Chalco can produce AMS 7222 UNS A92117 QQ A-430 2117 aerospace aluminium wire rod, has AS9100 Collin Aviation Certification.

Specifications of Chalco 2117 aerospace aluminium rod wire

Alloy: 2117

Material temper: O, H13, H15

Standard: AMS 7222 UNS A92117 QQ A-430 ASTM B316

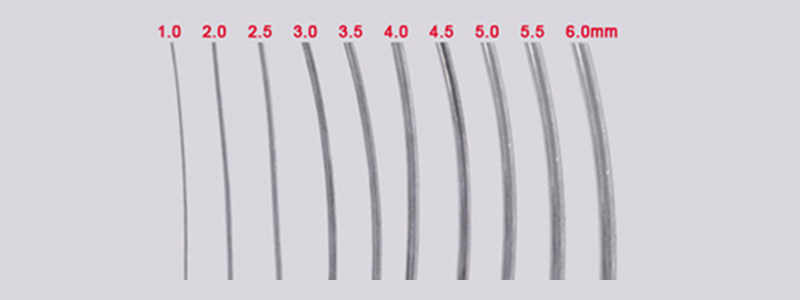

Wire diameter: 2-50mm

Disk weight: 1-300KG

Other dimensions may vary depending on the needs of the application.

Chemical composition of Chalco 2117A aerospace aluminum alloy

| Element | Composition(%) |

| Si | 0.8 |

| Fe | 0.7 |

| Cu | 2.2-3.0 |

| Mn | 0.2 |

| Mg | 0.20-0.5 |

| Cr | 0.10 |

| Zn | 0.25 |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |

| Si | 0.8 |

Mechanical properties of Chalco high quality 2117 aerospace aluminum rod wire

| Mechanical property | Value |

| Tensile strength | 300MPa |

| Yield strength | 240 Min MPa |

| Elongation | 10% |

Product features of Chalco 2117 aviation aluminum alloy rod wire

2117 aluminum alloy is a high-strength aluminum alloy mainly composed of aluminum, copper and magnesium

High strength: 2117 aluminum alloy has high strength, which is about 30% higher than that of ordinary aluminum alloys, and can be used for aerospace structural components that withstand high stress.

Good corrosion resistance: 2117 aluminum alloy has good corrosion resistance.

Easy processing and forming: 2117 aluminum alloy has good processing and forming properties, and parts of various shapes and sizes can be manufactured by forging, extrusion, rolling and other processes.

Good weldability: 2117 aluminum alloy has good weldability and can be welded by various welding processes.

Good heat treatment performance: 2117 aluminum alloy has good heat treatment performance, and its strength and hardness can be further improved by solution treatment and aging treatment.

Application of Chalco 2117A industrial aerospace grade aluminium rod wire

2117 Aviation & Aeronautics hot rolled aluminum alloy finished wire rod is mainly used in the aviation industry, including aircraft structural components, fuselage shells, engine components, and aerospace screws, nuts, small aerospace rivets and other fasteners.

Production process of Chalco 2117 (UNS A92117) aluminum rod wire

Raw material preparation: prepare high-purity aluminum, copper, magnesium and other materials, and at the same time need to control the oxygen content, water content and other indicators of raw materials.

Melting: after mixing the prepared raw materials in a certain proportion, put them into a high-temperature furnace for smelting. During smelting, parameters such as temperature, melting time, and atmosphere need to be strictly controlled to ensure the uniformity and purity of the alloy composition.

Stretching: after the smelted alloy billet is evenly heated, it is sent into the stretching machine. After multiple stretching and annealing treatments, the cross-sectional area is gradually reduced and the length is increased, so that it gradually becomes a wire.

Cooling: send the stretched aluminum wire into the cooling tank, and cool it quickly by soaking and spraying with cooling water, so that the physical properties of the wire are improved.

Straightening, cutting and packaging: the cooled aluminum wire is straightened and cut, and then packaged and shipped according to customer needs.

Why choose Chalco Aluminium as 2117 aerospace aluminum rod wire aircraft materials manufacturer?

Chalco provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting future challenges.

We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements. In addition, our R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

We have passed the AS9100 certification required by the aviation industry and the Colin Aviation certification, and produce according to the AMS 7222 UNS A92117 QQ A-430 standard required by customers, providing a strong guarantee for the quality of aerospace materials produced by our company.

The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.