6A02 aluminum alloy is an aluminum-magnesium-silicon heat-treatable and strengthened aluminum alloy with medium strength, good corrosion resistance and weldability, suitable for forging and stamping, and is often used in the manufacture of aircraft engine parts.Quick Quote

Why choose Chalco Aluminum's 6A02 aluminum forgings?

Quality could full meet world wide aviation standard

GJB 2351-2004

HB 5204-96

Production and management comply with international aviation quality system certification

AS9100

OHSAS 18001

ISO14001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

Specs of 6A02 aluminum forgings

| FORGING | TYPE | MAX. WEIGHT | MAX. DIMENSION |

| Open Die Forging | Cube | ≤9T |

Length≤7000mm, Width≤2000mm, Height≤500mm |

| Disk | ≤5T | Diameter≤2500mm | |

| Ring | ≤5T |

Outer diameter of quenching parts≤2500mm, Outer diameter of non-quenching parts≤4000mm, Height≤500mm |

|

| Cylinder | ≤5T |

Outer diameter 200-800mm, Length≤2000mm; Outer diameter 801-2000mm, Length≤1500mm; |

|

| Axle | ≤8T |

Length≤7000mm, Diameter≤800mm |

|

| Backward Extrusion | Forged Pipe |

Outer diameter≤830mm, Inner diameter≤650mm, Length≤1800mm |

|

| Closed Die Forging | Common Closed Die Forgings | - | PVA≤3.0㎡(Diameter≤1950mm) |

| Complex Closed Die Forgings | - | PVA≤1.5㎡(Diameter≤1400mm) |

Chemical composition of 6A02 aluminum alloy

| 6A02 Alloy % | |

| Si | 0.5-1.20 |

| Fe | 0.50 |

| Cu | 0.2-0.6 |

| Mn | 0.15-0.35 |

| Mg | 0.45-0.90 |

| Ni | - |

| Zn | 0.20 |

| Al | Remainder |

Mechanical property of 6A02 aluminum forgings

| Standard | GJB 2351 HN 5204 | ||

| Type | Free forgings and Die forgings | Die forgings | |

| Temper | T6 | T6 | |

| L | Rm/MPa | 275 | 295 |

| Rp0.2/MPa | - | 215 | |

| A5% | 10 | 12 | |

| LT | Rm/MPa | - | 265 |

| Rp0.2/MPa | - | - | |

| A5% | - | 4.0 | |

| ST | Rm | - | - |

| A5% | - | - | |

| HBS | 85 | 85 | |

Features of 6A02 aluminum forgings

Excellent mechanical properties: 6A02 aluminum forgings have high strength, hardness and ductility, and are suitable for working environments that withstand high strength and high strain.

Excellent corrosion resistance: 6A02 aluminum forgings can operate stably for a long time in various harsh environments, and have strong resistance to oxidation and corrosion.Quick Quote

Good processing performance: 6A02 aluminum forgings are suitable for various processing techniques, such as forging, die forging, extrusion, etc., and aluminum forgings with complex shapes can be obtained.

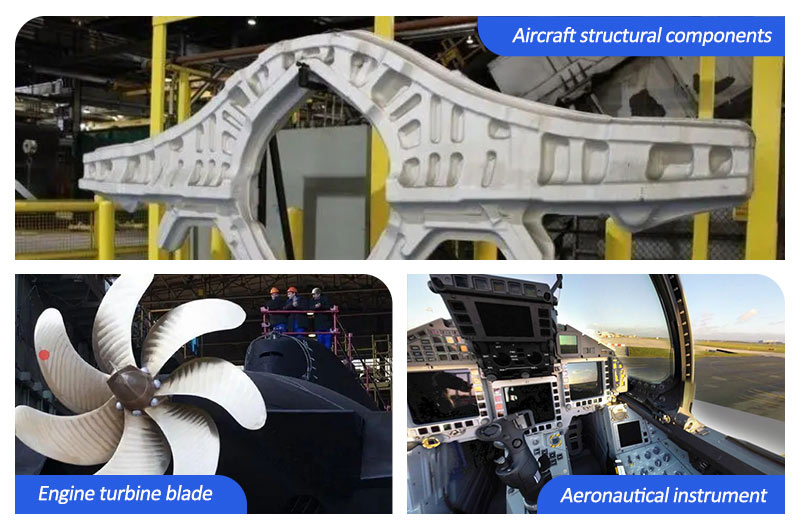

Uses of 6A02 aluminum forgings

Aircraft structural parts: 6A02 aluminum forgings are suitable for manufacturing aircraft main wings, fuselage, landing gear and other structural parts, which improves the strength and stability of the aircraft.

Aeroengine parts: 6A02 aluminum forgings are suitable for manufacturing turbines, blades, combustion chambers and other components in aeroengines, which improves the reliability and durability of the engines.Quick Quote

Aviation instruments: 6A02 aluminum forgings are suitable for manufacturing various aviation instruments, such as flight instruments, radar, navigation instruments, etc., which improves the accuracy and reliability of the instruments.

Avionics devices: 6A02 aluminum forgings are suitable for the manufacture of various avionics devices, such as aviation communication equipment, radar antennas, missile guidance systems, etc., which improves the reliability and anti-interference performance of the equipment.

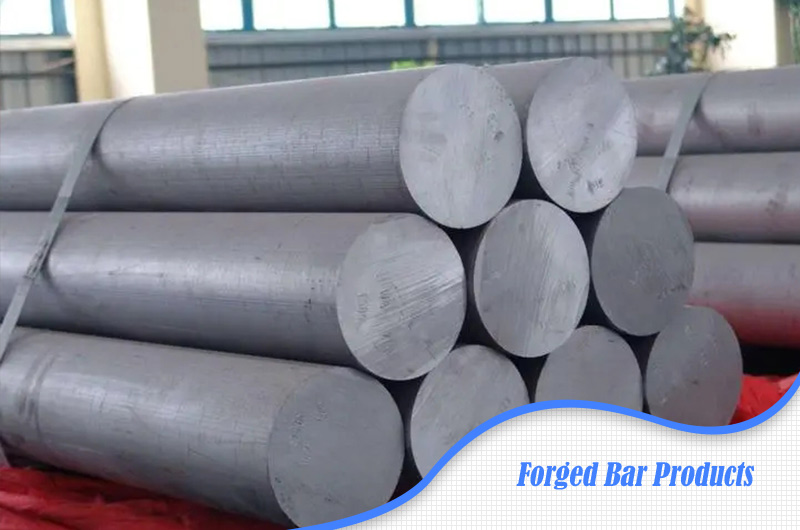

Chalco Aluminum forging product type

Our factory has special planing, cutting, heat treatment, straightening, machining and testing equipment to ensure consistent high quality and fast turnover of forged bar products. Our bar forging products are used in a variety of applications, such as aerospace, defense, infrastructure, mining, nuclear energy, oil and gas, heavy industrial equipment and power generation.Quick Quote

-

Forging block

Forging blockOur custom forged block, not only allow for a near-net shape, but they also have inherent advantages achieved through the forging process.

High Strength Precision Shapes Improved Material Properties -

Forged bar products

Forged bar productsOur factory has special planing, cutting, heat treatment, straightening, machining and testing equipment to ensure consistent high quality and fast turnover of forged bar products.

High Strength Good processability Good mechanical properties -

Forged aluminum pipe

Forged aluminum pipeForged aluminum tubes can not only be produced into straight cylindrical shape, but also have an infinitely variable outer diameter and inner diameter. We also provide various wall thicknesses and configurations to meet customer requirements.

High Strength Corrosion resistance Exact dimensions -

Forged aluminum ring

Forged aluminum ringWhen purchasing hubs and spindles, product integrity is critical often making or breaking a part in the field. Machined castings or hot-rolled machined bars tend to have poor structural integrity or inclusions that lead to problems with cracking and part failure.

High Strength High precision Good internal quality -

Hub and tool forgings

Hub and tool forgingsWhen purchasing hubs and spindles, product integrity is critical. Machined castings or hot rolled bars often have poor structural integrity or inclusions, leading to cracking and part failure.

High Strength Lightweight Good heat dissipation -

Forged step shafts, crankshafts and rotor shafts

Forged step shafts, crankshafts and rotor shaftsOur years of custom forging expertise allow us to manufacture custom forged crankshafts to meet the most exacting specifications. At Chalco, we produce guaranteed sound-centered forged step shafts, crankshafts and rotor shafts with any combination of round, square, rectangle or polygonal dimensions, concentric or eccentric configurations and tapers or custom shapes.

High strength and stiffness good mechanical properties High reliability

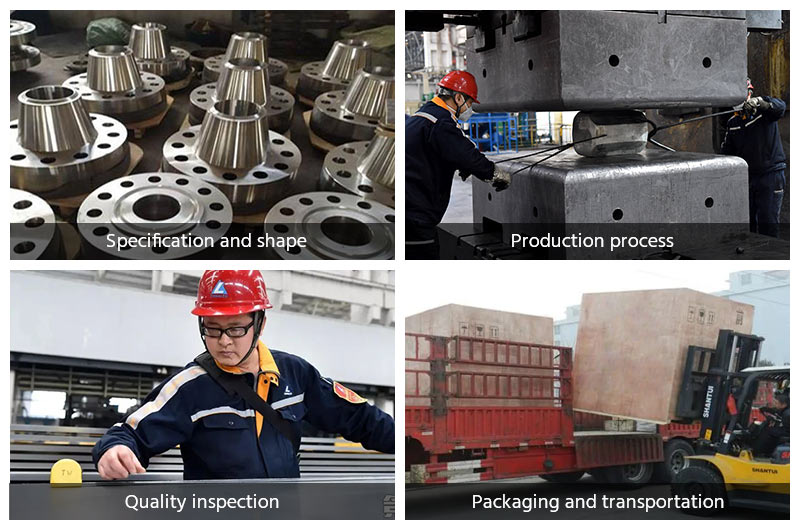

What precautions should be taken when purchasing 6A02 aluminum forgings?

When purchasing 6A02 aluminum forgings, you need to pay attention to the following points:

Choose a reputable supplier: purchasing aluminum forgings is an important investment, and it is crucial to choose a reputable supplier with production experience.

Determine the specifications and quality standards of aluminum forgings: before purchasing aluminum forgings, it is necessary to determine the size, weight and quality standards of the forgings to ensure that the forgings meet the use requirements.

Check the appearance and quality of forgings: before purchasing aluminum forgings, it is necessary to check the appearance of forgings, including whether the surface is smooth, free of cracks, bubbles and other defects. At the same time, it is necessary to check whether the performance indicators such as hardness, strength, and ductility of the forging meet the quality standards.Quick Quote

Consider the subsequent processing of aluminum forgings: if further processing of aluminum forgings is required, the processing performance and forming ability of the forgings need to be considered to ensure the processing effect and quality.

Pay attention to the storage and transportation of aluminum forgings: aluminum forgings need to be properly stored and transported to avoid damage or contamination of forgings, which will affect their quality and performance.

In short, before purchasing 6A02 aluminum forgings, it is necessary to conduct sufficient research and comparison, select a suitable supplier, and strictly follow the quality standards for inspection and acceptance to ensure the quality and reliability of forgings.