marine shipbuilding development

Aluminum plates, aluminum rods, aluminum pipes, aluminum profiles, etc. are applied to various parts of the ship's hull, providing the overall shape of the ship's hull, support for the hull, and components for various applications. In addition, some deeply processed aluminum plate products also provide more support for the manufacturing of ships.

Marine aluminum plates, known for their high strength, corrosion resistance, and lightweight properties, are widely used in the construction of hulls, decks, and ship structures. Chalco marine grade aluminum plate has the CCS, DNV, NK, CCS, ABS, BV, LR, KR, etc. certifications.Quick Quote

Ultra-wide ship plates, up to 2650mm for sheet and 3000mm for plates, reduce welding needs, enhance structural integrity, and improve aesthetics. They offer high strength, excellent corrosion resistance, and durability, ideal for shipbuilding.Quick Quote

The surface of the aluminum plate has various raised patterns such as diamond and square patterns. Usually used on ship decks, stairs, equipment, and dashboard; Not only does it have a decorative effect, but it also provides additional anti slip performance. Quick Quote

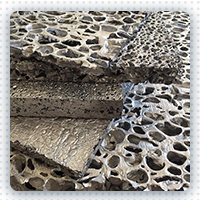

Marine foam plate has the characteristics of good fire resistance, flame retardancy, moisture-proof and dust-free. It solves the problem of traditional sound-absorbing materials being prone to moisture absorption and endangering the health of crew members. More suitable as a soundproofing material for ship cabins. Quick Quote

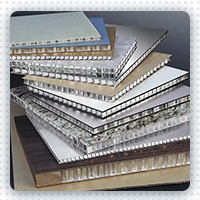

Aluminum alloy honeycomb plate

a composite material composed of an aluminum hexagonal honeycomb core layer. The core is sandwiched between two aluminum plates adhered on both sides. Can be manufactured into various thicknesses. It is commonly used on ship decks, gangways, outfitting boards, and other parts. Due to its honeycomb hollow structure, it can more effectively reduce the weight of the hull structure, improve the ship's load-bearing capacity and fuel efficiency. Quick Quote

Stiffened plate aluminum ribbed plates for ships

It is a reinforcing material used for ship structures. It plays a strengthening and supporting role in key areas and structures of the ship's hull. Quick Quote

Surface treatment that cannot be ignored - anodizing, coating, cathodic protection

Anodizing, coating, and cathodic protection are commonly used surface treatment methods for ship class aluminum. In addition to adding aesthetic effects to the ship, they can also effectively enhance the protective performance and enhance the corrosion resistance of aluminum.

-

Coating-protective and aesthetic

Coatings include polyurethane, epoxy... The natural oxide film on aluminum hinders paint adhesion, so surface treatment is needed to improve coating adhesion.

-

Anodizing-corrosion resistance

Anodizing thickens aluminum's oxide film, ideal for 5000 and 6000 series alloys, and is used for decoration, hard coatings, and corrosion resistance.

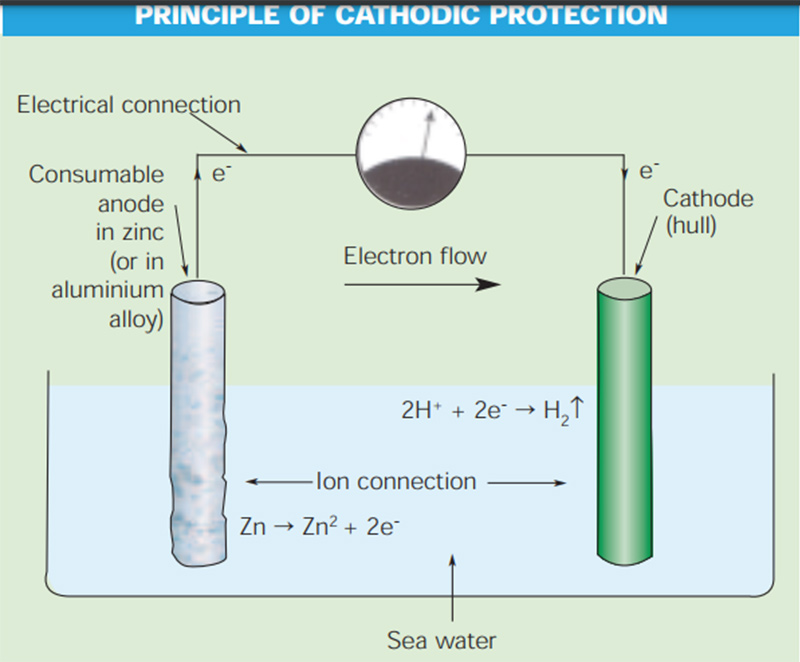

Cathodic protection-Sacrificial Anode of Zn-Al-Cd Alloy

It is an electrochemical method to protect ship metal from corrosion by using active metals as cathodes. Aluminum, forming a protective oxide film in seawater, can serve as a cathode material to slow down corrosion.

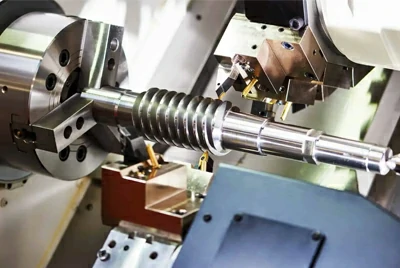

Chalco's marine aluminum processing capabilities

Precision Cutting and CNC Machining: Utilizing state-of-the-art CNC machines and cutting tools, we deliver complex shapes and tight tolerances for hull parts, fittings, and structural components. This precision machining supports efficient assembly and superior fit in shipbuilding projects.

Bending and Forming: Our advanced bending and forming equipment enable the fabrication of complex curved profiles and frames, ensuring optimal structural strength and design flexibility. These processes maintain material integrity, critical for corrosion resistance and mechanical performance.

Welding and Fabrication: We offer professional welding solutions including TIG, MIG, and friction stir welding, suitable for joining marine aluminum alloys without compromising corrosion resistance. Our skilled welders and quality controls guarantee robust, leak-proof joints essential for ship hulls and superstructures.

Surface Preparation for Coating: Beyond processing, we prepare aluminum surfaces to ensure excellent adhesion of paints and coatings. This includes shot blasting, sanding, and cleaning, enhancing corrosion protection and aesthetic quality.

Heat Treatment: Heat treatment processes such as solution treatment and aging improve mechanical properties and stress relief, optimizing aluminum plates and profiles for demanding marine conditions.

Our integrated processing lines and quality management systems allow us to provide customized solutions, fast turnaround, and consistent quality for marine aluminum components, supporting the demanding requirements of modern shipbuilding.

Chalco - best partner for shipbuilding projects or private ship repairs

Product and delivery advantages: Chalco has its own independent production line, mold workshop, and testing laboratory. Hot selling 5052, 5083, 5383, 5086, 6061, 6063 and other 5000 and 6000 series alloys are in stock or can be customized for production

Full size profile molds: Chalco has over 2000 sets of molds with different aluminum row sizes. It can produce aluminum plates, aluminum rods, aluminum tubes, aluminum profiles, as well as marine pattern plates, honeycomb plates, foam plates and stiffened plates.

Complete certification: CCS, DNV, NK, CCS, ABS, BV, LR, KR, etc.

Chalco's marine partnerships – aluminum solutions for diverse vessel types

Chalco provides marine-grade aluminum products and processing services to a wide spectrum of shipbuilders. From small personal crafts to large commercial and military vessels, we deliver tailored aluminum solutions trusted across the global maritime industry.

Our marine aluminum serves the following vessel types:

- Private fishing boats

- Pleasure yachts and sailboats

- Passenger ferries

- Commercial cargo ships

- Offshore supply vessels

- Oil and chemical tankers

- Patrol boats and coast guard cutters

- Naval ships and military craft

With broad application expertise and proven supply capability, Chalco is your reliable partner in marine aluminum.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote