6A02 aluminum profiles have elements such as aluminum, magnesium, manganese, silicon, etc., have good machinability and welding performance, and are often used in aircraft structures.

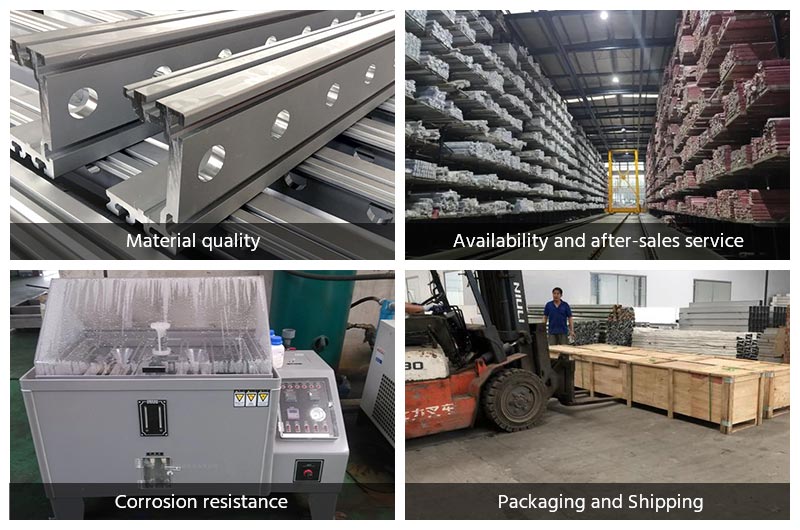

CHALCO can produce GJB 2507 6A02 aluminum Extrusions, which can be customized in size and specification, with good quality. It is one of the aviation aluminum suppliers for Collins Aerospace, Boeing, Airbus and so on.

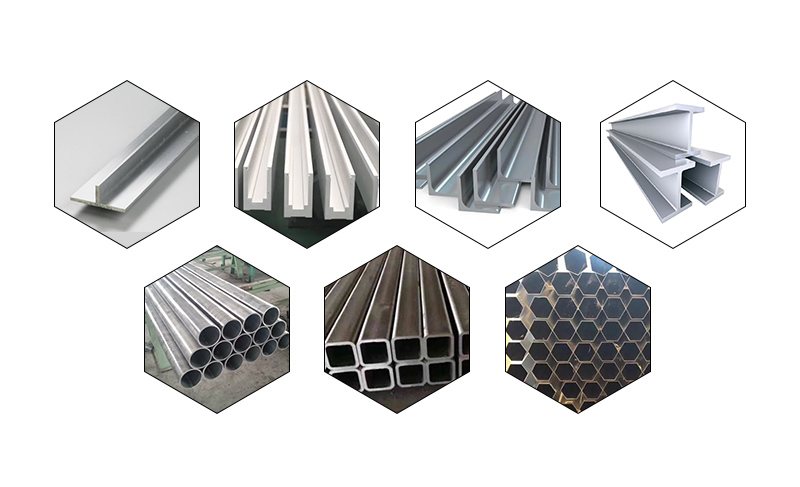

Shapes and specification of 6A02 aerospace aluminum profile

6A02 aluminum alloy extruded aluminum can usually be produced into various shapes, such as round tubes, square tubes, rectangular tubes, trapezoidal tubes, hexagonal tubes, etc.

| Common sizes | |

| 6A02 aluminum alloy round tube | Outer diameter 6-360 mm, wall thickness 0.5-30 mm |

| 6A02 aluminum alloy square tube | Side length 6-220 mm, wall thickness 0.5-20 mm |

| 6A02 aluminum alloy rectangular tube | Aspect ratio not exceeding 6:1, wall thickness 0.5-20 mm |

| 6A02 aluminum alloy trapezoidal tube | The length of the upper and lower bottom sides is less than 200 mm, the height is not more than 150 mm, and the wall thickness is 0.5-20 mm |

| 6A02 aluminum alloy hexagonal tube | Outer diameter 6-220 mm, wall thickness 0.5-20 mm |

| 6A02 aluminum alloy extruded flat material | Thickness 0.5-10mm, width 10-300mm |

| 6A02 aluminum alloy pentagon profile | Outer diameter 6-150mm, wall thickness 0.5-20mm |

| 6A02 aluminum alloy octagonal profile | Outer diameter 6-150mm, wall thickness 0.5-20mm |

| 6A02 aluminum alloy U profile | Opening width 10-200mm, wall thickness 0.5-20mm |

| 6A02 aluminum alloy L profile | Leg length 10-200mm, wall thickness 0.5-20mm |

| 6A02 aluminum alloy T profile | Waist width 10-200mm, wall thickness 0.5-20mm |

| 6A02 aluminum alloy unequal angle | Unequal side length 6-200mm, wall thickness 0.5-20mm |

| 6A02 aluminum alloy U profile | Opening width 10-200mm, wall thickness 0.5-20mm |

| 6A02 aluminum alloy L profile | Leg length 10-200mm, wall thickness 0.5-20mm |

6A02 aluminum profile temper analysis

-

6A02 O temper

Fully annealed, offering high ductility, ideal for deep drawing and complex forming applications.

-

6A02 T4 temper

Solution heat-treated and naturally aged, providing good strength and workability, suitable for lightweight structures.

-

6A02 T5 temper

Artificially aged after extrusion, offering moderate strength and good corrosion resistance, ideal for structural applications.

-

6A02 T6 temper

Solution heat-treated and artificially aged, delivering high strength for applications requiring superior mechanical properties.

-

6A02 T62 temper

Further aged after T6 treatment, offering enhanced strength and stability, suitable for high-stress components.

-

6A02 H32 temper

Work-hardened, providing moderate strength and ductility, suitable for applications requiring a balance of strength and formability.

Chemical composition of 6A02 aluminum profiles

| Weight% | Alloy 6A02 |

| Si | 0.5-1.2 |

| Fe | 0.5 |

| Cu | 0.2-0.6 |

| Mn | 0.15-0.35 |

| Mg | 0.45-0.9 |

| Zn | ≤0.25 |

| Ti | 0.15-0.4 |

| Cr | 0.45-0.9 |

| Zn | 0.2 |

| Other each | 0.05 |

| Other total | 0.15 |

| Al | Bal |

Physical properties of 6A02 aviation extruded aluminum profiles

| Physical property | |

| density | 2.78 g/cm3 |

| Thermal expansion coefficient | 23.2 × 10-6 K-1 |

| Thermal conductivity | 121-160 W/(m·K) |

| Longitudinal modulus of elasticity | 70.3 GPa |

| Transverse modulus of elasticity | 25.5 GPa |

| Shear modulus of elasticity | 27.1 GPa |

| Longitudinal Poisson's ratio | 0.33 |

| Transverse Poisson's ratio | 0.33 |

Mechanical properties of 6A02 extruded aluminum profiles

| Alloy | Temper | Thickness (mm) | Tensile strength | Yield strength | Elongation A/% |

| 6A02 | T4 | ALL | ≥177 | - | 14 |

| 6A02 | T6 | ALL | ≥294 | ≥225 | 10 |

It should be noted that these values are only the minimum required values in the specification. In actual use, according to specific application requirements, higher mechanical performance requirements may be required, so stricter quality control and testing are required.

Characteristics of 6A02 aviation aluminum profile material

High strength: after proper heat treatment, the 6A02 aviation aluminum profile has relatively high strength, hardness and corrosion resistance, which can meet the use requirements of aircraft structural parts.

Good corrosion resistance: 6A02 aviation aluminum profile contains a certain amount of copper element, which makes it have better corrosion resistance and can be used in harsh environments such as ocean and high temperature.

Easy processing: 6A02 aviation aluminum profiles have good forgeability and machinability, and are easy to carry out extrusion, stretching, forging and other processing techniques to make aluminum profiles of various shapes.

Lightweight: 6A02 aviation aluminum profiles are lighter than ordinary steel, which can reduce the weight of aircraft and improve fuel efficiency and flight performance.

Good weld ability: 6A02 aviation aluminum profiles have good weldability, and are used to manufacture and process helicopter blades and complex-shaped profiles with high plasticity and corrosion resistance.

Application of 6A02 aluminum profiles in aircraft

6A02 aluminum profiles are widely used in aircraft, and are usually used to manufacture parts that require high strength, high corrosion resistance and high reliability in aircraft structures.

Fuselage skeleton structure: 6A02 aluminum profiles are often used to manufacture aircraft fuselage skeleton structures, such as wings and fuselages.

Aircraft structural parts: 6A02 aluminum profiles are also commonly used in the manufacture of aircraft structural parts, such as support rods, drawbars, etc.

Landing gear: 6A02 aluminum profiles are also used to manufacture aircraft landing gear, such as landing gear legs, hydraulic cylinders, etc.

Engine components: 6A02 aluminum profiles are also used to manufacture aircraft engine components, such as intake ducts, exhaust pipes, etc.

It should be noted that the specific application parts of 6A02 aluminum profiles may vary due to factors such as aircraft models and airlines, and the above list is only a part of them.

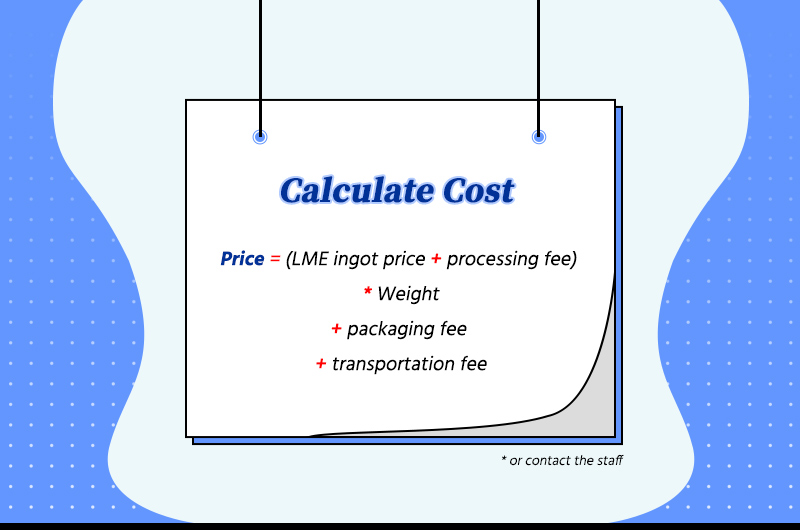

6A02 aviation aluminum profile price

6A02 aluminum profile price: (LME ingot price + processing fee)×weight + packaging fee + transportation fee

The price of 6A02 aluminum profiles will be affected by a variety of factors, such as market supply and demand, raw material prices, processing costs, specifications, and other factors. Different manufacturers and suppliers may have different pricing strategies and price levels. In addition, it is also affected by factors such as currency exchange rate and international economic situation.

Therefore, please contact Chalco aluminum for inquiry, we will provide you with the best quotation and service.

Matters needing attention when purchasing 6A02 aviation aluminum profiles

Specifications and dimensions: confirm whether the specifications and dimensions of 6A02 aviation aluminum profiles meet the project requirements. The specifications and dimensions of 6A02 aviation aluminum profiles need to meet relevant standards and requirements, such as ASTM, GB, etc.

Quality level and certification: confirm the quality level and certification status of 6A02 aviation aluminum profiles. 6A02 aviation aluminum profiles need to meet relevant quality standards and certification requirements, such as ISO9001, AS9100, etc.

Reputation and qualification of suppliers: purchasing 6A02 aviation aluminum profiles requires selection of reputable, qualified and experienced suppliers to ensure product quality and delivery time.

Surface quality and appearance: 6A02 aviation aluminum profiles need to have good surface quality and appearance, and there must be no obvious scratches, dents, oxidation and other quality problems.

Mechanical properties: 6A02 aviation aluminum profiles need to have good mechanical properties, such as strength, hardness, toughness, etc., to ensure that the product can meet the project requirements.

Quotation: confirm whether the quotation provided by the supplier is reasonable. To purchase 6A02 aviation aluminum profiles, it is necessary to compare the prices and services of different suppliers and choose the most cost-effective supplier.