2024 aluminum alloy is an aluminum alloy with copper as the main component. It has high strength and excellent fatigue resistance. It is widely used in high-strength structures and components, especially in the fields of transportation and aviation. The alloy also has excellent friction welding performance and good machinability.

Chalco's 2024 aluminum alloy wire has excellent tensile strength, high yield strength, good toughness, high temperature resistance, corrosion resistance and other characteristics, and is widely used in aerospace, automotive industry, construction, military industry and other fields. All wires undergo strict quality testing to ensure that they meet the high standards of customers.

Chalco 2024 aluminum wire product basic parameters introduction

Alloy: A92024

Temper: O, T4, T6, T3, T351, T851

Wire diameter: 2 mm to 30 mm (0.08 in to 1.1 in)

Wire gauge (SWG): 8 SWG, 10 SWG, 20 SWG, 30 SWG, 32 SWG, etc.

Length: 1000 mm to 6000 mm

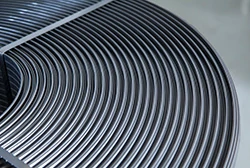

Packing: loose coil/tight coil (spool); shrink wrap, jute wrap, bubble wrap or as per requirement

Treatment: Cold forming, heat treatment, stress relief and welding

Product type:

Cold rolled 2024 aluminum wire — High strength, precision, smooth surface

Production executable standards: ASTM B211 / ASME SB211Quick Quote

Cold-rolled aluminum wire is produced through a rolling process at room temperature, which can improve the strength and hardness of the aluminum wire while maintaining good surface smoothness. It is suitable for fields with high precision and high strength requirements. It mainly covers the following product types:

2024 cold rolled round wire

High-strength round aluminum wire, suitable for structural connectors in the fields of aviation, automobiles, etc.

2024 cold rolled flat wire

Higher strength flat aluminum wire is widely used in manufacturing brackets, frames and other parts.

2024 cold rolled fine wire

Good strength and ductility, often used in precision electronics or small parts. Can also be used to make wire rope.

2024 high precision wire

Cold rolled aluminum wire with high precision surface treatment, suitable for electronic and mechanical components requiring high precision.

2024 cold rolled spring wire

Aluminum wire with high tensile strength is used to manufacture small structural parts such as springs and has good fatigue resistance.

Cold heading 2024 aluminum wire — High strength, small parts, precise forming

Production executable standards: ASTM B565 / ASME SB565, ASTM B316 / ASME SB316Quick Quote

The cold heading process presses aluminum wire into small parts (such as rivets, bolts, etc.) at room temperature, which is suitable for the production of small parts with high strength requirements. It mainly covers the following product types:

2024 cold heading wire for rivets

High-strength aluminum wire suitable for making rivets, which are widely used in the aerospace and automotive industries.

2024 rivet wire for bolts

High-strength aluminum wire, specially used for producing aluminum alloy bolts, provides stable fastening performance.

2024 rivet wire for fasteners

Used to manufacture various aluminum alloy fasteners, widely used in electronics, automobiles and other fields that require high-strength connections.

Extruded 2024 aluminum wire — High ductility, mass production, versatile shapes

Production executable standards: ASTM B221 / ASME SB221Quick Quote

Extruded aluminum wire is made by heating aluminum alloy and extruding it into aluminum wires of different shapes through a die. It is suitable for large-scale production, maintains high strength and ductility, and is widely used in a variety of industries.

2024 extruded round wire

High-strength aluminum alloy round wire, widely used in lightweight structural parts and brackets.

2024 extruded square wire

Square aluminum wire with high strength and good shape accuracy is used to manufacture components such as frames and brackets.

2024 extruded flat wire

High-strength aluminum wire in a flat form, commonly used in applications such as radiators and heat exchangers.

Hot rolled 2024 aluminum wire — High strength, low impurities, accurate dimensions

Production executable standard: AMS 4102 / ISO Al99.0CuQuick Quote

2024 continuous casting and rolling aluminum wire adopts advanced continuous casting and rolling technology. First, the molten aluminum alloy is cast into aluminum billets, and then processed into aluminum wires of the required shape through continuous rolling. This process ensures the uniform composition of the aluminum alloy, reduces impurities and pores, and improves production efficiency and material properties. The aluminum wire produced has high strength, good corrosion resistance, smooth surface, high dimensional accuracy, and is widely used in aerospace, automotive and other fields with high strength and lightweight requirements.

2024 hot rolled round wire

2024 hot rolled square wire

2024 hot rolled flat wire

2024 steel core aluminum wire

Combining the characteristics of aluminum and steel through hot rolling, it provides stronger mechanical properties and corrosion resistance.

2024 large diameter wire

It can produce larger diameter aluminum wire for use in fasteners that require high strength, commonly found in heavy machinery and aviation.

Anodized 2024 aluminum wire — enhanced corrosion resistance, durable surface, aesthetic finish

Chalco's anodized 2024 aluminum wire provides enhanced corrosion resistance, durable surface hardness, and a sleek finish. We offer a full range of advanced surface treatments—including anodizing, powder coating, and chemical conversion—with in-house R&D and strict quality control to ensure superior, consistent, and long-lasting protection.Quick Quote

Unique advantages of 2024 aluminum wire

2024 aluminum wire stands out among aluminum alloys for its exceptional mechanical properties and structural reliability. It is widely used in aerospace, automotive, and military applications that demand high strength, fatigue resistance, and lightweight performance.

- Delivers outstanding tensile strength and fatigue resistance.

- Maintains excellent performance under dynamic loads and vibrations.

- Combines high strength with low weight for lightweight structural design.

- Provides good corrosion resistance in humid and marine environments.

- Performs reliably at elevated temperatures.

- Supports precise machining, cutting, and forming.

- Ideal for fasteners, structural parts, and load-bearing components.

With its exceptional strength, fatigue resistance, corrosion performance, and lightweight characteristics, 2024 aluminum wire stands out among high-performance materials. These advantages make it especially suitable for aerospace structures, automotive components, precision fasteners, and other load-bearing applications where reliability under stress is critical. If you're seeking a material that offers both durability and performance in demanding environments, 2024 aluminum wire is the solution you can trust—contact us to explore specifications, custom options, and how we can meet your project needs.Quick Quote

Chalco 2024 aluminum wire technical parameters

| Aluminum 2024 Wires Equivalent Grades | ||||||

| European Standard | OLD | Wlq | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlCu4Mg1 | AU4G1 | 3.1355 | A92024 | AlCu4Mg1 | 2024 | AlCuMg2 |

| Aluminum 2024 wires chemical composition | ||||||||||

| Grade | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other |

| min. | Bal | 3.80 | 0.30 | 1.20 | ||||||

| max. | Bal | 0.50 | 0.50 | 4.90 | 0.90 | 1.80 | 0.10 | 0.25 | 0.15 | 0.05 |

| ASTM B221 Gr 2024 chemical composition | |

| Element | % |

| Al | 90.0%-95.0% |

| Cu | 3.8%-4.9% |

| Mn | 0.3%-0.9% |

| Mg | 1.2%-1.8% |

| Si | 0.5%-0.9% |

| Cr | 0.10% |

| Zr | 0.25% |

| Ti | 0.15% |

| Other | ≤0.05% |

| Mechanical properties of 2024 aerospace aluminum wire | |

| tensile strength | 470-505 MPa |

| yield strength | 325-470 MPa |

| elongation | 10-12% |

| hardness | 120-140 HB |

| Physical properties of 2024 aerospace aluminum wire | |

| density | 2.78 g/cm 3 |

| Linear expansion coefficient | 23.5×10 -6 /K |

| Thermal conductivity | 120-130 W/(m·K) |

| conductivity | 30-34 MS/m |

| resistivity | 0.058 Ω·mm 2 /m |

| Elastic modulus | 73.1 GPa |

| Poisson's ratio | 0.33 |

Chalco's manufacturing capabilities and quality assurance for 2024 aluminum wire

Rich product range: We offer a wide range of 2024 aluminum wires, including cold-rolled round wire, cold-headed aluminum wire, extruded aluminum wire and hot-rolled aluminum wire, to meet the needs of different industries and applications, ensuring quality and reliability.

Excellent material properties: Our 2024 aluminum wire has excellent high strength, fatigue resistance and corrosion resistance, suitable for applications under high load, high pressure and extreme environment, ensuring the long-term stability of customer products.

Customized service: According to the specific requirements of customers, we provide customized services, and can tailor aluminum wires of different shapes (round wire, square wire, flat wire, etc.) to meet special design needs.

Advanced production technology: The latest production processes such as cold rolling, cold heading, extrusion, etc. are used to ensure the high precision, high strength and excellent surface quality of the aluminum wire, providing long service life and reliability.

Stable supply capacity: With strong production capacity and global procurement network, we are able to ensure timely delivery to meet large-volume demands.

Fast response & flexible delivery: We promise to respond within 24 hours (usually within the same hour) to ensure timely resolution of your needs. We provide stock replacements and shorten manufacturing time to ensure on-time delivery.

Fully verifiable materials: We provide a full set of material test certificates, from raw materials to final dimensional reports, ensuring that every batch of products meets your requirements.

- Appearance size inspection

- Mechanical properties testing (such as tensile strength, elongation, cross-sectional shrinkage, etc.)

- Ultrasonic testing

- Chemical analysis

- Hardness testing

- Pitting protection test

- Penetration test

- Intergranular corrosion test

- Impact analysis

- Metallographic test

Backed by these capabilities, Chalco's 2024 aluminum wire has been widely adopted in aerospace components, automotive fasteners, structural brackets, and precision mechanical parts — and we continue to serve partners across aviation, transportation, defense, and engineering sectors. For detailed application requirements, please explore the following parts or contact our technical team for project consultations and purchasing inquiries.Quick Quote

Chalco 2024 aluminum wire application areas

2024 aluminum wire for aerospace

Used for high-strength connectors, rivets, and fasteners in aircraft structures and cabins, ensuring safety and stability under high pressure and load.

Contact us now

2024 al wire for auto manufacturing

Used to manufacture connecting parts of automotive structural parts: fasteners, screws, rivets, etc.; withstand high strength requirements and reduce the weight of the vehicle, improve fuel efficiency and safety.

Contact us nowMilitary grade 2024 aluminum wire

Used to manufacture high-strength fasteners, rivets and connectors in military equipment to ensure that the equipment can withstand high pressure and high temperature in complex environments.

Contact us now

2024 wire for industrial manufacturing

Used to manufacture high-strength components: fasteners and connectors in industrial equipment, especially in heavy machinery and equipment that need to withstand high loads and fatigue.

Contact us now2024 aluminum wire for construction

Used to manufacture connectors, rivets, etc., which are used for high-strength support and connection components in building structures. Particularly suitable for projects that require lightweight and high strength.

Contact us now

2024 aluminum wire for high temperature equipment

2024 aluminum wire excels in high-temperature environments, making it ideal for heat exchangers, engine components, and high-temperature fasteners.

Contact us nowChalco 2024 aluminum wire buying guide

Chalco 2024 aluminum wire plays an important role in many high-strength applications due to its excellent strength, corrosion resistance and superior processing performance. When purchasing 2024 aluminum wire, you need to consider several factors to ensure that you choose the right product to meet specific engineering needs. The following are the key points to pay attention to when purchasing Chalco 2024 aluminum wire:

How to choose among various alloys and products

Choosing the right aluminum alloy and product type is key to the success of your project. If you're unsure whether 2024 aluminum wire is the best fit, here are some alternatives to consider:

- 2024 aluminum wire: Known for high strength and excellent fatigue resistance, ideal for aerospace, automotive fasteners, and structural components.

- 7075 aluminum wire: Offers even higher strength and superior corrosion resistance, perfect for demanding aerospace and military applications.

- 6061 aluminum wire: Balanced strength and corrosion resistance, suitable for general structural and mechanical uses where weldability is important.

- 2219 aluminum wire: Exceptional performance at high temperatures, often used in aerospace engine parts and heat exchangers.

- 7050 aluminum wire: High strength with excellent corrosion resistance, frequently chosen for heavy-duty aerospace structures.

- Aluminum wire for fasteners: Specially designed for rivets, bolts, and other fasteners requiring precise mechanical properties and durability.

Confirm specifications and dimensions

It is very important to choose the right aluminum wire specifications (diameter, length, etc.). Common specifications include thin wire (such as 0.5mm), medium wire, spring wire, etc. Different application scenarios require aluminum wires of different diameters and shapes to ensure that the product meets the design requirements.

- Diameter: Select the appropriate wire diameter based on application requirements.

- Shape: 2024 aluminum wire can be provided in various forms such as round wire, square wire, flat wire, etc. The specific needs should be considered when choosing.

Production process

2024 aluminum wire has different production processes, such as cold rolling, cold heading, extrusion, etc. According to application requirements, choose the appropriate processing technology:

- Cold rolled aluminum wire: has higher strength and hardness, suitable for applications with high precision and high strength requirements.

- Cold heading aluminum wire: suitable for the production of small fasteners (such as rivets and bolts).

- Extruded aluminum wire: suitable for mass production, maintaining strength and ductility.

- Hot rolled aluminum wire: suitable for the production of large sizes and complex shapes.

Strength and performance requirements

2024 aluminum alloy has high tensile strength and fatigue resistance, suitable for applications with high pressure and load. When purchasing, you should understand the required strength standards to ensure that the aluminum wire you choose can meet the requirements of specific applications.

- Tensile Strength: Make sure the aluminum wire you choose meets the required tensile strength standards.

- Corrosion resistance: Especially in aerospace, military and other environments, there are high requirements for corrosion resistance.

Supplier reputation and service

Choose a reputable supplier to ensure product quality and provide good after-sales service. As a well-known aluminum alloy manufacturer, Chalco provides high-quality 2024 aluminum wire and customized services to meet the needs of different customers.

- After-sales service: Ensure that suppliers can provide timely technical support and after-sales service.

- Customized service: If you have specific sizes or special needs, choose a supplier that can provide customized aluminum wire products.

Cost and delivery time

Price is an important factor in purchasing decisions. Understand the price differences under different specifications, processes and production batches. At the same time, confirm the supplier's delivery cycle to ensure on-time delivery.

- Bulk Purchase Discounts: When you buy in large quantities, you can usually enjoy certain price discounts.

- Lead Time: Choose suppliers who can provide prompt delivery to avoid production delays.

Sample testing

If conditions permit, you can apply for sample testing first to ensure that the quality and performance of the aluminum wire meet the requirements. This is especially important for high-precision applications, which can avoid later production problems caused by quality problems.

When purchasing Chalco 2024 aluminum wire, you should first confirm the product specifications, production process and strength requirements, and ensure that the product meets the relevant quality standards. At the same time, choose a reputable supplier and make appropriate choices based on the needs of the application field. By comprehensively considering these factors, you can ensure that the 2024 aluminum wire you purchase can meet your engineering needs and provide excellent performance and durability.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote