Aluminum profile production shipin

Why choose Chalco 6010-T4 automobile aluminum profile?

Chalco production capacity

Chalco Aluminum has an aluminum alloy profile extrusion production line, and can produce seamed aluminum tubes andseamless aluminum tubes at the same time, which can meet the production requirements of various automotive profiles.

Automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British StandardsInstitution), providing quality compliance for continuously expanding the automotive product market and achievinghigh-quality development.

Instant QuoteWell-known brand material certifications

Serving Tesla, Ford, Shanghai Automobile, Weilai Automobile, BAIC New Energy, Changan Automobile and other famousnew energy automobile manufacturers, confirmed the material certification relationship, and completed the parts ofmany automobile factories such as BAIC New Energy and Weilai Automobile Model car plate material certification.

Specs of 6010-T4 automobile aluminum profile

| Alloy | Profile name | Sectional shape | Sectional size(mm) |

| 6010-T4 | Angle aluminum | Right angle | 10×10-100×100 |

| 6010-T4 | Square | Tube square | 10×10-150×150 |

| 6010-T4 | round tube | round | Φ10-Φ150 |

| 6010-T4 | Hex | Tube hex | 10-100 |

| 6010-T4 | U-groove | U-shaped | 10×10-100×100 |

| 6010-T4 | T-slot | T-shaped | 10×10-100×100 |

| 6010-T4 | I-beam | I-beam | 20×20-200×200 |

| 6010-T4 | H Beam H Shape | H Shape | 50×50-500×300 |

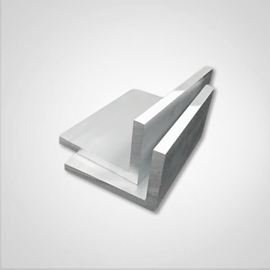

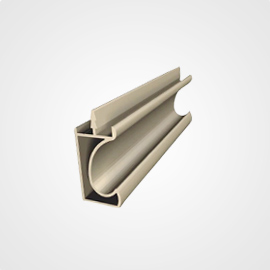

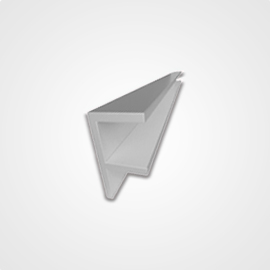

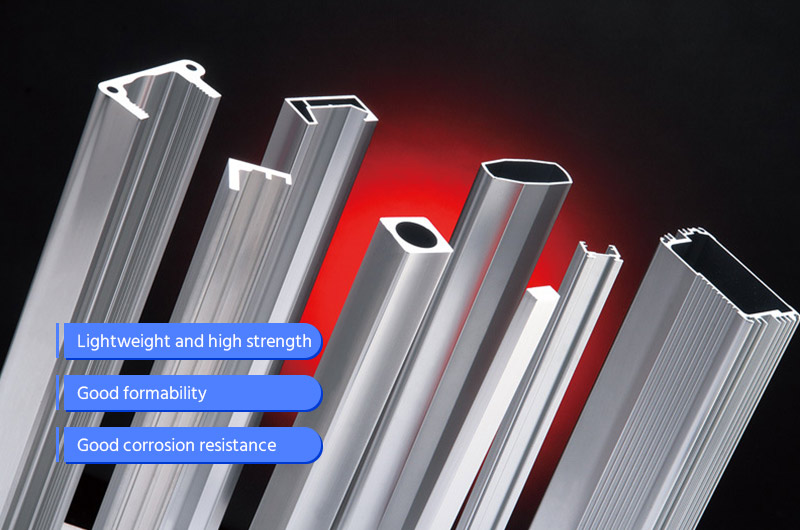

Chalco's hot-selling extruded profiles shapes

With decades of experience in the aluminum extrusion industry, Chalco has achieved an annual production capacity of100,000 tons. We also possess molds for 2000 standard aluminum extruded profiles. Take advantage of our latestpromotional policy with waived mold fees.

Typically, 6063 is used for architectural applications, while 6061 is utilized for structural purposes. Chalco alsooffers various other alloy numbers such as the 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, and7000 series. Our sales engineers can assist you in selecting the right alloy for your project.

Instant Quote

Aluminum Angle

Aluminum T bar

Aluminum I Beam

Extruded Aluminum Channel

Aluminum Flat Bar

Aluminium G Profile

F-shaped-Aluminium-Extrusion

Aluminium J Profile

Square-Aluminum-Extrusion

Z-Aluminium-Extrusion

Oval Aluminum Extrusion

Y Section Aluminium Extrusion

Chemical composition of 6010-t4 automobile aluminum profile

| Element | Composition (%) |

| (Al) | 97.80% |

| (Mg) | 0.6-1.1% |

| (Si) | 0.50-0.9% |

| (Fe) | 0.35% |

| (Mn) | 0.2-0.5% |

| (Ti) | 0.10% |

| (V) | 0.05% |

Mechanical property of 6010-T4 automobile aluminum profile

| Alloy | Temper | Tensile strength(MPa) | Yield strength(MPa) | Elongation(%) |

| 6010 | T4 | 250 | 145 | 12 |

| 6010 | T6 | 280 | 240 | 8 |

Features of 6010 T4 automobile aluminum profile

Lightweight and high strength: compared with steel, aluminum alloy materials have lighter weightand higher strength, which can reduce the overall weight of the car, improve fuel efficiency and reduce emissions.

Good formability: 6010 aluminum alloy has excellent machinability and formability, and can be bent,press-formed and other processing according to needs, which is convenient for manufacturing parts with complexshapes.

Good corrosion resistance: aluminum alloy materials form a dense oxide film in the air, which caneffectively prevent corrosion and oxidation of the aluminum surface and improve the durability and stability ofparts.

Instant QuoteHigh reliability: 6010 aluminum alloy material has good fatigue strength and crack resistance, andcan withstand long-term dynamic load and vibration, ensuring the reliability and safety of parts.

Environmental protection: compared with steel materials, the production process of aluminum alloymaterials can reduce energy consumption and carbon dioxide emissions, which meets environmental protectionrequirements.

Usage of 6010 T4 automobile aluminum profile

Body: the use of 6010 aluminum profiles can reduce the weight of the car, improve the fuel economyand performance of the vehicle, and has good corrosion resistance and wear resistance, which can improve the servicelife and safety of the car.

Chassis: 6010 aluminum alloy has excellent strength and machinability, and can be used tomanufacture chassis components, such as brackets, shock absorbers, suspension systems, etc.

Instant QuoteWheels: using 6010 aluminum alloy to make wheels can reduce the weight of the hub, improve thedurability and performance of the hub, and have good corrosion resistance.

Other components: 6010 aluminum profiles can also be used to manufacture other auto parts, such asdoors, windows, roofs, etc.

Precautions for using 6010 T4 automobile aluminum profile

Protect the surface of the aluminum material: the aluminum alloy material is sensitive tooxidation, and the surface of the aluminum material needs to be cleaned, treated, and protected before use to avoidoxidation and corrosion of the material surface.

Choose the appropriate processing method: 6010 aluminum profiles have good processing performance,but it is necessary to select the appropriate processing method according to the specific situation to avoidproblems such as deformation, cracks, and deterioration of parts caused by improper processing.

Maintain material strength: when using 6010 aluminum profiles, it is necessary to control thetemperature of the material to avoid the decrease of material strength due to excessive temperature, which willaffect the service life and safety of parts.

Pay attention to the installation method: when installing 6010 aluminum profiles, it is necessaryto choose an appropriate installation method according to the design requirements to ensure the stability and safetyof the parts.

Instant QuotePay attention to storage and transportation: when storing and transporting 6010 aluminum profiles,it is necessary to pay attention to moisture-proof, shock-proof, anti-collision, sun-proof and other measures toavoid damage and deformation of the aluminum surface.