Chalco is a trusted aluminum forging supplier dedicated to delivering high-quality forged components.

Our facilities are capable of producing a wide range of aluminum forgings—from simple shapes to highly complexgeometries.

We also support custom forging solutions tailored to your specific requirements.

Aluminum forging specifications

- ASTM B247, BS 1472, DIN 1749

- AMS 4127 (7075‑T73 / T7351), AMS 4133 (2024), AMS 4143 (7075‑T6), AMS 4144 (7050 and other 7xxx series)

- Custom specifications also supported, including AMS, DEF STAN, or customer-defined standard

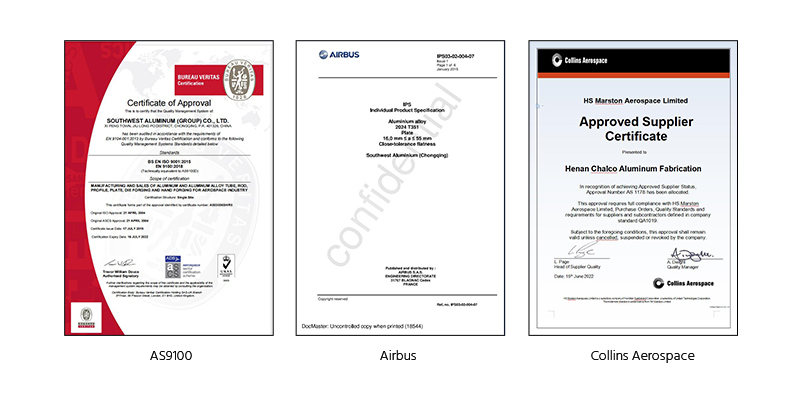

Our forgings are produced under ISO 9001:2015 and AS9100D quality systems, with NADCAP approval for heat treatmentand optional NDT (UT / PT).

Full traceability from Heat No. to final inspection is ensured. Compliance documents like MTCs, UT reports, and heatcharts are available, and small-batch sampling is supported.

Instant Quote

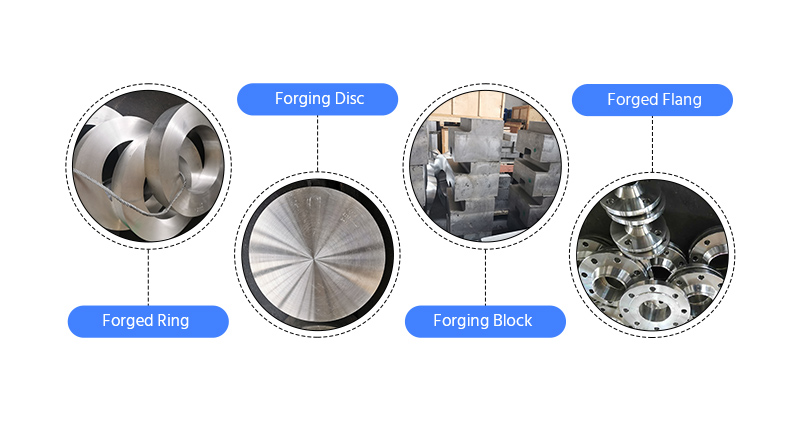

Chalco's full range of aluminum forging parts

Products in Chalco include forged bars, forged aluminum tubes, rolled forged rings, discs, hubs, blocks, shafts, andother forged shapes. We can also provide customized aluminum forging production services to meet your applicationneeds.

Instant Quote

Forged tube & fitting

Seamless, high pressure resistance, custom OD/ID

Forged shaft

High torque strength, long bar, precision balanced

Forged & rolled ring

Seamless structure, optimized grain flow, OD up to 1800 mm

Seamless rolled ring

Near-net shape, high fatigue resistance, aerospace grade

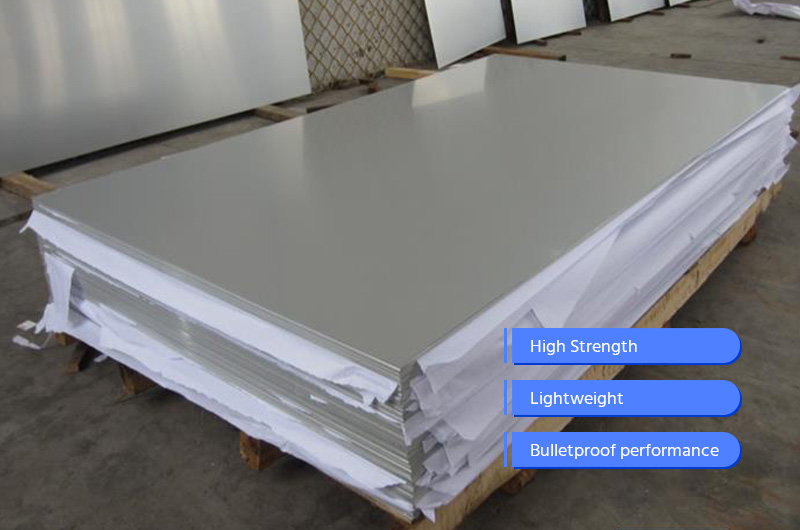

Forged plate

Flatness guaranteed, no porosity, high consistency

Forging block

High strength, high toughness, excellent machinability

Forged disc

Precision roundness, aerospace and automotive use

Forged bar

Full-size range, consistent microstructure, T6 / T651

Hub & tool forgings

High safety, long service life, custom design supported

Ultra-large forgings

Oversized capability, one-piece structure, industrial scale

Custom aluminum forging tailored to your most complex requirements — contact us now to bring your design to life.

Aluminum forging capabilities

Our value-added services include heat treatment, physical testing, non-destructive testing (NDT), rough and finishmachining. Contact Chalco today to explore our aluminum forging solutions!

Custom shapes, sizes, and weights are available depending on your application.

Instant Quote| Forging Shape | Max Forging Size | Max Weight |

| Aluminum Ring | OD 3" to 72" (76 mm – 1,830 mm) | Up to 10,000 lbs (4,536 kg) |

| Aluminum Disc | Diameter 3" to 72" (76 mm – 1,830 mm) | Up to 15,000 lbs (6,804 kg) |

| Aluminum Block | Cross-section up to 54" (1,372 mm) | Up to 15,000 lbs (6,804 kg) |

| Aluminum Flat Bar | Width 3" to 72" (76 mm – 1,830 mm) | Up to 20,000 lbs (9,072 kg) |

| Aluminum Round Bar | OD 3" to 72" (76 mm – 1,830 mm) | Up to 20,000 lbs (9,072 kg) |

Choose the right aluminum forging alloy for your application

- 6061 forged aluminum

Excellent corrosion resistance and weldability, ideal for structural applications.

- 7075 aluminum forging

Superior strength-to-weight ratio, commonly used in aerospace and automotive industries.

- 2618 aluminum forging

High strength at elevated temperatures, perfect for aerospace and high-performance engines.

- 6063 aluminum forging

Good surface finish and corrosion resistance, suitable for architectural and decorative uses.

- 6082 aluminum forging

High strength and good machinability, widely used in transport and structural applications.

- 7079 aluminum forging

High mechanical strength with improved stress corrosion resistance.

- 2024 aluminum forging

High fatigue resistance and excellent strength, best for aerospace components.

- 7050 aluminum forging

Excellent toughness and corrosion resistance, suitable for aerospace structural parts.

- 2014 aluminum forging

High strength and good machinability, ideal for aerospace and structural parts.

- 7175 aluminum forging

Superior strength and fatigue resistance, commonly used in aircraft structural components.

- 4032 aluminum forging

High wear resistance and low thermal expansion, preferred in automotive and engine parts.

- 5456 aluminum forging

High strength and seawater resistance, perfect for shipbuilding and pressure vessels.

Looking for other aluminum forging alloys? We offer a full range of custom options — scroll down to explore more.

Instant QuoteIndustry-focused aluminum forging solutions tailored to your application

Chalco Aluminum Forging prides itself on producing high-quality aluminum forgings, particularly in the aerospace,defense, automotive and recreational motorsports sectors.

Instant QuoteAerospace forgings

Aircraft structures, rocket adapters, space frames, satellite panels, and aerospace-grade fasteners.

Runway lampshade

Helicopter sling bracket

Aircraft valve

Defense applications

Missile casings, armored vehicle frames, launch tubes, and tactical weapon components.

Weapon receiver

AR 57 upper receiver

Machine gun scope

Transportation forgings

Forged wheels, suspension arms, transmission components, and heavy vehicle linkages.

Clutch plates

Suspension parts

Automobile struts

Industrial & construction

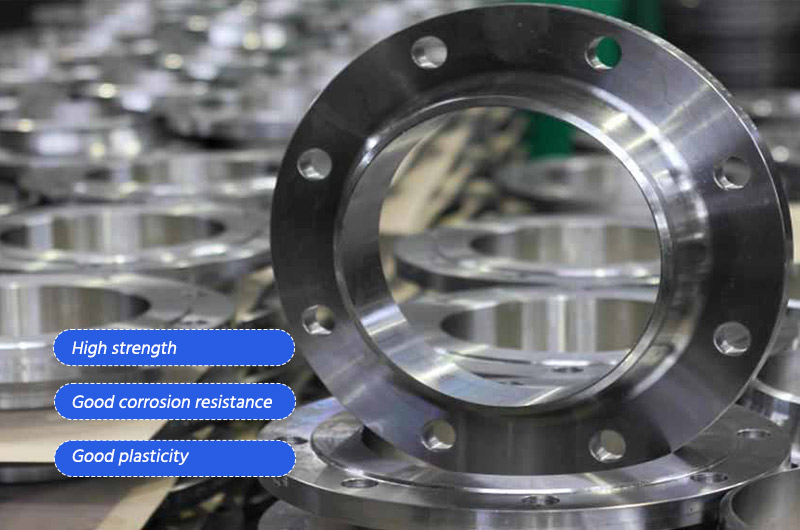

Structural connectors, load-bearing joints, brackets, and pressure equipment components.

Hammer

Big Hub

Professional

Medical & precision components

Orthopedic parts, surgical components, and precision medical-grade equipment.

Leg support

Valve

Consumer & sporting goods

Archery parts, bike frames, semiconductors, cookware, and high-performance gear.

Crossbow riser

Compound bow

Explore our full range of advanced aluminum forging processes

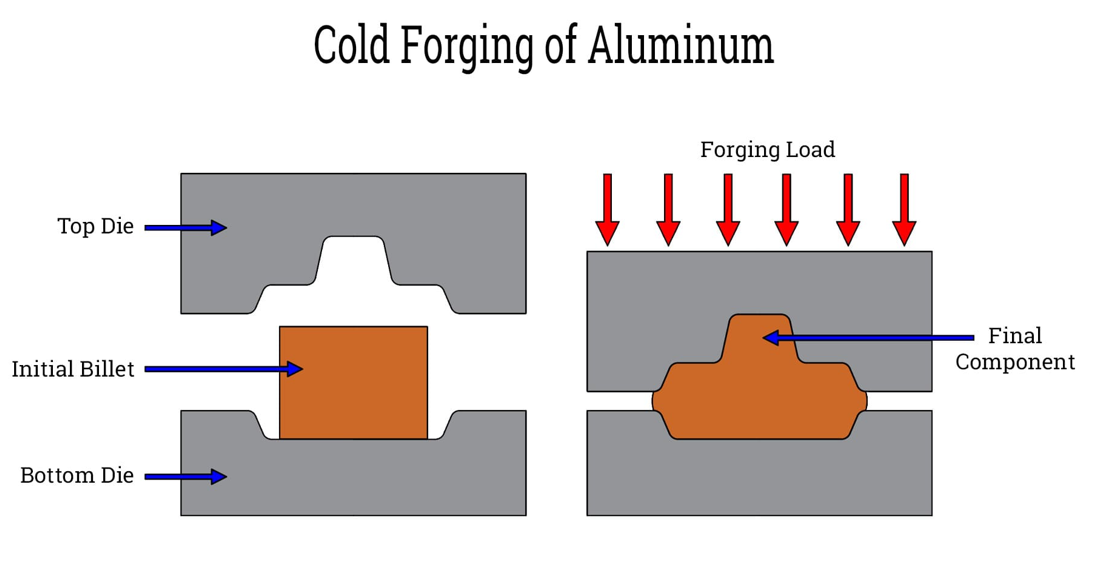

Aluminium Cold Forging

Delivers excellent dimensional accuracy, fine surface finish, and superior material utilization — idealfor high-volume precision components.

Contact us now

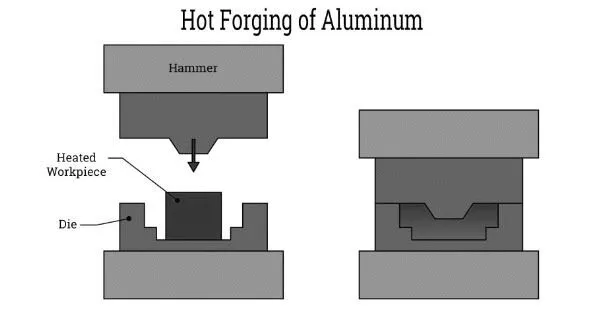

Aluminium Hot Forging

Forms complex shapes with superior strength-to-weight ratio — suitable for aerospace, automotive, andhigh-performance parts.

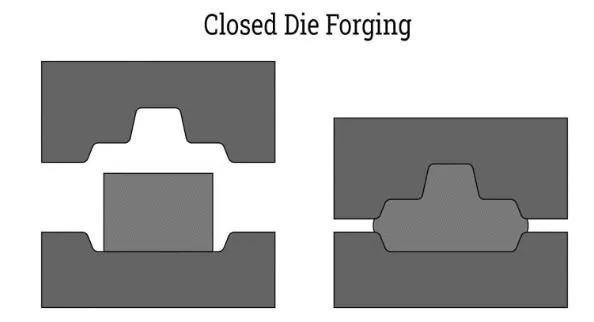

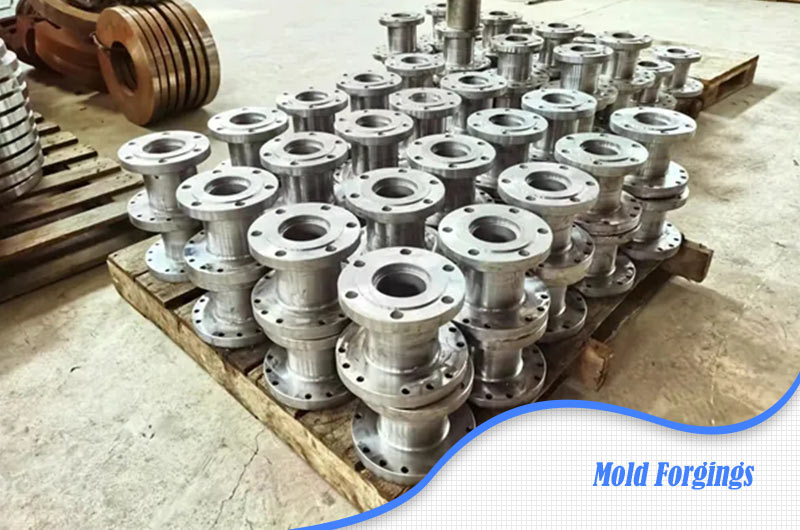

Contact us nowClosed Die Aluminum Forging

High-precision forging using tightly shaped dies — ideal for 6061, 7075, 2024 aluminum in criticalapplications.

Contact us now

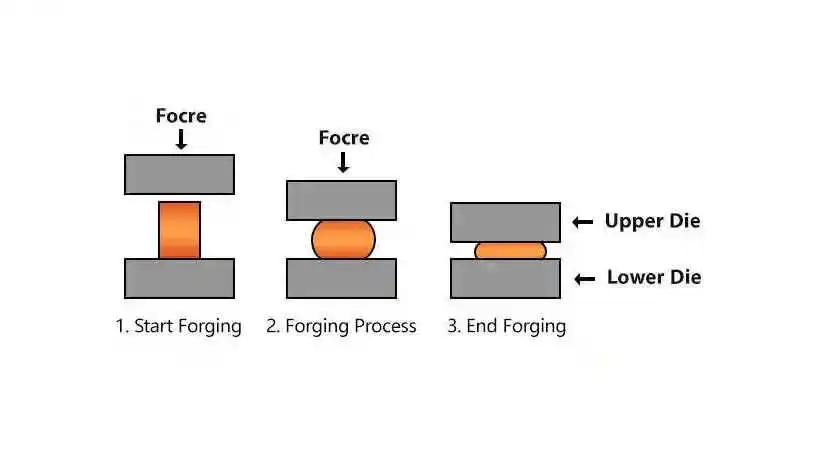

Open Die Forging

Ideal for large and simple-shaped parts with refined grain structure and improved mechanical properties.

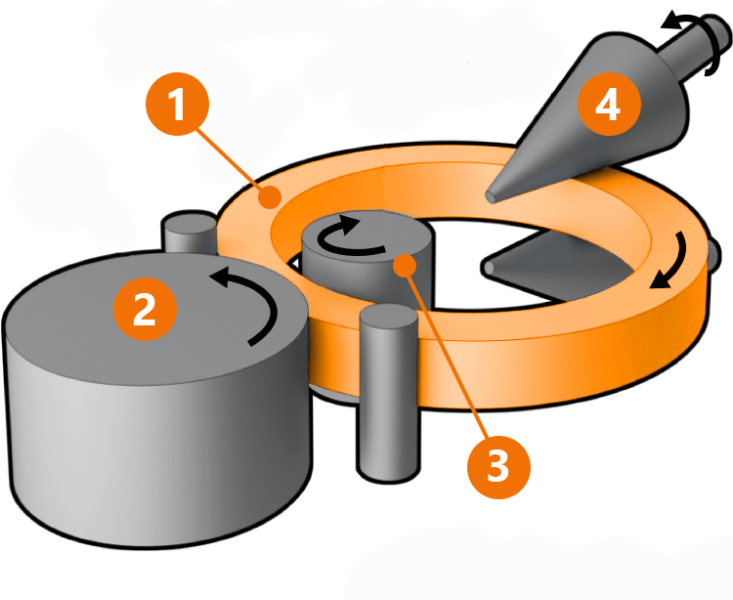

Contact us nowRing Rolling

Produces seamless aluminum rings with exceptional strength — up to Ø72 in (1828 mm) for aerospace andenergy use.

Contact us now

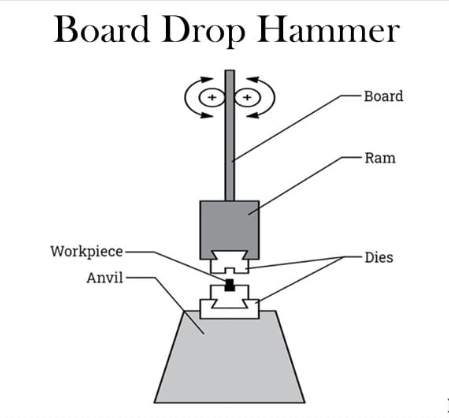

Drop Hammer Forging

High-speed forging with hammer strikes ensures fine detail and reliability — great for structural parts.

Contact us now3D Forged Aluminum

Advanced CAD-to-forging for complex geometries — from mold design to finished precision components.

Contact us now

Top benefits of forged aluminum components

- High strength-to-weight ratio

- Lightweight / Low density

- Excellent corrosion resistance

- High thermal conductivity

- Design flexibility

- Good surface finish

- High fracture toughness

- Outstanding fatigue and crack growth resistance

- Reliable cryogenic performance

Why chalco is your trusted aluminum forging manufacturer & supplier

- Certified Quality Assurance: ISO 9001:2015 and AS9100D certified – every forged part comeswith full traceability and MTCs.

- One-Stop Manufacturing: We offer forging, heat treatment, CNC machining, NDT, and custompackaging — all under one roof.

- Engineering Expertise: Our team provides alloy selection guidance, CAD support, and processoptimization tailored to your needs.

- Wide Forging Capability: From open die and closed die to ring rolling and aluminum hotforging — up to 20,000 lbs per piece.

- Proven Global Experience: We supply aluminum forgings to 48+ countries across NorthAmerica, Europe, Asia, and the Middle East.

As one of the leading aluminum forging companies, Chalco provides end-to-end solutions from die design to finalinspection.

Whether you're looking for reliable aluminum forging suppliers or high-precision aluminum forging manufacturers, weare your trusted partner for demanding industries like aerospace, automotive, and defense.

Classification of common alloys for chalco aluminum forgings

1000 series aluminum forgings

Chalco has AS9100 certification produces 1xxx aerospace aluminum forgings according to BS 5 L34, BS 2 L87, EN 573-3,AMS 4120, ASTM B247, QQ-A-367, etc. standards. 1xxx aluminum alloy mainly includes forged bars, forged rings, wheelrims and other forged products, which are used in aircraft structural parts, engine parts, hydraulic systems andother parts.

- 1200-forging

1200 aluminum alloy mainly includes forged bars, forged rings, wheel rims and other forged products,which are used in aircraft structural parts, engine parts, hydraulic systems and other parts.

Thermal conductivity Good conductivity High temperaturestability

2000 series aluminum forgings

2000 series aluminum alloys are used in many industries, including aerospace, national defense and power generation.The following are some typical 2 series alloy models for Chalco's aluminum forgings.

2A50-forging

2A70-forging

2B50-forging

2618-forging

2025-forging

2018-forging

2219-forging

2014-forging

Forging Performance

4000 series aluminum forgings

4000 series aluminum alloy forgings are mainly used to manufacture materials for pistons and cylinders of steamengines, as well as complex forgings that work below 200 ℃ and bear heavy loads.

Instant Quote- 4032-forging

4032 aluminum forgings produced according to AMS 4145, QQ-A-367 4032 standards are usually used tomanufacture forged pistons, forged compressor parts, wear-resistant parts, etc.

High strength Good wear resistance Good heat resistance

5000 series aluminum forgings

5000 series aluminum alloys are used in many industries, including various national defense departments. Thefollowing are some typical 5 series alloy models for Chalco's aluminum forgings.

6000 series aluminum forgings

6000 series aluminum alloys are used in many industries, including oil and gas, petrochemical and marine sectors.The following are some typical 6 series alloy models for Chalco's aluminum forgings.

6061 6082 Wheel Hub Forging

6a10-auto-forging

6082-auto-forging

6061-auto-forging

6a02-forging

6082-forging

6061-forging

6151-forging

Forging Performance

7000 series aluminum forgings

7000 series aluminum alloys are used in many industries, including aerospace, national defense and racing. Thefollowing are some typical 7 series alloy models for Chalco's aluminum forgings.

Instant QuoteAluminum forging process

- 1Preparation: A clean aluminum billet, sized appropriately for the final part, is prepared.

- 2Heating: The billet is heated to the optimal forging temperature (typically between 700°F and 950°F, depending on the alloy), making it soft and malleable.

- 3Forging: Sufficient force is applied using presses or hammers to shape the aluminum in stages: upsetting (widening the cross-section), drawing (extending the length), and finishing (achieving the final form).

- 4Cooling: The forged part is carefully cooled to room temperature to prevent cracking or warping, especially important for larger components.

- 5Machining & Finishing: The near-net-shape forging is then machined to achieve precise dimensions and may undergo surface treatments like polishing, anodizing, or coating for improved appearance and protection against corrosion.

For successful aluminum forging, ensure the right alloy and precise temperature control, and partner with us for optimized equipment and expert manufacturing.

Forged vs. cast aluminum vs. billet: What's the difference?

Forged Aluminum – High strength, excellent fatigue resistance, ideal for structural and load-bearing parts.

Cast Aluminum – Cost-effective, complex shapes possible, but lower strength and more internal porosity.

Aluminum Billet – Raw material (extruded or cast) used for further processing like forging or CNC machining.

- Need maximum strength and reliability? Choose forged aluminum.

- Need complex shapes at lower cost? Choose cast aluminum.

- Need base material for machining? Start with aluminum billet.

Aluminum forging FAQs

Q: Can aluminum be forged?

A: Yes. Forged aluminum offers higher strength and structural integrity than cast or machined parts. It's widelyused in aerospace, automotive, and industrial applications.

Q: What is aluminum hand forging?

A: Aluminum hand forging refers to manual, small-batch forging that allows for precise control over shape and grainflow — ideal for custom or prototype parts.

Q: Can forged aluminum be welded?

A: Yes, alloys like 6061 forged aluminum can be welded. Proper technique and post-weld treatment help maintainstrength and avoid defects.

Q: How strong is forged aluminum?

A: Very strong. It provides excellent impact resistance and is ideal for high-stress and safety-criticalapplications compared to cast parts.

Q: What is the forging temperature for aluminum?

A: Typically between 700°F and 950°F (370°C–510°C), depending on the alloy. Some may require temperatures up to1100°F (593°C).

Q: Can 6061 aluminum be forged?

A: Absolutely. 6061 is one of the most versatile forged aluminum alloys, suitable for discs, blocks, rings, andcustom shapes with excellent weldability and corrosion resistance.

Aluminum forgings related products

Explore our related offerings! Contact us for high-quality copper forgings, precision-machined parts, and reliable castings.

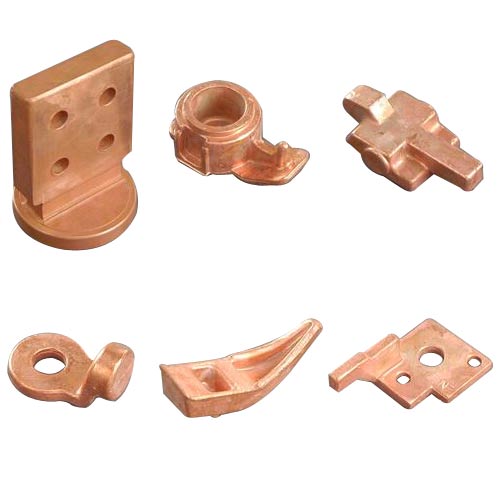

Copper Forgings

Machined Parts

Castings