2031 aviation metal aluminum wire is widely used in aircraft, helicopters, missiles and other structural components in the aviation industry, as well as satellites, spacecraft and other load components in the aerospace industry, has important significance.

Why choose Chalco 2031 aircraft aluminum flat wire?

Chalco is a professional manufacturer of aviation materials. It has AS9100 aviation certification and strictly complies with the following AMS aviation standards.

Standards

BS 2 L83 2031 standard: this is a standard issued by the British Standards Institute, which specifies the requirements for material number, mechanical properties, chemical composition, size and allowable defects of 2031 aviation aluminium wire.

AMS 4194C standard: this is a part of the American Aerospace Materials Specification, which covers the material and mechanical property requirements of 2031 aluminum wire and is applicable to the aerospace industry.

DIN 3.1255 standard: this is a German industrial standard, which specifies the requirements for chemical composition, mechanical properties, dimensions and allowable defects of 2031 aluminum aerospace wire, and is applicable to the aviation and aerospace industry.

MIL-W-6712E standard: this is a standard issued by the United States Department of Defense, covering the material and mechanical property requirements of 2031 aviation aluminum round wire, which is applicable to the military aviation and aerospace industry.

JIS H 4160 standard: this is a Japanese industrial standard, which specifies the requirements for chemical composition, mechanical properties, dimensions and allowable defects of 2031 aviation aluminum alloy wire, and is applicable to the aviation and aerospace industry.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO 45001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

The specification of 2031 aviation aluminum flat wire

| Alloy | 2031 |

| Temper | O, T3, T4, T6 |

| Diameter | 1mm-50mm |

| Packing | Spools |

| Standard | BS 2 L83 2031, AMS 4194C, DIN 3.1255, MIL-W-6712E, JIS H 4160 |

Chemical composition of 2031 aluminum alloy wire for aerospace

| Al | REM |

| Si | 0.50-1.3 |

| Fe | 0.6-1.2 |

| Cu | 1.8-2.8 |

| Mn | ≤0.50 |

| Mg | 0.6-1.2 |

| Cr | / |

| Ni | 0.6-1.4 |

| Zn | ≤0.20 |

| Ti | ≤0.20 |

| Note: EACH≤0.05; TOTAL≤0.15 | |

Mechanical properties of 2031 aircraft aluminum wire

| Temper | Tensile strength(MPa) | yield strength(MPa) | Elongation(%) | Hardness(HB) |

| T3 | 425 | 340 | 16 | 120-140 |

| T4 | 370 | 250 | 20 | 95-115 |

| T6 | 510 | 430 | 11 | 150-170 |

| O | 80 | 30 | 40 | 25-35 |

What are the advantages of Chalco 2031 T651 aviation aluminum flat wire?

Light weight and high strength

Compared with other common metal materials, aluminum has lower density, but higher strength and stiffness. 2031 high strength aluminum alloy wire has higher strength and hardness after heat treatment, which can meet the requirements for lightweight and high strength of materials in aviation, aerospace and other fields.

Corrosion resistance

Aluminum is a kind of metal material with good corrosion resistance, which is not easily affected by oxidation, corrosion and other factors. In some special environments, such as ocean and high temperature, aluminum has better corrosion resistance.

Good processability

Aluminum has good plasticity and machinability, and can be processed, formed, welded, cut and other operations in various ways. This makes 2031 aluminum square wire can be flexibly applied in different applications to meet different requirements.

Recyclability

Aluminum is a recyclable material. 2031 aviation aluminum wire rod can be recycled and reused, helping to reduce resource waste and environmental pollution.

Relatively low price

Compared with other high-performance metal materials, the price of 2031 aluminum aircraft wire is relatively low, which can provide more economic solutions in different applications.

What are the precautions for purchasing 2031 high strength aluminum alloy wire?

Select regular suppliers

When purchasing 2031 T4 aviation aluminum wire, it is necessary to select regular suppliers to ensure product quality and supply chain stability. It is recommended to select suppliers with relevant qualifications and certifications, such as ISO9001, AS9100, etc.

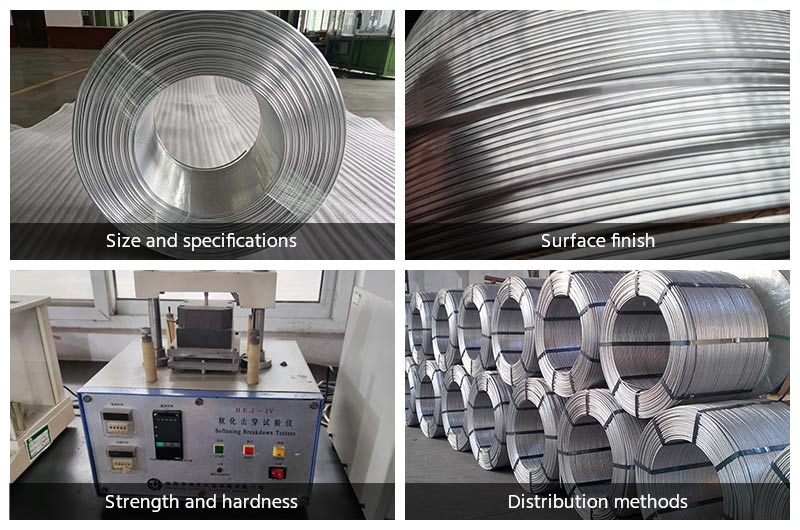

View product specifications

When purchasing 2031 T6 aerospace aluminum wire, it is necessary to carefully check the product specifications and technical parameters to ensure that the purchased products meet the requirements. In particular, it is necessary to pay attention to the requirements of chemical composition, mechanical properties, size and surface quality of products.

Quality certification

When purchasing 2031 aviation aluminum wires, it is necessary to understand and verify the product quality certification and relevant test reports provided by the supplier. The supplier can be required to provide the quality certificate issued by the third-party certification authority to ensure the product quality and reliability.

Packaging and transportation

When purchasing 2031 aluminum metal wire, attention should be paid to the packaging and transportation of the product to avoid damage or quality problems during transportation. It is recommended to select an experienced logistics company or transportation professional organization for transportation to ensure that the products can reach the destination safely.

Establish long-term cooperative relationship with suppliers

For users who need to use 2031 aluminum aircraft wire for a long time, it is suggested to establish a long-term cooperative relationship with suppliers to obtain better product price and service support. We can improve the procurement efficiency and reduce the procurement cost through regular procurement and batch procurement.

What are the applications of Chalco 2031 aircraft grade aluminum wire?

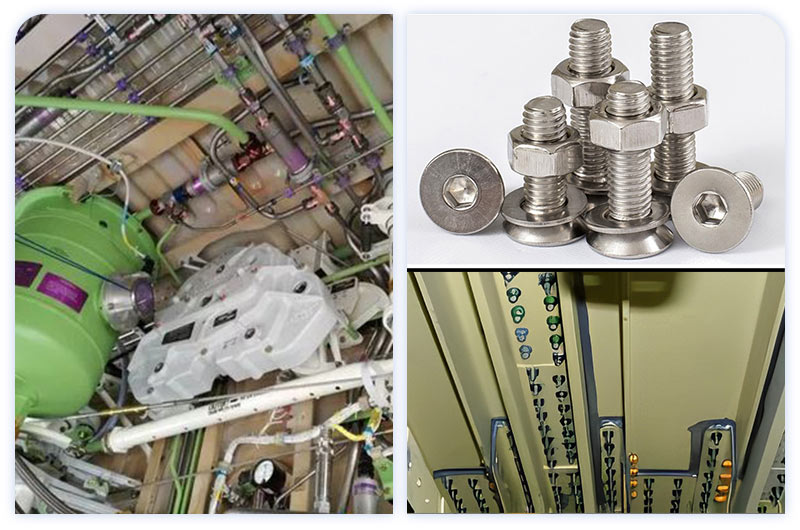

Aircraft structural components

2031 aerospace wire is widely used in aircraft structural components, such as fuselage, wing, beam, etc., due to its advantages of light weight, high strength, corrosion resistance, good processability, etc.

Aerospace equipment

2031 aluminium aircraft flat wire is also often used to manufacture various aerospace equipment and tools, such as engines, hydraulic systems, electrical connecting wires, instruments, etc.

Fuel system

The excellent corrosion resistance and high strength of 2031 aviation aluminum wire make it an ideal material for manufacturing fuel system, such as fuel tank, oil pipeline, etc.

Aviation ground support equipment

2031 aluminium high strength wire is also widely used in aviation ground support equipment, such as pulley, bracket, sling, traction rope, etc.

Aviation parts

2031 aluminum alloy wire for aviation can also be used to manufacture various aviation parts, such as fasteners, screws, nuts, etc.