As the most widely used aluminum-manganese alloy, 3003 aluminum coil is known for its moderate strength, excellent formability, and superior corrosion resistance. Through cold work hardening, its strength is increased by approximately 20%, meeting the requirements for deep drawing, stretching, welding, and weather resistance in transportation, chemical equipment, and architectural decoration fields.

Instant QuoteChalco can supply 3003 aluminum coils that comply with ASTM B209 and AMS-QQ-A-250/2 standards, with a regular thickness of 0.2-6 mm and a width of up to 2650 mm, providing a cold rolling tolerance of ±0.01 mm. We also support custom slitting (shearing, aluminum strip) and various surface treatments such as anodizing, powder coating, and embossing, fully meeting diverse requirements for quality, delivery time, and appearance.

Quick Navigation

Specifications of 3003 Aluminum Coil

| Equivalent Names | EN AW-3003;3.0517;A93003 |

| Temper | O,H12,H14,H16,H18,H19 |

| Thickness | 0.2–6.0 mm |

| Width | ≤ 2650 mm |

| Surface Treatment | Mill Finish,Pre-painted,Anodized,Powder Coating |

| Secondary Processing | Cutting,Perforation |

| Standards | ASTM B209,AMS-QQ-A-250/2,AMS 4006,AMS 4008 |

For more specification details or to obtain free samples, please contact our sales team immediately and enjoy 7-day rapid custom slitting services!

Instant QuoteTempers of 3003 Aluminum Coil

The mechanical properties and processing characteristics of 3003 aluminum coil are mainly determined by its temper. Through different degrees of annealing and cold work hardening, a balance can be achieved between softness, formability, and strength to meet diverse needs such as deep drawing, decorative panels, or high-rigidity structural components.

- 3003 O Aluminum Coil

Fully annealed at ~415 °C for maximum softness (HB 40), refined grain, and stress relief. Excellent for cold forming and deep drawing of complex parts.

- 3003 H14 Aluminum Coil

~25% cold worked, medium hardness (HRB 60), balances strength and ductility. Ideal for general stamping and kitchenware.

- 3003 H16 Aluminum Coil

~50% cold worked, higher hardness (HRB 75), improved rigidity with moderate formability. Used for decorative panels and enclosures.

- 3003 H18 Aluminum Coil

Fully hardened (~100% cold work, HRB 90+), minimal ductility, high rigidity. Suitable for nameplates, shelves, and precision thin parts.

To meet your project needs, we can provide a full range of 3003 aluminum coil tempers and customized thickness, width, and surface treatment solutions to help you quickly improve product performance and quality – welcome to contact us for quotations and technical support!

Instant QuoteProduct Categories of 3003 Aluminum Coil

3003 Hot Rolled Aluminum Coil

Hot rolling provides good ductility and cost advantages, suitable for producing medium-thick specifications ≥ 3 mm. Hot-rolled aluminum coils have coarser grains and better toughness than cold-rolled ones, commonly used for industrial structural supports, large storage tanks, and heavy-duty frames.

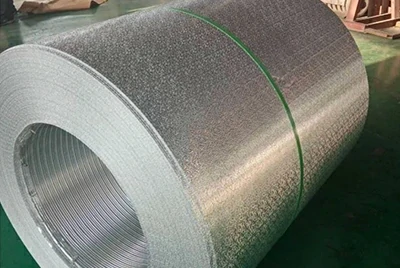

3003 Cold Rolled Aluminum Coil

Cold rolled to ±0.01 mm thickness tolerance with high surface finish. Strength increases ~20%, ideal for deep drawing, stamping, and forming. Widely used in precision parts, enclosures, and thin structural components.

3003 Anodized Aluminum Coil

An oxide film is electrochemically generated on the surface, significantly improving corrosion resistance and hardness, and allowing for multi-color dyeing. Suitable for outdoor curtain walls, decorative panels, and appliance housings that require both oxidation resistance and aesthetics.

3003 Color Coated Aluminum Coil

The surface is coated with PE or PVDF coatings, providing good weather resistance, rich color options, and processing adaptability. Widely used in curtain walls, ceilings, and roofing systems for building exteriors.

Coating: PE PVDF

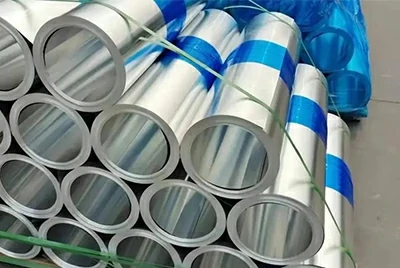

3003 Mirror Aluminum Coil Sheet

Achieves high reflectivity and excellent surface flatness through high-precision rolling and mirror polishing, widely used in lighting reflectors, solar reflectors, elevator decoration, and other high-reflection applications.

3003 Brushed Aluminum Coil

The surface exhibits a delicate brushed texture through unidirectional mechanical drawing, providing a good decorative effect while also offering anti-fingerprint and scratch-resistant properties. Suitable for appliance panels, signage, interior decorative panels, and architectural decoration.

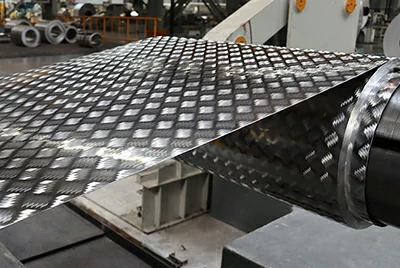

A non-slip, decorative, or functional embossed pattern (such as diamond or stucco) is formed on the surface through an embossing process. Suitable for elevator floors, ship decks, and decorative panels, combining anti-slip and aesthetic effects.

Formed into a wavy shape through cold bending or roll forming, increasing structural rigidity and drainage capacity, widely used in roofing, enclosure walls, and shading systems for buildings.

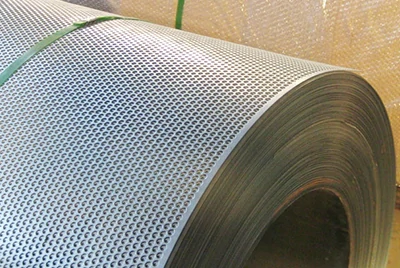

3003 Perforated Aluminum Coil

CNC punching technology can achieve various hole types and perforation rates (5%–60%), providing ventilation, heat dissipation, and decorative functions. Commonly found in air conditioning filter screens, speaker grilles, and architectural sunshades.

3003 Brazing Aluminum Coil

The core material is 3003, and the cladding material is 4043 alloy, forming a metallurgical bond through brazing, improving heat resistance and connection strength. Mainly used in automotive radiator fins and industrial heat exchanger components.

4343 (10%) + 3003 + 4343 (10%)

The surface is laminated or composited with insulation materials, improving thermal insulation and moisture-proof effects. Suitable for cold chain transportation, building insulation pipes, and refrigeration equipment.

3003 Fin Stock Aluminum Coil Strip

Specifically designed for heat exchanger fins, with precise matching of thickness, width, and punching slots; excellent thermal conductivity and corrosion resistance, commonly used in air conditioners, refrigerators, and radiators.

Five-bar, diamond, or stucco patterns are rolled onto the surface of the aluminum coil, enhancing anti-slip performance and visual recognition. Widely used for flooring, stair treads, construction machinery pedals, and anti-slip packaging.

The width can reach 2650mm, reducing splicing and suitable for large-size panel requirements. Commonly used for refrigerated truck skins, chemical storage tank linings, ship decks, and wind power tower cylinders.

3003 Aluminum Trim Coil

Possesses good ductility, corrosion resistance, and coating adhesion, commonly used for roof edges, door and window edges, and exterior wall cladding in architectural decoration, especially suitable for outdoor environments requiring bending and weather resistance.

Specific products of Aluminum Trim Coil:

3003 White Aluminum Trim Coil

White coating on 3003 substrate, offering durability and reflectivity. Used for refrigerated truck skins, clean rooms, medical equipment, and decorative applications.

3003 Black Aluminum Trim Coil

Black coating with excellent weather and fade resistance, ideal for curtain walls, decorative edging, and electronic enclosures, commonly used in high-end buildings and commercial projects.

3003 Wood Grain Aluminum Trim Coil

Wood grain texture via thermal transfer or roll coating, combining aesthetics with metal durability. Used for villa exteriors and door frames as a wood alternative.

Application Fields of 3003 Aluminum Coil

Building and Curtain Wall Systems

Roofing sheets, roof tiles

Wall cladding, aluminum curtain wall panels

Ceiling tiles

Gutters, eaves, downpipes

Billboard substrate

Food and Beverage

Food packaging containers

Easy-open can body stock

Kitchenware and cooking utensils

Storage and transportation equipment

Transportation

Power battery housings

Toolbox housings

Chassis protection plates

Refrigerated truck skins

Chemical and Petrochemical

Tank and pressure vessel sheets

Reactor vessel liners, piping supports

Pipe flange gaskets

Heating, Ventilation, and Air Conditioning (HVAC)

Condenser and evaporator fins

Fan housings, ventilation duct sheets

Air conditioner radiator housings

Home Furnishing and Decoration

Interior partitions, decorative grilles

Aluminum cabinet panels

Refrigerator/washing machine panels

Get Your Exclusive Solution Now: No matter which industry application you focus on, we can provide customized specifications, surface treatments, and technical support for 3003 aluminum coils according to your project needs, helping you quickly implement and enhance competitiveness – welcome to contact us at any time for detailed solutions and quotations!

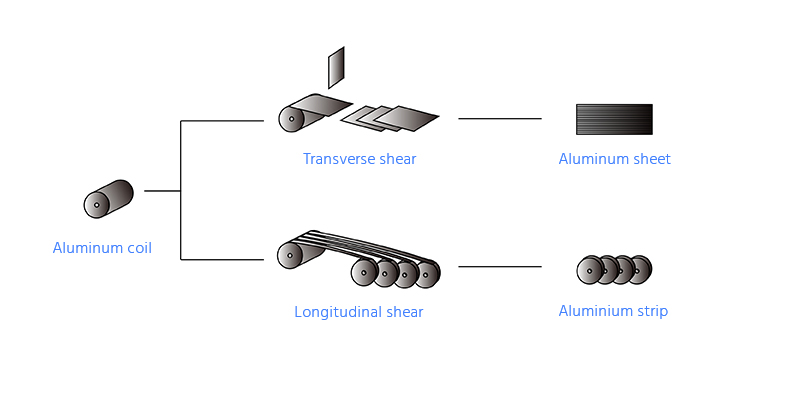

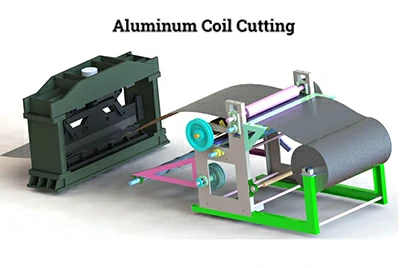

Instant QuoteChalco Aluminum Coil Processing Capabilities

Chalco possesses first-class aluminum coil deep processing production lines, capable of precisely processing high-quality aluminum coils into various aluminum sheets and aluminum strips through advanced leveling and cutting equipment. The cut-to-length process combines multi-roll tension leveling and CNC shearing to ensure excellent flatness and controllable thickness tolerance of the finished sheets. The slitting process utilizes high-precision slitting machines and online edge trimming systems to achieve an aluminum strip width tolerance of ±0.1 mm and burr-free edges, fully meeting the requirements for subsequent processing such as stamping, bending, and welding.

Aluminum Coil Cross Cutting – 3003 Aluminum Sheet

3003 aluminum coils are unwound on decoilers, leveled by multi-roll combinations to eliminate internal stress and waviness, and then precisely cut to the customer's specified length (100 mm–6000 mm) by a PLC-controlled shearing mechanism. Protective film can be applied to the surface of the finished sheets to ensure no scratches or creases.

Standard Sizes

| Dimensions (mm) | Typical Uses |

| 1000×2000 | Curtain wall panels, decorative panels |

| 1220×2440 (4′×8′) | Architectural decoration, furniture panels |

| 1250×2500 | Machinery shells, large equipment guard plates |

| 1500×3000 | Ship skins, rail transit interiors |

*Chalco can customize ultra-wide aluminum coil (≤ 2650 mm) or ultra-long (≤ 6000 mm) sheets.

Applications

3003 aluminum sheets are widely used in building curtain walls, mechanical equipment panels, and furniture decoration. Their high flatness and straightness meet the requirements for spraying, bending, and assembly. Their weather resistance and aesthetics also make them an ideal substrate for advertising signs and interior partitions.

Aluminum Coil Slitting – 3003 Aluminum Strip

3003 aluminum coils are pulled by high-precision slitting machines with automatic tension control into the slitting unit. The slitting width is flexibly adjustable (10–500 mm), and the thickness range is 0.2–3.0 mm. After slitting, online edge trimming and tension leveling are performed, and the aluminum strips are output in tightly wound coils, ensuring clean edges and stable dimensions.

3003 aluminum coils are pulled by high-precision slitting machines with automatic tension control into the slitting unit. The slitting width is flexibly adjustable (10–500 mm), and the thickness range is 0.2–3.0 mm. After slitting, online edge trimming and tension leveling are performed, and the aluminum strips are output in tightly wound coils, ensuring clean edges and stable dimensions.

Standard Sizes

| Width(mm) | Thickness(mm) |

| 10–100 | 0.2–1.0 |

| 101–300 | 1.0–2.0 |

| 301–500 | 2.0–3.0 |

*Controllable tolerance of ±0.1 mm, burr-free edges, and flat surface.

Applications

3003 aluminum strips are commonly used as fin stock for electronic heat sinks and HVAC systems, and can also be used as cable shielding and conductive strips. Their excellent plasticity and corrosion resistance make them perform well in lightweight applications such as automotive trim strips and furniture edge banding.

For more customized solutions regarding specifications, thickness, tolerance, or surface treatment (anodizing, spraying, wood grain transfer, etc.), please feel free to contact us at any time. Chalco will provide you with comprehensive technical support and accurate quotations!

1100 vs 3003 vs 5052 aluminum coil

| Property | 1100 Aluminum Coil | 3003 Aluminum Coil | 5052 Aluminum Coil |

| Alloy | Pure aluminum (99.0% min Al) | Manganese (1.0-1.5% Mn) | Magnesium (2.2-2.8% Mg), Chromium (0.15-0.35% Cr) |

| Features | Highest aluminum content, excellent formability and corrosion resistance, good electrical and thermal conductivity, low strength | Good corrosion resistance and formability, higher strength than 1100, widely used | High strength, excellent corrosion resistance (especially in harsh environments), good fatigue strength |

| Strength | Low (lowest tensile and yield strength) | Medium (higher than 1100, but lower than 5052) | High (highest tensile and yield strength) |

| Corrosion Resistance | Excellent (pure aluminum itself has good corrosion resistance) | Good (slightly worse than pure aluminum, but still has good corrosion resistance) | Excellent (excellent in marine and industrial environments) |

| Weldability | Excellent (easy to weld) | Good (can be welded by a variety of methods) | Good (weldability is acceptable, but requires attention) |

| Formability | Excellent (very easy to bend, stamp, etc.) | Good (has good formability) | Good (good formability, but high strength) |

| Electrical Conductivity | Excellent (pure aluminum has good electrical conductivity) | Good (slightly lower than 1100) | Medium (lower conductivity due to alloying elements) |

| Thermal Conductivity | Excellent (pure aluminum has good thermal conductivity) | Good (slightly lower than 1100) | Medium (lower thermal conductivity than 1100 and 3003) |

| Appearance | Bright, with the metallic luster of pure aluminum | Bright, but may vary slightly due to alloying elements | Bright, but may have slightly different colors due to alloying elements |

| Typical Applications | Decoration, heat sink, food container, wire and cable coating, stampings, etc. | Cookware, food processing equipment, chemical product storage containers, pipelines, architectural decoration, etc. | Automotive parts, aircraft parts, ship parts, pressure vessels, building curtain walls, signs, etc. |

| Cost | Relatively low | Medium | Relatively high |

If your priority is excellent formability, superior corrosion resistance, and good electrical and thermal conductivity, with lower strength requirements, then 1100 aluminum coil is your ideal choice.

If you need a good balance between strength, corrosion resistance, and formability, and are looking for a versatile and widely applicable material, then 3003 aluminum coil is a solid choice.

If your application environment is harsh (e.g., marine or industrial) and you have high demands for material strength and corrosion resistance, while also considering fatigue strength, then 5052 aluminum coil is a more suitable option.

We hope the above comparative analysis of 1100, 3003, and 5052 aluminum coils can help you make a better choice. If you have any other questions or need a more in-depth discussion, please feel free to contact us at any time!

Instant QuoteChemical Composition of 3003 Aluminum Coil

| Element | Content (%) |

| Silicon | 0.6 |

| Iron | 0.7 |

| Copper | 0.05 - 0.20 |

| Manganese | 1.0 - 1.5 |

| Magnesium | - |

| Chromium | - |

| Zinc | 0.1 |

| Titanium | - |

| Other-Each | 0.05 |

| Other-Total | 0.15 |

| Aluminum | remainder |

Physical Properties of 3003 Aluminum Coil

| Physical Property | Value |

| Density | 2.73 g/cm³ |

| Melting Point | 643 - 654 ℃ |

| Coefficient of Thermal Expansion | 23.6 × 10⁻⁶ /℃ (at 20-100℃) |

| Thermal Conductivity | 193 W/m·K (at 25℃) |

| Electrical Resistivity | 0.032 - 0.034 μΩ·m (at 20℃, 退火) |

| Modulus of Elasticity | 69 GPa |

| Poisson's Ratio | 0.33 |

Mechanical Properties of 3003 Aluminum Coil

| Alloy | temper | Specified Thickness, in. | Tensile Strength, ksi | Yield Strength (0.2% offset), ksi | Elongation in 2 in. or 4x Diameter, min, % | Bend Diameter Factor, N |

| 3003 | O | 0.006-0.007 | 14.0 - 19.0 | 5.0 | 14 | 0 |

| 3003 | O | 0.008-0.012 | 14.0 - 19.0 | 5.0 | 18 | 0 |

| 3003 | O | 0.013-0.019 | 14.0 - 19.0 | 5.0 | 20 | 0 |

| 3003 | O | 0.032-0.050 | 14.0 - 19.0 | 5.0 | 23 | 0 |

| 3003 | O | 0.051-0.249 | 14.0 - 19.0 | 5.0 | 25 | 0 |

| 3003 | O | 0.250-3.000 | 14.0 - 19.0 | 5.0 | 23 | - |

| 3003 | H12 | 0.017-0.019 | 17.0 - 23.0 | 12.0 | 3 | 0 |

| 3003 | H12 | 0.020-0.031 | 17.0 - 23.0 | 12.0 | 4 | 0 |

| 3003 | H12 | 0.032-0.050 | 17.0 - 23.0 | 12.0 | 5 | 0 |

| 3003 | H12 | 0.051-0.113 | 17.0 - 23.0 | 12.0 | 6 | 0 |

| 3003 | H12 | 0.114-0.161 | 17.0 - 23.0 | 12.0 | 7 | 0 |

| 3003 | H12 | 0.162-0.249 | 17.0 - 23.0 | 12.0 | 8 | 0 |

| 3003 | H12 | 0.250-0.499 | 17.0 - 23.0 | 12.0 | 9 | 0 |

| 3003 | H12 | 0.500-2.000 | 17.0 - 23.0 | 12.0 | 10 | - |

| 3003 | H14 | 0.009-0.012 | 20.0 - 26.0 | 17.0 | 1 | 0 |

| 3003 | H14 | 0.013-0.019 | 20.0 - 26.0 | 17.0 | 2 | 0 |

| 3003 | H14 | 0.020-0.031 | 20.0 - 26.0 | 17.0 | 3 | 0 |

| 3003 | H14 | 0.032-0.050 | 20.0 - 26.0 | 17.0 | 4 | 0 |

| 3003 | H14 | 0.051-0.113 | 20.0 - 26.0 | 17.0 | 5 | 0 |

| 3003 | H14 | 0.114-0.161 | 20.0 - 26.0 | 17.0 | 6 | 2 |

| 3003 | H14 | 0.162-0.249 | 20.0 - 26.0 | 17.0 | 7 | 2 |

| 3003 | H14 | 0.250-0.499 | 20.0 - 26.0 | 17.0 | 8 | - |

| 3003 | H14 | 0.500-1.000 | 20.0 - 26.0 | 17.0 | 10 | - |

| 3003 | H16 | 0.006-0.019 | 24.0 - 30.0 | 21.0 | 1 | 4 |

| 3003 | H16 | 0.020-0.031 | 24.0 - 30.0 | 21.0 | 2 | 4 |

| 3003 | H16 | 0.032-0.050 | 24.0 - 30.0 | 21.0 | 3 | 4 |

| 3003 | H16 | 0.051-0.162 | 24.0 - 30.0 | 21.0 | 4 | 6 |

| 3003 | H18 | 0.006-0.019 | 27.0 | 24.0 | 1 | - |

| 3003 | H18 | 0.020-0.031 | 27.0 | 24.0 | 2 | - |

| 3003 | H18 | 0.032-0.050 | 27.0 | 24.0 | 3 | - |

| 3003 | H18 | 0.051-0.128 | 27.0 | 24.0 | 4 | - |

| 3003 | H112 | 0.250-0.499 | 17.0 | 10.0 | 8 | - |

| 3003 | H112 | 0.500-2.000 | 15.0 | 6.0 | 12 | - |

| 3003 | H112 | 2.001-3.000 | 14.5 | 6.0 | 18 | - |

| 3003 | F | 0.250-3.000 | - | - | - | - |

Frequently Asked Questions

Is there a high risk of cracking when 3003 aluminum coil is subjected to complex bending? How can it be avoided?

3003 has good formability, but excessive bending still carries a risk of cracking. Choose a soft temper (O) or a suitable semi-hard temper (H12/H14), and pay attention to the bending radius, die design, and processing speed.

Will a humid environment corrode 3003 aluminum coil? Is extra protection needed?

3003 has better corrosion resistance than pure aluminum and can handle general humid environments. For long-term exposure to high humidity or corrosive media, surface treatments such as anodizing are recommended.

When welding 3003 aluminum coil, how can strength be guaranteed and cracking avoided?

Select a matching welding wire (such as ER4043/ER5356), precisely control welding parameters, thoroughly clean the weld, and avoid rapid cooling to prevent stress.

Can 3003 aluminum coil be directly painted or anodized? What is the effect?

Yes. Paint adhesion is good, and anodizing can improve wear resistance, but the color of the oxide film may not be as vibrant as that of other alloys.

How much more expensive is 3003 aluminum coil than 1100? How much cheaper is it than 5052? How can I find the most cost-effective option?

The price is between 1100 and 5052. Choose the appropriate temper based on strength and corrosion resistance requirements, optimize material usage, and partner with reliable suppliers.

The specifications for the 3003 aluminum coil I need are special. Can you customize them? How long is the delivery time?

Yes, Chalco can customize the production of non-standard specifications of 3003 aluminum coil. The delivery time depends on the specific specification deviations, required quantity, current production schedule, and whether there are any special process requirements. Please provide detailed specifications and quantity so that we can evaluate and give you an accurate delivery time.

What are the packaging methods for Chalco aluminum coils?

Chalco offers packaging in wooden pallets, cardboard/paper tubes, and boxes. Special packaging such as wooden boxes and iron drums can also be customized according to customer needs. All packaging emphasizes material quality and fixation to ensure transportation safety. Please inform us of any special requirements.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote