6061 aluminum tube, composed of magnesium and silicon, offers excellent performance with moderate strength, corrosion resistance, and formability. It is ideal for welding, brazing, and custom processing, including bending, cutting, and surface treatments like tin, copper, and nickel plating. After anodizing, it delivers enhanced durability and a superior finish.

Chalco's 6061 aluminum tubes are widely used in aerospace, navigation, electronics, and structural applications. Our seamless pipes feature excellent electrical performance, with a low skin effect and uniform current distribution, reaching up to 1.4A/mm2. Custom cutting lengths and surface coatings are available to suit your needs.

Specification: ASTM B221, ASTM B241, ASTM B429, AMS-QQ-A-200/8, AMS4082.

Instant QuoteSpecification of Chalco 6061 EC aluminum tubular busbar

| Temper | T6 T651 H112 |

| Outer diameter | Φ60mm-Φ450mm |

| Wall thickness | 3mm-15mm |

| Length | The length of a single bus pipe can reach 15 meters; deviation:+15~+25mm |

| Curvature | m/L<2.0mm |

| Size and Deviation | Click to view the [Size and Deviation Table] |

| Surface requirement | The surface is smooth and flat, without cracks, wrinkles, inclusions, deformation, or distortion. |

| Product requirement | The finished pipeline is completely straight; High dimensional accuracy and high tensile strength; Not prone to discharge and corona. |

| Profiles can be provided | Certificate of origin; Invoice and PL certified by Chamber of Commerce; Test certificate according to EN 10204 3.1; Other test reports that may be requested by the customer. |

Porduct detail of Chalco 6061 aluminum tubular products

- 6061 T6 aluminum tube

The T6 temper offers high strength and excellent mechanical properties, ideal for applications requiring durability and high load-bearing capabilities. It's commonly used in structural and heavy-duty applications.

- 6061 T4 aluminum tube

T4 temper aluminum is in the solution heat-treated state and is often used when additional strength is not the primary requirement. It offers good formability, making it suitable for applications requiring further processing like bending or forming.

- 6061 seamless tube

Chalco's seamless aluminum tubes ensure uniform mechanical and electrical properties, with no welds or joints that could compromise performance. These tubes are highly durable, offering excellent conductivity and strength for demanding applications.

- Tin plating 6061 tube

Tin plating is applied to enhance the conductivity and corrosion resistance of aluminum bus pipes. It provides a smooth surface finish and excellent protection against oxidation, making it ideal for outdoor and industrial use.

- Copper cladding 6061 tube

Copper plating is used to further enhance the electrical conductivity and corrosion resistance of aluminum bus pipes. This treatment is particularly useful for high-current applications and environments where superior conductivity is critical.

- Nickel plating 6061 tube

Nickel plating provides added protection against corrosion and improves the hardness of the aluminum pipe surface. It is ideal for harsh environments where enhanced durability and resistance to wear are required.

Technical Parameter of Chalco 6061 aluminum tubular pipe

Mechanical property of Chalco 6061 aluminum tubular pipe

| Temper | Wall thickness/mm | Room temperature Test Result | |||

| Tension Strength/MPa | Yield Strength/MPa | Elongation/% | |||

| A50mm | A | ||||

| Not less than | |||||

| O | all | 170 | 105 | 16 | 14 |

| T6 | <6.30 | 260 | 240 | 8 | - |

| >6.30 | 260 | 240 | 10 | 9 | |

Electrical property of Chalco 6061 aluminum SCH40 SCH80 seamless tubular busbar

| Physical and electrical properties of 6061 aluminum bus pipe (Schedule 40 pipe) | |||||||||

| Inch | O.D. | Wall | Area | Weight LBS/FT | I.R. | DC RES | 60Hz RAC/RDC | AC RES | CURR RATING |

| 1 | 1.315 | 0.133 | 0.494 | 0.581 | 68.24 | 38.360 | 1.00032 | 43.820 | 622 |

| 1 1/4 | 1.660 | 0.140 | 0.669 | 0.786 | 62.68 | 28.340 | 1.00039 | 32.370 | 705 |

| 1 1/2 | 1.900 | 0.145 | 0.800 | 0.940 | 59.45 | 23.690 | 1.00046 | 27.070 | 900 |

| 2 | 2.375 | 0.154 | 1.075 | 1.264 | 54.15 | 17.630 | 1.00055 | 20.1401 | 1128 |

| 2 1/2 | 2.875 | 0.203 | 1.704 | 2.004 | 49.85 | 11.170 | 1.00150 | 12.710 | 1520 |

| 3 | 3.500 | 0.216 | 2.228 | 2.621 | 45.19 | 8.500 | 1.00180 | 9.725 | 1865 |

| 3 1/2 | 4.000 | 0.226 | 2.680 | 3.151 | 42.05 | 7.070 | 1.00220 | 8.091 | 2145 |

| 4 | 4.500 | 0.237 | 3.174 | 3.733 | 39.28 | 5.968 | 1.00270 | 6.834 | 2436 |

| 4 1/2 | 5.001 | 0.247 | 3.688 | 4.337 | 36.81 | 5.136 | 1.00330 | 5.885 | 2728 |

| 5 | 5.563 | 0.258 | 4.300 | 5.057 | 34.31 | 4.406 | 1.00400 | 5.051 | 3063 |

| 6 | 6.625 | 0.280 | 5.581 | 6.564 | 30.23 | 3.394 | 1.00540 | 3.897 | 3719 |

| Physical and electrical properties of 6061 aluminum bus pipe (Schedule 80 pipe) | |||||||||

| Inch | O.D. | Wall | Area | Weight LBS/FT | I.R. | DC RES | 60Hz RAC/RDC | AC RES | CURR RATING |

| 1 | 1.315 | 0.179 | 0.639 | 0.751 | 68.81 | 29.650 | 1.00075 | 33.840 | 707 |

| 1 1/4 | 1.660 | 0.191 | 0.882 | 1.037 | 63.14 | 21.490 | 1.00105 | 24.570 | 901 |

| 1 1/2 | 1.900 | 0.200 | 1.068 | 1.256 | 59.89 | 17.730 | 1.00150 | 20.280 | 1039 |

| 2 | 2.375 | 0.218 | 2.254 | 1.737 | 54.56 | 12.820 | 1.00210 | 14.670 | 1322 |

| 2 1/2 | 2.875 | 0.276 | 3.016 | 2.650 | 50.23 | 8.406 | 1.00390 | 9.647 | 1746 |

| 3 | 3.500 | 0.300 | 3.678 | 3.547 | 45.55 | 6.281 | 1.00490 | 7.225 | 2199 |

| 3 1/2 | 4.000 | 0.318 | 4.407 | 4.326 | 42.39 | 5.150 | 1.00750 | 5.935 | 2507 |

| 4 | 4.500 | 0.337 | 5.180 | 5.183 | 39.61 | 4.298 | 1.00950 | 4.965 | 2862 |

| 4 1/2 | 5.001 | 0.355 | 6.112 | 6.092 | 37.13 | 3.657 | 1.01160 | 4.236 | 3221 |

| 5 | 5.563 | 0.375 | 8.405 | 7.188 | 34.63 | 3.099 | 1.01650 | 3.604 | 3631 |

| 6 | 6.625 | 0.432 | 0.639 | 9.844 | 30.58 | 2.254 | 1.02120 | 2.656 | 4532 |

Chemical component of Chalco 6061 aluminum alloy

| Element | Composition (%) |

| Si | 0.40-0.80 |

| Fe | 0.7 |

| Cu | 0.15-0.40 |

| Mn | 0.15 |

| Mg | 0.8-1.2 |

| Cr | 0.04-0.35 |

| Ni | - |

| Zn | 0.25 |

| Ga | - |

| V | - |

| Ti | 0.1 |

| Other | 0.15 |

| Min.Al | Remainder |

Production and Processing Capabilities of Chalco 6061 aluminum bus pipes

Advanced Manufacturing: Using casting hollow core billets, three-roll rolling, and cold stretching to ensure uniform mechanical and electrical properties.

Customization: Offering bending, cutting, welding, and custom lengths to meet specific project requirements.

Surface Treatments: Providing tin, copper, and nickel plating to enhance conductivity and corrosion resistance.

Quality Control: Strict quality checks at every stage to ensure product performance meets international standards.

Production Capacity: High-volume production to meet large-scale orders with fast turnaround times.

Instant QuoteAdvantages of Chalco 6061 electrical aluminum tubular busbar

Strength and Durability: 6061 aluminum alloy offers moderate strength, corrosion resistance, and excellent formability, making it a reliable choice for structural applications.

Wide Applications: Ideal for industries such as aerospace, automotive, marine, construction, and electronics.

Ease of Processing: Easily fabricated through various methods such as forging, welding (TIG, MIG, arc), cutting, and milling.

Aesthetic and Durable: Achieves a polished, durable finish after anodizing, enhancing both its appearance and longevity.

Lightweight and Economical: Weighs only half as much as copper, reducing material costs, making it a cost-effective solution for large-scale projects.

High Electrical Conductivity: Excellent conductivity and corrosion resistance, ensuring efficient energy transmission.

Thermal Performance: Superior heat resistance and rapid, uniform heat dissipation, making it suitable for high-load, high-performance applications.

Instant Quote

Cooperative field of Chalco 6061 aluminum tube pipe

Aerospace Sector: Used in aircraft for structural components, wings, and landing gear due to its exceptional strength-to-weight ratio and corrosion resistance.

Automotive Industry: Utilized in the manufacturing of vehicle body structures, chassis, and suspension systems to reduce weight and enhance fuel efficiency.

Construction and Engineering: Employed in building construction for door and window frames, staircase handrails, balcony railings, etc., owing to its weather resistance, decorative appeal, and ease of processing.

Marine Manufacturing: Used in shipbuilding for hull structures, marine equipment, and fittings to improve durability and performance under corrosive marine environments.

Outdoor Sports Equipment: Commonly found in the fabrication of bicycle frames, scooter handlebars, and other outdoor sports equipment due to its strength and durability.

Conductive power field:

- Aluminum alloy extruded pipes for high-frequency conductivity in power plants

- Current conductors in power construction projects;

- Connecting conductors in power equipment;

- High current DC ice melting device, etc.

Chalco other hot selling aluminum tube products

6061 Aluminum Tube for Bicycle

AMS 6061 Aluminum Tube

3003 Aluminum Tube

5083 Aluminum Tube

2024 Aluminum Tube

2219 Aluminum Tube

Cold Drawn Aluminum Tubing

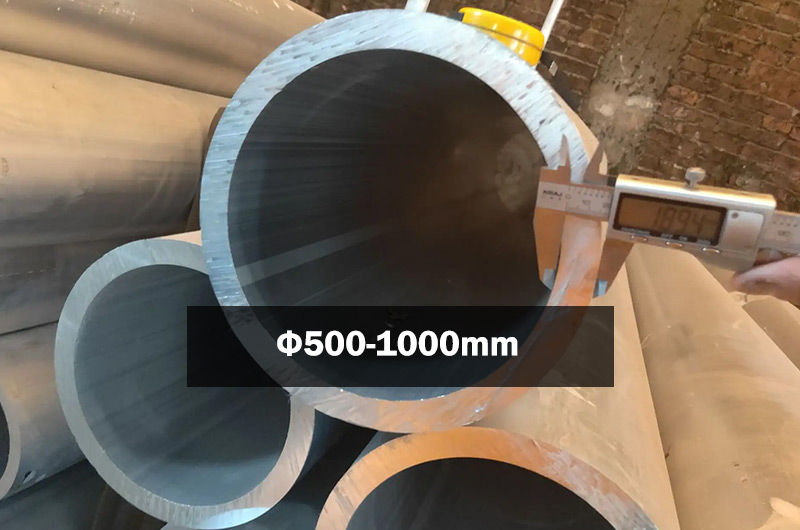

Large Diameter Aluminum Pipe

SCH40/SCH80 Aluminum Tube

More electrical aluminum products in Chalco

- EC Grade aluminum wire rod

- Conductive aluminum busbar

- Electrical aluminum tubular bus pipe

- Aluminum plate strip foil for capacitor

- Aluminum wire for electrical application

Deviation table Chalco 6061 aluminum tubular busbar

| Wall thickness deviation | ||||||||

| Nominal wall thickness | 3-5 | >5 -8 | >8-10 | >10-12 | >12-15 | >15 -20 | ||

| Ordinary level | Average & nominal wall thickness | ±0.30 | ±0.50 | ±0.70 | ±0.9 | ±1.10 | ±1.3 | |

| Any & nominal wall thickness | H14 | ±0.40 | ±0.60 | ±0.90 | ±1.10 | ±1.3 | ±1.6 | |

| T5A, T6, T10 | ±12% of the specified wall thickness, maximum value is 1.90 | |||||||

| High precision level | Average & nominal wall thickness | ±0.15 | ±0.20 | ±0.38 | ±0.50 | ±0.70 | ±1.00 | |

| Any & nominal wall thickness | H14 | ±0.2 | ±0.3 | ±0.5 | ±0.76 | ±1.00 | ±1.4 | |

| T5A, T6, T10 | ±10% of the specified wall thickness, maximum value is 1.70 | |||||||

| Outer diameter deviation | |||

| Nominal OD | Ordinary level | ||

| Average & Nominal outer diameter | Any & Nominal outer diameter | ||

| H14 | T5A, T6, T10 | ||

| 50.00-80.00 | ±0.24 | ±0.30 | ±0.45 |

| > 80.00-120.00 | ±0.35 | ±0.40 | ±0.62 |

| >120.00-150.00 | ±0.45 | ±0.50 | ±0.75 |

| >150.00-200.00 | ±0.65 | ±0.7 | ±1.00 |

| >200.00-250.00 | ±0.77 | ± | ±1.2 |

| >250.00-300.00 | ±0.96 | ±1 | ±1.5 |

| >300.00-350.00 | ±1.3 | ±1.4 | ±1.8 |

| Nominal OD | High precision level | ||

| Average & Nominal outer diameter | Any & Nominal outer diameter | ||

| H14 | T5A, T6, T10 | ||

| 50.00-80.00 | ±0.15 | ±0.15 | ±0.3 |

| > 80.00-120.00 | ±0.20 | ±0.20 | ±0.41 |

| >120.00-150.00 | ±0.25 | ±0.25 | ±0.5 |

| >150.00-200.00 | ±0.38 | ±0.38 | ±0.76 |

| >200.00-250.00 | ±0.50 | ±0.5 | ±1.00 |

| >250.00-300.00 | ±0.64 | ±0.64 | ±1.25 |

| >300.00-350.00 | ±0.9 | ±0.9 | ±1.6 |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote