3103 is a medium to low strength aluminum alloy that combines excellent corrosion resistance with good formability. The 3103 is typically supplied in H14 condition and has similar performance compared to the 3003.

The material shows improved mechanical properties compared to the 1xxx series aluminum alloys, especially at high temperatures. The weldability of 3103 aluminum plate is also very good, and its corrosion resistance to atmospheric erosion is also very good.Quick Quote

3103 Specifications for aerospace aluminum plates

Thickness: 0.5-150mm

Width: 1200-3500mm

Length: 2400-12000mm

Certifications: AS9100, OHSAS 18001, ISO 14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

Standard: BS 4 L59 3103-H16/H26 Sheet, BS 4 L60 3103-H12/H22 Sheet, BS 4 L61 3103-O Temper Sheet, BS EN 573, BS EN 485

Surface treatment: Anodizing, painting, laminating

Processing: Welding, stamping, bending, drilling

Equivalent grade: Alcoa-190, BA 60, BS N3, Aluman-100, Alcan GB-3S

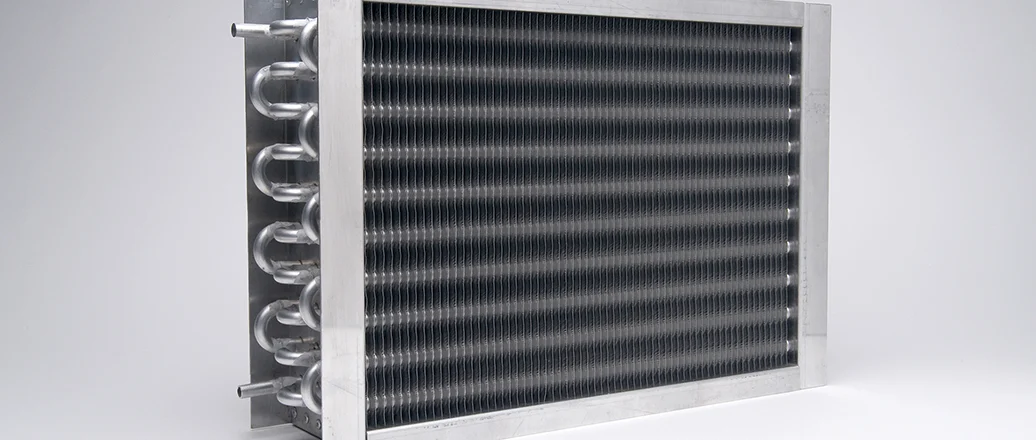

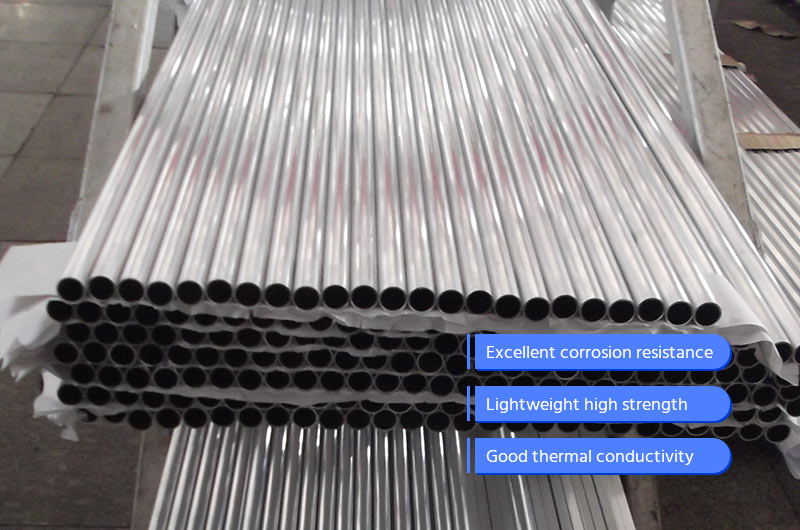

We also produce 3103 aluminum tubes for radiators, heat exchangers, and air-conditioning automotive pressure vessels. Please contact us for details.Quick Quote

Popular 3103 aluminum plate sizes

We stock 3103 aluminum plate in a variety of thicknesses and conditions, including H14, H16, H26 and O, with H14 being the most common.Quick Quote

| Description | Thickness mm | size mm |

| 0.5 mm 3103 Aerospace aluminum plate | 0.5 mm | Custom cutting available |

| 0.6 mm 3103 Aerospace aluminum plate | 0.6 mm | Custom cutting available |

| 0.8 mm 3103 Aerospace aluminum plate | 0.8 mm | Custom cutting available |

| 1.0 mm 3103 Aerospace aluminum plate | 1.0 mm | Custom cutting available |

| 1.2 mm 3103 Aerospace aluminum plate | 1.2 mm | Custom cutting available |

| 1.5 mm 3103 Aerospace aluminum plate | 1.5 mm | Custom cutting available |

| 2.0 mm 3103 Aerospace aluminum plate | 2.0 mm | Custom cutting available |

| 2.5 mm 3103 Aerospace aluminum plate | 2.5 mm | Custom cutting available |

| 3.0 mm 3103 Aerospace aluminum plate | 3.0 mm | Custom cutting available |

| 4.0 mm 3103 Aerospace aluminum plate | 4.0 mm | Custom cutting available |

| 5.0 mm 3103 Aerospace aluminum plate | 5.0 mm | Custom cutting available |

| 6.0 mm 3103 Aerospace aluminum plate | 6.0 mm | Custom cutting available |

| 8.0 mm 3103 Aerospace aluminum plate | 8.0 mm | Custom cutting available |

| 10.0 mm 3103 Aerospace aluminum plate | 10.0 mm | Custom cutting available |

| 12.0 mm 3103 Aerospace aluminum plate | 12.0 mm | Custom cutting available |

| 16.0 mm 3103 Aerospace aluminum plate | 16.0 mm | Custom cutting available |

| 18.0 mm 3103 Aerospace aluminum plate | 18.0 mm | Custom cutting available |

3103 aerospace aluminum sheet mechanical property

| 3003 O Aerospace Aluminum | 3003 H12 Aerospace Aluminum | 3003 H22 Aerospace Aluminum | 3003 H16 Aerospace Aluminum | 3003 H26 Aerospace Aluminum | |

| Tensile Strength | 90MPa | 125MPa | 145MPa | 165MPa | 185MPa |

| Elongation A50 mm | 40MPa | 85MPa | 115MPa | 145MPa | 165MPa |

| Shear Strength | 30% | 10% | 3% | 2% | 1% |

| Hardness Vickers | 40 | 35 | 45 | 50 | 55 |

3103 aerospace aluminum sheet chemical composition

| Manganese (Mn) | 0.90-1.50 |

| Iron (Fe) | 0.0-0.70 |

| Copper (Cu) | 0.0-0.10 |

| Magnesium (Mg) | 0.0-0.30 |

| Silicon (Si) | 0.0-0.50 |

| Zinc (Zn) | 0.0-0.20 |

| Other (Each) | 0.0-0.05 |

| Others (Total) | 0.0-0.15 |

| Chromium (Cr) | 0.0-0.10 |

| Titanium+Zirconium (Ti+Zr) | 0.0-0.10 |

| Aluminium (Al) | Balance |

3103 aviation aluminum sheet popular related products

heat-exchanger-aluminum-tube

3003-aluminum-bar

3003-seamless-tube

3003-aluminium-sheet

6061-T6 aluminum

6061-aluminum-plate

3103 aviation aluminum sheet characteristics

3103 aviation aluminum sheet is a high-performance aviation aluminum alloy material with the following characteristics:

High strength: 3103 aviation aluminum sheet has high strength, which can withstand large loads and pressures to ensure the safety of aircraft.

Lightweight: 3103 aviation aluminum sheet is lighter compared to other aviation materials, which helps reduce the self-weight of the aircraft and improve the comprehensive performance of the aircraft.Quick Quote

Good corrosion resistance: 3103 aviation aluminum sheet has good corrosion resistance, which can maintain stable performance in harsh environments and prolong the service life of the material.

Good processability: 3103 aviation aluminum sheet has good processability and can be molded and processed in a variety of processing methods to meet the needs of different aviation applications.

Good weldability: 3103 aviation aluminum sheet can be connected by a variety of welding methods, with good welding performance, and can achieve the effect of high-strength connection.

Good environmental protection: 3103 aviation aluminum sheet meets environmental protection standards, will not cause pollution to the environment, in line with the modern concept of environmental protection.

In summary, 3103 aviation aluminum plate has the characteristics of high strength, light weight, good corrosion resistance, good processability, good weldability and good environmental protection, which is one of the important materials in the aviation field.

3103 aerospace aluminum sheet application

3003 O temper aircraft aluminum sheet

3003 O aluminum sheet has good processing properties, high strength, low density, good corrosion resistance and good electrical conductivity. It has been widely used in the aerospace field.

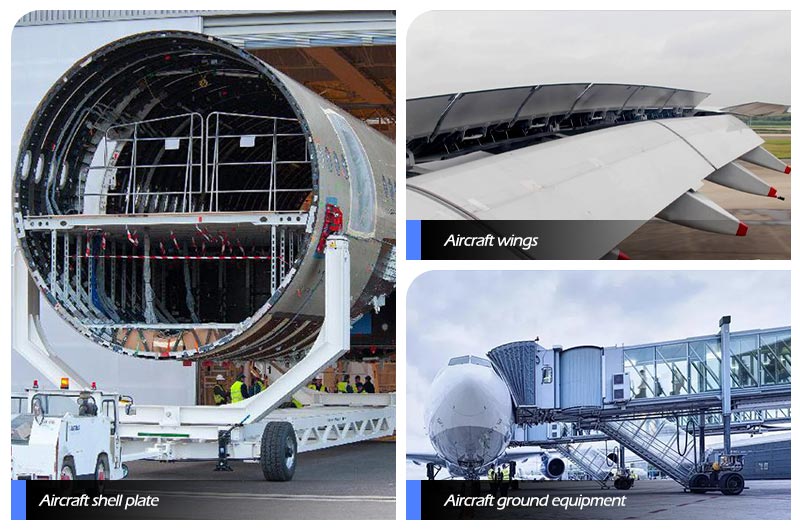

Aircraft shell plate: 3003 O-temper aircraft aluminum plate can be made into aircraft shell plate, used to protect the important parts of the aircraft, with good strength and rigidity, able to withstand the risk and pressure in flight.

Aircraft accessories: 3003 O temper aircraft aluminum sheet can also be used to make various accessories of aircraft, such as skins, wings, air intakes, etc. These parts play an important role in flight safety and flight performance.Quick Quote

Aircraft internal structure: 3003 O temper aircraft aluminum plate can also be used for the manufacture of internal structural parts of aircraft, such as beams, frames, bulkheads, etc. These parts play an important role in maintaining the structural integrity of the aircraft and improving flight efficiency.

Aircraft ground equipment: 3003 O temper aircraft aluminum plate can also be used for the manufacture of aircraft ground equipment, such as boarding bridges, aircraft bridges, baggage carts and so on.

3003 H12 temper aircraft aluminum sheet

3003 H12 aluminum plate has good mechanical properties and corrosion resistance. It has a wide range of applications in the aerospace field.

Aircraft structural parts: 3003 H12 temper aircraft aluminum plate can be used to manufacture structural parts of aircraft, such as beams, frames, bulkheads, etc. These parts play an important role in maintaining the structural integrity of aircraft and improving flight efficiency.

Aircraft accessories: 3003 H12 temper aircraft aluminum plate can also be used to manufacture a variety of aircraft accessories, such as skins, wings, air intakes, etc. These parts play an important role in flight safety and flight performance.

Aircraft shell plate: 3003 H12 temper aircraft aluminum plate can be made into aircraft shell plate, used to protect the important parts of the aircraft, with good strength and rigidity, able to withstand the risk and pressure in flight.

Aircraft ground equipment: 3003 H12 temper aircraft aluminum plate can also be used to manufacture aircraft ground equipment, such as boarding bridges, aircraft bridges, baggage carts, etc.

3003 H16 temper aircraft aluminum sheet

3003 H16 aircraft aluminum plate has high-strength and corrosion-resistant. The following are its applications in aviation.

Structural parts: 3003 H16 temper aircraft aluminum sheet is usually used to manufacture structural parts of aircraft, such as fuselage, bulkhead, flaps, flap shells, landing gear, etc.. Its high strength and light weight properties make it an ideal material for these components.Quick Quote

Housing: 3003 H16 temper aircraft aluminum sheet is also widely used in aircraft housing manufacturing. Due to its corrosion and oxidation resistance, it can be used in extreme climates and high altitude environments, while still providing excellent protection to maintain the structural integrity and stability of the aircraft.

Wings: 3003 H16-temper aircraft aluminum sheet can also be used to manufacture aircraft wings. Its lightweight characteristics can reduce the overall weight of the aircraft, improving aircraft performance and fuel economy. At the same time, its high strength can also provide sufficient support and stability for the wing.

3003 H22 temper aircraft aluminum sheet

3003 H22 temper aircraft aluminum sheet has high strength and excellent corrosion resistance. It is usually used in the aerospace field in the manufacture of structural components.

Fuselage: 3003 H22 temper aviation aluminum sheet can be used to manufacture the shell, top, bottom and other parts of the aircraft fuselage. Due to its high strength and excellent corrosion resistance, it can withstand heavy loads and high-speed wind cuts during flight, while maintaining aesthetic appearance and durability.

Wings: 3003 H22-temper aircraft aluminum sheet can also be used to manufacture wings for aircraft. In these components, it can provide stable strength and rigidity to ensure the structural integrity and flight stability of the aircraft under high speed flight and aerodynamic load.

Engine cowlings: due to its light weight and high strength, 3003 H22-temper aircraft aluminum sheet is also an ideal material choice for the manufacture of components such as aircraft engine cowlings. These components need to have excellent resistance to heat, corrosion and vibration to ensure proper engine operation.

3003 H26 temper aircraft aluminum sheet

3003 H26 aluminum sheet is a high-strength aluminum alloy with excellent corrosion resistance. It is commonly used in the manufacture of structural components in the aerospace field.

Fuselage: 3003 H26 temper aircraft aluminum sheet can be used to manufacture the shell, top, bottom and other parts of the aircraft fuselage. Due to its high strength and excellent corrosion resistance, it can withstand heavy loads and high-speed wind cuts during flight, while maintaining aesthetic appearance and durability.

Wings: 3003 H26-temper aircraft aluminum sheet can also be used to manufacture wings for aircraft. In these components, it can provide stable strength and rigidity to ensure the structural integrity and flight stability of the aircraft under high speed flight and aerodynamic load.

Engine cowlings: due to its light weight and high strength, 3003 H26-temper aircraft aluminum sheet is also an ideal material choice for the manufacture of components such as aircraft engine cowlings. These components need to have excellent resistance to heat, corrosion and vibration to ensure proper engine operation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote