Chalco specializes in supplying 6061 aluminum alloy sheets (6–350mm and above), focusing on applications requiring high strength and extra thickness. For thicker sheets, starting from 30mm , we can reliably supply products in the 30–350mm range.

- In the T6 condition, it is available in thicknesses up to 350mm, offering excellent hardenability to meet the requirements of heavy-duty structures and high-performance applications. Click to check [stock]

- In the T651 condition, thicknesses up to 260mm can be supplied. Stress relief through stretching ensures excellent dimensional stability of thick plates during CNC machining. Click to check [stock]

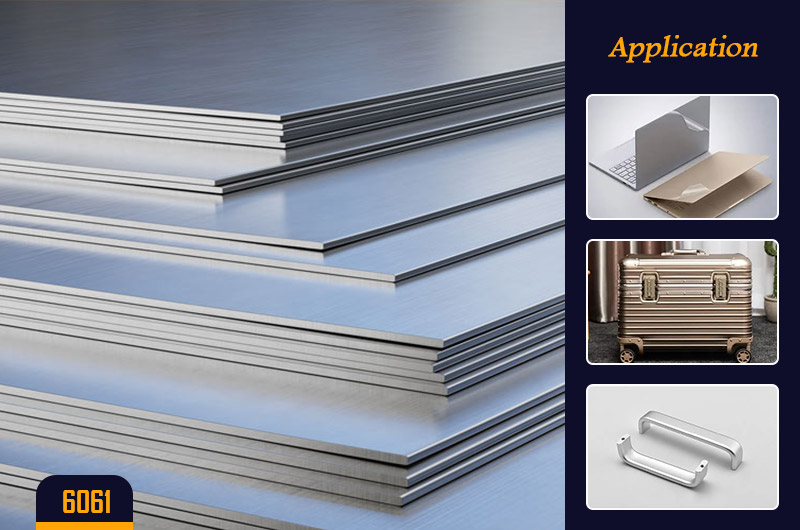

Leveraging its readily available inventory and rapid delivery capabilities, Chalco's 6061 thick plate is widely used in tooling fixtures, precision jigs, mold base plates, aerospace structural components, and ship parts.

Overview of Chalco 6061, T6, and T651 aluminum sheet thickness range

Chalco can supply 6061 T6 / T651 aluminum alloy plates, with thicknesses ranging from 30–350mm, as detailed below:

| Thickness range (mm) | Thickness range (inches) | Width (mm) | Length (mm) | Remark |

| 30–50 mm | 1.18''–1.97'' | 1000–2500 | 2000–6000 | We keep stock on hand and can cut to size. |

| 50–150 mm | 1.97''–5.90'' | 1000–2500 | 2000–6000 | Mainly T651, with large inventory. |

| 150–260 mm | 5.90''–10.24'' | 1000–2500 | 2000–6000 | T651, Customized + Some Stock |

| 260–350 mm | 10.24''–13.78'' | 1000–2500 | 2000–6000 | T6 is available up to 350mm or larger. |

Available Product Types of 6061 Aluminum Plates & Blocks

Rolled 6061 T6/T651 Thick Plate

Standard rolled plates in 30–350 mm thickness, suitable for molds, structural parts, and precision components.

6061 Tooling Plate & Machining Block

Stress-relieved, high-flatness plates and blocks designed for fixtures, jigs, and precision machining.

Forged 6061 Al Plate & Block

High-density forged material offering superior internal integrity for demanding structural and machining applications.

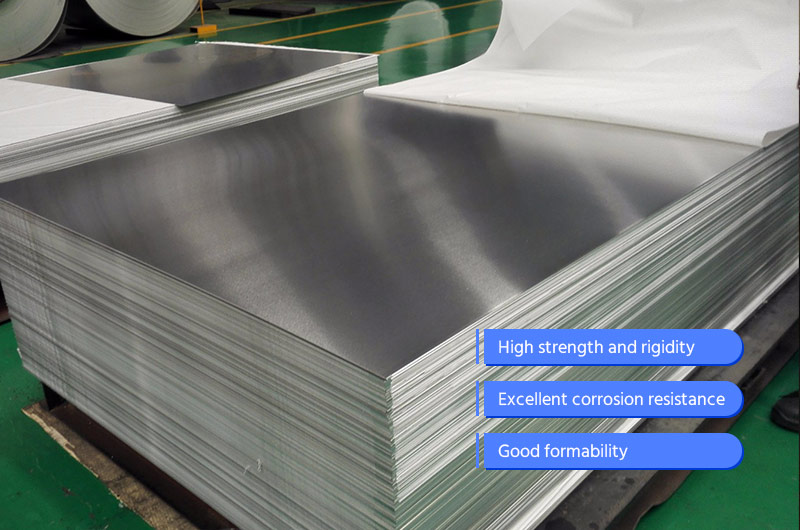

Product Advantages of 6061 T6/T651 Aluminum Plates

Chalco supplies 6061 thick plates (≥30 mm) engineered for high stability, large-size capability, and reliable machining performance. Key advantages include:

Excellent stability: T651 plates are fully stress-relieved, minimizing deformation during CNC deep-cavity machining.

Extra-thick capability: T6 plates are available up to 350 mm and beyond, covering heavy-duty structural and mold applications.

Machining-friendly: High cutting efficiency and predictable machining behavior for tooling, molds, and precision components.

Quality assurance: Compliant with ASTM/EN/GB standards, with available EN 10204 3.1 reports and ultrasonic testing.

Reliable supply: Popular thicknesses (30/50/100/150/200 mm) kept in ready stock with fast cutting and delivery support.

6061 T6 vs T651 — Differences & Selection Guide

Heat treatment: Both 6061 T6 and 6061 T651 undergo solution heat treatment and artificial aging. The key difference is that T651 is stretched after aging to remove residual stress and improve dimensional stability.

Residual stress: 6061 T6 retains more internal stress, especially in thicker sections, which may cause movement during deep-cavity or heavy material-removal machining. 6061 T651 is specifically stress-relieved to minimize deformation during CNC processing.

Mechanical properties: 6061 T651 generally offers slightly higher yield strength and more predictable machining behavior, making it preferred for precision tooling and mold applications.

Flatness & machining performance: T651 maintains better surface flatness and dimensional stability when machining pockets, slots, or large flat surfaces, while T6 may require additional stress-relief steps for critical machining.

Thickness capability: 6061 T6 can be supplied in greater thicknesses (up to 350 mm or more), whereas stretching limitations typically restrict 6061 T651 to around 260 mm.

- Choose T6 when:

- Very large or ultra-thick sections (≥260 mm) are required

- Higher structural strength across the whole plate is needed

- The part does not involve heavy pocketing or deep material removal

- Cost efficiency for large sections is a priority

- Choose T651 when:

- Deep-cavity or high-material-removal CNC machining is required

- Dimensional stability and minimum distortion are critical

- Used for molds, fixtures, tooling plates, or precision jigs

- A stress-relieved condition is needed to avoid movement during machining

In summary, 6061 T6 provides higher strength and supports greater thickness capability, making it suitable for large or ultra-thick structural applications. 6061 T651 offers superior dimensional stability and is the preferred option for CNC machining, molds, fixtures, and tooling plates.

Each temper meets different performance and processing requirements. If you need assistance selecting the most suitable temper for your project, our team can provide guidance based on your application needs.

Application scenarios for 6061 T6/T651 aluminum plates (30–350mm)

Chalco supplies 6061 T6/T651 aluminum alloy plates (≥30mm) in various thickness ranges to meet diverse needs, from tooling and fixtures to aerospace and marine structures.

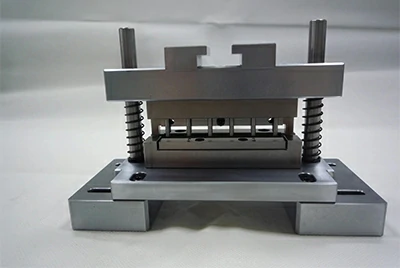

30–50mm: Tooling Fixtures and Precision Jigs

Suitable for CNC reference plates and fixture bases. Both T6 and T651 available, with T651 providing higher stability in deep cavity machining.

Chalco offers precision cutting and milling, delivering ready-to-use tooling plates.

50–150mm: Mold Base Plates and Die Casting Molds

Used for injection, die casting, and stamping molds. T651 ensures stability and durability after large-size machining.

Chalco provides pre-processing and flaw detection to speed up mold setup.

150–260mm: Aerospace Tooling and Structural Parts

Ideal for aerospace tooling, ship decks, and large machinery. T651 plates feature excellent stress relief for high-precision applications.

Chalco offers 100% UT inspection, cutting, and five-sided milling to meet aerospace and marine standards.

260–350mm (and above): Extra-Thick Plates

For large molds, heavy equipment, and special structures. T6 available up to 350mm or more (400mm subject to performance confirmation).

Chalco supports ultra-thick plate customization, deep heat treatment, and large-size pre-processing.

Chalco can help you with ultra-thick plate customization, deep heat treatment, and large-size pre-processing, so you don't have to worry about special requirements.

To learn more about our solutions for thick plates in different alloys and thickness ranges, please visit our aluminum alloy thick plate product overview or contact us directly for a customized quote.

6061 T6/T651 Aluminum Plate Technical Specifications

For 6061 aluminum thick plates (≥150–200 mm), several technical factors become increasingly important when evaluating material performance for structural and machining-intensive applications:

- Center-zone mechanical performance: Thick sections may show variation between surface and core properties; verifying mid-thickness strength ensures compliance with minimum requirements.

- Hardenability of thick sections: As plate thickness increases, full through-hardening becomes more challenging. Ultra-thick sizes (≥250–350 mm) may require application-specific review.

- Residual stress behavior: Internal stress distribution differs significantly in thick plates. T651 temper provides improved stability during heavy machining.

- Ultrasonic integrity of the core: Center-focused UT scanning is recommended for critical tooling, aerospace fixtures, and large machined parts to ensure internal soundness.

- Machining response of thick sections: Deep-cavity milling, heavy material removal, and 5-axis machining can amplify stress-release movement if the temper is not properly selected (T651 preferred).

The following technical tables summarize the standard size ranges, chemical composition, mechanical properties, and dimensional tolerances for Chalco 6061 T6/T651 aluminum thick plates.

| Size range (custom cuts available) | |||

| Thickness (mm) | Width (mm) | Length (mm) | Remark |

| 30–350 | 1000–2500 | 2000–6000 | Custom cutting to lengths is available upon request, with maximum thicknesses up to 350 mm for T6 and 260 mm for T651. |

| Chemical composition (typical values, wt%) | |||

| Si | Fe | Cu | Mn |

| 0.4–0.8 | ≤0.7 | 0.15–0.4 | ≤0.15 |

| Mechanical properties (typical values) | |||

| Temper | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) |

| T6 | ≥ 290 | ≥ 240 | ≥ 8 |

| T651 | ≥ 310 | ≥ 276 | ≥ 10 |

| Dimensional Tolerances for 6061 Thick Plates | |||

| Parameter | Typical Tolerance | Standard | Notes |

| Thickness tolerance | ±0.20–0.40 mm (depending on thickness range) | ASTM B209 | Tighter tolerances available upon request. |

| Width tolerance | ±2–3 mm | ASTM / EN | Varies with plate width and production route. |

| Length tolerance | ±3–4 mm | ASTM / EN | Applicable for standard cut-to-length plates. |

| Flatness tolerance | 0.8–1.5 mm per meter | Internal standard | Milled plates and tooling plates offer improved flatness. |

| Ultrasonic testing | Class A (or per customer requirement) | ASTM B594 | Full-surface or center-zone UT available. |

All thick plates are available with EN 10204 3.1 material certificates and ultrasonic testing reports (UT per ASTM B594), meeting the quality requirements of the aerospace, marine, and mold industries.

For special dimensions or performance parameters, please contact our technical team for customized solutions.

Chalco 6061 T6 T651 aluminum plate production and processing capabilities

Chalco not only supplies thick aluminum alloy plates, but also provides one-stop processing services to help you reduce outsourcing and speed up project delivery.

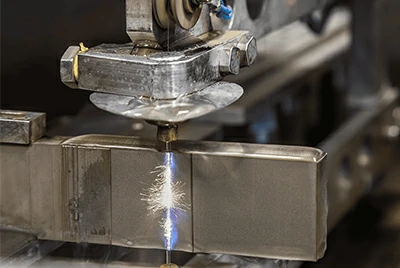

Precision cutting: sawing, waterjet cutting, CNC blanking, with dimensions controllable to ±0.1 mm.

Heat treatment capability: full range of T tempers (T6, T651, T652), stress relief, and improved dimensional stability.

Surface finishing: milling, planing, and large five-sided machining to ensure flatness and allowance for subsequent machining. To meet different machining and tooling requirements, multiple surface conditions are available:

- Saw-cut surface: economical option with natural saw texture; suitable for general structural use.

- Milled surface (one side / two sides): improved flatness and parallelism, ideal for tooling plates and CNC pre-machining.

- Flatness control: enhanced flatness available for mold bases and precision fixtures; values depend on thickness and plate size.

- Machining allowance: customizable positive allowance for subsequent finishing operations.

Ultrasonic testing: compliant with ASTM B594 / AMS-STD-2154 standards—ensuring aerospace and marine-grade quality.

Customized machining: drilling, grooving, and pre-processing of fixture base plates shorten the cycle time for customers' subsequent processes.

Large-size processing capability: width up to 3500 mm and length up to 38000 mm, meeting the needs of large molds and heavy-duty structures.

Documentation and Certification: We provide EN 10204 3.1 material reports, which can be accompanied by third-party SGS/TÜV/BV testing, ensuring complete traceability.

Choosing Chalco means buying more than just aluminum sheets; it means getting a ready-to-use solution – saving you time, reducing costs, and meeting stringent industry standards. Contact us for your customized sheet metal processing solution.

Alternative Aluminum Grades for Thick Plate Applications

6082 T651 Aluminum Plate

Higher-strength structural alloy used in machinery, transport, and load-bearing parts; common 6061 alternative in Europe.

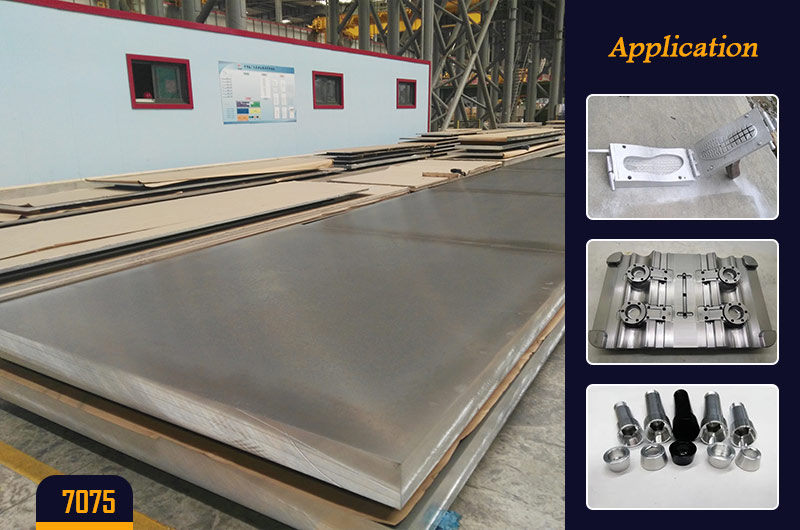

7075 T651 High-Strength Plate

Aerospace-grade alloy with outstanding strength and fatigue resistance; preferred when 6061 strength is insufficient.

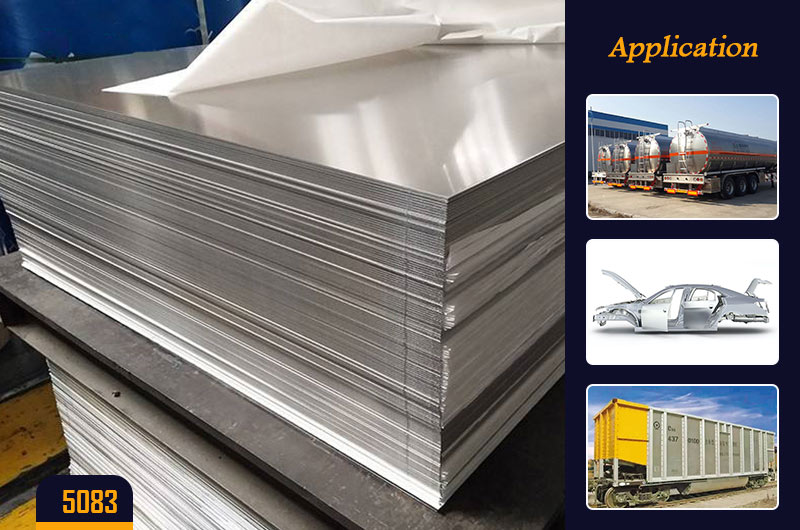

5083 High-Mg Aluminum Plate

Excellent corrosion resistance and weldability for pressure vessels, aerospace structures, and demanding environments.

5086 Aluminum Plate

Higher corrosion resistance and strength than 5083; suited for welded structures and offshore/heavy-duty applications.

Cast Tooling Plate (MIC-6 / ALCA5)

Ultra-flat, stress-relieved plate for jigs, fixtures, CNC bases, and precision machining requiring high stability.

6063 Aluminum Plate

Lower-strength but highly formable alloy for architectural parts and applications emphasizing surface quality.

Chalco 6061 T6 aluminum sheet in stock

Popular sizes available for immediate shipment.

- 30 / 40 / 50 / 100 / 150 mm

- Sizes of the entire series are available and updated in real time.

| Thickness T/in | Dimensions W × L (in) | weight Lbs | Weight (kg) | Thickness T/mm | Dimensions W×L (mm) |

| 1.181 | 59.055×118.110 | 803.585 | 364.500 | 30 | 1500×3000 |

| 1.260 | 59.055×118.110 | 857.157 | 388.800 | 32 | 1500×3000 |

| 1.378 | 59.055×118.110 | 937.516 | 425.250 | 35 | 1500×3000 |

| 1.575 | 59.055×118.110 | 1071.447 | 486.000 | 40 | 1500×3000 |

| 1.772 | 59.055×118.110 | 1205.377 | 546.750 | 45 | 1500×3000 |

| 1.969 | 59.055×118.110 | 1339.308 | 607.500 | 50 | 1500×3000 |

| 2.165 | 59.055×118.110 | 1473.239 | 668.250 | 55 | 1500×3000 |

| 2.362 | 59.055×118.110 | 1607.170 | 729.000 | 60 | 1500×3000 |

| 2.559 | 59.055×118.110 | 1741.101 | 789.750 | 65 | 1500×3000 |

| 2.756 | 59.055×118.110 | 1875.032 | 850.500 | 70 | 1500×3000 |

| 2.953 | 59.055×118.110 | 2008.962 | 911.250 | 75 | 1500×3000 |

| 3.150 | 59.055×118.110 | 2142.893 | 972.000 | 80 | 1500×3000 |

| 3.346 | 59.055×118.110 | 2276.824 | 1032.750 | 85 | 1500×3000 |

| 3.543 | 59.055×118.110 | 2410.755 | 1093.500 | 90 | 1500×3000 |

| 3.740 | 59.055×118.110 | 2544.686 | 1154.250 | 95 | 1500×3000 |

| 3.937 | 59.055×118.110 | 2678.616 | 1215.000 | 100 | 1500×3000 |

| 4.134 | 59.055×118.110 | 2812.547 | 1275.750 | 105 | 1500×3000 |

| 4.331 | 59.055×118.110 | 2946.478 | 1336.500 | 110 | 1500×3000 |

| 4.528 | 59.055×118.110 | 3080.409 | 1397.250 | 115 | 1500×3000 |

| 4.724 | 59.055×118.110 | 3214.340 | 1458.000 | 120 | 1500×3000 |

| 4.921 | 59.055×118.110 | 3348.271 | 1518.750 | 125 | 1500×3000 |

| 5.118 | 59.055×118.110 | 3482.201 | 1579.500 | 130 | 1500×3000 |

| 5.315 | 59.055×118.110 | 3616.132 | 1640.250 | 135 | 1500×3000 |

| 5.512 | 59.055×118.110 | 3750.063 | 1701.000 | 140 | 1500×3000 |

| 5.709 | 59.055×118.110 | 3883.994 | 1761.750 | 145 | 1500×3000 |

| 5.906 | 59.055×118.110 | 4017.925 | 1822.500 | 150 | 1500×3000 |

| 6.102 | 59.055×118.110 | 4151.856 | 1883.250 | 155 | 1500×3000 |

| 6.299 | 59.055×118.110 | 4285.786 | 1944.000 | 160 | 1500×3000 |

| 6.496 | 59.055×118.110 | 4419.717 | 2004.750 | 165 | 1500×3000 |

| 6.693 | 59.055×118.110 | 4553.648 | 2065.500 | 170 | 1500×3000 |

| 6.890 | 59.055×118.110 | 4687.579 | 2126.250 | 175 | 1500×3000 |

| 7.087 | 59.055×118.110 | 4821.510 | 2187.000 | 180 | 1500×3000 |

| 7.480 | 59.055×118.110 | 5089.371 | 2308.500 | 190 | 1500×3000 |

| 7.677 | 59.055×118.110 | 5223.302 | 2369.250 | 195 | 1500×3000 |

| 7.874 | 59.055×118.110 | 5357.233 | 2430.000 | 200 | 1500×3000 |

| 8.268 | 59.055×118.110 | 5625.095 | 2551.500 | 210 | 1500×3000 |

| 8.661 | 59.055×118.110 | 5892.956 | 2673.000 | 220 | 1500×3000 |

| 9.055 | 59.055×118.110 | 6160.818 | 2794.500 | 230 | 1500×3000 |

| 9.449 | 59.055×118.110 | 6428.680 | 2916.000 | 240 | 1500×3000 |

| 9.843 | 59.055×118.110 | 6696.541 | 3037.500 | 250 | 1500×3000 |

| 10.236 | 59.055×118.110 | 6964.403 | 3159.000 | 260 | 1500×3000 |

| 10.630 | 59.055×118.110 | 7232.265 | 3280.500 | 270 | 1500×3000 |

| 11.024 | 59.055×118.110 | 7500.126 | 3402.000 | 280 | 1500×3000 |

| 11.417 | 59.055×118.110 | 7767.988 | 3523.500 | 290 | 1500×3000 |

| 11.811 | 59.055×118.110 | 8035.849 | 3645.000 | 300 | 1500×3000 |

| 12.205 | 59.055×118.110 | 8303.711 | 3766.500 | 310 | 1500×3000 |

| 12.598 | 59.055×118.110 | 8571.573 | 3888.000 | 320 | 1500×3000 |

| 12.992 | 59.055×118.110 | 8839.434 | 4009.500 | 330 | 1500×3000 |

| 13.386 | 59.055×118.110 | 9107.296 | 4131.000 | 340 | 1500×3000 |

| 13.780 | 59.055×118.110 | 9375.158 | 4252.500 | 350 | 1500×3000 |

| 14.173 | 59.055×118.110 | 9643.019 | 4374.000 | 360 | 1500×3000 |

| 14.567 | 59.055×118.110 | 9910.881 | 4495.500 | 370 | 1500×3000 |

| 14.961 | 59.055×118.110 | 10178.743 | 4617.000 | 380 | 1500×3000 |

| 15.354 | 59.055×118.110 | 10446.604 | 4738.500 | 390 | 1500×3000 |

| 15.748 | 59.055×118.110 | 10714.466 | 4860.000 | 400 | 1500×3000 |

Chalco 6061 T651 aluminum sheet in stock

Popular sizes available for immediate shipment.

- 30 / 50 / 100 / 150 mm

- Sizes of the entire series are available and updated in real time.

| Thickness T/in | Dimensions W × L (in) | weight Lbs | Weight (kg) | Thickness T/mm | Dimensions W×L (mm) |

| 1.181 | 59.055×118.110 | 803.585 | 364.500 | 30 | 1500×3000 |

| 1.260 | 59.055×118.110 | 857.157 | 388.800 | 32 | 1500×3000 |

| 1.378 | 59.055×118.110 | 937.516 | 425.250 | 35 | 1500×3000 |

| 1.575 | 59.055×118.110 | 1071.447 | 486.000 | 40 | 1500×3000 |

| 1.772 | 59.055×118.110 | 1205.377 | 546.750 | 45 | 1500×3000 |

| 1.969 | 59.055×118.110 | 1339.308 | 607.500 | 50 | 1500×3000 |

| 2.165 | 59.055×118.110 | 1473.239 | 668.250 | 55 | 1500×3000 |

| 2.362 | 59.055×118.110 | 1607.170 | 729.000 | 60 | 1500×3000 |

| 2.559 | 59.055×118.110 | 1741.101 | 789.750 | 65 | 1500×3000 |

| 2.756 | 59.055×118.110 | 1875.032 | 850.500 | 70 | 1500×3000 |

| 2.953 | 59.055×118.110 | 2008.962 | 911.250 | 75 | 1500×3000 |

| 3.150 | 59.055×118.110 | 2142.893 | 972.000 | 80 | 1500×3000 |

| 3.346 | 59.055×118.110 | 2276.824 | 1032.750 | 85 | 1500×3000 |

| 3.543 | 59.055×118.110 | 2410.755 | 1093.500 | 90 | 1500×3000 |

| 3.740 | 59.055×118.110 | 2544.686 | 1154.250 | 95 | 1500×3000 |

| 3.937 | 59.055×118.110 | 2678.616 | 1215.000 | 100 | 1500×3000 |

| 4.134 | 59.055×118.110 | 2812.547 | 1275.750 | 105 | 1500×3000 |

| 4.331 | 59.055×118.110 | 2946.478 | 1336.500 | 110 | 1500×3000 |

| 4.528 | 59.055×118.110 | 3080.409 | 1397.250 | 115 | 1500×3000 |

| 4.724 | 59.055×118.110 | 3214.340 | 1458.000 | 120 | 1500×3000 |

| 4.921 | 59.055×118.110 | 3348.271 | 1518.750 | 125 | 1500×3000 |

| 5.118 | 59.055×118.110 | 3482.201 | 1579.500 | 130 | 1500×3000 |

| 5.315 | 59.055×118.110 | 3616.132 | 1640.250 | 135 | 1500×3000 |

| 5.512 | 59.055×118.110 | 3750.063 | 1701.000 | 140 | 1500×3000 |

| 5.709 | 59.055×118.110 | 3883.994 | 1761.750 | 145 | 1500×3000 |

| 5.906 | 59.055×118.110 | 4017.925 | 1822.500 | 150 | 1500×3000 |

| 6.102 | 59.055×118.110 | 4151.856 | 1883.250 | 155 | 1500×3000 |

| 6.299 | 59.055×118.110 | 4285.786 | 1944.000 | 160 | 1500×3000 |

| 6.496 | 59.055×118.110 | 4419.717 | 2004.750 | 165 | 1500×3000 |

| 6.693 | 59.055×118.110 | 4553.648 | 2065.500 | 170 | 1500×3000 |

| 6.890 | 59.055×118.110 | 4687.579 | 2126.250 | 175 | 1500×3000 |

| 7.087 | 59.055×118.110 | 4821.510 | 2187.000 | 180 | 1500×3000 |

| 7.480 | 59.055×118.110 | 5089.371 | 2308.500 | 190 | 1500×3000 |

| 7.677 | 59.055×118.110 | 5223.302 | 2369.250 | 195 | 1500×3000 |

| 7.874 | 59.055×118.110 | 5357.233 | 2430.000 | 200 | 1500×3000 |

| 8.268 | 59.055×118.110 | 5625.095 | 2551.500 | 210 | 1500×3000 |

| 8.661 | 59.055×118.110 | 5892.956 | 2673.000 | 220 | 1500×3000 |

| 9.055 | 59.055×118.110 | 6160.818 | 2794.500 | 230 | 1500×3000 |

| 9.449 | 59.055×118.110 | 6428.680 | 2916.000 | 240 | 1500×3000 |

| 9.843 | 59.055×118.110 | 6696.541 | 3037.500 | 250 | 1500×3000 |

| 10.236 | 59.055×118.110 | 6964.403 | 3159.000 | 260 | 1500×3000 |

Contact Chalco

In addition to thick plates, Chalco maintains large inventories of 6061 aluminum coil, 6061 aluminum bar, round bar, and 6061 aluminum tube. For 6061 extrusions and 6061 forgings, we offer a wide range of existing dies and support rapid customized production to meet project-specific shapes and dimensions. Additional 6061 products such as 6061 wire, aluminum slugs, 6061 tooling plate, 6061-T6 plate, and aerospace-grade 6061 sheet ensure comprehensive supply capability across machining, mold making, structural parts, and aerospace applications.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote