6063 aluminum tube is widely used for its corrosion resistance and flexibility in construction, transportation, electronics, and home decor. It's applied in making door and window frames, automotive structures, and furniture. Its surface treatment enhances aesthetics and durability, meeting environmental standards.

Chalco's 6063-T6 aluminum magnesium seamless busbar tube is a top product known for its high heat resistance. It operates safely in temperatures ranging from 150°C to 200°C, maintaining over 88% of its tensile strength at room temperature and 250°C. This feature is ideal for ice melting and large-capacity substation projects.

Instant QuoteSpecification of Chalco 6063 aluminum tubular pipe

| Temper | T5 T6 T10 |

| Outer diameter | Φ60mm-Φ450mm |

| Wall thickness | 3mm-15mm |

| Length | The length of a single bus pipe can reach 15 meters; deviation:+15~+25mm |

| Curvature | m/L<2.0mm |

| Size and Deviation | Details Size and Deviation Click to view the [Size and Deviation Table] |

| Surface requirement | The surface is smooth and flat, without cracks, wrinkles, inclusions, deformation, or distortion. |

| Product requirement | The finished pipeline is completely straight; High dimensional accuracy and high tensile strength; Not prone to discharge and corona. |

| Profiles can be provided | Certificate of origin; Invoice and PL certified by Chamber of Commerce; Test certificate according to EN 10204 3.1; Other test reports that may be requested by the customer. |

Product detail of Chalco 6063 aluminum tubular buspipe

- 6063 seamless tubular products

High purity, no welding seams, stable electrical performance. Suitable for high-pressure or airtight electrical systems.

- 6063 welded tubular products

Cost-effective option for mass production. Ideal for general structural or electrical connection applications.

- 6063 tin-plated electrical bus pipe

Tin plating enhances oxidation resistance and weldability. Suitable for environments with frequent electrical contact and exposure.

- 6063 nickel-plated electrical bus pipe

Nickel coating improves corrosion resistance and mechanical strength. Ideal for harsh or high-humidity environments.

- 6063 copper-clad electrical tube

Combines aluminum's lightweight advantage with copper's superior conductivity. Perfect for high-performance power transmission needs.

- 6063 anodized tubular products

Anodized surface offers improved durability and appearance. Suitable for outdoor use or visible installations.

Technical parameter of Chalco 6063 tube pipe

Physical and Mechanical property of Chalco 6063 tube pipe

| Physical properties | Density(g/cm2)(20℃) | 2.75 | ||

| Melting point ℃ | 630-650 | |||

| Thermal conductivity (K/℃*cm*s) | 0.5 | |||

| Mechanical properties | Temper | T10 | T6 | |

| Tensile Strength (Mpa) | Standard value | 180 | ≥205 | |

| Measured value | ≥206 | ≥225 | ||

| Yield strength (Mpa) | Standard value | ≥160 | ≥175 | |

| Measured value | ≥170 | ≥190 | ||

| Elongation (%) | Standard value | - | ≥8 | |

| Measured value | ≥12 | 9 | ||

Electrical property of Chalco 6063 aluminum tubular busbar

| Physical and electrical properties of 6063 aluminum bus pipe (Schedule 40 pipe) | |||||||||

| Inch | O.D. | Wall | Area | Weight LBS/FT | I.R. | DC RES | 60Hz RAC/RDC | AC RES | CURR RATING |

| 1 | 1.315 | 0.133 | 0.494 | 0.581 | 68.24 | 31.120 | 1.00039 | 36.580 | 681 |

| 1 1/4 | 1.660 | 0.140 | 0.669 | 0.786 | 62.68 | 22.990 | 1.00050 | 27.030 | 859 |

| 1 1/2 | 1.900 | 0.145 | 0.800 | 0.940 | 59.45 | 19.220 | 1.00064 | 22.600 | 984 |

| 2 | 2.375 | 0.154 | 1.075 | 1.264 | 54.15 | 14.300 | 1.00082 | 16.820 | 1234 |

| 2 1/2 | 2.875 | 0.203 | 1.704 | 2.004 | 49.85 | 9.019 | 1.00220 | 10.620 | 1663 |

| 3 | 3.500 | 0.216 | 2.228 | 2.621 | 45.19 | 6.897 | 1.00300 | 8.126 | 2040 |

| 3 1/2 | 4.000 | 0.226 | 2.680 | 3.151 | 42.05 | 5.736 | 1.00380 | 6.761 | 2347 |

| 4 | 4.500 | 0.237 | 3.174 | 3.733 | 39.28 | 4.842 | 1.00470 | 5.712 | 2664 |

| 4 1/2 | 5.001 | 0.247 | 3.688 | 4.337 | 36.81 | 4.167 | 1.00570 | 4.920 | 2984 |

| 5 | 5.563 | 0.258 | 4.300 | 5.057 | 34.31 | 3.574 | 1.00680 | 4.224 | 3348 |

| 6 | 6.625 | 0.280 | 5.581 | 6.564 | 30.23 | 2.754 | 1.00950 | 3.263 | 4064 |

| Physical and electrical properties of 6063 aluminum bus pipe (Schedule 80 pipe) | |||||||||

| Inch | O.D. | Wall | Area | Weight LBS/FT | I.R. | DC RES | 60Hz RAC/RDC | AC RES | CURR RATING |

| 1 | 1.315 | 0.179 | 0.639 | 0.751 | 68.81 | 24.060 | 1.00100 | 28.300 | 774 |

| 1 1/4 | 1.660 | 0.191 | 0.882 | 1.037 | 63.14 | 17.440 | 1.00140 | 20.520 | 985 |

| 1 1/2 | 1.900 | 0.200 | 1.068 | 1.256 | 59.89 | 14.390 | 1.00200 | 16.940 | 1137 |

| 2 | 2.375 | 0.218 | 1.477 | 1.737 | 54.56 | 10.400 | 1.00280 | 12.260 | 1446 |

| 2 1/2 | 2.875 | 0.276 | 2.254 | 2.650 | 50.23 | 6.820 | 1.00720 | 8.071 | 1907 |

| 3 | 3.500 | 0.300 | 3.016 | 3.547 | 45.55 | 5.096 | 1.01030 | 6.050 | 2363 |

| 3 1/2 | 4.000 | 0.318 | 3.678 | 4.326 | 42.39 | 4.178 | 1.01380 | 4.972 | 2735 |

| 4 | 4.500 | 0.337 | 4.407 | 5.183 | 39.61 | 3.487 | 1.01710 | 4.168 | 3118 |

| 4 1/2 | 5.001 | 0.355 | 5.180 | 6.092 | 37.13 | 2.967 | 1.02100 | 3.559 | 3505 |

| 5 | 5.563 | 0.375 | 6.112 | 7.188 | 34.63 | 2.515 | 1.02600 | 3.032 | 3949 |

| 6 | 6.625 | 0.432 | 8.405 | 9.844 | 30.58 | 1.829 | 1.04570 | 2.247 | 4891 |

Chemical component of Chalco 6063 aluminum alloy

| Element | Composition (%) |

| Si | 0.2-0.6 |

| Fe | ≤0.35 |

| cu | ≤0.1 |

| Mn | ≤0.1 |

| Mg | ≤0.9 |

| Cr | ≤0.10 |

| Zn | - |

| Ti | - |

| Ni | - |

| Other each | ≤0.05 |

| Other total | ≤0.15 |

| Al | Remain |

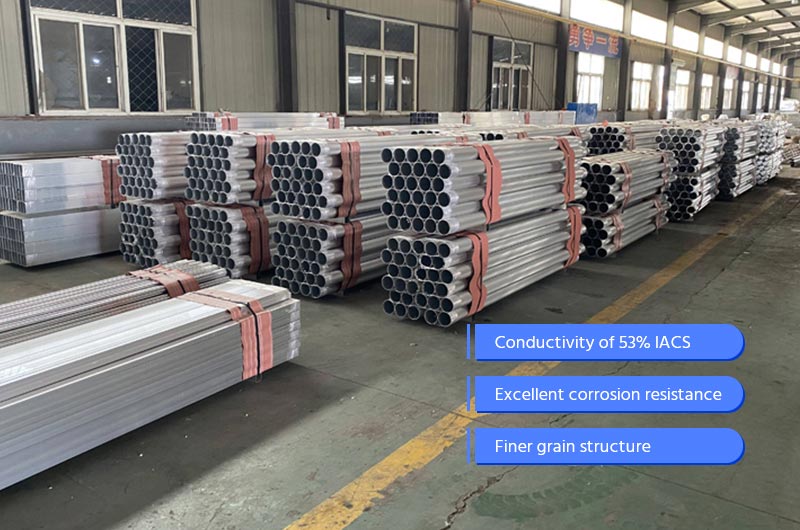

Advantage of Chalco 6063 aluminum tube pipe

- Excellent corrosion resistance and surface quality, ideal for anodizing, painting, or plating.

- Easy to form and weld, suitable for complex shapes and assembly.

- Lightweight with good strength, meeting the needs of modern lightweight structures.

- High conductivity up to 53% IACS, making it suitable for electrical busbar applications.

- Utilizes Chalco's proprietary LDRE and 6Z63 alloys, offering enhanced conductivity and thermal resistance.

- Environmentally friendly and recyclable, supporting sustainable development.

Production and Processing Capability of Chalco 6063 electrical aluminum tube pipe

Advanced Forming Process: Produced using Chalco's proprietary casting hollow billet + three-roll rolling + cold drawing technique, ensuring uniform mechanical and electrical performance along both the length and cross-section.

Precision Processing: Capable of tight tolerance cutting, bending, welding, and fabrication to meet custom electrical and structural specifications.

Surface Treatments: AvailableSupport for tin plating, nickel plating, and copper cladding to enhance conductivity, corrosion resistance, and durability.

Customized Alloys: Use of Chalco-developed rare-earth and heat-resistant aluminum materials, delivering superior weldability, conductivity, and thermal performance.

Instant QuoteCooperative field of Chalco 6063 aluminum tube pipe

Construction and Building Engineering: Used for manufacturing door and window frames, balcony railings, and decorative materials in building structures.Transportation: Employed in vehicles such as cars, trains, and ships for body structures, seats, and handrails.

Home Decor: Used for making furniture, curtain tracks, light fixture brackets, and other home decor products.

Industrial Equipment: Utilized for manufacturing structural components and transmission pipelines in various industrial equipment.

Outdoor Sports Equipment: Applied in the production of components for bicycles, skateboards, camping gear, and other outdoor sports equipment.

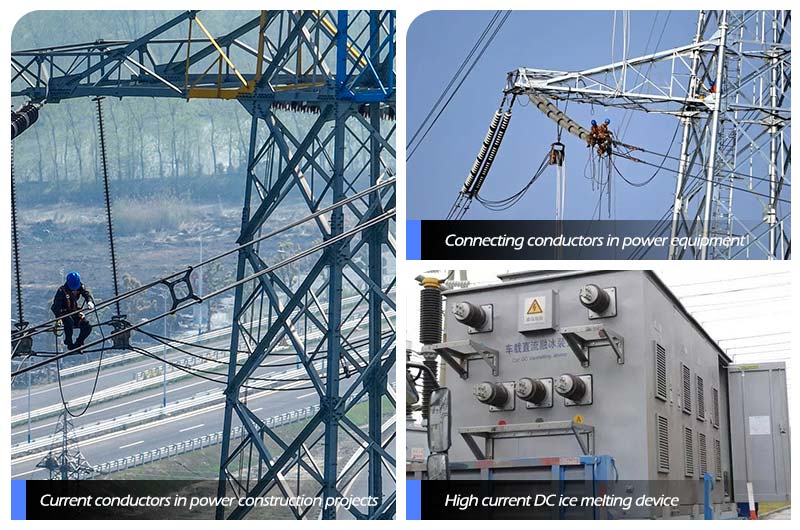

6063 aluminum seamless tubular busbars, ranging from 400V to 72kV. These are used for conductor connections in power grid transmission lines, substation transformers, and power equipment.

- Aluminum alloy extruded pipes for high-frequency conductivity in power plants

- Current conductors in power construction projects;

- Connecting conductors in power equipment;

- High current DC ice melting device, etc.

Chalco other hot selling aluminum tube products

6061 Aluminum Tube for Bicycle

AMS 6061 Aluminum Tube

3003 Aluminum Tube

5083 Aluminum Tube

2024 Aluminum Tube

2219 Aluminum Tube

Cold Drawn Aluminum Tubing

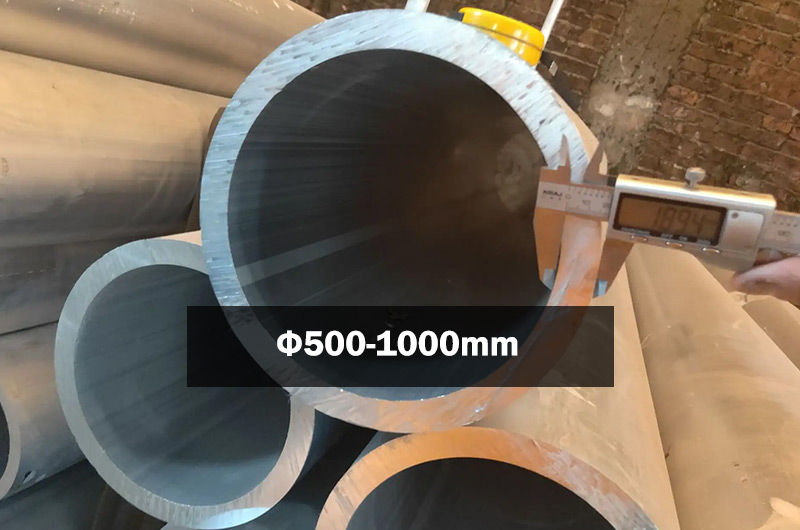

Large Diameter Aluminum Pipe

SCH40/SCH80 Aluminum Tube

More electrical aluminum products in Chalco

- EC Grade aluminum wire rod

- Conductive aluminum busbar

- Electrical aluminum tubular bus pipe

- Aluminum plate strip foil for capacitor

- Aluminum wire for electrical application

Deviation table of Chalco 6063 aluminum tubular busbar

| Wall thickness deviation | ||||||||

| Nominal wall thickness | 3-5 | >5 -8 | >8-10 | >10-12 | >12-15 | >15 -20 | ||

| Ordinary level | Average & nominal wall thickness | ±0.30 | ±0.50 | ±0.70 | ±0.9 | ±1.10 | ±1.3 | |

| Any & nominal wall thickness | H14 | ±0.40 | ±0.60 | ±0.90 | ±1.10 | ±1.3 | ±1.6 | |

| T5A, T6, T10 | ±12% of the specified wall thickness, maximum value is 1.90 | |||||||

| High precision level | Average & nominal wall thickness | ±0.15 | ±0.20 | ±0.38 | ±0.50 | ±0.70 | ±1.00 | |

| Any & nominal wall thickness | H14 | ±0.2 | ±0.3 | ±0.5 | ±0.76 | ±1.00 | ±1.4 | |

| T5A, T6, T10 | ±10% of the specified wall thickness, maximum value is 1.70 | |||||||

| Outer diameter deviation | |||

| Nominal OD | Ordinary level | ||

| Average & Nominal outer diameter | Any & Nominal outer diameter | ||

| H14 | T5A, T6, T10 | ||

| 50.00 - 80.00 | ±0.24 | ±0.30 | ±0.45 |

| > 80.00- 120.00 | ±0.35 | ±0.40 | ±0.62 |

| >120.00-150.00 | ±0.45 | ±0.50 | ±0.75 |

| >150.00 - 200.00 | ±0.65 | ±0.7 | ±1.00 |

| >200.00 - 250.00 | ±0.77 | ± | ±1.2 |

| >250.00 - 300.00 | ±0.96 | ±1 | ±1.5 |

| >300.00 - 350.00 | ±1.3 | ±1.4 | ±1.8 |

| Nominal OD | High precision level | ||

| Average & Nominal outer diameter | Any & Nominal outer diameter | ||

| H14 | T5A, T6, T10 | ||

| 50.00 - 80.00 | ±0.15 | ±0.15 | ±0.3 |

| > 80.00-120.00 | ±0.20 | ±0.20 | ±0.41 |

| >120.00-150.00 | ±0.25 | ±0.25 | ±0.5 |

| >150.00-200.00 | ±0.38 | ±0.38 | ±0.76 |

| >200.00-250.00 | ±0.50 | ±0.5 | ±1.00 |

| >250.00-300.00 | ±0.64 | ±0.64 | ±1.25 |

| >300.00-350.00 | ±0.9 | ±0.9 | ±1.6 |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote