Why choose Chalco?

Certifications

AS9100,

OHSAS 18001,

ISO14001,

ISO 9001,

NADCAP HT,

NADCAP NDT,

IATP16949

Standard

AMS 4191 2319 Welding Wire

Production request

When producing 2319 aircraft aluminum wire, production requirements need to be established in accordance with relevant standards and specifications to ensure that the product meets the design requirements and the requirements of the aviation industry. The following are some possible production requirements:

- Raw material selection;

- Production process;

- Product quality;

- Testing and inspection;

- Packaging and transportation;

- Environmental requirements.

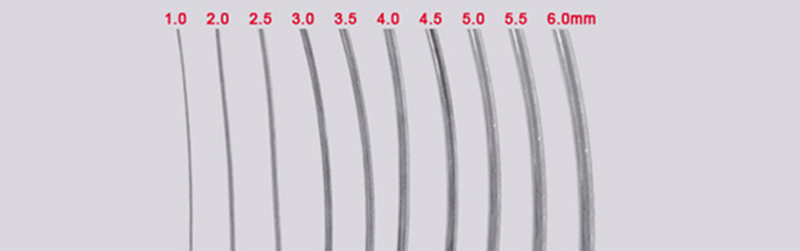

2319 aircraft aluminum wire size

0.5mm-12mm diameter

People concern about 2319 aerospace aluminum wire

Points of interest to customers of 2319 aircraft aluminum wire may include the following.

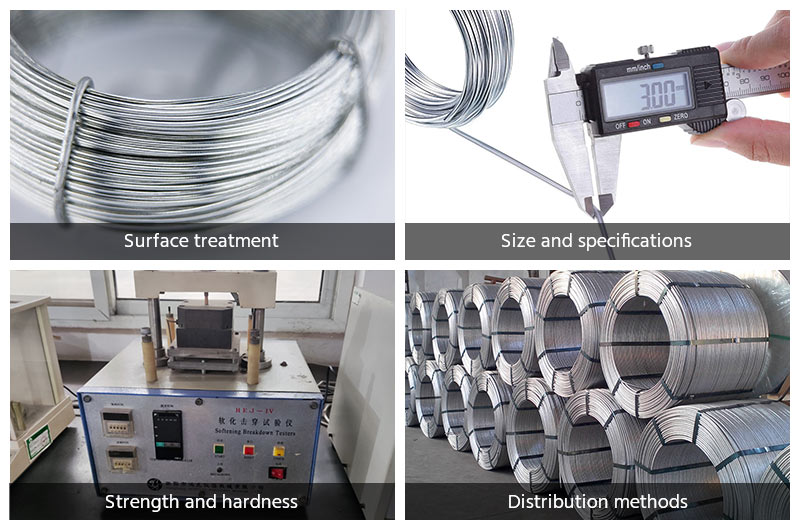

Material quality and performance: customers are usually concerned with aspects such as chemical composition, mechanical properties, and surface quality of the aluminum wire to ensure that the product meets their requirements and application scenarios.

Size and accuracy: the size and accuracy of the aluminum wire is important for certain applications, and customers may be concerned about the requirements for diameter, roundness, straightness, surface finish, etc.

Production process and quality control: customers usually focus on production process, quality control and testing methods to ensure that the products meet the relevant standards and quality requirements.

Delivery time and service: customers are usually concerned about the delivery time and service quality of aluminum wire to ensure that the products are delivered on time and receive timely after-sales service.

Cost and price: customers are usually concerned about the cost and price of aluminum wire to ensure that the product is reasonably priced and within their budget.

In short, customer concerns will vary depending on the application scenario, requirements and individual needs.

2319 aerospace aluminum wire chemical composition

| Alloy | % |

| Al | 93 |

| Cu | 6.3 |

| Mn | 0.3 |

| Zn | 0.18 |

| Ti | 0.15 |

| Va | 0.10 |

2319 aerospace aluminum wire mechanical property

| Mechanical property | Value |

| Tensile strength(MPa) | ≥450 |

| Yield strength(MPa) | ≥370 |

| Elongation(%) | ≥10 |

| Section shrinkage(%) | ≥25 |

2319 aviation aluminum wire characteristics

2319 aviation aluminum wire has several characteristics as follows.

Good welding performance: 2319 aluminum alloy wire has good welding performance and is suitable for a variety of welding processes, such as TIG, MIG, arc, etc. It also has good anti-cracking and corrosion resistance properties, which can ensure the quality and stability of welded joints.

High strength and excellent fatigue properties: 2319 aluminum alloy wire has high tensile strength and yield strength, which can withstand large loads and vibrations. It also has excellent fatigue properties and can work stably under cyclic loads for a long time.

Good processing performance: 2319 aluminum alloy wire has good processing performance and can be processed by various processes such as drawing, extrusion, forming and cutting. At the same time, it also has good plasticity and toughness, and can adapt to complex deformation processes and processing requirements.

Good corrosion resistance: 2319 aluminum alloy wire has good corrosion resistance, and can resist the erosion of the atmosphere, water and chemical media. In addition, it also has good stress corrosion resistance and can work stably for a long time under high stress environment.

In short, 2319 aviation aluminum wire has the characteristics of high strength, good processing performance, corrosion resistance and excellent fatigue performance, which can meet the strict requirements of aviation, aerospace and other high-end fields.

2319 aerospace aluminum wire application

2319 aviation aluminum wire is widely used in aviation, aerospace, military and other fields, mainly for the manufacture of various aircraft, rockets, satellites and other structural parts and components, such as skin plates, frames, support rods, fasteners, engine components, etc.

Aircraft structural parts: 2319 aviation aluminum wire can be used to manufacture a variety of aircraft structural parts, such as skin plates, frames, support rods, etc. It has good strength and corrosion resistance, and can meet the requirements of aircraft in high strength and complex environments.

Engine parts: 2319 aviation aluminum wire can be used to manufacture various parts of aircraft and engines, such as turbine blades, impellers, intake ducts, exhaust pipes, etc. It has good high temperature performance and fatigue performance and can work stably for a long time under high temperature and high-speed environment.

Rocket and satellite structural parts: 2319 aviation aluminum wire can be used to manufacture various structural parts of rockets and satellites, such as combustion chambers, missile shells, spacecraft shells, etc. It has good strength and corrosion resistance and can withstand the extreme environment of high speed and high temperature.

In short, 2319 aviation aluminum wire has excellent performance and wide application prospects, and is one of the important materials in high-end fields such as aviation, aerospace and military industry.