Why choose Chalco?

As an aluminum materials company, we are proud to collaborate with renowned partners such as Guala Colosures, Nippon Colosures, CSI Colosures, Herti, Mala Colosures, and Federfin tech. The selection of these partners validates our exceptional capabilities in terms of quality, reliability, and innovation.

Specifications of 5052 aluminum sheet strip and foil

| Dimensions of aluminum closures rolled | |||

| Parameter | Range | Standard | Tolerance |

| Thickness (mm) | 0.18 - 0.25 | 0.18, 0.20 | +0.005/-0.005 |

| Width (mm) | 50 - 1250 | 813, 845, 833.8, 835 | +0.5, -0 |

| Length (mm) | 400 - 1000 | 655, 706 | +0.5, -0 |

| Diagonal difference for sheet (mm) | 1 max | - | - |

| Coil sizes (mm) | OD: 1450 max ID: 75, 150, 300, 508 | - | - |

| Coil density (kg/mm) | 3.5 max | - | - |

| Offer for thickness and width outside the range may be quoted on specific request | |||

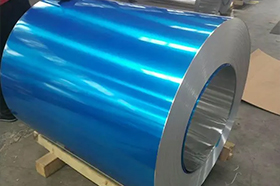

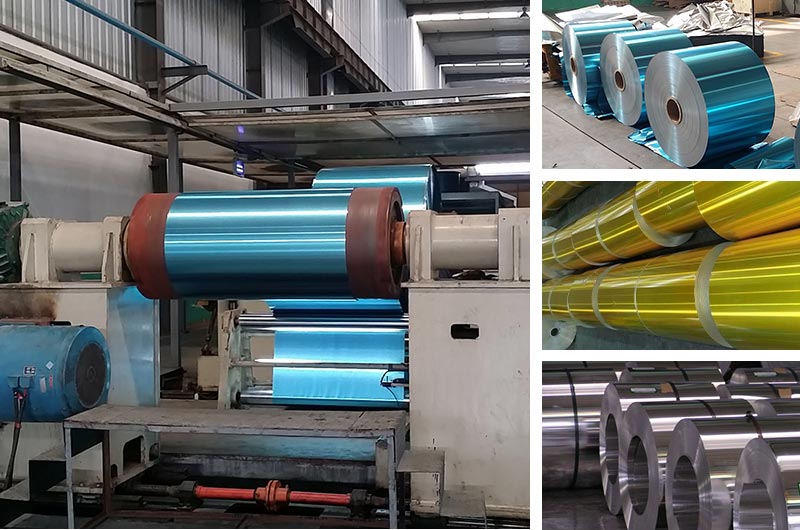

| Surface | Mill finish, color coated, chromated, varnished | ||

| Earring | Typical value: < 2 per cent for >=0.18 mm thickness | ||

Product features of Chalco 5052 aluminum foil

- Ring Pull stock generally adopts 5182 aluminum alloy processing, the Ring Pull Can Lid material generally use 5052 and 5182 aluminum alloys processed;

- Flexible, stamping deformation is not easy to crack;

- Small density, light weight, smooth surface, feel good;

- Environmental protection is easy to recycle and reuse.

Quality Assurance of Chalco 5052 aluminum sheet foil

Surface processing is good, does not allow to have a black, marks, tire tracks, corrosion, pressure folds, creases, straightening roller printing, oil stain, stick injuries, scratches, metal and non metal pressed into etc. obvious defects, the strip flatness degree greater than 10I (or wave height is less than or equal to 3 mm, wavelength is preferably more than 400mm).

- Strict control of good width tolerance: Thickness tolerance: + 0.01mm (preferably 0.005mm) Width tolerance: + 1mm Flatness requirements: height less than 3mm, within 1 meters of the wave number is less than 3;

- Sheet shape control: Combined with roll, bending roll, spray the use of control good flatness, ensure hot machine convex degree control between 0.1 ~ 0.8%, hot online visual without obvious wave.

- Appearance quality: No end edge crack, roll end neat, no staggered pyramid.

Other hot selling aluminum foil products

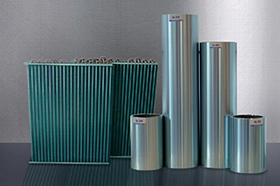

Hydrophilic Lacquered Aluminum Foil

Air Conditioner Aluminum Foil

Heat seal aluminum Foil

Aluminum Foil for Lacquered EOE POE Lid

Color Coated Chocolate Aluminium Foil

Color Coated Aluminum Sheet and Foil

Earring of 5052 aluminum sheet strip and foil

| Temper | Earring |

| H18, H19 | ≤4% |

Unevenness of 5052 aluminum sheet strip and foil

| Thickness mm | Longitudinal unevenness | Horizontal unevenness | ||

| Wave height mm | Wave per meter length | Wave height mm | Wave height mm | |

| not more than | ||||

| 0.150-0.250 | 2.0 | 4 | 1.5 | 2 |

| >0.250-0.500 | 3.0 | 3 | 1.5 | 2 |

Mechanical properties of 5052 aluminum sheet strip and foil

| Temper | Thickness mm | Mechanical properties | |

| Tensile strength MPa | Elongation % | ||

| Not less than | |||

| H18 | 0.200-0.500 | 280-320 | 3 |

| H19 | ≥285 | 2 | |

Camber and layering of 5052 aluminum sheet strip and foil

Layering of strip and foil≤1.0 mm, Camber≤5.0 mm.

Thickness tolerance of 5052 aluminum sheet strip and foil

| Thickness mm | Thickness tolerance mm |

| 0.150-0.250 | ±0.005 |

| >0.250-0.500 | ±0.010 |

Width tolerance of 5052 aluminum sheet strip and foil

| Width mm | Width tolerance mm |

| ≤800.0 | +0.5 0 |

| >800.0 | +1 0 |

Chemical composition of 5052 aluminum sheet strip and foil

| Element | Content (%) |

| Aluminum, Al | Remainder |

| Magnesium, Mg | 2.2-2.8 |

| Chromium, Cr | 0.15-0.35 |

| Silicon, Si | ≤0.25 |

| Iron, Fe | ≤0.40 |

| Copper, Cu | ≤0.10 |

| Manganese, Mn | ≤0.10 |

| Zinc, Zn | ≤0.10 |