Drawn aluminum tube refers to aluminum tubing that is cold-worked through multiple-pass drawing after initial extrusion. Compared to extruded tubes, drawn tubes offer superior dimensional accuracy (up to ±0.05 mm), smoother surface finish (Ra ≤ 1.6 μm), and enhanced concentricity and mechanical performance.

Chalco offers a full range of cold drawn, seamless drawn,precision drawn aluminum tubes—from aerospace-grade ±0.05 mm precision tubes to cost-effective long-length tubing for heat exchangers and structural systems.

Drawn aluminum tube - premium selection

Cold Drawn Aluminum Tube

Cold drawn aluminum tubes are manufactured by cold working through multiple drawing passes after extrusion, resulting in high dimensional accuracy, superior concentricity, and improved mechanical properties. Compared to standard extruded tubes, cold drawn tubes achieve tighter tolerances (as low as ±0.05 mm), better surface finish (Ra ≤ 1.6 μm), and are ideal for precision assembly or CNC machining.

Cold Drawn Aluminum Tube

Outer Diameter: 6–140 mm

Wall Thickness: 0.5–10.0 mm

Length: 2 m, 3 m, up to 6 m (custom lengths)

Standards: ASTM B210, AMS 4088, ASTM B483, EN 754

Alloy Recommendations

High-strength aluminum-copper alloy with excellent fatigue resistance and dimensional stability after drawing. Commonly used in aircraft spars, landing gear components, and structural frames.

Corrosion-resistant and formable alloy suitable for medium-pressure piping and structural tubes. Ideal for heat exchangers, chemical transport, and HVAC systems.

Versatile alloy with good weldability and strength. Cold drawn 6061 tubes offer excellent precision for hydraulic systems, mechanical parts, and engineering structures.

Ultra-high strength aluminum-zinc alloy. After cold drawing, 7075-T6 offers superior load-bearing capacity and crack resistance for demanding structural and military applications.

Seamless Drawn Aluminum Tube

Seamless drawn aluminum tubes are produced from high-quality extruded billets by piercing, cold drawing (or cold rolling), multiple annealing, and precision straightening. With no weld seam, they offer uniform dense structure, superior structural integrity and pressure resistance, excellent corrosion performance, and tight dimensional control (Ra ≤ 0.8 μm). Ideal for aerospace, chemical and energy heat exchangers, high-pressure fluid lines, marine piping, and hydraulic/pneumatic systems.

Outer Diameter: 6–200 mm

Wall Thickness: 1.0–25.0 mm

Length: up to 8 m (custom lengths available)

Standards: ASTM B210, WW-T-700

Delivery Form: Straight Length / Coil

Related Seamless Tube Products

Thick-wall seamless tubes for high-pressure service and industrial fluid lines.

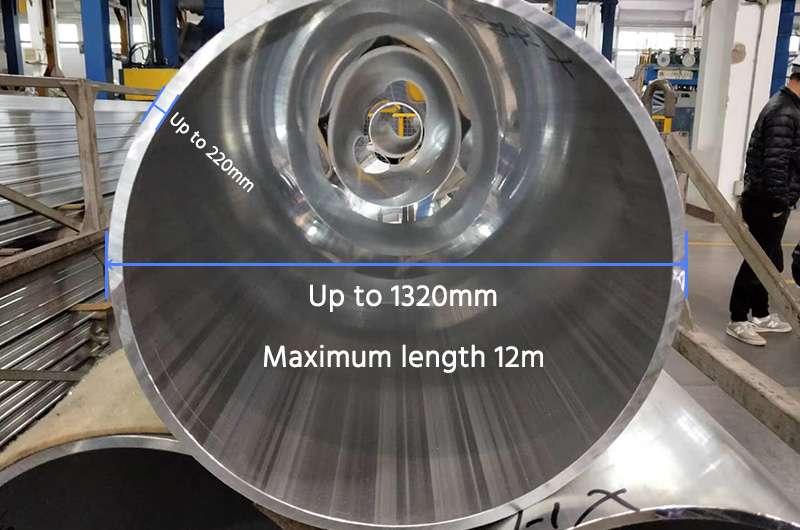

Up to very large diameters for heavy equipment, marine and aerospace structures.

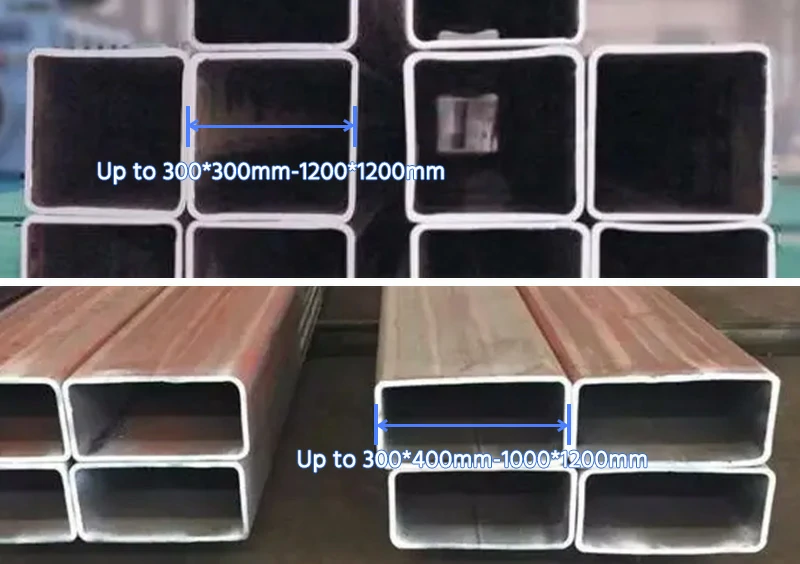

High stability square sections for frames, decks and industrial structures.

Seamless construction for gas cylinders and chemical/energy pressure systems.

Alloy Recommendations

-

1100 Seamless Aluminum Tube | WW-T-700/1Inquire Now

1100 Seamless Aluminum Tube | WW-T-700/1Inquire NowExcellent corrosion resistance; used in chemical equipment, food processing and low-pressure piping. -

3003 Seamless Aluminum Tube | WW-T-700/2Inquire Now

3003 Seamless Aluminum Tube | WW-T-700/2Inquire NowGood formability and corrosion resistance; widely used in heat exchangers and HVAC piping. -

2024 Seamless Aluminum Tube | WW-T-700/3Inquire Now

2024 Seamless Aluminum Tube | WW-T-700/3Inquire NowHigh-strength Al-Cu alloy with excellent fatigue performance for aerospace structures. -

5052 Seamless Aluminum Tube | WW-T-700/4Inquire Now

5052 Seamless Aluminum Tube | WW-T-700/4Inquire NowExcellent seawater resistance; used in marine piping and offshore engineering. -

5086 Seamless Aluminum Tube | WW-T-700/5Inquire Now

5086 Seamless Aluminum Tube | WW-T-700/5Inquire NowHigh-magnesium corrosion-resistant alloy for refrigeration, ship pipelines and pressure vessels. -

6061 Seamless Aluminum Tube | WW-T-700/6Inquire Now

6061 Seamless Aluminum Tube | WW-T-700/6Inquire NowBalanced strength and weldability for mechanical structures and hydraulic systems. -

7075 Seamless Aluminum Tube | WW-T-700/7Inquire Now

7075 Seamless Aluminum Tube | WW-T-700/7Inquire NowUltra-high strength alloy for aerospace, defense and other high-load applications.

Looking for high-performance seamless aluminum tubes that meet ASTM B210 and WW-T-700 standards?

With full in-house production, strict quality control, and flexible delivery, Chalco is your trusted partner for aerospace, marine, chemical, and industrial projects. Contact us today to get a quote or request samples.

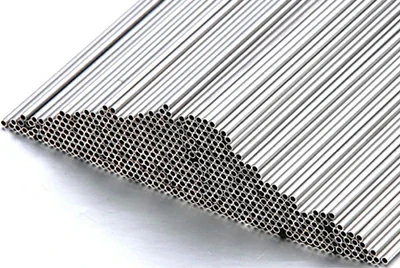

Precision Drawn Aluminum Tube

Precision drawn aluminum tubes are manufactured through multiple stages of cold drawing, annealing, and straightening. This process delivers exceptional dimensional accuracy, superior surface finish (Ra ≤ 0.8 μm), and consistent mechanical performance. They are widely used in applications that require high precision in dimensions, surface quality, and assembly fit, such as heat exchangers, compact structural components, medical equipment, and automated systems.

Precision Drawn Aluminum Tube

Outer Diameter: 3–60 mm

Wall Thickness: 0.25–6.0 mm

Surface Roughness: Ra ≤ 0.8 μm

Standards: EN 754-2, ASTM B210

Delivery Form: Straight Length / Coil

Alloy Recommendations

- 1100 Precision Drawn Tube

Excellent ductility and corrosion resistance for flexible connectors and conduits.

ASTM B210, WW-T-700/1

- 3003 Precision Drawn Tube

Ideal for radiators, condensers, and engineered tubing applications.

ASTM B210, WW-T-700/2

- 6063 Precision Drawn Tube

Heat-treatable alloy with excellent finish, used for trim, framing, and lightweight structures.

ASTM B483

Product recommendations

Small Aluminum Tube

Compact tubes for sensors and precision assemblies

Aluminum Capillary Tube

For fluid control in medical and HVAC applications

Coiled Aluminum Tube

Easy-to-install coils for refrigeration and fluid lines

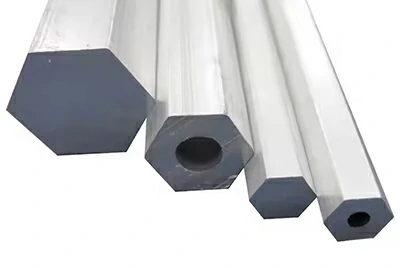

Full-Shape Drawn Aluminum Tube Supply

Chalco offers drawn aluminum tubes in multiple cross-sectional shapes, including round, square, rectangular, oval, and custom designs such as hexagonal and streamlined profiles. All products are manufactured using precision cold drawing, with strict dimensional tolerance control and optional surface finishes such as anodizing, powder coating, or polishing. Suitable for both large-scale production and small-batch prototyping.

Outer diameter: 5–220mm

Wall thickness: 0.5–10 mm

Uniform strength and high adaptability, widely used in aerospace structures, fluid transfer, heat exchanger systems, and mechanical components.

Click to view round tube size chart.

Side length: 10–120 mm

Wall thickness: 1–7 mm

Rigid structure and easy assembly, ideal for frames, supports, railings, and industrial automation equipment.

Click to view square tube size chart.

Drawn Rectangular Aluminum Tube

Side length: 10–120 mm

Wall thickness: 1–7 mm

Space-saving and flexible in layout, suitable for heat exchanger frames, instrument housings, and decorative structures.

Click to view rectangular tube size chart.

Streamlined profile with low wind resistance, commonly used in aerospace, rail transit, and automotive structural parts.

High structural stability and multi-faceted grip design, often applied in industrial tools, fastening systems, and decorative frames.

Drawn Streamlined Aluminum Tube

Aerodynamic contour for reduced drag, ideal for transport equipment, sports gear, and performance-oriented designs.

Looking for the right drawn aluminum tube shape for your project? Chalco offers full-shape seamless and precision drawn aluminum tubes, with customizable alloys, dimensions, and surface treatments. Contact our engineering team today to get a fast quote and tailored technical support.

Instant QuoteDrawn aluminum tubing - performance

- Thin wall

- High precision and strict Tolerances

- Better surface finish

- Higher mechanical properties

- Excellent strength

- High Dimension Tolerances

Drawn aluminum tube - ideal applications

Aerospace Drawn Aluminum Tube Solutions

Chalco supplies high-performance drawn aluminum tubes that meet AMS aerospace standards, delivering outstanding strength-to-weight ratio, fatigue resistance, and dimensional stability. They satisfy stringent requirements in airframe structures, hydraulics, fuel delivery, and environmental control systems (ECS). Every tube is rigorously inspected to ensure compliance with international aerospace manufacturing and delivery specifications.

Standards: ASTM B241, AMS-WW-T-700/4, AMS 4066, AMS 4068, AMS 4070, AMS 4080, AMS 4081, AMS 4088, AMS 4069.

Applications: Hydraulic & pneumatic systems, fuel transfer lines, cooling lines, aircraft interiors and support frames.

Recommended Products

- 2024 Aerospace Aluminum Tube: High strength with excellent fatigue performance—widely used for wing and fuselage structure parts.

- 2219 Aerospace Aluminum Tube: Superior high-temperature capability—ideal for engine areas and fuel systems.

- 5052 Aerospace Aluminum Tube: Outstanding corrosion resistance—used in A/C and hydraulic lines.

- 6061 Aircraft Aluminum Tube: Good weldability and balanced properties—common for structural members and hydraulic tubing.

- 7075 Aerospace Aluminum Tube: Ultra-high strength—ideal for heavily loaded structural locations.

Military-Grade Drawn Aluminum Tube Solutions

Chalco provides high-performance drawn aluminum tubes engineered to meet demanding military specifications, delivering exceptional strength, impact resistance, and corrosion performance. They are widely used in armored vehicles, weapon systems, naval vessels, and aerospace defense structures. All products undergo strict quality inspection to ensure compliance with international defense manufacturing and delivery standards.

Standards: ASTM B241, AMS-WW-T-700/4, MIL-DTL-25995, MIL-T-7081, MIL-T-7085, AMS 4066, AMS 4088.

Applications: Armored vehicle frames, structural reinforcements, ballistic panels, naval equipment piping, and aerospace defense systems.

Recommended Products

- 2024 Aluminum Round Tube: High strength and fatigue resistance—ideal for load-bearing defense structures.

- 2219 Aluminum Tube: Excellent high-temperature capability—suitable for military aircraft engines and fuel systems.

- 5083 Aluminum Pipe: Superior corrosion resistance—widely used in naval and marine defense applications.

- 7039 Aluminum Tube: High ballistic resistance—perfect for armored vehicle structures and protective panels.

- 7075 Aluminum Tube: Ultra-high strength—ideal for heavy-load defense aerospace components.

Automotive Heat Exchanger Drawn Aluminum Tube Solutions

Chalco supplies high-performance drawn aluminum tubes for automotive condensers, evaporators, and heat exchangers. These tubes offer outstanding thermal conductivity, lightweight construction, corrosion resistance, and precise dimensional control, ensuring high heat exchange efficiency, reduced vehicle load, and extended system lifespan. Ideal for automotive HVAC and cooling systems.

Standards: ASTM B241, ASTM B210, EN 754-8.

Applications: Condensers, evaporators, intercoolers, oil coolers, and battery thermal management systems in passenger and commercial vehicles.

Recommended Products

- 3003 Aluminum Tube: Excellent corrosion resistance and formability—ideal for condenser and evaporator applications.

- 6061 Aluminum Tube: High strength and weldability—suitable for structural cooling components and intercoolers.

- 6063 Aluminum Tube: Superior surface quality—perfect for precision-formed cooling parts.

If you would like to learn more about heat transfer system solutions, please visit our Aluminum Heat Transfer Solutions page.

Outdoor Telescopic Pole Drawn Aluminum Tube Solutions

Chalco provides precision drawn aluminum tubes for outdoor telescopic poles, featuring high dimensional accuracy, smooth surface finish, and excellent strength-to-weight ratio. With tighter tolerances, they are highly compatible with CNC machining for custom fittings and connections. These tubes are lightweight, corrosion-resistant, and ideal for long-term outdoor use.

Standards: ASTM B241, EN 754-8.

Selection Notes: Choose round telescopic tubes for lightweight structures such as flagpoles and fishing rods; square telescopic tubes for applications requiring higher load capacity like adjustable frames and equipment supports; tent poles for portable outdoor shelters; 7005 aluminum tubes for high-strength sports and expedition gear.

Recommended Products

- Square Telescopic Tube: High load capacity—ideal for adjustable outdoor structures.

- Round Telescopic Tube: Lightweight—suitable for flagpoles, fishing rods, and light equipment.

- Tent Pole: Durable and easy to assemble—perfect for camping and field shelters.

- 7005 Aluminum Tube: High-strength alloy—designed for sports, adventure, and heavy-duty outdoor use.

Looking for durable, lightweight, and CNC-ready telescopic aluminum tube solutions for your outdoor projects? Contact Chalco today to get custom sizes, surface treatments, and quick delivery tailored to your needs.

Instant Quote

Drawn Aluminum Tube Manufacturing Process

Chalco adopts a precise multi-step process to produce cold drawn aluminum tubes, ensuring high dimensional accuracy, smooth surfaces, and consistent mechanical properties for demanding industrial applications.

- Material Preparation: Select and prepare high-quality aluminum alloy billets, ensuring purity and consistency.

- Heating & Drawing: Heat billets to optimal temperature, then reduce diameter and wall thickness through controlled drawing passes.

- Multi-Pass Drawing: Perform multiple drawing stages for tighter tolerances and superior surface finish.

- Finishing: Straightening, cutting, and surface finishing to meet exact specifications.

- Heat Treatment: Optional tempering or stress relief to enhance strength and stability.

- Surface Treatment: Polishing, anodizing, or coating for enhanced corrosion resistance and appearance.

Surface Treatment for Drawn Aluminum Tubes

To enhance corrosion resistance, appearance, and adaptability for various applications, Chalco offers a full range of surface treatment options for drawn aluminum tubes:

- Anodizing: Boosts corrosion resistance and hardness — ideal for outdoor and curtain wall use

- Powder Coating: Adds color, texture, and additional surface protection

- Electroplating: Combines decorative finish with enhanced corrosion resistance, suitable for high-end applications

- Polishing & Brushing: Improves appearance — used in displays, exhibition frames, and decorative structures

Precision Fabrication & Machining (CNC, Welding, Bending)

Chalco provides complete fabrication and secondary processing services for drawn aluminum tubes, ensuring they can be used directly in final assemblies:

- Cutting: Length tolerance ±0.2 mm

- Bending: U-shape, S-shape, spiral

- End Finishing: Chamfering, drilling, shrinking

- CNC Machining: Drilling, tapping, milling

- Welding: Flange welding, connector assembly

Quality Requirements for Cold Drawn Aluminum Tubes

To ensure optimal performance and reliability, Chalco strictly controls the mechanical properties, dimensional accuracy, and surface quality of our cold drawn aluminum tubes. All products meet or exceed international standards, providing precision and consistency for demanding applications.

- Mechanical Properties: Strength, hardness, and other mechanical parameters are tailored to meet the technical specifications of your application.

- Dimensional Accuracy & Tolerance: Outer diameter, inner diameter, and wall thickness comply with required tolerance standards to ensure perfect fit during assembly.

- Surface Quality: Smooth, clean surfaces inside and out; minor defects such as scratches, dents, or ink marks are within allowable limits, while serious defects like cracks, folds, or corrosion are strictly prohibited.

Drawn aluminum tube vs. Extruded aluminum tube

| Comparison Item | Drawn Aluminum Tube | Extruded Aluminum Tube |

|---|---|---|

| Alloys | 1100, 3003, 2024, 5052, 5086, 6061, 7075 | 1100, 3003, 2024, 5052, 5086, 6061, 6063, 6082, 7075 |

| Size Range | OD ≤ 220 mm; Wall thickness ≤ 12 mm (High precision) | OD ≤ 400 mm; Wall thickness ≤ 40 mm (Suitable for large cross-sections) |

| Dimensional Accuracy & Tolerances | Tighter tolerances, better roundness/concentricity, high straightness | Standard extrusion tolerances; larger variation due to thermal expansion/contraction |

| Manufacturing Process | Extrude billet → Multi-pass drawing & straightening; cold working with work hardening | Extrude billet through mold at high temperature; hot working (heat treatment optional) |

| Surface Quality | Smoother, oxide-free, anodizing-friendly | Extrusion lines and oxide layer; usually requires straightening or peeling before machining |

| Mechanical Properties | Cold work hardening increases strength and hardness; heat treatable | Excellent weldability and formability; multiple heat treatment options (T5/T6, etc.) |

| Machining Efficiency | Smooth feeding, low vibration; ideal for high-speed CNC & automated loading | Often requires pretreatment (straightening/peeling) before machining; less efficient |

| Batch Dimensional Consistency | High consistency between batches (multi-pass + straightening) | More variation due to extrusion speed and temperature changes |

| Cost | Higher (multi-step processing + tighter tolerances) | Lower (single-pass extrusion, bulk supply) |

| Typical Applications | Aerospace/medical, hydraulic/pneumatic cylinders, precision jigs, instruments, precision structural components | Structural frames, architectural decoration, radiators, general engineering pipelines, brackets, busbars |

For projects requiring high dimensional accuracy, smooth surfaces, and batch consistency—especially in aerospace, medical, or hydraulic systems—choose Drawn Aluminum Tube.If structural flexibility and cost efficiency are more important, and your application is in general engineering or construction, see our Extruded Aluminum Tube.

Cold drawn aluminum tube suppliers

Chalco boasts advanced dual-action reverse extrusion production lines, equipped with complementary extrusion equipment such as gas injection rapid preheating furnaces, hot peelers, infrared continuous temperature monitoring systems, and steam-air quenching. We also have multiple drawing production lines, including a 50-ton hydraulic drawing machine, a horizontal 14-roller straightening machine, precision cutting, and bounce inspection equipment.

As one of China's leading aluminum manufacturers, Chalco possesses hundreds of molds capable of producing a full range of cold drawn aluminum tube sizes. We can fulfill orders with various sizes and shapes, offering competitive prices and one-stop supply to alleviate your concerns. Chalco also provides services like CNC machining, bending, sawing, milling, and more. All our products are CE and ISO9001 certified, and we can customize products to meet specific standards, such as JIS, EN, ASTM, and others, according to customer requirements. For more information, please email us to discuss further. Chalco looks forward to collaborating with you!

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Chalco cold drawn aluminum tube production capacity

Detailed specification table of cold drawn aluminum round tube

| Diameter/mm | Wall Tthickness/mm | |||||||||||||

| 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | |

| 5 | ★ | ★ | ★ | |||||||||||

| 8 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| 10 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| 12 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| 14 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| 16 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||||||

| 20 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||

| 25 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 40 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||

| 50 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||

| 60 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||

| 70 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||||

| 80 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| 100 | ★ | ★ | ★ | ★ | ★ | |||||||||

| 120 | ★ | ★ | ★ | ★ | ★ | |||||||||

| 140 | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| 160 | ★ | ★ | ★ | ★ | ★ | |||||||||

| 180 | ★ | ★ | ★ | ★ | ||||||||||

| 200 | ★ | ★ | ★ | ★ | ★ | |||||||||

| 220 | ★ | ★ | ★ | ★ | ★ | |||||||||

Detailed specification table of cold drawn aluminum square tube

| Side Length/mm | Wall Tthickness/mm | |||||||||

| 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | |

| 10 | ★ | ★ | ||||||||

| 14 | ★ | ★ | ★ | |||||||

| 18 | ★ | ★ | ★ | |||||||

| 22 | ★ | ★ | ★ | ★ | ★ | |||||

| 28 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 36 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 42 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 50 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 55 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 60 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 70 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 80 | ★ | ★ | ★ | ★ | ★ | |||||

| 90 | ★ | ★ | ★ | ★ | ★ | |||||

| 100 | ★ | ★ | ★ | ★ | ★ | |||||

| 110 | ★ | ★ | ★ | ★ | ★ | |||||

| 120 | ★ | ★ | ★ | ★ | ★ | |||||

Detailed specification table of cold drawn aluminum rectangular tube

| Side Length(Width×High)/mm | Wall Tthickness/mm | |||||||||

| 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | |

| 14.00×10.00 | ★ | ★ | ★ | |||||||

| 16.00×12.00 | ★ | ★ | ★ | |||||||

| 18.00×10.00 | ★ | ★ | ★ | ★ | ||||||

| 18.00×14.00 | ★ | ★ | ★ | ★ | ||||||

| 20.00×12.00 | ★ | ★ | ★ | ★ | ★ | |||||

| 22.00×14.00 | ★ | ★ | ★ | ★ | ★ | |||||

| 25.00×15.00 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 28.00×16.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 28.00×22:00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 32.00×18.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||

| 32.00×25.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||

| 36.00×20.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||

| 36.00×28.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||

| 40.00×25.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 40.00×30.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 45.00×30.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 50.00×30.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 55.00×40.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 60.00×40.00 | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||

| 70.00×50.00 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 80.00×60.00 | ★ | ★ | ★ | ★ | ★ | |||||

| 90.00×70.00 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 100.00×80.00 | ★ | ★ | ★ | ★ | ★ | ★ | ||||

| 110.00×90.00 | ★ | ★ | ★ | ★ | ★ | |||||

| 120.00×100.00 | ★ | ★ | ★ | ★ | ★ | |||||

FAQs

Is a cold drawn aluminum tube suitable for high-precision bearing or hydraulic use?

Yes. Cold drawing delivers tight dimensional control and improved roundness/concentricity. Typical tolerances reach ±0.05 mm (up to ±0.02 mm on request) with optional surface roughness down to Ra ≤ 0.8 μm, making it a good fit for precision fits, pneumatic and hydraulic systems.

Cold drawn vs. precision drawn — which should I choose?

Precision drawn tubes are cold drawn and then further straightened and finished for even tighter tolerances and a finer surface. Choose precision drawn when you need the smallest tolerances and best finish for high-end assemblies; choose cold drawn when you need high accuracy with better cost efficiency for structural or pressure-line use.

Can you manufacture to my drawing and deliver ready-to-assemble parts?

Yes. We customize OD, wall, length, temper, and tolerances to your drawing and provide value-added operations such as cutting, drilling, threading, bending, CNC machining, and welding—so tubes arrive ready for direct assembly.

Will these tubes withstand outdoor or corrosive environments?

Yes. We offer surface finishes such as anodizing (typical film 8–12 μm), powder coating, and e-coat to boost corrosion resistance and appearance for coastal, chemical, or outdoor use.

What is the typical lead time?

Standard sizes ship in about 7–10 days. Custom sizes usually deliver in 2–4 weeks depending on quantity and processing; expedited production is available.

How are the tubes packed and protected for shipment?

Packed with moisture-proof film and rigid protection, fixed in wooden crates with anti-corrosion covering, compliant with ASTM B241. Optional single-tube sleeves or separators ensure the tubes are ready to use on arrival.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote