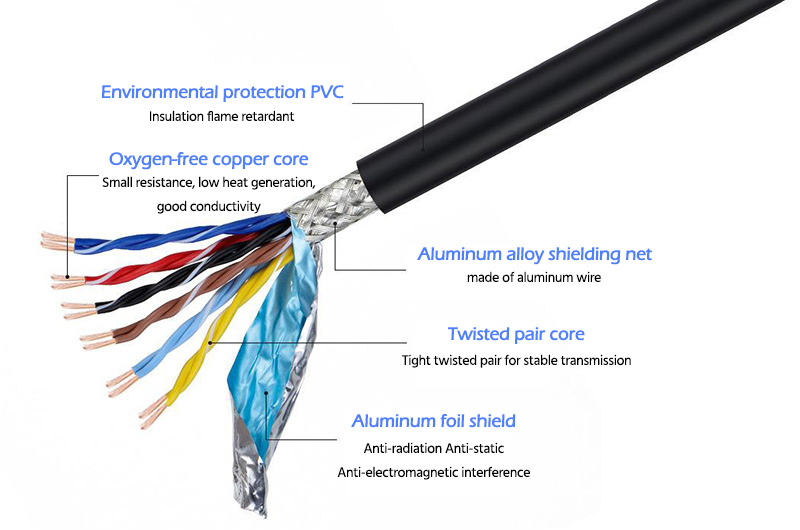

Braided shielding wire is a vital element in modern cable systems, engineered to block electromagnetic interference (EMI), radio-frequency interference (RFI), and electrostatic discharge (ESD). Woven from fine copper, tinned copper, aluminum, or aluminum alloy strands, the braid ensures reliable conductivity for grounding while offering abrasion and bending protection to cables.

Chalco supplies a comprehensive range of braided shielding wires with options in diameter, strand temper (hard or soft), and surface finish. These customizable designs deliver consistent shielding performance for automotive, industrial, aerospace, and communication applications.

Product Types of Braided Shielding Wire / Braided Sleeving

Braided shielding wires are available in different shapes and structures to suit various cable designs and performance requirements. Below are the main types we supply:

-

Round / Tubular Braided Sleeving

Also known as tubular braid or braided cable sleeving, this round structure wraps cables tightly for EMI/RFI shielding, grounding, and flexible harness protection in automotive, data, and aerospace wiring.

-

Flat Braid / Grounding Straps

Produced by compressing tubular braid into a flat ribbon, flat braided shielding offers superior flexibility and low resistance, widely used as grounding straps, bonding jumpers, and lightning protection conductors.

-

Expandable / Flexible Braided Shielding

Expandable braided sleeving can stretch to fit different cable diameters, providing excellent flexibility while maintaining EMI protection. Ideal for dynamic harnesses and automotive wiring looms.

-

High-Coverage / High-Density Braided Shielding

High-density braids offer up to 95–100% optical coverage, delivering maximum EMI attenuation. Common in aerospace, defense, and communication systems requiring the highest shielding performance.

For detailed parameters of our braided shielding wires, please see the Specifications & Technical Data section below. Beyond standard round, flat, single-layer, and double-layer braids, Chalco also develops expandable, split, and hybrid braid structures to meet complex EMI/RFI challenges where conventional braids may not be sufficient.

If your shielding projects also involve alternative solutions such as spiral shielding wires or aluminum foil tapes, our team can provide supporting materials and tailored recommendations. Contact us today to explore the most suitable option for your application.

Material Choices for Braided Shielding Wire / Braided Sleeving

The shielding performance, durability, and cost of a braid depend greatly on both the strand diameter and the material used. Typical strand diameters are shown below, followed by material options to match different EMI/RFI needs and environments.

| Diameter (mm) | Approx. AWG | Notes |

| 0.10 | ≈ 38 AWG | Ultra-fine, dense coverage for EMI/RFI shielding |

| 0.12 | ≈ 36 AWG | Common for high-flexible data & signal cables |

| 0.16 | ≈ 34 AWG | Balanced strength and flexibility |

| 0.20 | ≈ 32 AWG | General-purpose for industrial & automotive use |

| 0.24 | ≈ 31 AWG | Heavier duty, better tensile strength |

| 0.26 | ≈ 30 AWG | Thicker wires for durability in rugged applications |

With Chalco's in-house production, custom wire diameters and tolerances beyond these ranges are available upon request, ensuring exact match to your shielding and mechanical requirements.

-

Bare Copper Braided Shielding Wire

Key Benefits: Highest conductivity, excellent EMI attenuation

Considerations: Susceptible to oxidation without plating

Applications: High-integrity signals, lab/bench cables

-

Tinned Copper Braided Shielding Wire

Key Benefits: High conductivity with enhanced corrosion resistance

Considerations: Easy solderability, long service life

Applications: Automotive, telecom, humid/salt-spray environments

-

Nickel-Plated Copper Braided Shielding Wire

Key Benefits: Oxidation resistance at elevated temperatures

Considerations: Stable shielding in high-temp zones

Applications: Aerospace, defense, high-temp electronics

-

High Purity Aluminum Braided Shielding Wire

Key Benefits: Lightweight, economical, good conductivity-to-weight ratio

Applications: Automotive harnesses, weight-sensitive cable assemblies

-

Aluminum Alloys (1350, 5454 ...) Braided Shielding Wire

Key Benefits: Stronger and more corrosion-resistant than pure Al

Applications: 1350 for high conductivity; 5454 for heavy-duty shielding with better fatigue life...

-

Stainless Steel / Special Alloys Braided Shielding Wire

Key Benefits: Superior mechanical strength & abrasion resistance

Considerations: Lower conductivity; ideal for protection + shielding

Applications: Oil & gas, industrial machinery, ruggedized cables

Our braided shielding wires are manufactured from high-quality aluminum, copper, and alloy wires produced in-house, guaranteeing full control over raw material standards and final product performance. Detailed single-wire specifications can be found in the Specifications & Technical Data section below.

If you require other alloys, special plating, or unique constructions, Chalco can deliver. Reach out now to request technical advice, samples, and a quick quote for your application.

Key Features & Benefits of Chalco Braided Sheilding Wire / Braided Sleeving

- EMI/RFI Shielding: Dense braided construction provides excellent electromagnetic and radio-frequency interference suppression, ensuring stable signal transmission in communication and control systems.

- High Conductivity & Grounding: Copper and aluminum alloy wires deliver reliable electrical continuity, enabling efficient grounding and discharge of external interference.

- Lightweight vs Copper: Aluminum and its alloys significantly reduce cable weight compared with pure copper, cutting installation costs in large-scale harnesses or EV wiring.

- Mechanical Strength & Flexibility: Braid structures withstand repeated bending and vibration while maintaining tensile strength, suitable for automotive and aerospace applications.

- Corrosion Resistance: Tinned copper, nickel-plated, and aluminum alloys offer long-term resistance against oxidation, moisture, and chemical environments.

- Wide Temperature Range: Nickel- or silver-plated braids ensure stable performance from sub-zero cold to high-temperature zones, meeting the needs of aerospace and industrial electronics.

Together, these benefits make Chalco braided shielding wires a cost-effective and high-performance choice across industries.

Applications of Braided Shielding Wire / Braided Sleeving

Data & Communication Cables

Use Case: Applied in high-speed data lines, Ethernet, HDMI, and USB multi-core cables.

Benefit: Copper or tinned copper braids provide low resistance and stable EMI/RFI shielding, preserving signal integrity.

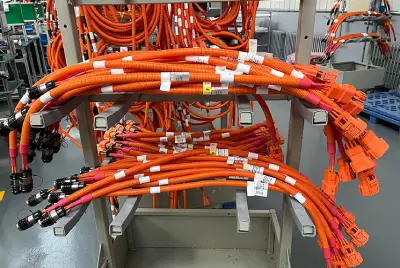

Automotive Wiring Harness & EV Cables

Use Case: Used in vehicle wiring harnesses, charging systems, and high-voltage EV cables.

Benefit: Lightweight aluminum braids cut cable mass; copper ensures current capacity for reliable performance in harsh environments.

Industrial Control & Power Systems Cable

Use Case: Applied in factory automation, robotics, PLC systems, and power distribution.

Benefit: Tinned copper braids resist oxidation, reduce EMI, and enhance equipment safety and efficiency.

Aerospace & Defense Cable

Use Case: Essential in avionics, military communication cables, radar, and navigation wiring.

Benefit: High-density copper braids—optionally combined with aluminum—deliver lightweight, high-attenuation shielding in extreme conditions.

Marine & Chemical Environments Cable

Use Case: Used in shipboard cables, offshore platforms, and chemical plant wiring.

Benefit: Aluminum or nickel-plated copper braids withstand salt spray and chemicals, extending cable service life.

Medical Devices / Audio & Video Lines

Use Case: Applied in medical monitors, surgical instruments, precision devices, audio and stage cables.

Benefit: Flexible copper or tinned copper braids minimize noise interference for stable data and clear sound.

From data cables to aerospace systems, Chalco braided shielding wires deliver reliable protection across industries. Contact our team today to discuss your project and get a fast quotation.

Customization & Supply Capability of Chalco Braided Sheilding Wire / Braided Sleeving

Chalco provides full customization options to ensure braided shielding wires perfectly match your cable design and performance needs. Whether for small R&D batches or large-scale industrial projects, our supply chain and in-house manufacturing allow us to deliver fast and flexible solutions.

- Wire Diameters & Strand Counts: Customizable single wire gauges, multi-strand bundles, and braid densities (coverage 70%–95%).

- Braid Structures: Round, flat, single-layer, double-layer, or hybrid designs available upon request.

- Material & Finish Options: Supplied in natural metallic finish (bare copper, tinned copper, nickel-plated copper, aluminum, stainless steel). Optional PET textile overbraids in black, red, yellow, or custom colors are available for cable identification and abrasion protection.

- Surface Treatments: Bare, tinned, or nickel-plated finishes for improved conductivity, oxidation resistance, and extended service life.

- Packaging Options: Spools, coils, or cut lengths with labeling and protective wrapping for easy installation.

- Flexible Supply: Support for low-volume prototypes, bulk orders, and OEM/ODM cooperation with short lead times.

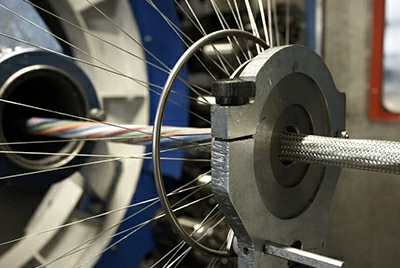

- Braiding Capability: Advanced looms allow consistent weave angle control, uniform optical coverage, and scalable production from small tubes to wide flat braids, ensuring stable shielding performance across applications.

| Braided Finish & Surface Options | |||

| Appearance / Color | Coating / Construction | Compatible Materials | Typical Use / Notes |

| Natural Copper (bright) | Uncoated bare copper | Copper | Excellent conductivity & EMI attenuation; may oxidize over time in humid or salt environments. |

| Silver (tinned finish) | Hot-dip / electro-tinned (Sn) | Copper | Improved corrosion resistance, easy soldering; widely used in automotive and telecom cables. |

| Dull Silver / Gray | Nickel-plated (Ni) | Copper | High-temperature resistance (≈200 °C); strong oxidation resistance for harsh environments. |

| Natural Aluminum | Uncoated Al / Al-alloy | Aluminum, Al-alloys (1350 / 5052 / 5454) | Lightweight, economical; good conductivity-to-weight ratio for large harness applications. |

| Natural Stainless Steel | Uncoated stainless braid | Stainless Steel | High mechanical strength & abrasion resistance; lower conductivity but ideal for rugged protection. |

Contact our team today to request samples, discuss custom specifications, or receive a fast quote tailored to your project. If your shielding projects also involve spiral shielding or foil shielding requirements, feel free to reach out — our team can provide suitable recommendations and supporting materials.

Chalco Braided Shielding Wire – Specifications & Technical Data

Chalco braided shielding products are engineered under ISO-certified systems, aligned with IEC/ASTM performance requirements, and fully compliant with RoHS & REACH. To support design and selection, we present finished braid (oversleeve) performance data first, followed by strand-level (single wire) reference values.

- Wire Gauge Range: 0.10–0.26 mm (≈38–30 AWG), offered in hard (for tensile strength) or soft temper (for flexibility and smooth braiding).

- Material Options: High-conductivity copper, tinned copper, nickel-plated copper, lightweight aluminum/alloys (e.g., 1350, 5052, 5454), and stainless steel for mechanical strength.

- Coverage & Sizes: Optical coverage 70%–95% (custom up to 100%), braid diameters typically from ≈3 mm to ≈38 mm to match cable bundle sizes.

- Temperature Performance: Tin-plated copper braids rated to 150 °C; nickel-plated copper to 200 °C; aluminum/alloy versions up to 150 °C depending on finish.

- Compliance: Manufactured under ISO 9001 with IEC/ASTM conformity; optional UL testing & certification. Fully RoHS & REACH compliant.

| Finished Braided Oversleeves – Family, Coverage & Size Range | |||

| Braid Family / Material | Optical Coverage | Supplied Diameters | Notes |

| Tinned Copper Braid (standard) | ≥ 90% | ≈ 3.0 – 30.0 mm | General EMI/RFI shielding; good solderability and corrosion resistance. |

| Tinned Copper Braid (high coverage) | ≥ 93% up to 100% | ≈ 2.5 – 38.0 mm | Higher attenuation for sensitive signals and low-leakage assemblies. |

| Nickel-Plated Copper Braid | ≥ 93% up to 100% | ≈ 2.5 – 38.0 mm | High-temperature & oxidation resistance; aerospace/defense/industrial. |

| Aluminum / Aluminum-Alloy Braid | ≈ 70% – 95% | ≈ 3.0 – 30.0 mm | Lightweight & cost-effective; ideal for large harnesses and weight-sensitive builds. |

| Operating Temperature – By Material / Plating | ||

| Material / Plating | Typical Operating Range | Remarks |

| Tinned Copper | −65 °C to +150 °C | Standard choice for EMI/RFI; good corrosion resistance and solderability. |

| Nickel-Plated Copper | −65 °C to +200 °C | Elevated-temperature zones; oxidation resistance in harsh environments. |

| Aluminum / Aluminum-Alloy | ≈ −40 °C to +150 °C | Lightweight; limit depends on alloy & finish; contact us for details. |

| Typical Size Options (Examples) | |||

| Nominal Diameter (mm) | Approx. Diameter (in) | Common Copper Variant | Common Nickel-Copper Variant |

| 3.0 | 0.12 | Standard tinned copper braid, ≥ 90% coverage | Nickel-plated copper braid, high temp |

| 6.0 | 0.24 | Tinned copper braid, ≥ 93% coverage | Nickel-plated copper braid, ≥ 93% coverage |

| 10.0 | 0.40 | High-coverage tinned copper up to 100% | Nickel-plated copper, up to 100% coverage |

| 20.0 | 0.79 | Tinned copper for large cable bundles | Nickel-plated copper for high-temp bundles |

Note: Other diameters and constructions available on request. Coverage (70%/85%/95%/100%), strand counts, and lay angles are customizable to meet target shielding effectiveness (SE). Full attenuation data and construction details can be provided for validation.

| Strand-Level Reference (Aluminum Alloy Example) | ||||

| Temper | Diameter (mm) | Tensile Strength (MPa) | Elongation (%) | DC Resistance @ 20 °C (Ω/m) |

| Hard (LHP-Y) | 0.12 | ≥ 300 | ≥ 4 | ≤ 0.052* |

| 0.16 | ≥ 310 | ≥ 4 | ≤ 0.052* | |

| 0.20 | ≥ 310 | ≥ 4 | ≤ 0.052* | |

| 0.24 | ≥ 310 | ≥ 4 | ≤ 0.052* | |

| Soft (LHP-R) | 0.12 | ≥ 220 | ≥ 7 | ≤ 0.052* |

| 0.16 | ≥ 230 | ≥ 7 | ≤ 0.052* | |

| 0.20 | ≥ 230 | ≥ 7 | ≤ 0.052* | |

| 0.24 | ≥ 230 | ≥ 7 | ≤ 0.052* | |

| Knotting / Flex Fatigue Indicator (Al Alloy Strand) | |

| Temper | Reduction of Pull-Off Force Before/After Knotting (%) |

| LHP-Y (Hard) | ≤ 40 |

| LHP-R (Soft) | ≤ 30 |

Example Alloy Composition (5454 aluminum braid wire): Mg 2.8–3.8%, balance Al, other elements ≤ 1.5%.

*DC resistance values depend on exact diameter and alloy temper. Full strand-level data (including resistivity curves and detailed diameter lists) are available upon request. Copper / tinned copper / nickel-plated copper and stainless-steel strand data can also be supplied for direct comparison.

Need a braid construction matched to a target SE (dB), coverage %, cable diameter, or temperature class? Contact us for an engineering-backed recommendation or a customized datasheet package.

Buying Guide & FAQ

Foil vs Braided Shielding

| Type | Advantages | Limitations | Typical Use |

|---|---|---|---|

| Braided | High strength, flexible, stable coverage (70%–95%) | Heavier, higher cost | Automotive, aerospace, military cables |

| Foil | Near 100% coverage, lightweight, cost-effective | Low bending endurance | Data cables (USB, HDMI, Ethernet) |

Copper Braid vs Aluminum Braid

| Material | Advantages | Limitations | Best For |

|---|---|---|---|

| Copper | Excellent conductivity, durable | Heavier, higher cost | High-performance, long-life systems |

| Aluminum | Lightweight, economical, good conductivity | Lower mechanical strength | Bulk installations, cost-sensitive projects |

Coverage % Selection Guide

| Coverage | Feature | Recommended Use |

|---|---|---|

| 70% | Balanced cost and flexibility | General industrial wiring |

| 85% | Standard shielding level | Automotive, marine |

| 95% | Maximum shielding | Aerospace, defense, sensitive electronics |

Foil vs Braided Shielding – How to choose?

Braided shielding provides excellent mechanical strength and flexibility, while foil shielding offers nearly 100% coverage at lower cost. For critical EMI protection, both are often combined.

Copper Braid vs Aluminum Braid – What's the difference?

Copper braid ensures best conductivity and mechanical durability. Aluminum braid is lighter and more economical, ideal for weight-sensitive or cost-sensitive projects.

How to select coverage percentage?

Choose 70% when you need flexibility, 85% as a balanced industrial option, and 95% when maximum shielding is required in aerospace, defense, or sensitive electronics.

Tinned vs Bare Copper – Which should I choose?

Tinned copper resists corrosion and lasts longer in humid or marine environments. Bare copper offers slightly better conductivity at lower cost, suitable for indoor applications.

Customization?

Yes, Chalco supports full customization: single wire diameter, braid density, plating, coil/spool packaging, and OEM/ODM orders.

Why Choose Chalco for Braided Shielding Wire

After answering your key questions, here's why Chalco is the trusted partner for shielding solutions:

- Proven Capability: In-house drawing, stranding, and braiding with advanced equipment.

- Material Options: Copper, aluminum, tinned, nickel-plated wires for different performance needs.

- Certified Quality: ISO, SGS, and RoHS-compliant manufacturing for global projects.

- Flexible Supply: From small R&D runs to bulk OEM orders, with fast lead times.

Still have questions or special requirements? Contact Chalco experts today for a tailored solution and instant quotation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote