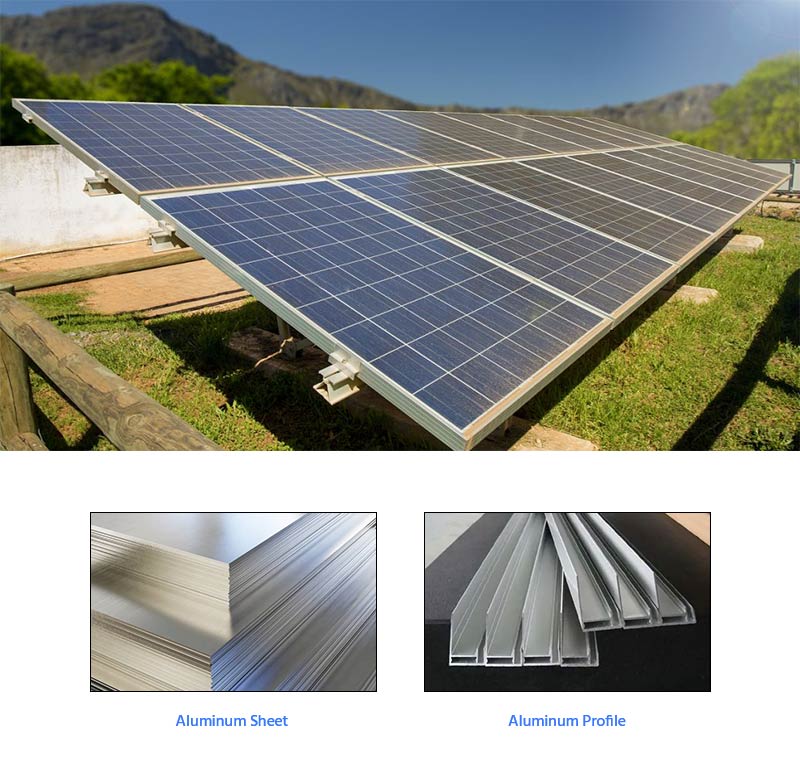

With its advantages of light weight, high strength, corrosion resistance and durability, aluminum is widely used in building solar panel frames and photovoltaic supports. Research shows that aluminum is the most widely used material in solar photovoltaic (PV) applications, accounting for more than 85% of most solar PV modules.

Chalco provides high-quality aluminum products for the solar industry, serving key components like photovoltaic panel frames, reflectors, inverter housings, and heat dissipation parts. Chalco also offers complete integrated mounting systems and structural solutions—including roof and ground mounts, street lights, solar carports, agricultural greenhouses, and foundation piles—to ensure efficient and stable solar project operation.

Specification of Chalco aluminum products for solar panel

Alloy: 6061 6063 6082 6060 6005 6463

Product type: aluminum profile, aluminum sheet, aluminum strip, aluminum flat bar, etc.

Deep processing: drilling, bending, welding, precision cutting, punching, etc.

Surface treatment: mill finish, powder coating, anodizing, wooden grain, electrophoresis, PVDF painting, sanding blasting, polishing, etc.

Anodizing: smooth, frosted; Layer code: AA10, AA15, AA20, AA25

Electrophoretic coating: glossy or dull transparent paint film; Paint film code: EA21, EB16

Standard and certification: CEE, TUV, GB 5237-2008, JISH, AAMA, GB, BS, En; CE, DNV, ISO9001

Solar panel sizes: [click to check the Refernce Table]

Key aluminum applications in solar components

Aluminum is essential in solar systems for its light weight, strength, and corrosion resistance. Chalco provides specialized aluminum products for key solar parts—panel frames, reflectors, inverter housings, and heat dissipation components—ensuring durability and high performance.

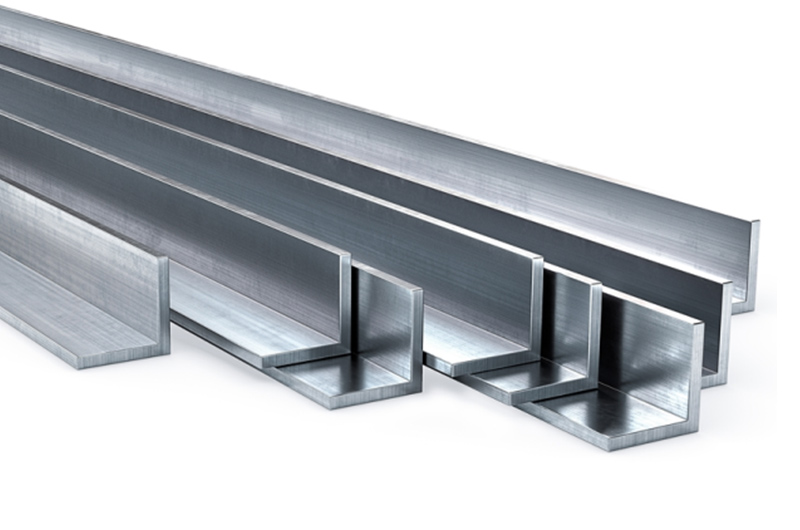

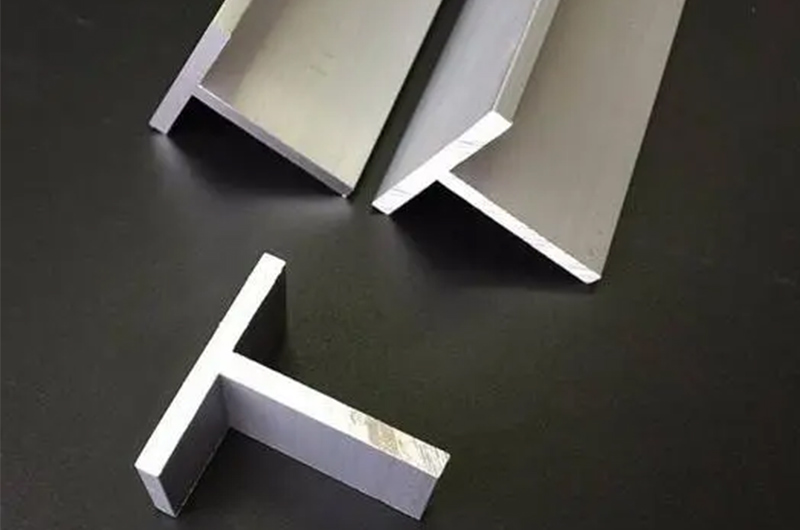

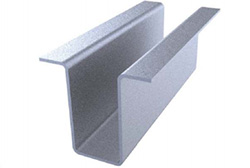

Instant QuoteAluminum profiles for photovoltaic panel frames

Chalco provides high-quality aluminum profiles specially designed for solar photovoltaic panel frames, mainly using alloys such as 6061, 6063, and 6082. Our aluminum profiles offer high strength, excellent corrosion resistance, and good machinability, ensuring secure fixation of solar modules and stability under various environmental conditions. We support multiple surface treatments, including anodizing and powder coating, to meet diverse customer requirements. Custom cutting, drilling, and machining services are available based on client specifications. See below for alloy options and typical product displays.

Aluminum T profile

Contact our team to discuss customized aluminum profile solutions that ensure durable and reliable photovoltaic panel framing for your solar projects.

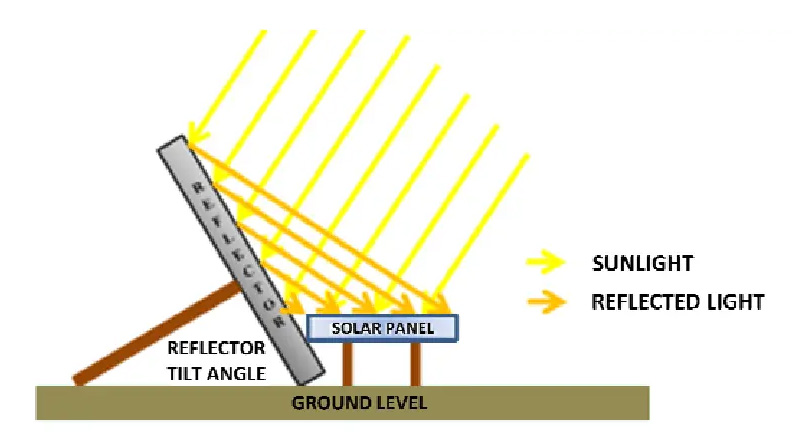

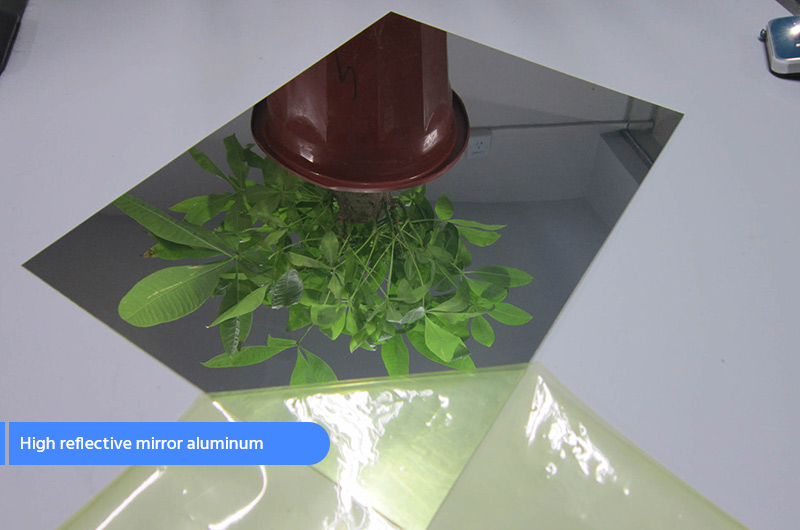

Instant QuoteAluminum sheets for solar reflectors and heat collectors

Chalco supplies high-performance aluminum sheets and mirror-finished materials designed for solar reflectors and thermal collectors. These components are essential in improving solar absorption by redirecting or concentrating sunlight toward photovoltaic panels or heat collection surfaces. Our mirror aluminum sheets feature high reflectivity (up to 95% with PVD coating), excellent weather resistance, and superior durability, making them ideal for use in solar collectors, parabolic dishes, and solar cookers.

Aluminum mirror sheet

High-reflective mirror aluminum sheets offer 95% ±2% thermal absorptivity for solar collectors, reflectors, and cookware, ensuring durability and high energy efficiency.

Mirror sheet for solar cookware

Mirror aluminum sheets concentrate sunlight onto the cooking surface, providing efficient heat distribution for cooking without electricity or fuel.

High reflective mirror sheet

Delivers superior reflectivity (94%) and durability, making it ideal for enhancing energy capture in solar collectors and concentrators.

Discover Chalco's high-quality aluminum sheets designed specifically for solar reflectors and heat collectors—contact us today to enhance your solar project's efficiency!

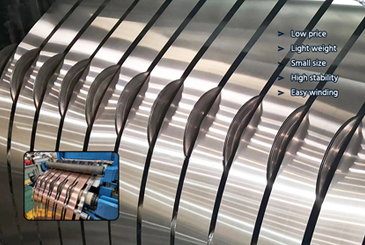

Instant QuoteAluminum strips and busbar for inverter housings

In solar systems, inverters and electrical busbars are vital for converting and transmitting power. Chalco provides aluminum solutions that combine high conductivity, excellent heat dissipation, and strong environmental resistance. Our aluminum busbars and housings are ideal for energy-efficient and cost-effective solar power electronics.

Aluminum Strip for Solar Cell Interconnection

Aluminum busbar (Copper/Aluminum/CCA)

Aluminum transformer strip

Explore Chalco's precision aluminum strips and busbars for inverter housings—get in touch now to optimize your solar inverter solutions!

Instant QuoteAluminum components for heat dissipation & shielding

Effective heat dissipation and EMI shielding are essential to maintain the performance and longevity of solar electronics. Chalco supplies extruded aluminum heat sinks, shielding plates, and protective housings designed for thermal and structural functions in demanding solar environments.

Extruded Heat Sink Fins

High-precision extrusion for optimized heat dissipation in solar inverters.

Heat Sink Housings

Custom extrusion and precision machining for durable protective housings.

Heat Sink Protective Covers

Formed and fabricated covers providing robust environmental protection.

Embossed Aluminum Sheets

Advanced embossing technology enhances surface area for better cooling.

Anodized Aluminum Sheets

Durable anodizing for corrosion resistance and improved thermal performance.

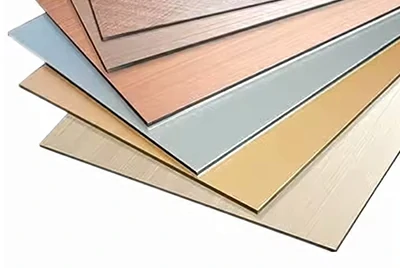

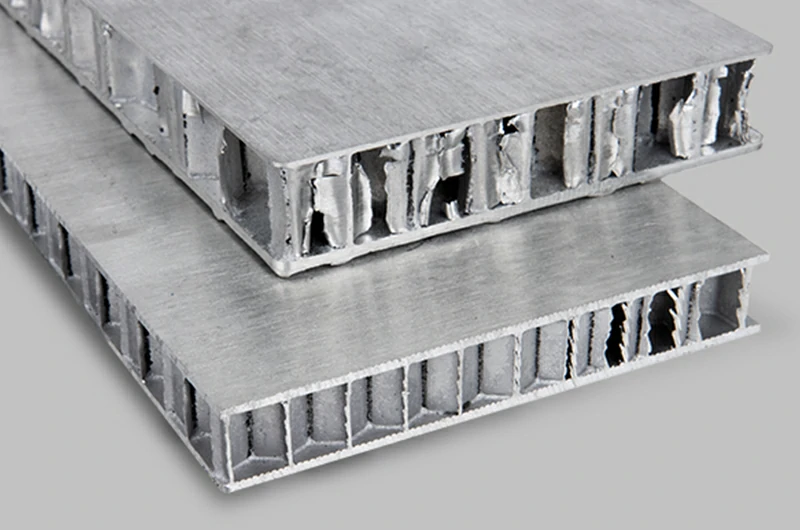

Aluminum-Based Composite Panels

Laminated composite panels combining structural strength and heat management.

Lightweight honeycomb panels manufactured for solar support and shielding.

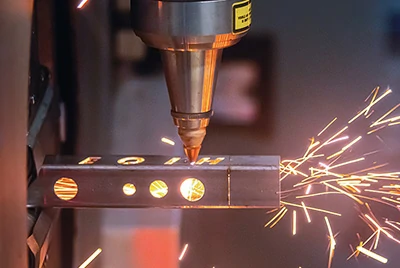

Precision CNC machining tailored for complex heat dissipation components.

Welded Assemblies

Expert welding and assembly services for reliable, integrated heat sinks.

Enhance your solar system's performance with Chalco's reliable aluminum components for heat dissipation and shielding—contact us today to learn more!

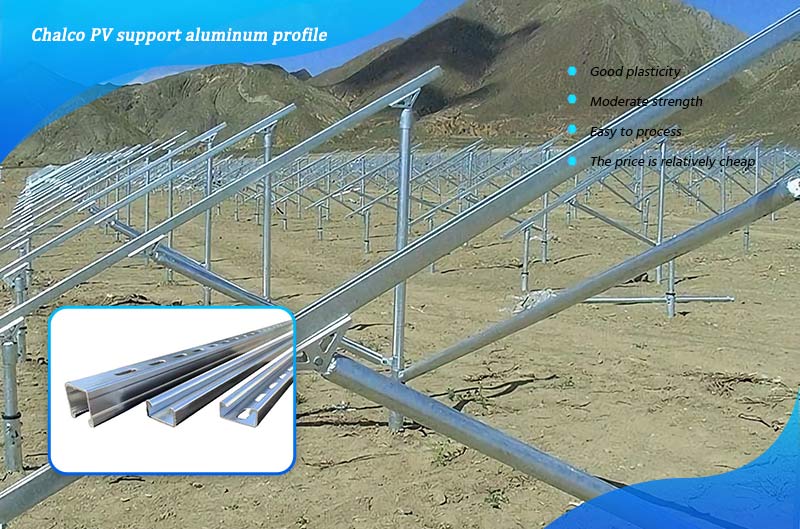

Instant QuoteChalco integrated aluminum mounting systems for solar projects

Chalco offers comprehensive solutions for solar projects, covering a wide range of sizes and applications to meet the diverse needs of solar components. Whether for small-scale applications like streetlights or large structures such as carports, we provide customized aluminum profiles tailored to ensure stable and efficient installation and operation of solar systems. Our expertise in producing high-quality, durable aluminum materials ensures optimal performance across all types of solar projects.

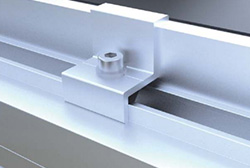

Instant QuoteIntegrated aluminum profiles & connectors for solar mounting systems

Using lightweight and durable aluminum alloy materials; Suitable for various locations, can be installed on both land and rooftops. Design with adjustable holes for easy installation, no on-site drilling required.

Contact us now

H-type connection metal parts (A)

H-type connection metal parts (B)

Foot

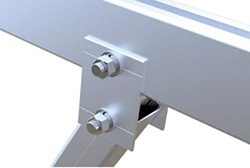

Rail clamps

Mid clamps

End clamps

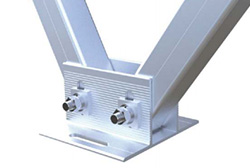

Single-post aluminum mounting solutions for solar applications

Single-leg structure, easy to install on sloped and uneven ground; Pile and post are integrated, making construction convenient and shortening the project timeline. Reduces production costs, suitable for large-scale projects.

Contact us now

Stand column

Sidestay

Underpinning

Aluminum structures & connectors for pile foundation solar mounts

The structure without inclined supports enhances installation capability on sloped and uneven ground. Good construction performance can shorten the project timeline and reduce costs. Able to control land construction costs.

Contact us now

Connector

Rail clamps

Underpinning

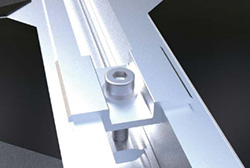

Base clip frame solutions with aluminum profiles for PV panels

Snow-resistant, suitable for snowy regions. Secured with four metal pieces on the panel, resistant to strong winds. Easier and safer panel installation from below in high rack situations.

Contact us now

Clamps

Rails

Angle adjustment connector

Integrated aluminum structures for solar street light poles

Solar street lights feature integrated PV panels, LED lamps, and control units mounted on a single aluminum pole. Chalco offers lightweight, corrosion-resistant aluminum components for durable, easy-to-install solutions.

Contact us now

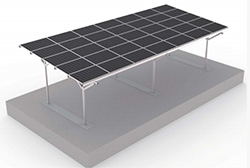

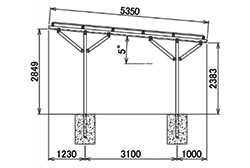

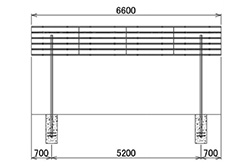

Aluminum canopy structures for solar carport installations

Raise the inclined pillars to avoid door interference. Low-cost installation suitable for low wind and low snow areas.

Contact us now

Aluminum frame systems for solar agricultural greenhouses

No limit on the number of tiers, can be infinitely configured. Ensures ample working space for people and agricultural machinery. Adjusting panel spacing can regulate shading rates.

Contact us now

Why choose Chalco solar energy aluminum products

- Chalco stock various aluminum extruded solar panel frames and photovoltaic support aluminum alloys, with a variety of finishes to choose from. If the existing products are not suitable for your needs, we can also customize them according to customer requirements.

- All extrusion parts can be cut, drilled or machined according to customer specifications. As a professional aluminum profile supplier, Chalco operates the latest CNC drilling and processing center, which can provide accurate processing and cost-effective parts in a short cycle time.

- Because the panel frame is exposed to the natural environment, it has high requirements for corrosion resistance. Chalco provides anodized aluminum profiles to further enhance the corrosion resistance of solar aluminum alloy frames.

- After the production of aluminum profiles, we will provide strict product quality inspection and precise product film pasting, packaging and transportation. Ensure product quality at any link of production and delivery.

Solar energy projects aluminum material purchasing guide

Aluminum profile material choosen guidance

- Load-bearing Capacity: Aluminum profiles must support solar panels and the system, with material properties, dimensions, and shapes ensuring stability.

- Wind Load Resistance: Profiles must withstand wind loads at various speeds to ensure system stability and longevity.

- Thermal Expansion: Aluminum profiles must accommodate temperature changes to prevent deformation or damage.

Properties of Chalco aluminum profile

| Alloy | Temper | Wall thickness | Tensile strength Rm(MPa) | Yield strength RP0.2(MPa) | elongation % |

| 6005 | T5 | ≤5.00 | ≥260 | ≥240 | ≥8 |

| 6060 | T5 | ≤5.00 | ≥160 | ≥120 | ≥6 |

| T6 | ≤3.00 | ≥190 | ≥150 | ≥6 | |

| T66 | ≤3.00 | ≥215 | ≥160 | ≥8 | |

| 6061 | T6 | ≤5.00 | ≥265 | ≥245 | ≥8 |

| 6063 | T5 | ≤5.00 | ≥160 | ≥110 | ≥8 |

| T6 | ≤3.00 | ≥205 | ≥180 | ≥8 | |

| T66 | ≤3.00 | ≥245 | ≥200 | ≥6 | |

| 6463 | T5 | ≤5.00 | ≥150 | ≥110 | ≥6 |

| T6 | ≤5.00 | ≥195 | ≥160 | ≥8 |

Surface treatment can be provided by Chalco

To enhance the durability of aluminum alloys in solar projects, surface treatment processes are crucial. Proper surface treatment not only improves corrosion resistance but also enhances aesthetics and long-term reliability.

Chalco offers a variety of aluminum alloy surface treatment solutions to ensure material durability in various environments. Whether it's anodizing, spraying, or electrophoretic coating, we provide high-quality services tailored to customer needs, extending the lifespan of aluminum alloys and improving their performance in solar systems.

- Anodizing: Anodizing creates a protective oxide film on aluminum alloys, enhancing corrosion resistance, surface hardness, and wear resistance, ideal for solar projects in harsh environments.

- Powder Coating: Powder coating applies a durable layer to aluminum alloys, offering excellent UV, corrosion, and wear resistance, with customizable colors for different solar system designs.

- Electrophoretic Coating: Electrophoretic coating uses electric current to deposit a uniform layer on aluminum alloys, providing excellent corrosion resistance and protection against UV and harsh weather.

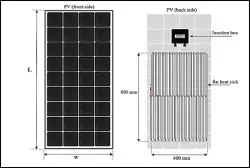

Solar panel sizes reference table

| Power (w) | Number of cells(pcs) | Size of cells(mm) | Solar panel frame size(mm) | Weight (Kg) |

| 5 | 2*18 | 78*12 | 280x190x17 | 0.7 |

| 10 | 4*9 | 52*31.2 | 250x350x17 | 1.2 |

| 20 | 4*9 | 78*39 | 420x360x17 | 2.3 |

| 30 | 2*18 | 156*26 | 360x550x20 | 2.5 |

| 40 | 4*9 | 156*39 | 670*420×25 | 3.2 |

| 50-60 | 4*9 | 156*52 | 540x670x25 | 4.2 |

| 80-90 | 4*9 | 156*78 | 780x670x30 | 6.6 |

| 100 | 4*9 | 156*104 | 1000x670x30 | 8 |

| 110-120 | 4*18 | 156*52 | 1020x670x35 | 8.8 |

| 130 | 4*9 | 156*117 | 1120*670*35 | 10.5 |

| 140 | 4*9 | 156*63 | 1200*670*35 | 10.5 |

| 150-180 | 4*9 | 156.75*156.75 | 1480x670x35 | 12 |

| 190-200 | 6*12 | 125*125 | 1580x808x35 | 15.5 |

| 210-230 | 6*8 | 156.75*156.75 | 1320x992x35 | 17 |

| 250-270 | 6*9 | 156.75*156.75 | 1482x992x40 | 18 |

| 280-310 | 6*10 | 156.75*156.75 | 1640x992x40 | 18 |

| 340-380 | 6*12 | 156.75*156.75 | 1956x992x40 | 23 |

| 460-500 | 8*12 | 156.75*156.75 | 1956x1310x45 | 29 |

Solar module size and application reference table

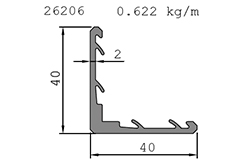

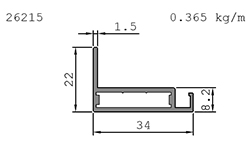

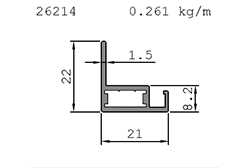

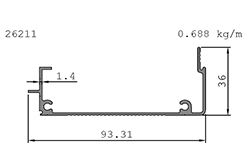

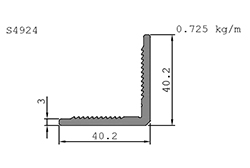

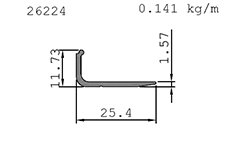

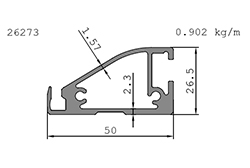

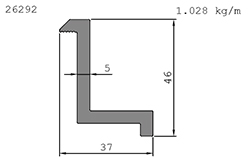

| Profile Cross-Section | Suitable Solar Component Size | Applicable Solar Type |

| 15*15, 17*17, 18*18, 20*20, 23*17, 25*25, 25*20, 30*25, 28*25 | Suitable for solar street lights and other small solar power devices | |

| 30*25, 35*30mm | 1200*540 mm | Suitable for 30-100W solar components |

| 35*35mm | 1580*808 mm | Suitable for 80-180W solar components |

| 40*35mm | 1580*808mm, 1640*990mm | Suitable for 120-200W solar components |

| 45*35mm | 1580*808mm, 1650*992mm | Suitable for 180-250W solar components |

| 50*35mm | 1650*992mm, 1960*992mm | Suitable for 200-300W solar components |

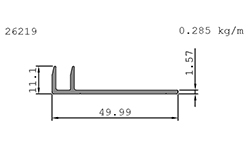

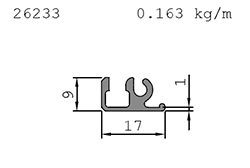

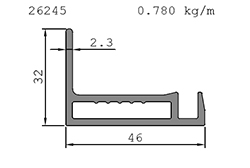

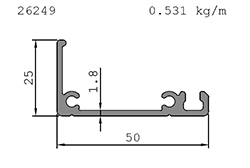

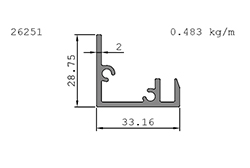

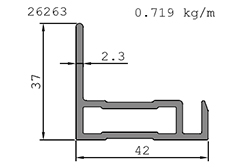

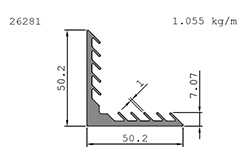

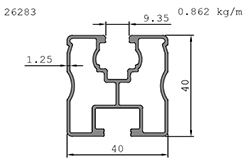

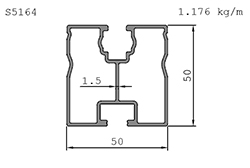

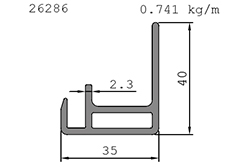

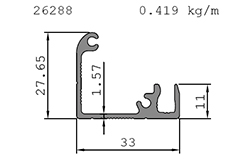

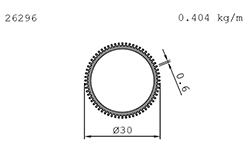

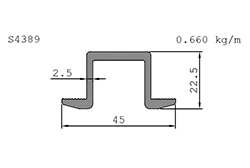

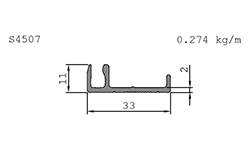

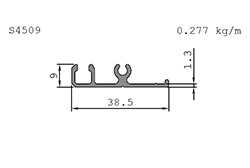

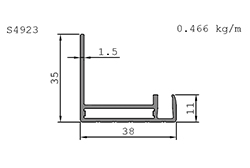

Chalco solar aluminum profiles cross-section reference

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote