Laminated foil, also known as laminated aluminum foil or composite aluminum foil, is a multi-layer composite material made by laminating aluminum foil with one or more functional materials (such as PET film, PE foam, kraft paper, bubble film, glass fiber cloth, etc.) through thermal lamination or adhesive process.

Compared with single-layer aluminum foil, laminated foil has significant advantages in barrier properties, heat reflection, structural strength and processing compatibility, and can simultaneously meet multiple requirements such as material lightweight, structural durability and functional integration. It is widely used in many engineering fields such as industrial packaging, building insulation, electronic and electrical protection, and thermal management systems.

Chalco laminated aluminum foil product overview

| Product Series Name | Contains structure combination examples | Recommended aluminum foil substrate alloy |

| Aluminum-plastic composite foil series | Aluminum foil + PET / BOPP / heat sealing film / adhesive film | 1235-O / 8011-O / 8079-O |

| Aluminum paper composite foil series | Aluminum Foil + Kraft Paper / White Board | 1145-O / 8011-H22 |

| Aluminum Bubble Layer Composite Foil Series | Aluminum foil + PE foam / XPE foam / bubble layer | 8079-H18 / 1235-O / 3003-H24 |

| Aluminum cloth composite foil series | Aluminum Foil + Glass Fiber / Woven Fabric | 8011-H18 / 3003-H18 |

| Personalized custom structure | Aluminum foil + PET + foam / kraft paper / PE film, etc. (multi-layer composite structure) | 1235-O / 8011-H22 (customizable) |

Aluminum foil thickness: 6μm – 50μm, single layer or multi-layer composite is supported

Total composite thickness: 0.05 mm – 2.0 mm (adjusted according to the number of structural layers and application)

Maximum width: 1500 mm (supports slitting on demand)

Supply form: roll/sheet, support secondary processing such as die-cutting, adhesive backing, punching, laminating, etc.

Surface treatment technology: matte, mirror, electrophoretic coating, anti-static treatment, printing layer, adhesive layer pre-coating, etc.

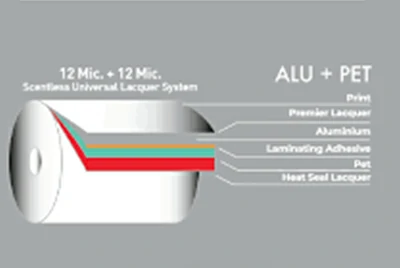

Aluminum plastic laminated foil

Aluminum foil base alloy: 1235-O / 8011-O / 8079-O 1235-O / 8011-O / 8079-O ( excellent flexibility, suitable for flexible packaging and heat sealing processes )

Composite layer materials: PET, BOPP, heat-sealing film, antistatic film, self-adhesive film and other functional film materials can be double-layered or multi- layered.

Aluminum-plastic composite foil is a basic composite material widely used in industrial flexible packaging and electronic structure packaging, with good barrier properties, heat seal compatibility and printability. By compounding with a variety of functional film materials, the structure can meet a variety of composite functional requirements such as airtightness, conductivity, anti-static, printing display or label rolling, and is suitable for the performance integration of complex packaging systems and structural layer materials.

Chalco aluminum-plastic laminated foil product technical description:

- The surface aluminum foil is treated with electrostatic degreasing and tension control, with a surface tension of ≥38 dyn /cm, ensuring lamination strength and subsequent printing adhesion

- Supports solvent-free dry lamination/wet heat-sealing lamination/die-cutting coating integrated solution, suitable for high-speed lamination film production line

- Optional functional film lamination (such as anti-static, anti-fog, anti-fingerprint) to enhance the terminal packaging system integration capability

Chalco aluminum-plastic laminated foil product performance advantages

- Excellent barrier properties

- Strong heat sealing compatibility

- Thin and light structure, can be die-cut

- Good printability

- Support functional membrane composite

Chalco aluminum-plastic laminated foil application areas:

Food packaging bags (such as dry goods, seasonings)

Used for packaging of dry goods, seasonings, etc., providing excellent air tightness and barrier properties.

Medical blister/composite sealing film

The backing material of tablet blisters, it meets the requirements of sealing, peeling and printing.

Industrial desiccant bag/deoxidizer packaging

Suitable for deoxidizer/desiccant packaging, with good damage resistance and moisture resistance.

Chalco aluminum-plastic composite foil series can be delivered in rolls or die-cut sheets, supporting drawing customization, structural proofing and collaborative development of multifunctional composite films, suitable for all kinds of industrial and consumer-grade high-performance film/ packaging structures.

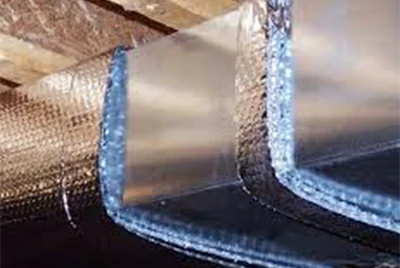

Instant QuoteAluminum bubble laminated foil

Aluminum foil base alloy: 8079-H18 / 1235-O / 3003-H24 (with good flexibility, corrosion resistance and heat reflection ability)

Composite layer materials: PE foam, XPE closed-cell foam layer, single-layer/double-layer bubble film, etc., thickness and structure can be customized, supporting flame retardant/coating and other functional composites

Aluminum bubble laminated foil combines aluminum foil with foam or bubble layers, offering heat reflection, cushioning, and lightweight insulation. It's ideal for large-area thermal control in buildings, HVAC ducts, and vehicle cabins, featuring good flexibility, moisture resistance, and easy cutting for engineering-grade insulation systems.

Chalco aluminum bubble laminated foil technical description:

- Adopt directional expansion aluminum foil lamination process to maintain overall flatness and reduce the risk of composite stress warping

- The foam/bubble material is preheated and pre-shrinked to improve the composite bonding strength and thickness stability

- It can realize double-sided aluminum foil reflective structure/film-coated reinforcement layer structure to meet the dual needs of thermal insulation and strength

Chalco aluminum bubble layer laminated foil product performance advantages:

- Highly reflective, suitable for thermal management systems

- Energy absorption and compression resistance, good structural buffering effect

- Moisture-proof and heat-insulating, suitable for building insulation

- Flexible and cuttable, easy to construct

- Can be laminated and composited, suitable for multiple scenarios

Chalco bubble layer laminated foil application areas:

Roof reflective/insulating layer

Used in the thermal insulation layer of building roofs to reflect radiant heat and improve energy saving.

Cold chain insulation packaging bags/transport liners

Used in the transportation of frozen food or medicine, providing lightweight insulation protection.

Duct insulation layer

Used for the outer layer of air ducts in air conditioning/ventilation systems, integrating heat insulation, moisture resistance and protection.

Chalco aluminum foam composite foil series supports cutting to set thickness, coil/sheet delivery, composite structure drawing customization and engineering-level project proofing, and is suitable for multiple functional requirements such as thermal insulation, coating, and anti-collision.

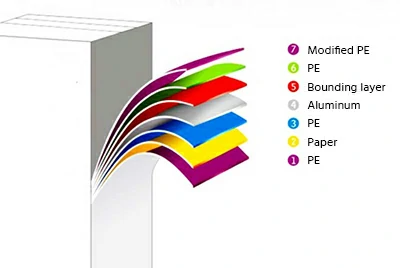

Instant QuoteAluminum paper laminated foil

Aluminum foil base alloy: 1145-O / 8011-H22 (with good printing adhesion and bending performance)

Composite layer materials: kraft paper, white cardboard, coated paper and other packaging grade paper materials, supporting double-sided/multi-layer composite and printing coating processing

Aluminum-paper composite foil is made by combining aluminum foil with various paper materials through dry lamination or adhesive lamination process. It is widely used in various printing and packaging, anti-corrosion envelopes and structural packaging scenarios. The aluminum layer provides excellent barrier properties and metallic luster, while the paper layer has good stiffness and printability. It is a classic product among paper-based composite materials.

Chalco aluminum paper composite laminated foil technical description:

- Use precision-controlled aluminum foil surface roughening and annealing to improve paper layer adhesion and composite stability

- The paper surface can be coated/plated, and supports subsequent processing such as laser printing, UV glazing, offset gravure printing, etc.

- Compliance requirements of food, medicine, daily chemicals, etc.

Chalco aluminum paper composite foil product performance advantages:

- Strong metal texture, improving packaging texture

- Good printability, suitable for various printing methods

- The composite is strong and the layers are not easy to peel off

- The structure can be cut, die-cut and embossed

- Support environmentally friendly material system, wide range of applications

Chalco aluminum-paper composite laminated foil application areas:

Cigarette box lining sealing film

It is often used in the inner layer of high-end cigarette packs, and has decorative and odor-isolating functions.

Food grade aluminum paper packaging bag

Aluminum foil and kraft paper are composited to combine structural strength and food-grade barrier properties.

Aluminum paper composite daily packaging bags

Ideal for lightweight bags like facial masks, samples, and personal care products, with excellent printability and eco-friendliness.

Chalco provides customized structural development of aluminum + paper composite materials, supports die-cutting proofing, printing adaptation testing and stable batch delivery, which is suitable for the multiple needs of paper-based packaging customers for durability, aesthetics and barrier properties.

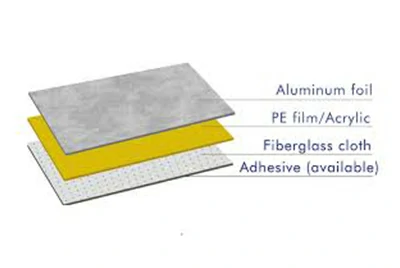

Instant QuoteAluminum fabric laminated foil

Aluminum foil base alloy: 8011-H18 / 3003-H18 (high strength, excellent tear resistance and heat resistance)

Composite layer materials: glass fiber cloth, polyester woven cloth, coated glass fiber cloth, flame retardant woven layer, etc., can be single-sided/double-sided composite as needed

Aluminum cloth composite foil is formed by hot pressing or gluing aluminum foil and glass fiber cloth or industrial woven cloth. It has excellent high temperature resistance, tear resistance, flame retardancy and reflective properties. It is suitable for engineering scenarios with high requirements for structural protection and temperature control, such as buildings, industrial equipment, wind turbine blades, and military equipment. Single-sided/double-sided aluminum composite is optional, and flame retardancy level customization is supported.

Chalco aluminum cloth composite laminated foil product technical description:

- Adopt high temperature hot pressing compound + edge anti-warping treatment, suitable for high frequency vibration and thermal expansion and contraction environment

- Supports directional fiber arrangement/coated glass fiber base cloth composite to improve mechanical strength and reflection uniformity

- Can pass UL94 and DIN 4102 flame retardant rating tests and meet industrial and building fire protection regulations

Chalco aluminum cloth composite laminated foil product performance advantages:

- High temperature resistance, suitable for harsh thermal environments

- Strong tear resistance and good structural stability

- Flame retardant, meets industrial safety standards

- High reflectivity for thermal management systems

- Supports multiple functions such as reinforcement, coating, anti-corrosion, etc.

Chalco aluminum cloth composite laminated foil products cooperation areas

Industrial fire curtain/insulation cloth

Suitable for flame retardant and heat insulation scenarios, such as workshop protective curtains or equipment covers.

Cable channel covering materials

Covering cables in high temperature areas can prevent fire, moisture and corrosion.

High temperature reflective shielding structure

Used for reflective insulation in high heat source areas such as engine compartments/industrial furnaces, etc.

Chalco provides customized aluminum + fabric composite material solutions, supporting structural design, lamination process optimization, and flexible order delivery. It meets the diverse demands of insulation, durability, and mechanical strength in packaging, construction, and industrial fabric applications.

Instant QuoteMulti-layer composite structure laminated foil & laminated foil customization

Aluminum foil base alloy: 1235-O / 8011-H22 (supports composite grade surface treatment and can be adapted to multi-layer architecture)

Composite layer materials:5 PET film, PE foam, Kraft paper, bubble layer, woven cloth, heat-sealing film, antistatic film, adhesive layer, etc., can be freely combined and designed.

Chalco supports the customization of 3-layer or more multifunctional composite structural foil materials according to customer application requirements, combining the barrier and light reflectivity of aluminum foil with the flexibility, strength, thermal insulation or adhesion characteristics of various substrates to create composite solutions suitable for complex working conditions. This type of structure can achieve multi-dimensional advantages such as integrated functions, process cost reduction and construction convenience while maintaining lightweight, and is suitable for the development of high-performance alternative solutions in engineering, equipment and packaging systems.

Chalco multi-layer composite structure laminated foil technical description:

- Provide composite structure design assistance and drawing verification services, support proofing, structural testing and material selection recommendations

- Supports solvent-free dry lamination/thermal lamination/adhesive lamination process combination with ≥3 layers

- Customizable mechanical matching in different directions / bending stiffness / composite thickness control / surface tension optimization

Chalco multi-layer composite foil performance advantages:

- Multifunctional integration, taking into account multiple properties such as thermal insulation, barrier, reflection, etc.

- The structure can be flexibly configured to adapt to complex geometry and application requirements

- Supports extreme performance combinations such as high strength/heat resistance/flame retardancy

- Reduce on-site assembly steps, suitable for prefabrication industrial production

- Provide material selection suggestions and structural analysis, and support project proofing cooperation

Chalco multi-layer composite structure laminated foil products cooperation areas

Chalco multi-layer composite structural foil supports customization of the complete service process from drawing evaluation, functional composite to mass production, targeting high-performance engineering systems, assembly manufacturing and brand packaging projects. You are welcome to provide application requirements for joint development and technical verification.

Instant QuoteChalco laminated foil manufacturing capabilities and supporting services

In order to meet the diverse needs of different industries for aluminum foil composite materials in terms of function, structure and performance, Chalco has built a full-process integrated manufacturing system covering aluminum foil raw materials → composite manufacturing → post-processing → precision cutting → packaging and delivery. This not only greatly improves the consistency of product batches, but also ensures the technical stability and delivery efficiency of customers from proofing to mass production.

Aluminum foil raw material guarantee capability

Own aluminum foil rolling production line: support 1235, 8079, 8011, 3003, 1145 and other composite special alloys

Fine state control: common soft foil and hard foil states such as O / H18 / H22 / H24 can be provided

Thickness control capability: Aluminum foil thickness ranges from 6μm to 50μm, supporting ultra-thin soft composite and strong structural composite requirements

Stable surface quality: high cleanliness annealing, anti-oxidation treatment, surface tension control ≥38 dyn /cm

Batch consistency guarantee: traceability from coil to compounding, meeting the requirements of high-standard industries such as aviation/pharmaceuticals/electronics

Composite manufacturing capabilities

Various lamination methods: support dry lamination, hot lamination, solvent-free lamination and adhesive process

Structural layers: Single layer, double layer, triple layer, multi-layer composite structure can be customized

Automated production line: roll- to-roll continuous lamination to ensure efficiency and consistency in large-scale delivery

Composite width control: Maximum width is 1500 mm, suitable for industrial-grade coating and architectural-grade coiled materials

| Customizable parameter range | |

| Aluminum foil thickness | 6μm – 50μm |

| Total composite thickness | 0.05 mm – 2.0 mm (customized according to structure) |

| Maximum composite width | 1500 mm |

| Layer configuration | Single layer/ double layer/ triple layer/ multi-layer optional |

| Surface treatment | Anodizing/ electrophoresis/ adhesive/ punching, etc. |

| Delivery form | Coil/ Sheet/ Die-cut/ Roll-to-roll delivery |

Surface treatment and function expansion

Surface technology: support mirror, matte, frosted, electrophoresis, spraying, hot stamping and other processing

Functional superposition: can be covered with heat-sealing film, self-adhesive adhesive , anti-static film, flame-retardant coating, perforated ventilation and other functional structures

Customized pre-treatment: Aluminum surface can be anodized, electrostatically degreased, tension controlled, suitable for printing and gluing requirements

Chalco laminated foil products cooperation areas

Building insulation and energy-saving systems

Used in energy-saving structures such as roof reflective films, wall insulation layers, and pipe coverings, which require lightness, moisture resistance, and heat reflection.

- Bubble Layer Composite Foil

- Al cloth composite foil

- PET composite structure

- Roof Laminated Foil

- Aluminum insulation foil

Packaging and flexible packaging systems

It is suitable for food and medicine packaging, industrial desiccant bags, roll envelopes, etc., and needs to take into account barrier properties, heat sealing properties and printability. Some high-end packaging scenarios can also introduce holographic laminated film structures to enhance appearance recognition and anti-counterfeiting capabilities.

- Al-plastic composite foil

- Al paper composite foil

- Al+PET+heat sealing layer

- Al+Holographic Film

- Al paper cigarette foil

- Chocolate Wrapping Foil

Thermal management of industrial equipment

Used for equipment surface insulation, air duct covering, electrical cabinet heat reflection and other structural protection under high temperature or vibration conditions.

- Al cloth composite foil

- Multi-layer foam structure

- Al+glass fiber+coating

Electromagnetic shielding and electronic packaging

It is widely used in conductive tapes, anti-interference layers, and EMI structures of equipment housings, which require conductivity, anti-static properties, and structural stability.

- Al + conductive film

- Aluminum+PET+adhesive

- Functional multilayer

Automobile and new energy systems

It is suitable for battery pack thermal management, in-vehicle insulation layer, floor reflective film, etc., requiring light weight, high reflectivity and temperature resistance.

- Al Bubble Layer Composite

- Multi-layer PET+foam

- Reflective Laminated Foil

Defense industry and electronic assembly

Used for high-reliability structural layers, cabin flame-retardant insulation layers, and EMI composite components, requiring flame retardancy, thermal conductivity, and structural stability.

- Al cloth composite foil

- Al/PET/flame retardant film

- Aluminum/anti-static film

FAQ

How do I choose the right laminate?

Please determine the priority requirements (such as barrier properties, heat resistance, printability, whether heat sealing is required, etc.) according to your application scenario. Chalco can provide structural recommendations and drawing analysis services to help you quickly match the best composite solution.

Does it support small batch prototyping and customized production?

Yes. Chalco can provide structural proofing services to meet the needs of the entire process from test verification to batch delivery, which is particularly suitable for early verification of engineering applications or special packaging projects.

What foil thicknesses and laminate widths do you offer?

The aluminum foil thickness range is 6μm–50μm, the total composite thickness range is 0.05–2.0 mm, the maximum composite width is 1500 mm, and it supports fixed thickness control and slitting delivery.

Can it support functional structures such as heat sealing, adhesive backing, die-cutting or anti-static film?

Functional composite structures such as heat-sealing film, self-adhesive layer, anti-static film, flame-retardant coating, etc. can be superimposed according to project needs, and can be adapted to processing techniques such as die-cutting, punching, and film laminating.

What delivery forms do you offer? Is it suitable for export?

It supports various forms such as coils, flat sheets, die-cut sheets, punched parts, etc., with an accuracy control of ±0.5 mm. The packaging method is vacuum film + corrugated box + export wooden box, which is suitable for automated equipment and long-distance transportation.

Can you provide test reports and quality certification?

We can provide material COA, thickness/barrier/peel strength test data, and support third-party test reports to meet ISO 9001, RoHS, REACH, ASTM and other industry standards.

Is it supported to upload drawings for structural customization?

recommendations and structural combination solutions based on your composite structure, dimensions and application requirements.

Get samples and quote support

Want to quickly match your engineering project or packaging solution?

Welcome to upload drawings or parameter requirements, we will provide you with:

- Material structure recommendation

- Proofing and technical verification

- Customized quotation and delivery time confirmation

[ ] or []

Instant QuoteChalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote