Chalco supplies copper brazing rods for professional joining applications, covering HVAC, refrigeration, pipeline installation, automotive, and industrial manufacturing. Our product range includes phosphorus copper and copper alloy brazing rods with different flux configurations to match varied process requirements.

- High joint strength with excellent corrosion resistance

- Good fluidity for fast wetting and effective gap filling

- Available in phosphorus copper, flux-coated, and fluxless rod types

- Global supply capability with fast delivery and OEM customization support

Chalco Copper Brazing Rod Product Types & Supply Specifications

Chalco supplies a comprehensive range of copper brazing rods designed for copper-to-copper, copper-to-brass, copper-to-steel, and copper-to-aluminum joining applications. Our product range covers multiple alloy systems and supply forms to support both on-site installation and industrial production requirements.

- Alloy systems: High-copper alloys, brass brazing alloys, phos-copper brazing alloys, silver-copper alloys, and other special copper-based alloys

- Standard diameters: 1.5 mm / 2.0 mm / 2.5 mm / 3.0 mm

- Standard lengths: 330 mm / 500 mm / 1000 mm

- Supply forms: Straight rods, coils, wires, and preformed rings

- Packing options: 5 pcs / 10 pcs small packs, 0.5 kg / 1 kg industrial packs; OEM customization supported

Copper to Copper Brazing Rods

Phos-Copper brazing rods (AWS BCuP series) are the standard choice for copper-to-copper and copper-alloy joining. Phosphorus provides self-fluxing behavior, while silver-containing grades improve joint toughness and corrosion resistance, making them suitable for both installation and maintenance applications.

Contact us now

- Phosphorus: Self-fluxing for copper joints; no additional flux required

- Silver addition: Enhances toughness and corrosion resistance

- Material limitation: Not recommended for steel due to phosphorus-induced embrittlement

- Typical applications: Copper tubing joints in HVAC systems, household appliances, and electrical connectors

| Alloy (AWS) | ISO Equivalent | Chemical Composition (wt%) | Melting Range (℃) | Recommended Brazing Temperature (℃) |

| BCuP-2 | CuP 181 | Cu + 7% P | 710–793 | 740–790 |

| BCuP-3 | CuP 281 | P 5.8–6.2%, Ag 4.8–5.2% | 645–815 | 680–740 |

| BCuP-4 | CuP 283 | Cu + 7% P + 6% Ag | 643–724 | 680–720 |

| BCuP-5 | CuP 284 | Cu + 5% P + 15% Ag | 645–800 | 670–720 |

| BCuP-6 | CuP 280 | Cu + 7% P + 2% Ag | 643–788 | 670–720 |

Copper to Brass Brazing Rods

Brass brazing rods (AWS RBCuZn series) are commonly used for copper-to-brass and copper-to-copper joining. These copper–zinc based alloys provide good fluidity and cost efficiency, while nickel, manganese, or silicon additions improve joint strength and corrosion resistance for demanding applications.

Contact us now

- Cost-effective solution: Good fluidity with competitive material cost

- Enhanced performance options: Ni/Mn-containing grades provide improved fatigue strength and corrosion resistance

- Typical applications: Valves, gas fittings, sanitary hardware, and brass components

| Grade (GB/T) | Grade (AWS/ISO) | Cu (%) | Zn (%) | Other Elements | Melting Range (℃) | Recommended Joint Gap (mm) |

| RBCuZn-A | – / Cu470 | 56–64 | Bal. | Si <0.5, Sn <1.0, Fe <0.25 | 870–900 | 0.05–0.25 |

| RBCuZn-C | AWS C68100 / Cu681 | 56–64 | Bal. | Si 0.01–0.5, Mn 0.75–1.10, Sn <0.5, Fe 0.25–1.25 | 870–900 | 0.05–0.25 |

| RBCuZn-D | AWS C77300 | 46–50 | Bal. | Si 0.04–0.15, Ni 9–11 | 920–940 | 0.05–0.25 |

| BCu59Zn(Sn) | ISO Cu470 | 57–61 | Bal. | Sn 0.2–0.5 | 875–895 | 0.05–0.25 |

| BCu60Zn(Si) | ISO Cu470a | 58.5–61.5 | Bal. | Si 0.2–0.4 | 875–895 | 0.05–0.25 |

Copper to Steel Brazing Rods

Copper-to-steel brazing requires alloys with good metallurgical compatibility and controlled melting behavior. Chalco supplies silver-copper, brass, and special copper alloy rods (CuNi, CuMnNi) to support different strength, temperature, and service conditions.

Contact us now

- Cost-sensitive production: Brass brazing alloys such as RBCuZn-D

- Low-temperature, high-reliability joints: Silver-based alloys (BAg-1, BAg-7)

- High-temperature or corrosive environments: CuNi or CuMnNi alloy systems

| Alloy | Chemical Composition (wt%) | Melting Range (℃) | Recommended Brazing Temperature (℃) |

| RBCuZn-D | Cu + 40 Zn + Ni + Mn | 870–890 | 900–940 |

| BAg-1 | 45 Ag + Cu + Zn + Cd | 645–815 | 680–740 |

| BAg-7 | 56 Ag + Cu + Zn | 620–660 | 650–710 |

| CuNi Series | Cu + 10–30 Ni | 1100–1140 | 1150–1200 |

| CuMnNi Series | Cu + 20–40 Mn + Ni | 975–1000 | 1000–1050 |

Copper to Aluminum Brazing Rods

Copper-to-aluminum brazing involves dissimilar metals with different melting behavior. Chalco supplies Zn–Al–Cu and Al–Si based brazing rod systems to achieve stable joints with controlled heat input and long-term reliability.

Contact us now

- Zn–Al–Cu alloys: Lower melting range with good fluidity, suitable for mass production and controlled brazing processes

- Al–Si alloys: Excellent wetting behavior and improved resistance to galvanic corrosion for durability-focused applications

- Flux requirement: Special flux is typically required to ensure dense joints and reliable mechanical strength

| Alloy System | Main Composition | Melting Range (℃) | Recommended Brazing Temperature (℃) |

| Zn-Al-Cu | Zn 40–50%, Al 5–10%, Cu | 380–500 | 420–500 |

| Al-Si | Al-Si (10–12%) + Cu | 520–600 | 550–620 |

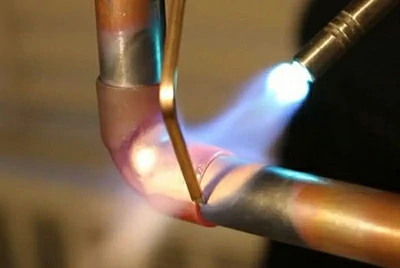

Flux-Coated & Fluxless Copper Brazing Rods

Flux-Coated: Rods coated with flux, suitable for on-site construction and pipeline maintenance.

Fluxless: Bare rods requiring separate flux, commonly used in automated factory production.

Contact us now

| Type | Melting Range (℃) | Recommended Brazing Temperature (℃) |

| Flux-Coated | 650–750 | 700–760 |

| Fluxless | 650–850 | 700–780 |

The above list highlights only part of Chalco's copper brazing rod offerings. As part of an integrated brazing solution portfolio, Chalco also supplies silver brazing rods for high-strength and low-temperature joining, and aluminum brazing rods for aluminum and copper–aluminum brazing applications. Additional brass, silver-based, and aluminum alloy formulations can be customized to meet specific project requirements, with one-on-one technical selection and quotation support available from our sales team.

Chalco copper brazing rod application fields & selection guide

Copper brazing rods are widely applied in HVAC, construction piping, automotive, and electrical systems. By selecting the right alloy according to the base metal and working environment, joint strength, corrosion resistance, and long-term reliability can be ensured.

HVAC & Refrigeration

Applications: Evaporators, condensers, air-conditioning copper pipe joints

Recommendation: Phos-copper alloys for copper-to-copper; use flux when brazing copper-to-brass or copper-to-steel

Construction & Plumbing

Applications: Water pipes, valves, sanitary brass fittings

Recommendation: Brass brazing alloys; flux-coated rods for on-site work

Automotive & Electrical

Applications: Radiators, oil coolers, hydraulic pipelines, electrical connectors, and automotive heat exchanger systems using brazed sheet and brazed foil

Recommendation: Silver-based alloys for high strength or temperature resistance; brass alloys for cost-sensitive mass production

Copper–Aluminum Transition

Applications: Copper tube–aluminum fin joints, auto A/C lines, power electronics

Recommendation: Zn-Al-Cu or Al-Si alloys with special flux to prevent galvanic corrosion

For tailored recommendations and samples, please contact Chalco to get the best copper brazing solution for your project.

Chalco Copper Brazing Rod Technical Advantages

- Wide melting range (380–1140℃), covering HVAC, automotive, and industrial needs

- Silver alloys → higher strength & toughness; Phos-copper → self-fluxing; Tin → better wetting & crack resistance

- Compatible with flame, induction, and furnace brazing

- Available in flux-coated (easy repair) and fluxless (automation) types

Comparison with Other Filler Materials

| Category | Copper Brazing Rods | Soldering Brazing Rods | Aluminum Brazing Rods | Fusion Welding |

| Strength | High, suitable for pressurized structures | Low | Medium, suitable for aluminum | High, but large heat-affected zone |

| Temperature Resistance | High, long-term stability | Low | Medium, limited by aluminum alloys | High, but prone to distortion |

| Process Requirements | Flame/Induction/Furnace, minimal heat effect | Low temperature, simple operation | Narrow range, strict control required | High heat input, advanced equipment |

| Flux | Some self-fluxing / flux-coated options | Required | Usually required | Not required, but complex process |

| Applications | HVAC, automotive pipelines, industrial repair | Small appliances, low-pressure fittings | Aluminum heat exchangers, aluminum pipes | Thick-walled & heavy-duty components |

Compared with soldering and aluminum brazing rods, Chalco copper brazing rods offer higher strength, better temperature resistance, and wider application adaptability, making them the ideal choice for HVAC and industrial pipelines.

Why Choose Chalco for Brazing Projects

Chalco is not only a supplier of individual brazing consumables, but a material-focused partner providing integrated brazing solutions for aluminum and copper joining projects.

- Complete brazing material coverage: From brazing rods to aluminum brazing foil, aluminum brazing strip, and brazing ring preforms, all key filler materials can be supplied from one source.

- System-oriented supply capability: Products are supplied as coordinated material systems rather than isolated consumables, improving joint consistency and sourcing efficiency.

- Project and production support: Suitable for both on-site repair and automated mass production applications such as HVAC, automotive, and industrial assemblies.

- Flexible customization & global delivery: Alloy selection, form, packaging, and logistics can be tailored to project requirements with reliable international supply.

Frequently Asked Questions (FAQ)

Q1: What is the difference between copper brazing rods and copper welding rods?

A1: Copper brazing rods are used in brazing at lower temperatures where the base metal does not melt. Copper welding rods are used in fusion welding where both base and filler metal melt together, suitable for structural joints.

Q2: Do copper-to-aluminum brazing rods require flux?

A2: Yes, dissimilar copper–aluminum joints must use special flux to prevent oxidation and ensure wetting.

Q3: What diameter brazing rod is commonly used for copper pipe?

A3: For household and HVAC systems, 2.0–2.5mm is common. For industrial thick-wall pipes, 3.0mm is recommended.

Q4: Can phos-copper brazing rods braze brass?

A4: Yes, but flux is required, since zinc in brass oxidizes easily.

Chalco supplies a full range of copper brazing rods, including Phos-Copper, Brass, Silver-Copper, and Copper-Aluminum systems, available in flux-coated and fluxless forms. Whether for HVAC, automotive, construction, or industrial manufacturing, we provide high-quality brazing solutions. Contact us anytime for samples, technical selection advice, fast quotations, or OEM/ODM services with global delivery.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote