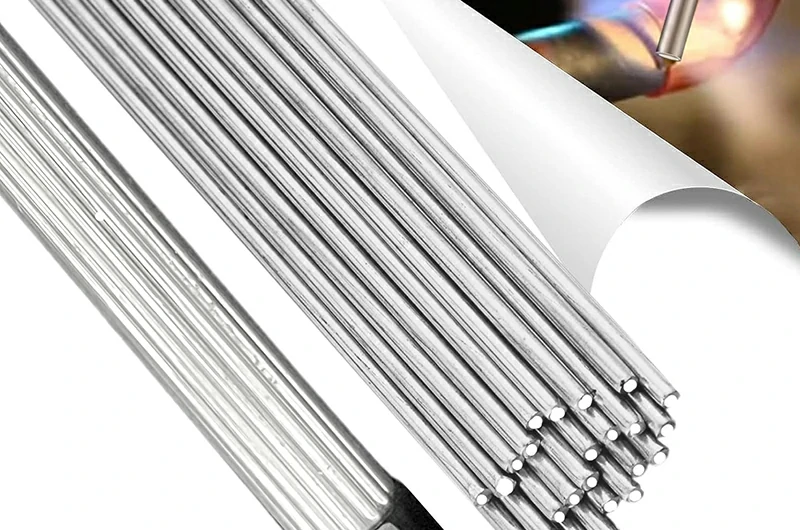

Chalco supplies a full range of aluminum brazing rods designed for repair, assembly, and production applications requiring controlled heat input and reliable joint performance. Our aluminum brazing rod portfolio includes low-temperature, flux-coated, fluxless, and high-strength options to support different joint conditions and process requirements.

Low-temperature brazing capability: Enables aluminum joining at lower temperatures than welding, helping reduce heat distortion and base-metal damage.

Clean, reliable joints: Good wetting behavior supports smooth joints with consistent mechanical strength.

Multiple rod configurations: Flux-coated, fluxless, and high-strength aluminum brazing rods available to match different brazing conditions.

Typical application coverage: Commonly used in HVAC refrigeration systems, automotive heat exchangers, Cu–Al tubing, and aluminum component repair.

Aluminum Brazing Rod Types and Options

Aluminum brazing rods are commonly classified based on flux configuration and performance requirements. The following product types cover typical repair, assembly, and production brazing scenarios.

Low Temperature Aluminum Brazing Rods

Typical working range: 380–420 ℃ (716–788 ℉)

Typical uses: thin-wall and heat-sensitive parts; window frames, doors, gutters, HVAC lines

Key features: low heat input, reduced deformation risk, easy operation

Flux-Coated Aluminum Brazing Rods

Flux configuration: external coating; no additional flux required during brazing

Typical uses: HVAC repair, aluminum doors and windows, furniture repair

Key features: effective oxide removal, clean and reliable joint formation

Fluxless Aluminum Brazing Rods

Alloys: Al–Si (4045 / 4047 / 4343) solid rods

Typical use: vacuum and controlled-atmosphere furnace brazing for industrial production

Notes: mainly used with VAC/CAB and clad materials

Flux Core Aluminum Brazing Rods

Structure: aluminum-alloy sheath with internally contained flux

Typical uses: batch HVAC and automotive brazing operations

Key features: controlled flux release during heating, suitable for automated or semi-automated processes

High Strength Aluminum Brazing Rods

Typical alloys: Al–Si series (e.g., 4047)

Typical uses: automotive radiators, oil coolers, trailer bodies

Key features: higher joint strength with improved crack resistance

Related Brazing Materials from Chalco

Beyond aluminum brazing rods, Chalco also supplies the following brazing materials for broader metal-joining requirements:

- Copper Brazing Rods: For copper and copper-alloy joining in air-conditioning, refrigeration, and electrical industries, offering high joint strength and good electrical conductivity.

- Silver Brazing Rods: Silver-based alloys with low melting points and excellent wetting performance, widely used in precision instruments, refrigeration equipment, and high-end manufacturing.

For detailed specifications, quotations, or project-based recommendations, please contact our sales team for further support.

Chalco Aluminum Brazing Rod – Supply Specifications & Alloy Range

The following specifications reflect Chalco's standard supply range for aluminum brazing rods. Additional sizes, packaging formats, and alloy configurations can be provided based on project requirements.

Rod diameter: 1.6 mm / 2.0 mm / 2.4 mm

Standard length: 330 mm / 500 mm

Form: Straight rods

Packing options: 5 pcs / 10 pcs small packs; 0.5 kg / 1 kg industrial packs; customized packing supported

Chalco supplies aluminum brazing rods across multiple alloy systems. Typical alloy families available for supply include:

-

4045 / 4047 / 4343

Al–Si brazing alloys with good fluidity and stable melting behavior, commonly supplied for heat exchangers and compatible with non-corrosive PFA / Nocolok® flux systems.

-

Zn–Al Series

Zn–Al brazing alloys supplied for copper-to-aluminum joining applications, widely used in HVAC, refrigeration, and automotive air-conditioning pipelines.

-

Al-Bronze / Mg Series

Special-purpose aluminum brazing alloys supplied for wear-resistant or high-temperature repair applications under specific service conditions.

Technical Notes for Aluminum Brazing Rod Selection

The following technical notes and temperature ranges are provided as general selection references for aluminum brazing rods. Actual brazing parameters should be determined based on equipment capability, joint design, base-metal thickness, and service conditions.

Standards reference: Melting points and recommended brazing temperature ranges are based on AWS A5.8/A5.8M and EN ISO 17672 and are intended for selection guidance rather than fixed process instructions.

Flux selection notes: Listed flux configurations reflect common industry practices. Final flux selection should consider environmental regulations, process compatibility, and application-specific requirements.

Application guidance: Typical application scenarios are provided for reference. Customized alloy formulations and technical recommendations can be evaluated based on project conditions.

Al–Si Brazing Rods

Al–Si aluminum brazing rods are commonly used for aluminum-to-aluminum joints and heat exchanger applications due to their stable melting behavior and good fluidity.

| Alloy Grade | Chemical Composition | Melting Point Range (°C) | Recommended Brazing Temperature (°C) |

| 4045 | Al–Si (~10% Si) | 570–585 | 595–620 |

| 4047 | Al–Si (~12% Si) | 577–582 | 600–630 |

| 4343 | Al–Si (~7% Si) | 573–585 | 595–625 |

Zn–Al Alloys (Copper to Aluminum Brazing Rods)

Zn–Al brazing alloys are typically selected for copper-to-aluminum joints where controlled heat input and dissimilar-metal compatibility are required.

| Alloy Grade | Chemical Composition | Melting Point Range (°C) | Recommended Brazing Temperature (°C) |

| Zn-5Al | Zn–5%Al | 385–410 | 450–520 |

| Zn-10Al | Zn–10%Al | 370–420 | 460–520 |

Al-Bronze / Mg Alloys (Special Purpose Brazing Rods)

Al-bronze and magnesium-based brazing rods are used for special repair or service conditions involving wear resistance or elevated operating temperatures.

| Alloy Grade | Chemical Composition | Melting Point Range (°C) | Recommended Brazing Temperature (°C) |

| Zn-5Al | Zn–5%Al | 385–410 | 450–520 |

| Zn-10Al | Zn–10%Al | 370–420 | 460–520 |

*For magnesium-based or aluminum–magnesium repair applications, strict process control, surface protection, and safety procedures are required.

Technical Variants of Aluminum Brazing Rods

The following technical variants represent special-purpose aluminum brazing rods used under specific mechanical or thermal service conditions.

| Alloy Grade | Chemical Composition | Melting Point Range (°C) | Recommended Brazing Temperature (°C) |

| Al-Bronze Rods | Cu–Al Alloy (Al 8–12%) | 1020–1040 | 1050–1100 |

| Mg-Based Rods | Al–Mg Alloy (Mg 3–5%) | 570–630 | 600–650 |

Industry Selection Guide for Aluminum Brazing Rods

Chalco aluminum brazing rods cover multiple alloy systems and brazing process options for HVAC, automotive, construction, and industrial maintenance applications. The following guidance summarizes typical aluminum brazing rod selections based on common industry use scenarios.

HVAC and Refrigeration Systems

Zn–Al series brazing rods and low temperature aluminum brazing rods are commonly selected for evaporators, condensers, and copper-to-aluminum joints to limit heat input and maintain heat-exchange efficiency. Post-braze protective coatings are recommended, and galvanic corrosion between dissimilar metals should be considered in system design.

Automotive and Transportation

In automotive and transportation applications, Al–Si brazing alloys such as 4045 / 4047 / 4343 are widely used for radiators, oil coolers, and A/C components, where aluminum brazing rods are commonly applied for repair and aftermarket maintenance, while automotive brazed sheets and automotive brazed foils are supplied for batch production and thermal management assemblies.

Construction and Home Improvement

Flux-coated aluminum brazing rods are typically used for door and window frames, gutters, and wall panels, offering simplified operation without the need for additional flux during brazing.

Industrial Equipment and Molds

Mg-based brazing rods or low temperature aluminum brazing rods are commonly applied for crack repair, build-up, and remanufacturing work where controlled heat input and cost efficiency are required.

Furniture, Marine, and Daily Goods

Al–Si brazing rods (4045 / 4047) are commonly used for aluminum-to-aluminum joints. For copper-to-aluminum connections, Zn–Al series brazing rods are selected with appropriate corrosion isolation measures. Finished joints are typically neat in appearance and suitable for long-term service.

For project-based selection, joint condition evaluation, or customized alloy recommendations, please contact our technical sales team for further support.

Note: Brazing is not recommended for high-strength aluminum alloys such as 2011, 2014, 2017, 2024, and 7075 due to potential post-braze strength loss or cracking. These high Cu/Zn or high-strength series are sensitive to joint softening and are not suitable for routine brazed repair.

Aluminum Brazing System Solutions from Chalco

In practical aluminum brazing applications, joint performance is determined not only by the brazing rod itself, but by the compatibility between filler materials, flux systems, and base materials. Chalco supplies a complete aluminum brazing material system to support different brazing processes, component designs, and production scenarios.

Our aluminum brazing solutions integrate multiple brazing materials and semi-finished forms, allowing customers to select coordinated combinations rather than isolated consumables.

- Aluminum Brazing Foil: Thin brazing filler foil supplied for controlled-gap joints, widely used in heat exchangers and automotive brazed assemblies.

- Aluminum Brazing Strip: Supplied in strip form for continuous brazing lines and stamped or formed components requiring consistent filler distribution.

- Brazing Ring & Preforms: Pre-shaped brazing fillers designed for precise joint placement, improving brazing efficiency and joint consistency.

- Brazing Flux: General brazing flux systems used to remove oxide films and promote wetting during aluminum brazing processes.

- Aluminum Brazing Flux: Aluminum-specific flux formulations compatible with Al–Si brazing alloys and controlled-atmosphere brazing systems.

- Aluminum Filler Rods: A broader category covering aluminum brazing rods and filler materials for repair, assembly, and production joining.

- Aluminum Welding Wire: Supplied for fusion welding applications where brazing is not suitable due to strength or service conditions.

By supplying aluminum brazing rods together with foils, strips, preforms, and flux systems, Chalco supports integrated brazing solutions for both manual repair and industrial mass production.

Frequently Asked Questions (FAQ)

Q1: Where can I source suitable aluminum brazing rods for my application?

A: Aluminum brazing rods are typically sourced through professional metal or brazing-material suppliers. Compared with general retail searches, working with an established supplier helps ensure consistent alloy composition, stable brazing performance, and technical support for project-based applications.

Q2: Do you supply aluminum brazing kits?

A: Yes. Aluminum brazing kits can be supplied upon request, typically including brazing rods, compatible flux (if required), and commonly used specifications. These kits are suitable for maintenance, repair, and on-site brazing work.

Q3: Do you provide related brazing supplies?

A: In addition to aluminum brazing rods, we supply related brazing consumables and support customization of rod diameter, length, and packaging. Standard items are available for quick delivery for HVAC, automotive, and general repair applications.

Ordering & Delivery

The following information outlines Chalco's standard ordering, customization, and delivery capabilities for aluminum brazing rods:

Inventory & delivery: Common specifications of aluminum brazing rods and related brazing supplies are kept in stock to support fast shipment.

Customization: Aluminum brazing rods can be supplied with customized diameters, lengths, alloy selections, and packaging formats, supporting OEM and project-based requirements.

Global supply: Products can be shipped by sea, air, or express delivery to Europe, North America, Southeast Asia, Japan, Korea, and other international markets.

Project support: Samples and volume supply are available. Technical and commercial support is provided for aluminum brazing rod selection, pricing inquiries, and project coordination.

Contact Chalco to request specification sheets, current quotations, or samples, and discuss aluminum brazing rod solutions tailored to your application.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote