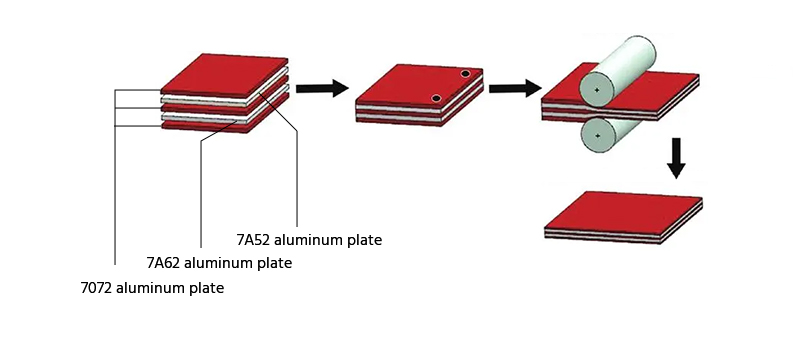

Chalco pioneered the layered composite technology of aluminum armor plates to meet the different performance requirements of different application environments and parts of use. By using hot rolling composite method, 7072 7A52 7A62 aluminum alloy plates were overlaid and heated. Pressure was applied at a certain amount to produce 5-layer, 7-layer, and 9-layer composite aluminum alloy plates.

Composite aluminum plates are commonly used in military and armor fields, ensuring that military armor plates have the maximum hardness, ductility, explosion-proof performance, and impact resistance at the lightest weight.Quick Quote

Specification of Chalco armored vehicle composite aluminum plate

| Type | Composite material alloy | Layer | Thickness mm | Common specification mm |

| Chalco-5 | 7072/7A52/7072/7A62/7072 | 5 | 18, 20, 21, 25, 30 | 1500×5000 |

| Chalco-7 | 7072/7A52/7072/7A52/7072/7A62/7072 | 7 | 25 | 1500×5000 |

| Chalco-9 | 7072/7A52/7072/7A52/7072/7A62/7072/7A62/7072 | 9 | 35, 40 | 1500×5000 |

Performance parameters of Chalco aluminum armor plate product

| Alloy | Tensile strength MPa | Yield strength MPa | Elongation % | Shear strength | Impact strength at high strain rates (3000-5000/s) |

| 7072 aluminum plate | 260-330 | 160-220 | 12-18 | - | - |

| 7A52 aluminum plate | ≥410 MPa | ≥345 MPa | ≥7 | - | - |

| 7A62 aluminum plate | 380-450 | 340-400 | 6-10 | - | - |

| Composite plate | ≥581MPa | ≥530MPa | ≥9.5% | ≥107MPa | ≥792MPa |

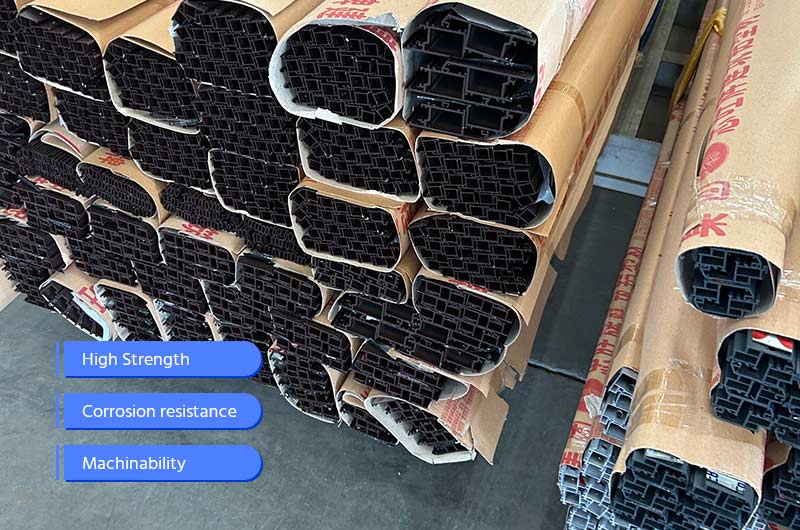

Chalco hot selling armored plate products

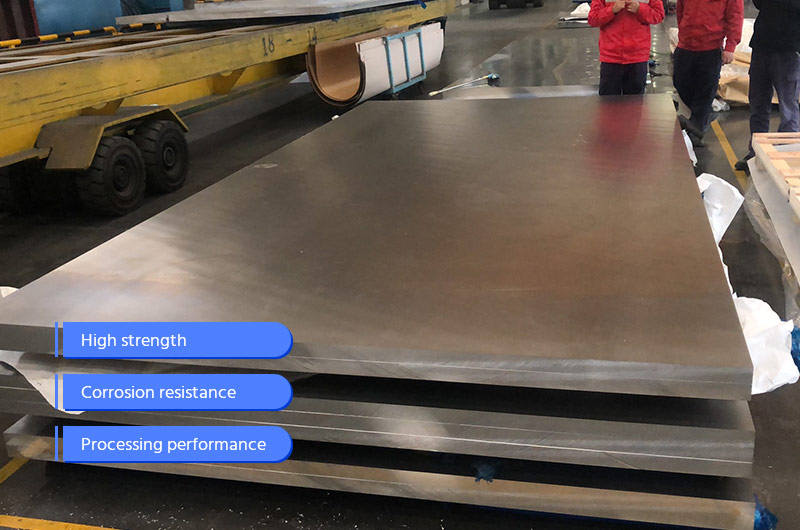

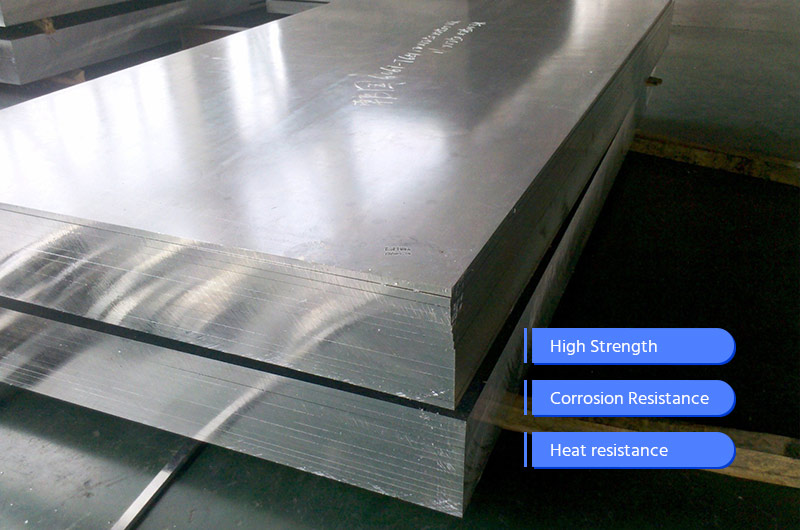

High-strength aluminum alloy, typically exhibiting excellent tensile strength and corrosion resistance.Commonly used in armored vehicles for body and chassis, providing good ballistic performance and structural strength.

Contact us now

Good corrosion resistance and weldability, along with moderate tensile strength and ductility, utilized in naval vessels for armor plates and structural components.

Contact us nowHigh-hardness aluminum alloy with good modulus of elasticity and impact resistance, employed in light armored vehicles for armor plates and protective components.

Contact us now

Maintains strength while providing high ductility, offering excellent energy absorption capabilities. Commonly used in armored vehicle floors and side armor.

Contact us nowUltra-high-strength aluminum alloy, known for its outstanding penetration resistance and ballistic performance.

Contact us now

Renowned for its exceptional strength and toughness, offering superior blast protection and durability.

Contact us nowProperty advantage of Chalco composite armor plate

- The protection coefficient of composite armor is significantly higher than that of homogeneous armor, so its mass is smaller than that of homogeneous armor under the same bulletproof ability.

- The thickness coefficient of composite armor against armor piercing shells is higher than that of homogeneous armor, so its thickness is smaller than that of homogeneous armor under the same bulletproof ability.

- Composite armor has designability and can be designed with various performance, quality, and thickness according to different needs and combat environments to meet the requirements of different applications.

Composite armor with layered composite structures has become an indispensable protective composite material in recent years due to impedance differences at internal material interfaces, lightweight design, high degrees of freedom, and strong impact resistance.Quick Quote

Advantages of Chalco composite aluminum plate in military

Homogeneous armor is usually only suitable for specific weapons and is difficult to resist various anti armor weapons simultaneously. In order to improve bulletproof performance and respond to different threats, composite armor made of high-performance materials has become the main research direction.Quick Quote

- The outer panel uses hard aluminum, and the very hard panel has high resistance to projectile penetration;

- The high toughness back plate can undergo plastic flow on a large area around the impact point to suppress the debris generated by the intermediate layer;

- Multi interface energy absorption changes the trajectory of the projectile and prevents debris damage through material layering, improving the penetration resistance of composite armor. Even with the same density, the elasticity resistance is higher than that of homogeneous armor.

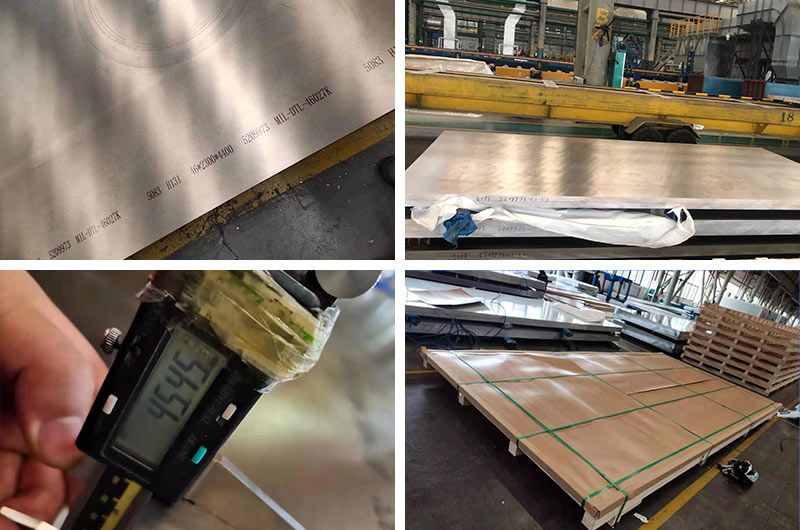

Production capacity of Chalco armor aluminum plate

- Chalco has obtained certifications such as ENISO9100:2018, Nadcap Non Destructive Testing, Nadcap Materials Testing Laboratories, and Nadcap Heat Treatment to ensure product quality and reliability.

- The melting and casting factory has multiple melting and casting production lines, adopting the latest semi continuous low liquid level vertical well casting technology, equipped with electromagnetic stirring, online hydrogen and slag measurement systems, as well as advanced online degassing and filtering systems, which improve casting efficiency and product quality.

- Adopting the hot continuous rolling and cold rolling production lines of German Siemens, equipped with advanced electrical configuration, closed-loop control, regulation system, multi zone cooling system, and temperature control system, to ensure the production of high-quality aluminum armor plates.

Through advanced equipment and processes, Chalco is able to achieve efficient sawing, milling, rolling, and cold rolling, improving production efficiency while reducing production costs.Quick Quote