Chalco offers a wide range of standard aluminum extrusions, including aluminum angles, bars, tubes, beams, channels,and T-profiles. We use high-quality aluminum alloys such as 6063, 6061, 6005, and 6082 to ensure lightweightstrength and excellent corrosion resistance.

Our standard profiles are known for their flexibility and cost-effectiveness. They meet diverse project needs,making it easy to adapt designs and reduce overall expenses.

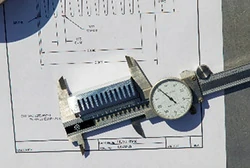

Specifications of standard aluminum extrusions & profiles

Standards: ASTM B308, AMS-QQ-A-200/8, ASTM B221, EN 755, EN 573, ISO 6362, ASTM B429, EN 12020, GB/T 5237, UL 94,MIL-STD-810, MIL-DTL-32342

Certifications: ISO 9001, ISO 14001, RoHS, REACH, CE, BBA, AS9100

We provide detailed factory quality inspection reports. These include key metrics such as tensile strength, yieldstrength, and chemical composition analysis. Every batch is strictly tested to fully comply with ASTM and GBstandards!

Instant QuoteSize options for standard aluminum extrusions & profiles

Chalco has long been a leader in manufacturing both standard and custom aluminum extrusions and fabricated aluminumproducts.

We operate a wide range of advanced, top-tier extrusion equipment capable of handling billets up to 32inches (800 mm) in diameter.

The final extruded aluminum parts can range from 25 to 50 feet in length, depending on the desiredsurface finish.

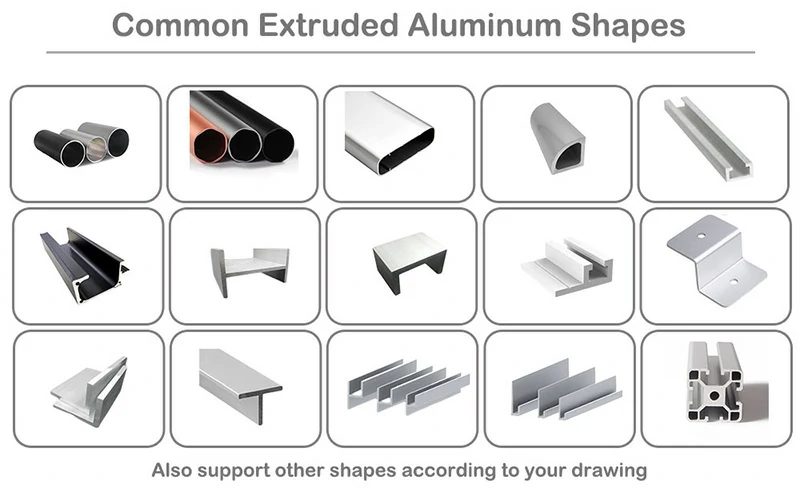

Extensive selection of standard aluminum extrusions

Whether for large-scale projects or small batches, our standard profiles deliver consistent performance, fastdelivery, and trusted precision.

Chalco offers free samples, top-tier service, and quality—your go-to source for aluminum extrusions.

Chalco stocks standard aluminum extrusions

Aluminum Angle

Aluminum T bar

Aluminum I Beam

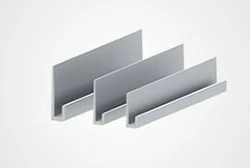

Aluminum Channel

Z Aluminium Extrusion

F shaped Aluminium Extrusion

Y Section Aluminium Extrusion

J Section Aluminium Extrusion

Aluminum Hat Channel

Aluminium G Profile

Aluminum round tubes

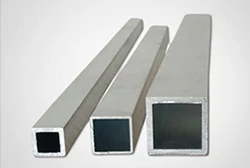

Aluminum square tubes

Aluminum round bars

Aluminum square bars

Aluminum Flat Bar

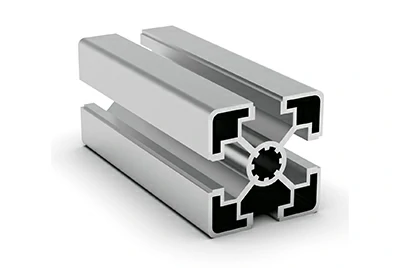

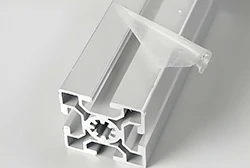

Standard t slot sizes

10 Series Aluminum Extrusion

15 Series Aluminum Extrusion

45 Series Aluminum Extrusion

2020 2040 Aluminum Extrusion

3030 3060 Aluminum Extrusion

4040 4080 Aluminum Extrusion

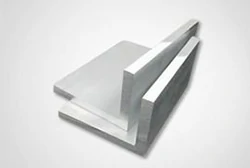

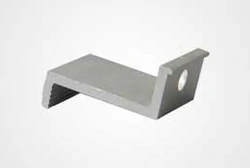

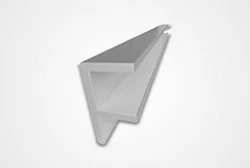

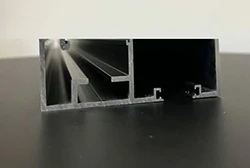

Custom aluminum extrusions

Looking for something unique? We specialize in custom aluminum extrusions, shapes, cross-sections, lengths, andsurface finishes.

Custom finishes

Custom lengths

Custom Profiles

Don't settle for what you can find—let us help you create and get exactly what you need.

At Chalco Aluminum, we design and source custom extrusions tailored to your specific requirements.

Request a free custom quote today.

Instant Quote

Once the technical drawings are finalized and approved, we move quickly into the prototyping phase. This allows youto validate the solution before full-scale production begins.

Our agile end-to-end process ensures optimal performance while significantly reducing development time andproduction costs.

Whether you need tight tolerances, complex geometries, or specific alloy properties, we have the expertise to turnyour unique requirements into efficient, high-quality aluminum solutions.

Alloy options for Chalco's standard aluminum extrusions & profiles

We manufacture standard 6000 series aluminum extrusions to customer specifications, including 6005/6005A aluminum,6061 aluminum, and 6063 aluminum.

- 1050 standard aluminum extrusions

Excellent electrical conductivity, corrosion resistance, and workability. Ideal for electricalapplications and chemical equipment.

- 1070 standard aluminum extrusions

Soft texture and great ductility, perfect for applications requiring superior formability andconductivity.

- 1100 standard aluminum extrusions

Commercially pure aluminum, capable of being extruded into a wide range of complex shapes.

- 3003 standard aluminum extrusions

High strength, commonly used for extruding heat exchanger tubes.

- 3004 standard aluminum extrusions

Greater strength with excellent formability and corrosion resistance.

- 3103 standard aluminum extrusions

Good strength and corrosion resistance, often used in structural applications and HVAC systems.

- 6060 standard aluminum extrusions

Good extrudability, medium strength, and excellent anodizing quality.

- 6061 standard aluminum extrusions

High strength with excellent extrudability and weldability, making it ideal for structural partslike frames and piping.

- 6063 standard aluminum extrusions

Superior surface finish, suitable for parts with complex designs such as thin walls or fine details,and for decorative applications.

- 6005 standard aluminum extrusions

A stronger alloy for structural applications requiring higher mechanical performance withoutcompromising corrosion resistance.

- 7075 standard aluminum extrusions

Higher yield, tensile, and weld strength, though with a higher cost.

- 2024 standard aluminum extrusions

High strength and excellent fatigue resistance make it ideal for aerospace and structuralapplications.

Applications of standard aluminum extrusions & profiles

Across industries, standard aluminum extrusions are used in a wide range of products, including doors and windows, power systems, automotive, aerospace, rail transit, marine, defense, building, and thesignage and display sectors.

Aluminum's versatility makes it an excellent choice for producing lightweight, durable parts and components.

Automotive profiles

Structural and functional components that combine lightweight design with mechanical strength—ideal forimproving vehicle efficiency and reducing emissions.

Contact us now

Electronics profiles

Extrusions used for housings, heat sinks, and components requiring excellent thermal conductivity andprecise tolerances.

Contact us nowEnergy profiles

Solutions for renewable energy systems, power distribution, and LED lighting, where conductivity andcorrosion resistance are critical.

Contact us now

Architectural profiles

Structural and finishing profiles for facades, doors, windows, and modular systems, offering long-termdurability and aesthetic appeal.

Contact us nowMarine profiles

Marine grade standard aluminum extrusions offer excellent corrosion resistance and strength, making themideal for ships, docks, and offshore structures.

Contact us now

Aerospace profiles

Aerospace standard aluminum extrusions offer high strength and lightweight properties, ideal foraircraft frames and structural components.

Contact us nowHVAC and refrigeration

Ducts and profiles optimized for airflow management, insulation support, and energy efficiency.

Contact us now

Industrial machinery

Custom extrusions for machine parts, frames, and automation systems where strength and dimensionalaccuracy are essential.

Contact us nowSignage profiles

Signage standard aluminum extrusions provide clean finishes and excellent formability, perfect forframes, displays, and architectural signs.

Contact us now

Defense and military

Defense standard aluminum extrusions provide high strength, durability, and reliability for militaryvehicles, equipment, and tactical applications.

Contact us nowAdvantages of standard aluminum extrusions & profiles

The key advantage of standard aluminum extrusions is their flexibility. You can easily modify or adjust your projector design using standard profiles.

This also brings excellent cost efficiency—since these are not custom types, you can source materials at a lowerprice.

Instant Quote- High strength-to-weight ratio: Delivers excellent strength while remaining lightweight—durable yet easy tohandle.

- Good corrosion resistance: The natural oxide layer enhances weather resistance, ideal for outdoor and marineenvironments.

- Excellent thermal and electrical conductivity: Perfect for use in heat sinks, electrical structures, and relatedapplications.

- Wide alloy selection: Offers options to meet various needs such as strength, corrosion resistance, andmachinability.

- Strong design flexibility: Available in various cross-sectional shapes, supporting both standard and customsolutions.

- Easy to process and install: Lightweight and user-friendly, helping reduce installation difficulty and laborcosts.

- Great surface treatment compatibility: Suitable for anodizing, electrophoresis, powder coating, and more.

- Eco-friendly and recyclable: A green material that supports sustainable development goals.

Low cost and fast delivery: no mold fees, quick supply, and excellent cost performance.

Surface finishes for standard aluminum extrusions & profiles

Many standard aluminum extrusions are ordered with a basic mill finish. However, if a finished surface is required,they can be painted, powder coated, or anodized.

Here are the surface finish options we offer for standard aluminum extrusions—choose the one that best suits yourproject needs:

- Mill Finish: Smooth, raw aluminum surface—cost-effective and ready for secondary processing.

- Clear Anodized: Long-lasting surface gloss with excellent corrosion resistance.

- Anodizing: Highly decorative, wear- and corrosion-resistant—ideal for modern design applications.

- Powder Coating: Vibrant colors with strong, durable protection—perfect for long-term outdoor use.

- Brushed Finish: Fine, silk-like surface texture—enhances aesthetic appeal with a modern look.

- Satin Anodized: Matte, refined appearance with a smooth touch—adds a premium finish to the product.

- Wood Grain Sublimation: Realistic wood-like appearance—eco-friendly, durable, and perfect for upscale decorativeapplications.

Clear satin

Light bronze

Black

Gold

Silver

Wine red

In addition to the standard colors and finishes listed above, we also offer a wide range of custom color options tomeet your personalized design needs.

Contact us to request a detailed color chart for our standard aluminum extrusions.

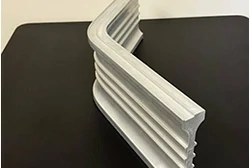

Instant QuoteProcessing of standard aluminum extrusions

In addition to offering standard, custom, and OEM extrusions, as well as anodizing and powder coating finishes,Chalco Aluminum also provides light metal fabrication and assembly services for your standard aluminum extrusions,including:

- Drilling/Countersinking

- Welding

- Cutting to length, Mitering

- Forming/Bending

- Punching

- Deburring

- Assembly

- Brushing/Straight lining

Chalco's die capabilities

With over 4,000 existing dies, we can accelerate the production of a wide variety of standard extruded aluminumparts.

By partnering with us for your aluminum extrusion needs, you get high-quality parts faster and at a lower cost.

Standard aluminum extrusions & profiles inventory program

Ample stock of standard profiles

We keep a wide range of standard aluminum profiles in stock and ready for immediate delivery. This allows us torespond quickly to your orders and help you save on procurement time.

Flexible supply solutions

Whether you need small batches delivered frequently or large volumes in a single shipment, we can adapt our deliveryschedule to match your project timeline and ensure uninterrupted supply.

Low and flexible minimum order quantities (MOQ)

We offer free samples and accept small-batch orders to support your early-stage trials or sample needs.

Reliable delivery time

We guarantee fast shipping within 3–7 days for standard stock profiles, ensuring your project stays on schedule.

When placing an order, please specify the alloy, temper, length, quantity, surface finish, final application, andany special instructions regarding dimensions, length or shipping tolerances, custom packaging, labeling, orcertifications.

Quality assurance of Chalco extrusions

- Inspected according to ASTM international standards

- SPC / PPAP documentation available upon request

- Complete physical and chemical testing certifications

- Advanced laboratories and comprehensive testing equipment

Chalco operates a state-of-the-art in-house quality inspection lab, backed by a QC team of over 100 professionals.

Every shipment is 100% inspected before loading to ensure product quality and give you complete peace of mind.

Custom packaging and shipping for standard aluminum extrusions & profiles

- Protective film wrap (PE/PVC): Scratch- and dust-resistant; ideal for anodized, powder-coated, or othersurface-treated profiles.

- Kraft paper / foam interlayer / honeycomb board protection: Added reinforcement between layers to prevent impactand compression damage.

- Wood pallet packaging (Fumigation Free): Suitable for ocean container loading and easy forklift handling.

- Wooden crate packaging: Moisture-proof and pressure-resistant; ideal for air freight or small-volume shipments.

- Full container load (FCL): Recommended for large-volume orders; suitable for sea export.

- Less than container load (LCL): Available for small-volume orders to reduce logistics costs.

We support customer-specified logistics and trade terms, including FOB, CIF, DDP, and more.

Protective film

Kraft paper

Wooden crate

Pallet

Full container load (FCL)

Full container load (FCL)

FAQs: standard aluminum extrusions & profiles

What are the most common types of aluminum extrusions?

The most common type is 6063 aluminum alloy extrusions, widely used in thin-wall and architectural applications.

6063 is preferred for its excellent extrudability, strong anodizing response, and smooth surface finish—making itideal for buildings, window frames, door frames, and more.

What's the difference between 6061 and 6063 standard aluminum extrusions & profiles?

6061 aluminum alloy has higher strength than 6063 and is often used in structural applications, machinery, andaerospace components.

6063, on the other hand, is primarily used in applications where good surface finish and appearance are important,such as architecture, window frames, and electrical enclosures.

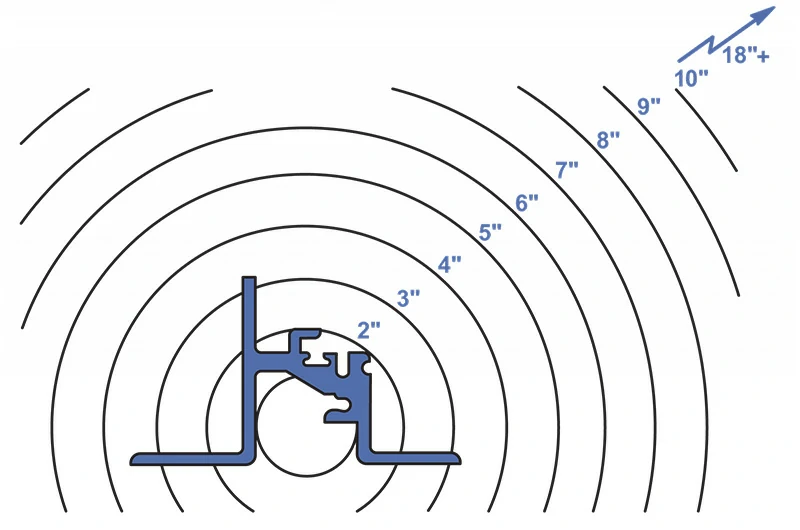

What are the optimal extrusion sizes for standard aluminum extrusions & profiles?

Extrusion size is commonly measured by circumscribing circle diameter (CCD). Sizes ranging from 1 to 10 inches aretypically the most cost-effective.

Profiles with CCDs under 8 inches are especially economical, and most common extrusions fall below 12 inches in sizedue to efficiency and lower production costs.

What is the optimal extrusion ratio for standard aluminum extrusions & profiles?

For hard alloys, the extrusion ratio typically ranges from 10:1 to 35:1.

For soft alloys, it can range from 10:1 up to 100:1.

Higher extrusion ratios allow for more complex profile designs but may also affect production cost and efficiency.

What's the difference between cold extrusion and hot extrusion?

Hot extrusion accommodates a wider range of materials and tolerances and is suitable for less ductile materials.

Cold extrusion, performed at room temperature, requires higher deformation force but achieves greater quality andprecision.

What is the extrusion process for standard aluminum extrusions & profiles?

- Heating the aluminum billet

- Inserting a mandrel into the die (for hollow profiles only)

- Forcing the aluminum through the extrusion press to form the desired shape

- Cutting the extruded profile

- Aging, quenching, or heat treating if needed

- Cooling the extruded parts

- Polishing, anodizing, or coating the extrusion for the final finish