Aluminum profile production shipin

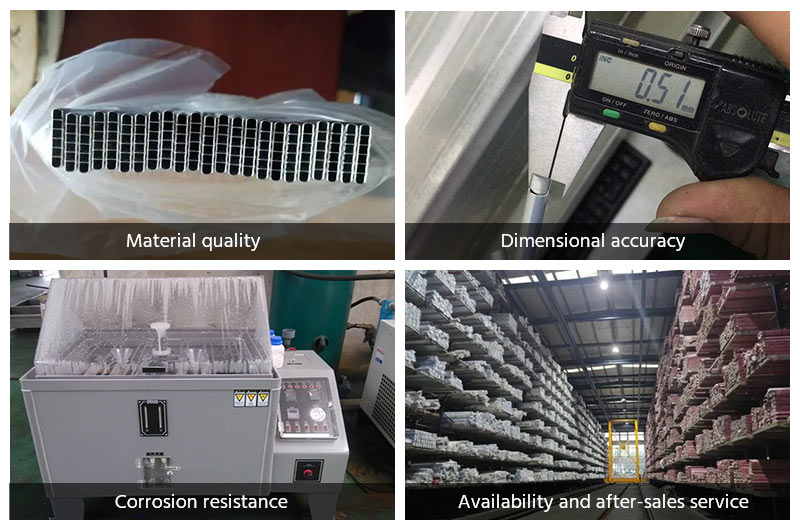

Why choose Chalco Aluminum's 2010 T6 automotive aluminum profile?

Chalco auto aluminum profile production capacity

The 2010 T6 Aluminum auto profiles produced by Chalco adopt a strict quality and environmental management system,passed ISO 9001 and ISO 14001 certification, IATF16949 certification.

Well-known brand material certifications

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile andother famous new energy automobile manufacturers. Some models of automotive plate material certification.

Instant Quote

2010 automotive aluminum profiles specification

| Alloy | 2010 |

| Temper | T6 |

| Production standards | GB/T 33910, ASTM B221, EN755 |

| Size | Commonly used circular profiles with a diameter of 10-250mm and a thickness of 0.5-50mm, as well asrectangular profiles with a length, width, and height of 20-100mm, 10-80mm, and 0.5-10mm, andspecial-shaped profiles of different sizes |

| Length and width | According to the specific vehicle and application |

| Surface treatment of aluminum profiles | Surface treatment of aluminum profiles Anodizing, electrophoretic coating, sandblasting and othermethods |

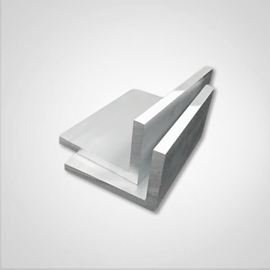

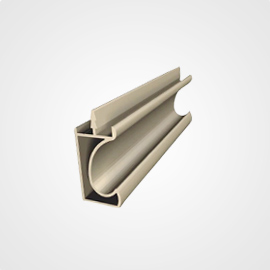

| Common shapes | 2010 aluminum alloy profiles used in the automotive industry come in a variety of shapes: 2010 aluminum alloy round tube, 2010 aluminum alloy square tube, 2010 aluminum alloy angle aluminum, 2010 aluminum alloy U profile, 2010 aluminum alloy T profile, 2010 aluminum alloy Z profile, 2010 aluminum alloy H profile. |

It should be noted that different car manufacturers and different models may have different aluminum profilespecifications and application requirements. Therefore, the specific specifications and applications need to beconfirmed according to the actual situation.

Instant Quote

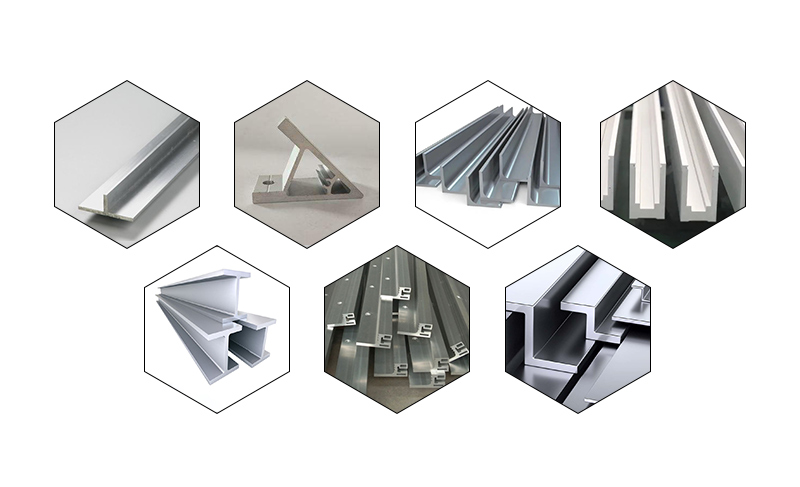

Chalco's hot-selling extruded profiles shapes

With decades of experience in the aluminum extrusion industry, Chalco has achieved an annual production capacity of100,000 tons. We also possess molds for 2000 standard aluminum extruded profiles. Take advantage of our latestpromotional policy with waived mold fees.

Typically, 6063 is used for architectural applications, while 6061 is utilized for structural purposes. Chalco alsooffers various other alloy numbers such as the 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, and7000 series. Our sales engineers can assist you in selecting the right alloy for your project.

Instant Quote

Aluminum Angle

Aluminum T bar

Aluminum I Beam

Extruded Aluminum Channel

Aluminum Flat Bar

Aluminium G Profile

F-shaped-Aluminium-Extrusion

Aluminium J Profile

Square-Aluminum-Extrusion

Z-Aluminium-Extrusion

Oval Aluminum Extrusion

Y Section Aluminium Extrusion

2010 alloy chemical composition limits

| Chemical composition limits | ||||||||||||

| Weight% | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others | Al | |

| 2010 | ≤0.5 | ≤0.5 | 0.7-1.3 | 0.1-0.4 | 0.4-1.0 | ≤0.14 | - | ≤0.3 | - | each | total | Re |

| 0.05 | 0.15 | |||||||||||

2010 T6 aluminum profiles for auto mechanical properties

| Material | Temper | Tensile strength(MPa) | Yield strength(MPa) | Elongation in 2" (%) |

| GB/T 33910 2010 aluminum profile for automotive | T6 | According to the measured results | According to the measured results | According to the measured results |

| ASTM B221 2010 aluminum profile for automotive | T6 | Not less than 275MPa | Not less than 240MPa | 10% |

| EN 755 2010 aluminum profile for automotive | T6 | Not less than 250MPa | Not less than 230MPa | 10% |

It should be noted that these mechanical performance data are based on the test results of standard samples, andwill be affected by various factors in actual use, such as profile size, shape, wall thickness, etc. Therefore, itneeds to be evaluated and confirmed according to the actual situation in specific applications.

2010 aluminum alloy profiles are widely used in the automotive field

Braking system: 2010 aluminum alloy profiles are often used in parts such as brake calipers andbrake discs in automobile braking systems, because their high strength and excellent thermal conductivity make thebraking system more stable and reliable.

Wheels and rims: 2010 aluminum alloy profiles are also widely used in automotive wheels and rims.Due to their light weight, high rigidity and excellent corrosion resistance, they can improve vehicle performanceand fuel economy.

Instant QuoteEngine components: 2010 aluminum alloy profiles are also used in automotive engine components, suchas engine radiators and air intakes. Its high strength and thermal conductivity can help the engine dissipate heatmore effectively, improving the performance and life of the engine.

Body structure: although the strength of 2010 aluminum alloy is not as good as other aluminumalloys, it still has application in body structure. It is often used on components such as automotive interiors anddoor panels to improve their corrosion resistance and surface finish.

In short, 2010 aluminum alloy profiles are widely used in the automotive field and can be used in braking systems,hubs and rims, engine components, and body structures. Due to its light weight, high stiffness and excellentcorrosion resistance, it can improve vehicle performance, fuel economy and safety.

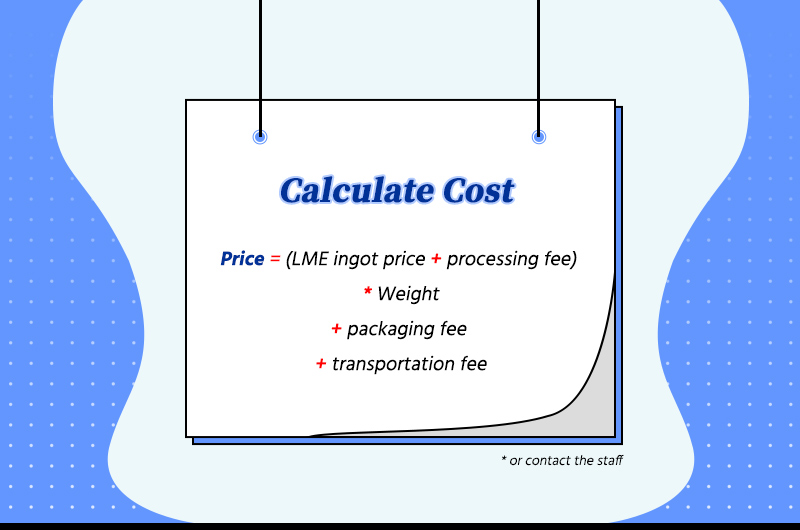

Prices of 2010 aluminum automotive profile

2010 aluminum profile price:

(LME ingot price + processing fee) × weight + packaging fee + transportation fee

The price of aluminum profiles in 2010 will be affected by many factors, such as market supply and demand, rawmaterial prices, processing costs, specifications, and other factors. Different manufacturers and suppliers may havedifferent pricing strategies and price levels. In addition, it is also affected by factors such as currency exchangerate and international economic situation.

Therefore, please contact Chalco aluminum for inquiry, we will provide you with the best quotation and service.

When purchasing 2010 aluminum auto profiles, you need to pay attention to the following items

Material certification: when selecting suppliers, suppliers with qualifications and experienceshould be preferred, and at the same time required to provide qualified material certification certificates. Thematerial certification certificate should include information on the chemical composition, mechanical properties,processing technology and surface treatment of the material, so as to ensure that the purchased 2010 aluminumprofiles meet the corresponding standards and requirements.

Specifications and dimensions: according to the required specific use and design requirements,select the appropriate 2010 aluminum profile specifications and dimensions. Attention should be paid to theperformance and price differences between different specifications and sizes, and selection and trade-offs should bemade according to actual needs.

Instant QuoteSurface treatment: the surface treatment of 2010 aluminum profiles include oxidation, anodicoxidation, electrophoretic coating, sandblasting and other methods. Choose the appropriate surface treatment methodaccording to the specific requirements to improve the corrosion resistance, wear resistance and aesthetics of the2010 aluminum profile.

Supply cycle and delivery method: when negotiating with suppliers, it is necessary to clarifydetails such as the supply cycle and delivery method. Ensure that the purchased 2010 aluminum profiles can besupplied in time, and at the same time require suppliers to provide reasonable transportation and delivery methodsto ensure the safety of the goods and timely arrival at the destination.

Price and after-sales service: price is a factor that cannot be ignored in the procurement process.It should be evaluated and compared according to the price and after-sales service of different suppliers, and thesupplier with high cost performance should be selected for cooperation. At the same time, a good cooperativerelationship should be established with suppliers in order to obtain better service and support in futurecooperation.