6951 aluminum bar is a high-strength aluminum alloy with excellent welding performance and good corrosion resistance. It is widely used in aerospace, automotive and other high-demand industrial fields.

This aluminum bar is particularly suitable for structural components that need to bear loads and performs well in brazing and welding processes. With its excellent mechanical properties and durability, 6951 aluminum bar has become an important material choice in the manufacturing and engineering fields.

Chalco 6951 aluminum rod product introduction

Chalco aluminum rod production and processing methods: drawing, extrusion, forging

Chalco round bar diameter range: 5 -100mm (cold drawn bar); φ5-600mm (extruded bar); φ100-650mm (forged bar)

Aluminum rod length: can be cut to any length.

Aluminum rod surface treatment: mill finish, anodizing, bright surface, painting/coating, polishing ...

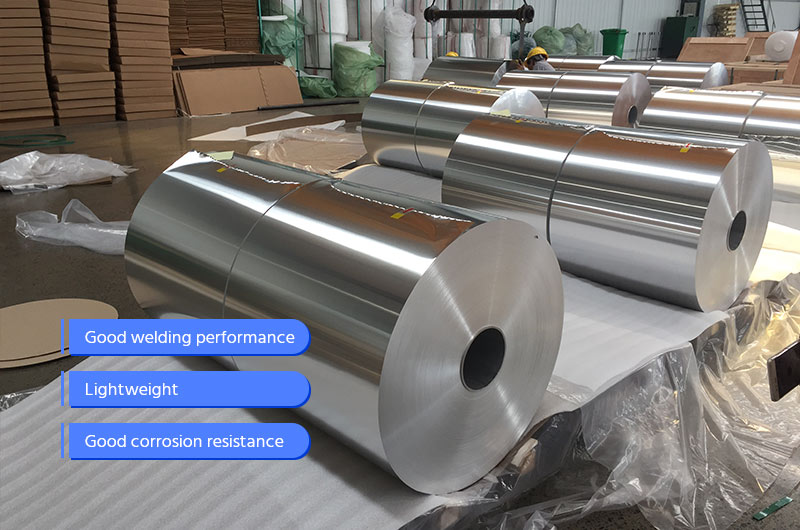

6951 Aluminum Rod Product features: Excellent welding performance; High strength; Good corrosion resistance

6951 Aluminum Bar Equivalent Names: UNS A96951; Aluminium 6951-T6; AA6951-T6; Al6951-T6

Chalco 6951 aluminum rod hot selling product types

6951 T6 aluminum rod

6951 aluminum rods in T6 temper offer high strength and excellent corrosion resistance, ideal for extreme environments. Widely used in aerospace and high-performance structures, they reduce weight while enhancing performance with their lightweight, high-strength properties.

6951 extruded rod

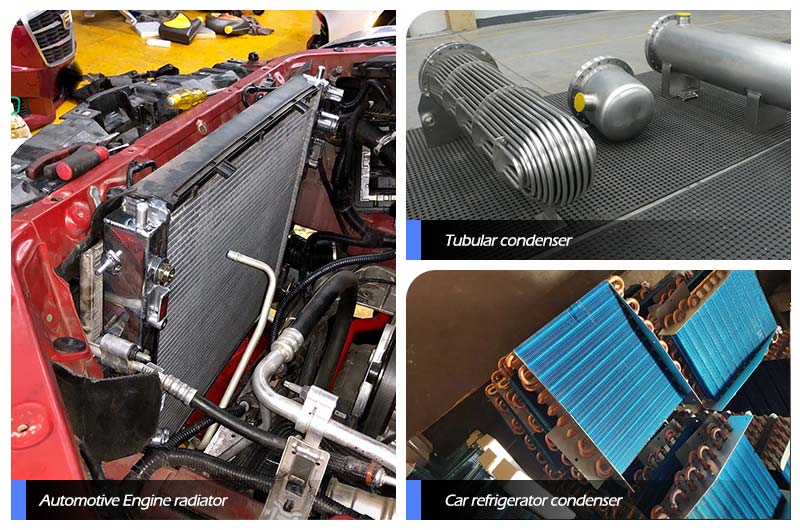

Extruded 6951 aluminum offers uniform cross-sections and excellent surface quality, ideal for structural parts in aerospace, meeting high strength and lightweight demands. Its properties make it perfect for aerospace heat transfer devices.

6951 aluminum round bar

With a circular cross section, it is easy to process and form, suitable for a variety of mechanical and structural applications. It is often used to make shafts, supports and connectors, and is widely used in aviation, automobiles and other industrial fields.

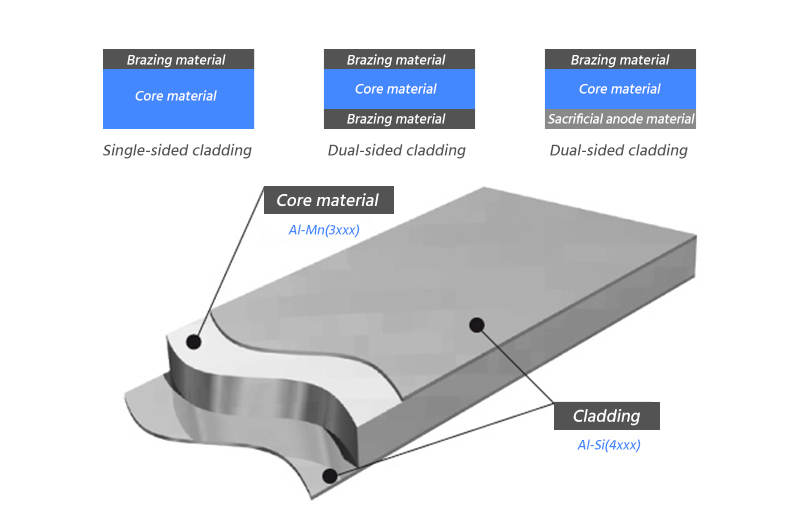

6951 brazing bar

For brazing process, it has good fluidity and strength to ensure a strong connection. It is widely used in heat exchangers, automotive components and aerospace structures where high-strength connections are required.

6951 welding rod

It has good welding performance and is suitable for connection and repair work in high temperature environment. It is mainly used in the manufacture of heat exchangers and other equipment that require efficient heat conduction to ensure the strength and durability of the connection parts.

6951 aluminum rod chemical composition

| Element | Component (%) |

| Fe | max 0.8 |

| S | 0.2 - 0.5 |

| Mn | max 0.1 |

| Cu | 0.15 - 0.4 |

| Mg | 0.4 - 0.8 |

| Zinc | max 0.2 |

| Others | each 0.05; total 0.15 |

| Al | remainder |

6951 aluminum bar mechanical property

| Wrought aluminum-magnesium-silicon alloy 6591 | ||||

| Property | Value in metric units | Value in US units | ||

| Density | 2.70 *1 | kg/m3 | 169 | lb /ft3 |

| Modulus of elasticity | 69 | GPa | 10000 | ksi |

| Thermal expansion (20 oC) | 23.4*10 -6 | oCˉ1 | 13.0*10 -6 | in/(in* ºF) |

| Specific heat capacity | 890 | J/(kg*K) | 0.213 | BTU/(lb*ºF) |

| Thermal conductivity | 213 | W/(m*K) | 1480 | BTU*in/(hr*ft²*ºF) |

| Electric resistivity | 3.16*10-8 | Ohm*m | 3.16*10-6 | Ohm*cm |

| Tensile strength (annealed) | 110 | MPa | 16000 | psi |

| Yield strength (annealed) | 40 | MPa | 5800 | psi |

| Elongation (annealed) | 30 | % | 30 | % |

| Shear strength (annealed) | 75 | MPa | 10900 | psi |

| Hardness (annealed) | 28 | HB | 28 | HB |

| Tensile strength (T6) | 270 | MPa | 39200 | psi |

| Yield strength (T6) | 230 | MPa | 33400 | psi |

| Elongation (T6) | 13 | % | 13 | % |

| Shear strength (T6) | 180 | MPa | 26100 | psi |

| Hardness (T6) | 82 | HB | 82 | HB |

| Annealing temperature | 413 | ºC | 775 | °F |

| Solution temperature | 529 | ºC | 985 | °F |

| Aging temperature | 160 | ºC | 320 | °F |

Chalco 6951 aluminum rod performance advantages

- Excellent brazing performance: 6951 aluminum rod performs well in the brazing process, ensuring the strength and durability of the welded joint, suitable for heat exchangers and other applications requiring efficient connections.

- High Strength: 6951 aluminum alloy has superior strength properties and is suitable for applications requiring high strength and low weight, especially in the aerospace and automotive industries.

- Lightweight: Due to its high strength characteristics, Chalco 6951 aluminum bar can reduce the size of components without sacrificing performance, thereby reducing the overall weight and meeting the lightweight needs of modern industry.

- Corrosion resistance: 6951 aluminum alloy exhibits good corrosion resistance in corrosive environments, extending the service life of the product and reducing maintenance costs.

- Good processing performance: 6951 aluminum bar is easy to process and form, suitable for various manufacturing processes, including extrusion, cutting and forming, etc., to meet different design requirements.

- Thermal conductivity: 6951 aluminum alloy has good thermal conductivity, which makes it perform well in heat exchange applications and can effectively improve thermal efficiency.

Chalco 6951 aluminum bar cooperation areas

- Aerospace: The application of 6951 aluminum bars in the aerospace field includes the brazing connection of aircraft fuselage, wing beam and skin, and the component welding of engine radiator. These applications ensure the strength and lightness of the structure and meet the requirements of high performance and safety.

- Automotive industry: In the automotive industry, 6951 aluminum bars are used for brazing connections of radiators, condensers and oil coolers, as well as assembly of body structures. These applications improve heat exchange efficiency and overall strength, meeting the requirements of modern automobiles for lightweight and high performance.

- Mechanical Manufacturing: Used to make mechanical parts such as shafts, supports and connectors to meet high strength and precision requirements.

- Construction and Infrastructure: In the construction industry, 6951 aluminum bars can be used for lightweight frames and structural materials to improve the seismic resistance and durability of buildings.

- Energy field: used in renewable energy fields such as wind power generation and solar energy equipment. Due to its excellent performance, it can meet extreme working conditions.

- Military and Defense: Due to its high strength and lightweight characteristics, it is suitable for use in military equipment and protective structures to meet high performance requirements.

Chalco 6951 alloy other product types and related brazing products

6951 Aluminum Rod Buying Guide

1. How to calculate the weight when purchasing 6951 aluminum bars

When purchasing aluminum bars from Chalco, you can click [Calculator Service] to easily calculate the weight of 6951 aluminum bars.

2. What is the tolerance of 6951 aluminum bar?

The following are the various tolerances for different forms of 6951 aluminum alloy; they are:

- Round pull rods – Tolerance range is between 0.3 and 2.5 mm.

- Square pull rods - tolerance values range from 0.3 to 1.7 mm.

- Flat steel – Tolerance values range from 0.35 to 1.4 mm.

3. 6951 aluminum bar price

6951 aluminum bar price = (LME ingot price + processing fee) × weight + packaging fee + transportation fee

Please contact the sales staff to inquire about the price and processing fee per ton of various specifications of aluminum bars. The processing fee of 6951 aluminum bars of different sizes may vary greatly, and we will provide you with the best quotation.

4. How to choose 6951 aluminum rod supplier/stockist?

When selecting a 6951 Aluminum Rod supplier, several factors must be considered to ensure you receive high-quality material and reliable service.

- Customized service: Chalco can provide customized service according to customer needs. You only need to inform the length, quantity, surface finish, cutting, bending, color coating, end use and other special requirements.

- Competitive Price: Our products are priced competitively and we offer reasonable discounts for large quantities, giving you better prices and quality service.

- After-sales support: We provide fast after-sales support to ensure that you get timely help and support when using our products.

- Fast Delivery: We have abundant inventory to ensure fast shipment of any product, saving time for your project.

5. Chalco 6951 aluminum rod packaging

- Plastic or kraft paper packaging with moisture-proof desiccant inside.

- Mounted on wooden pallets, reinforced with steel straps and supplied with fumigation certificate.

- Packaging can be customized according to other customer requirements.

6. Chalco 6951 aluminum rod product quality assurance

- 6951 There shall be no cracks, bubbles or corrosion spots on the surface of round bars, square bars and hexagonal bars.

- 6951 The surface of round bars, square bars or hexagonal bars shall not have deep scratches, wear, dents or straightening marks exceeding the tolerance range.

- Documents we provide include - Certificate of Origin, Invoice and PL certified by Chamber of Commerce, Test Certificate in accordance with EN10204 3.1 and other test reports (as per customer's request).

- 6951 Aluminium Bar and Strip – The bars will be fully marked and details can be linked to the test certificate.

Chalco 6951 aluminum rod stock size reference chart

Below are some of Chalco's 6951 aluminum rods with hot-selling sizes. If you can't find the product that suits your needs, you can click [Contact]to communicate with our sales staff about the specific product. All lengths can be cut.

| Diameter (inch) | Diameter (Metric) | Weight (KG/ Metre ) | Availability |

| 3/8” | (9.53mm) | 0.202 | Available |

| 1./2” | (12.7 mm) | 0.355 | Available |

| 5/8” | (15.88 mm) | 0.561 | Available |

| 3/4” | (19.05 mm) | 0.807 | Available |

| 7/8 ” | (22.23 mm) | 1.097 | Available |

| 1” | (25.4 mm) | 1.419 | Available |

| 1.1/8 ” | (28.58 mm) | 1.816 | Available |

| 1.1/4” | (31.75 mm) | 2.241 | Available |

| 1.3/8” | (34.93 mm) | 2.690 | Available |

| 1.1/2” | (38.1 mm) | 3.226 | Available |

| 1.5/8” | (41.28 mm) | 3.747 | Available |

| 1.3/4 ” | (44.45 mm) | 4.360 | Available |

| 2” | (50.8 mm) | 5.675 | Available |

| 2.1/4” | (57.15 mm) | 7.190 | Available |

| 2.1/2” | (63.5 mm) | 8.867 | Available |

| 2.3/4” | (69.85 mm) | 10.730 | Available |

| 3” | (76.2 mm) | 12.769 | Available |

| 3.1/4 ” | (82.5 mm) | 14.986 | Available |

| 3.1/2” | (88.9 mm) | 17.380 | Available |

| 3.3/4” | (95.25 mm) | 20.165 | Available |

| 4” | (101.6 mm) | 22.700 | Available |

| 4.1/4” | (107.95 mm) | 25.627 | Available |

| 4.1/2” | (114.3 mm) | 28.730 | Available |

| 5” | (127 mm) | 35.469 | Available |

| 5.1/4” | (133.35 mm) | 39.105 | Available |

| 5.1/2” | (139.7 mm) | 42.994 | Available |

| 6” | (152.4 mm) | 51.076 | Available |

| 6.1/2” | (165.1 mm) | 59.943 | Available |

| 7” | (177.8 mm) | 69.650 | Available |

| 8” | (203.2 mm) | 90.802 | Available |

| 9” | (228.6 mm) | 115.120 | Available |

| 10” | (254 mm) | 140.065 | Available |