Chalco is a leading supplier of 4047 aluminum alloy, delivering high-performance solutions in foil, strip, sheet, and plate for brazing, cladding, and thermal management applications. With advanced rolling, casting, and precision cutting capabilities, Chalco ensures stable quality, excellent fluidity, and consistent alloy composition tailored for demanding industries such as automotive heat exchangers, electronics, and aerospace.

Our 4047 aluminum products are available in a wide range of gauges and dimensions, supporting both standard stock sizes and custom orders. Backed by ISO-certified quality systems, Chalco provides short lead times, flexible supply formats, and global delivery to meet customers' urgent and long-term production needs.

Quick Specs

Typical supply forms focus on foil, strip, sheet, and plate, while rod, bar, and wire can also be supplied upon request for special applications.

| Form | Min Size | Max Size | Typical Stock Size |

| Sheet | 0.003" Thk | 4" Thk | 0.190" Thk × 24" × 72" |

| Plate | 0.188" Thk | 4" Thk | 0.190" Thk × 24" × 72" |

| Coil/Strip | 0.003" Thk | 4" Thk | 4–12" W × 12–72" L |

| Foil | 0.003" Thk | 0.020" Thk | 4–12" W × 12–72" L |

| Rod / Round Bar / Wire | 0.010" Dia | 6" Dia | 72" Long |

Click to the detailed [stock size table]

About Chalco 4047 Aluminum Alloy —— Specification & Technical Parameters

4047 aluminum alloy (AA4047 / AlSi12) is an aluminum-silicon brazing and filler alloy containing 11–13% silicon, which is significantly higher than its 4043 counterpart. This high silicon content gives 4047 superior fluidity, reduced shrinkage, and outstanding resistance to hot cracking during brazing and welding. Thanks to these properties, 4047 aluminum is widely used in automotive heat exchangers, engine blocks, EV battery cooling plates, and HVAC components. It is also suitable for electronic housings, leak-tight joints, microwave circuit covers, and welding filler wires. As a filler alloy, 4047 melts at a lower temperature than the base metal, ensuring reliable wetting, strong joints, and stable performance under elevated temperatures.

| Specifications of 4047 Aluminum Alloy | |||

| AMS 4185 | QQ-B-365 | HMS 2273 | Mil-B-20148 |

| Alloy 718 | BALS i4 | AWS 5.8 | UNS A94047 |

| ASTM B-247 | AA4047 | EN AW-4047A | EN AW-Al Si12(A) |

Chalco supplies 4047 aluminum in compliance with the above specifications, ensuring reliable quality and full traceability.

| Technical Parameters and Quality Indicators of 4047 Aluminum Coil & Strip | |

| Composite structure | 4047/3003/4047 three-layer or 4047/6063, 4047/6951 heterogeneous composites |

| Coating thickness | 0.03–0.15 mm (customizable) |

| Coating type | Single-side, double-side, or multi-layer |

| Surface protection | Optional anti-oxidation film |

| Peel strength | ≥10 N/mm, no delamination |

| Testing | Ultrasonic NDT, salt spray >96h |

| Standards | ASTM B209/B928, EN 573/485/1396, GB/T 3190 |

| Chemical composition of 4047 alloy | |

| Element | Range |

| Si | 11.0–13.0% |

| Fe | ≤0.80% |

| Cu | ≤0.30% |

| Zn | ≤0.20% |

| Al | Balance |

| Mechanical properties (typical H18 temper) | |

| Tensile strength | 170–200 MPa |

| Yield strength | 80–120 MPa |

| Elongation | 1–5% |

| Hardness | 60–75 HB |

| Welding & brazing performance | |

| Melting range | 577–605°C |

| Brazing fluidity | Excellent |

| Hot crack resistance | Excellent (better than 4045) |

| Typical processes | Vacuum brazing, molten salt brazing, inert gas brazing |

4047 Aluminum Product Types — 4047 Aluminum Sheet, Coil and Strip

Chalco supplies 4047 aluminum sheet, coil and strip with high silicon content (AlSi12), low melting point and excellent brazing performance. These 4047 aluminum products are widely used in automotive heat exchangers, EV battery cooling plates, HVAC systems and electronic thermal control parts.

Available in standard stock or custom specifications, all 4047 aluminum sheet, coil and strip products are produced under strict quality control and supplied with full traceability.

-

4047 Aluminum Sheet – Panels for Brazed Structures

4047 Aluminum Sheet – Panels for Brazed StructuresChalco 4047 aluminum sheet is delivered in flat panels with high surface quality and formability, ideal for airtight joints, cooling plates and heat exchanger housings.

Applications: EV battery cooling plates, brazed thermal panels, HVAC housings

-

4047 Aluminum Coil – Continuous Rolls for Brazing

4047 Aluminum Coil – Continuous Rolls for BrazingChalco 4047 aluminum coil has uniform thickness and smooth surfaces, suitable for large-area brazing, cladding and roll-to-roll lamination.

Applications: heat exchanger substrates, cold plate laminations, slit coils

-

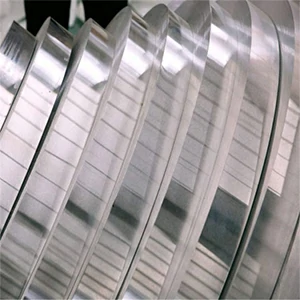

4047 Aluminum Strip – Precision Slit for Fins and Modules

4047 Aluminum Strip – Precision Slit for Fins and ModulesChalco 4047 aluminum strip is slit with high precision to ensure clean edges and dimensional stability, widely used in condenser fins, cooling channels and electronic packaging modules.

Applications: automotive condenser fins, compact heat exchanger components, electronic cooling systems

Looking for more brazing alloys? Chalco also provides other brazing strip and foil solutions: Aluminum Brazing Foil | Aluminum Brazing Strip

Advanced 4047 Aluminum Variants — 4047 Aluminum Foil, Clad Brazing Sheet and Custom Strip

In addition to standard 4047 aluminum sheet, coil and strip, Chalco also supplies 4047 aluminum variants for specialized brazing and thermal systems, including ultra-thin 4047 aluminum foil, 4047 aluminum custom slit strip, 4047 aluminum clad brazing sheet, and 4047 aluminum tube-forming clad strip. These products serve precision applications in automotive, HVAC, electronics and battery cooling.

-

4047 Aluminum Ultra-thin Foil

Thickness: 0.08–0.20 mm

Applications: electronic packaging, micro heat exchangers, precision connectors

-

4047 Aluminum Custom Slit Strip

Width: ≥5 mm (±0.1 mm accuracy)

Applications: condenser fins, electronic connectors, small cooling modules

-

4047 Aluminum Clad Brazing Sheet

Structure: 4047/3003, 4047/6061, multi-layer

Applications: heat exchanger plates, battery cooling parts, brazed fittings

-

4047 Aluminum Tube-forming Clad Strip

Thickness: 0.5–2.5 mm

Applications: condenser tubes, battery cooling pipes, HVAC small exchangers

In addition to sheet, coil and strip, 4047 aluminum is also available in brazing rod and filler rod form — ideal for welding and repair. Click to check product detail: Aluminum Brazing Rod | Aluminum Filler Rod

Key Application Areas of 4047 Aluminum Brazing Materials

Chalco 4047 aluminum coil, clad strip and foil are widely used where reliable brazing, corrosion resistance and stable thermal performance are required. From automotive heat exchangers to data-center cooling, 4047 aluminum solutions deliver proven results under diverse operating conditions.

Automotive Industry

4047 aluminum coil and 4047 aluminum clad brazing sheet are used in condensers, evaporators and oil coolers. They enable strong brazed joints, lightweight design and long-term corrosion resistance for automotive thermal systems.

Power Battery Cooling Systems

For EV battery cooling plates and hydrogen fuel cell modules, 4047 aluminum brazing strip ensures precise brazing, durability and effective heat dissipation under demanding conditions.

Industrial Heat Exchange Equipment

Applied in air coolers, plate heat exchangers and hydraulic oil coolers, 4047 aluminum clad coil provides high strength, dimensional stability and corrosion resistance.

Rail Transit and Ship Systems

4047 aluminum brazing coils and 4047 aluminum strips are used in high-speed rail and marine engine cooling systems, offering robust brazing quality and reliable operation in harsh environments.

Electronics and Communications

For 5G base stations, servers and data centers, 4047 aluminum strip provides efficient heat transfer with stable brazing and tight dimensional accuracy.

HVAC and Home Climate Systems

In commercial HVAC systems and home appliances such as condensers and heat pumps, 4047 aluminum clad coil offers reliable brazing performance, corrosion resistance and stable thermal efficiency.

Whether in automotive, energy, industrial or electronics sectors, Chalco provides 4047 aluminum coil, clad strip and foil solutions with proven performance and flexible customization to support your projects.

4047 Aluminum Coil & Strip Manufacturing Process and Quality Control

At Chalco, we integrate the entire production chain of 4047 aluminum sheet, coil and strip — from alloy melting, hot & cold rolling, composite rolling and slitting to surface finishing. This in-house control guarantees stable composition, precise dimensions, smooth surface quality and reliable brazing performance. Our inventory and customization options support both trial batches and mass production with fast delivery.

We supply not only single-material 4047 aluminum coils but also a wide range of composite brazing products (single-, double-sided or multi-layer). This one-stop capability helps reduce supply-chain complexity, cut procurement costs and accelerate project schedules.

| Chalco 4047 Aluminum Coil & Strip Production Capabilities | ||

| Key Process | Core Capability | Customer Benefit |

| Alloy Melting | High-purity feedstock; real-time spectrometer control | Consistent chemistry; fine grain structure |

| Hot & Cold Rolling | Multi-pass precision rolling; AGC thickness control | Excellent flatness; tight tolerance for brazing |

| Composite Rolling | Single/double-sided or heterogeneous coatings with 3003/6063/6951 cores | Flexible clad solutions for diverse brazing needs |

| Slitting & Surface Treatment | High-speed precision slitting (5–1600 mm); optional film coating | Custom widths; clean surface; smooth edges |

| Quality Control & Traceability | Ultrasonic & peel tests; ASTM/EN/ISO compliance | Reliable bonding; full batch traceability |

Why choose Chalco for 4047 aluminum coils and strips:

- Real-time spectrometer analysis ensures chemical consistency and brazing reliability.

- Automatic AGC rolling system delivers precise thickness and flatness.

- Ultrasonic and peel tests confirm strong, delamination-free bonding.

- Certified to ISO 9001, ASTM B209/B928, EN 485/1396 and customer-specific requirements.

- Flexible supply: inventory stock + custom sizes for samples and large orders.

- Each 4047 aluminum coil marked with a unique batch ID for full traceability.

Looking for certified 4047 aluminum coil and strip with stable quality? Contact Chalco to get samples and technical support.

Chalco 4047 Aluminum Stock Sizes

Chalco offers a wide selection of 4047 aluminum coils and strips to support automotive, battery, industrial, and electronic cooling projects. With precise composition control, excellent brazing performance, and stable quality, our 4047 aluminum stock (sheet, coil & strip) supports urgent production needs and spot purchases.

| 4047 aluminum coil dimensions | ||

| Size (Thickness × Width × Length) | Specification | Remarks |

| 0.003" × 4" × 24" | ASTM B209 | Standard coil stock |

| 0.005" × 6" × 24" | ASTM B209 | Thin sheet coil |

| 0.008" × 6" × 12" | ASTM B209 | Lightweight applications |

| 0.010" × 6" × 24" | ASTM B209 | General brazing use |

| 0.010" × 6" × 36" | ASTM B209 | Extended size option |

| 0.010" × 12" × 36" | ASTM B209 | Wide-format coil |

| 0.012" × 6" × 36" | ASTM B209 | Structural applications |

| 0.015" × 6" × 24" | ASTM B209 | Mid-thickness usage |

| 0.015" × 12" × 36" | ASTM B209 | General-purpose sheet |

| 0.020" × 12" × 72" | ASTM B209 | Large format coil |

| 0.025" × 3" × 24" | ASTM B209 | Narrow width option |

| 0.030" × 12" × 72" | ASTM B209 | Heavy-duty applications |

| 0.040" × 12" × 72" | ASTM B209 | Structural components |

| 0.045" × 6" × 36" | ASTM B209 | Medium-thickness usage |

| 0.050" × 12" × 72" | ASTM B209 | Common in heavy brazing |

| 0.060" × 12" × 72" | ASTM B209 | Industrial usage |

| 0.080" × 12" × 72" | ASTM B209 | Reinforced applications |

| 0.090" × 12" × 36" | ASTM B209 | High strength requirement |

| 0.125" × 12" × 72" | ASTM B209 | Heavy structure fabrication |

| 0.160" × 4.5" × 6" | ASTM B209 | Small part manufacturing |

| 0.190" × 24" × 12" | ASTM B209 | Specialty component use |

| 0.190" × 24" × 72" | ASTM B209 | Heavy plate size |

| 0.250" × 8" × 12" | ASTM B209 | Medium-thick plates |

| 0.500" × 6" × 12" | ASTM B209 | Thick plate stock |

| 0.500" × 12" × 36" | ASTM B209 | Heavy duty applications |

| 0.750" × 12" × 32" | ASTM B209 | Maximum thickness range |

| 4047 aluminum strip dimensions | ||

| Size (Thickness × Width × Length) | Specification | Remarks |

| 0.003" × 4" × 24" | ASTM B209 | Precision strip stock |

| 0.005" × 6" × 24" | ASTM B209 | Thin strip for forming |

| 0.008" × 6" × 12" | ASTM B209 | Lightweight strip |

| 0.010" × 6" × 24" | ASTM B209 | Strip for brazing |

| 0.010" × 6" × 36" | ASTM B209 | Extended strip format |

| 0.010" × 12" × 36" | ASTM B209 | Wide strip for fabrication |

| 0.012" × 6" × 36" | ASTM B209 | Medium gauge strip |

| 0.015" × 6" × 24" | ASTM B209 | General-purpose usage |

| 0.015" × 12" × 36" | ASTM B209 | Wide strip |

| 0.020" × 12" × 72" | ASTM B209 | Large dimension strip |

| 0.025" × 3" × 24" | ASTM B209 | Narrow cut strip |

| 0.030" × 12" × 72" | ASTM B209 | Industrial usage strip |

| 0.040" × 12" × 72" | ASTM B209 | Heavy structure usage |

| 0.045" × 6" × 36" | ASTM B209 | Mid-range thickness strip |

| 0.050" × 12" × 72" | ASTM B209 | Heavy duty strip stock |

| 0.060" × 12" × 72" | ASTM B209 | High load applications |

| 0.080" × 12" × 72" | ASTM B209 | Structural strip |

| 0.090" × 12" × 36" | ASTM B209 | Compact heavy strip |

| 0.125" × 12" × 72" | ASTM B209 | Thick strip option |

| 0.160" × 4.5" × 6" | ASTM B209 | Small size strip use |

| 0.190" × 24" × 12" | ASTM B209 | Specialty heavy strip |

| 0.190" × 24" × 72" | ASTM B209 | Large heavy strip format |

| 0.250" × 8" × 12" | ASTM B209 | Medium-thick strip |

| 0.500" × 6" × 12" | ASTM B209 | Maximum thickness strip |

| 0.500" × 12" × 36" | ASTM B209 | Heavy industrial usage |

| 0.750" × 12" × 32" | ASTM B209 | Extra heavy strip |

| 4047 Aluminum Flat Stock List | ||

| Size | Size | Size |

| 0.003" Thk x 4"w x 24" Lg | 0.020" Thk x 12"w x 72" Lg | 0.160" Thk x 4.5"w x 6" Lg |

| 0.003" Thk x 6"w x 24" Lg | 0.025" Thk x 3"w x 24" Lg | 0.190" Thk x 24"w x 12" Lg |

| 0.005" Thk x 6"w x 24" Lg | 0.030" Thk x 12"w x 72" Lg | 0.190" Thk x 24"w x 72" Lg |

| 0.008" Thk x 6"w x 12" Lg | 0.040" Thk x 12"w x 72" Lg | 0.250" Thk x 8"w x 12" Lg |

| 0.010" Thk x 6"w x 24" Lg | 0.045" Thk x 12"w x 36" Lg | 0.500" Thk x 6"w x 12" Lg |

| 0.010" Thk x 6"w x 36" Lg | 0.050" Thk x 12"w x 72" Lg | 0.500" Thk x 12"w x 36" Lg |

| 0.010" Thk x 12"w x 36" Lg | 0.060" Thk x 12"w x 72" Lg | 0.750" Thk x 12"w x 32" Lg |

| 0.012" Thk x 6"w x 36" Lg | 0.080" Thk x 12"w x 40" Lg | 0.800" Thk x 3.5"w x 47" Lg |

| 0.015" Thk x 6"w x 24" Lg | 0.080" Thk x 12"w x 72" Lg | 1.000" Thk x 12"w x 36" Lg |

| 0.015" Thk x 12"w x 36" Lg | 0.090" Thk x 12"w x 36" Lg | 1.375" Thk x 1.750"w x 3.600" Lg |

| 0.020" Thk x 0.20"w x 200' Lg Coil | 0.125" Thk x 12"w x 72" Lg | 1.500" Thk x 12"w x 36" Lg |

| 4047 Aluminum Flat Stock List | ||

| Size | Size | Size |

| 0.010" Dia x spool | 0.157" Dia x 36" Lg | 0.750" Dia x 72" Lg |

| 0.015" Dia x spool | 0.250" Dia x 72" Lg | 1" Dia x 72" Lg |

| 0.020" Dia x spool | 0.3125" Dia x 72" Lg | 1.500" Dia x 72" Lg |

| 0.025" Dia x spool | 0.375" Dia x 72" Lg | 2" Dia x 48" Lg |

| 0.040" Dia x coil | 0.500" Dia x 72" Lg | 2.500" Dia x 48" Lg |

| 0.062" Dia x 36" Lg | 0.5625" Dia x 72" Lg | 1.500" Dia x 72" Lg |

| 0.094" Dia x 36" Lg | 0.569" Dia x 75" Lg | 2" Dia x 48" Lg |

| 0.125" Dia x 36" Lg | 0.625" Dia x 72" Lg | 2.500" Dia x 48" Lg |

4047 Alloy Comparison and Related Product Recommendations

| Alloy | Feature Comparison | Recommended Application Scenarios |

| 4045 | Slightly weaker fluidity than 4047, slightly better corrosion resistance | Air conditioning heat exchanger, standard heat exchange plate |

| 4047 | Low melting point, excellent fluidity, good thermal crack resistance | Power battery liquid cooling plate, high airtight brazing structure |

| 4343 | Slightly higher melting point, good fluidity, excellent joint toughness | Industrial heat exchanger, special atmosphere brazing |

| 7072 | Very high corrosion resistance, used as a protective layer rather than brazing main material | Used as corrosion-resistant surface layer of composite materials |

Related Brazing Materials & Recommended Alloys

4043 aluminum

Widely used as a brazing and welding filler alloy, with stable flow and good bonding performance.

High-strength core alloy, commonly clad with 4047 for automotive and electronic heat exchangers.

Popular core alloy in brazed panels and cooling plates, balancing strength and corrosion resistance.

General brazing and welding filler rods, suitable for multiple aluminum alloys and applications.

High-performance welding wire with strong corrosion resistance and excellent brazing flow.

Stronger than 4043 while maintaining good weldability, widely used in structural brazing.

FAQs for 4047 Aluminum Coil & Strip

What thicknesses are available?

0.08 mm – 3.0 mm in coils or strips, with slitting and cut-to-length options.

What surface treatments can be provided?

Cold-rolled smooth, descaling, protective film, or customized flux coating.

Can you provide certificates?

Yes, including composition analysis, mechanical properties, ultrasonic, or peel strength reports.

Do you support small-batch or samples?

Yes, quick samples are available to shorten R&D cycles.

Which brazing processes are suitable?

Vacuum brazing, molten salt, and inert gas brazing (e.g., argon shielded).

Do you provide application support?

Yes, from alloy selection to process optimization and custom composite solutions.

As a leading 4047 aluminum supplier, Chalco delivers coil, sheet, and strip with full certification, competitive pricing, and global shipping support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote