Flexible busbars: key components for innovative power solutions

Flexible busbar is a highly flexible conductor formed by laminating multiple layers of copper or aluminum foil through crimping, welding or riveting. Compared with traditional rigid busbars, flexible busbars have better flexibility and seismic resistance, and can adapt to various complex electrical layouts and dynamic motion environments. Therefore, flexible busbars are widely used in new energy, rail transportation, communication equipment, industrial automation and other fields, and have outstanding performance in high current transmission, high reliability and space optimization.

Chalco Aluminum offers flexible busbars in a variety of specifications, including:

- Material selection: copper, aluminum, composite materials

- Surface plating: tin plating, nickel plating, silver plating

- Thickness (foil): 50 - 300 microns

- Insulation material: PVC, heat shrink tubing, epoxy coating

- Operating temperature: -40 °C to +105 °C (higher temperatures optional)

- Working voltage: Typical 1000V AC / 1500V DC (depending on insulation)

- Conformity to standards: UL67, Guide QEUY2 File E495516; UL 758 Requirements for cold bend testing of electrical wire materials at -40°C and -50°C (-40°F and -58°F); EAC and RoHS compliant

Copper flexible busbar

Copper flexible busbar is a highly conductive and flexible electrical busbar designed for efficient power distribution systems. Copper itself has extremely high conductivity, which can minimize power loss and is suitable for various electrical systems that require high current handling. Its flexible characteristics make the installation process more convenient and can easily adapt to small spaces and complex wiring layouts.

Jump to [Technical Specifications]

Experience superior conductivity and flexibility with our copper flexible busbars — perfect for high-performance electrical applications. Get a quote today!

Instant QuoteAluminum flexible busbar

Aluminum flexible busbars are lightweight and durable, providing an ideal solution for power distribution. Aluminum is not only lightweight, but also has good conductivity and flexibility, making it suitable for installation environments with limited space. While ensuring electrical performance, this product can effectively control costs and is widely used in new energy, power, and communications.

Jump to [Technical Specifications]

Lightweight and corrosion-resistant aluminum flexible busbars designed for efficient power distribution. Contact us for customized solutions!

Instant QuoteCCA flexible busbar

Copper clad aluminum flexible busbar combines the advantages of copper and aluminum. Its surface is copper layer, which ensures excellent conductivity, while the internal aluminum material remains light and cost-effective. The copper clad aluminum structure enhances the mechanical strength and electrical performance of the busbar, and is particularly suitable for electrical applications requiring high current handling capacity.

Jump to [Technical Specifications]

Combine copper conductivity with aluminum's lightness in our CCA flexible busbars — ideal for cost-effective, high-efficiency electrical systems. Request your sample now!

Instant QuoteLaminated flexible busbar

Laminated flexible busbars are made of multiple layers of conductive materials (such as copper or aluminum) to enhance the flexibility and electrical performance of the busbar. This design has strong electrical fatigue and high temperature resistance, making it very suitable for applications in high power and high temperature environments.

Jump to [Technical Specifications]

Maximize compactness and reliability with our laminated flexible busbars, engineered for complex power networks. Explore customization options with us!

Instant QuoteTinned flexible busbar

Tinned flexible busbars are copper or aluminum busbars with a layer of tin on the surface, which enhances the corrosion resistance of the busbar and is particularly suitable for use in harsh environments. The tin layer not only improves corrosion resistance, but also improves weldability and contact reliability, making it an ideal choice for preventing oxidation and corrosion in electrical systems.

Protect your connections from corrosion with our tinned flexible busbars — ensuring long-lasting performance in harsh environments. Inquire about availability!

Instant QuoteInsulated flexible busbar

Insulated flexible busbars have an insulating protective layer (such as PVC, rubber, etc.) on top of the conductive material, providing additional electrical safety to prevent short circuits and electrical accidents. The insulation design can also prevent environmental factors such as moisture and dust from affecting electrical performance, and is widely used in high-voltage power distribution systems.

Ensure safety and prevent short circuits using our insulated flexible busbars tailored for diverse electrical setups. Contact our experts for tailored advice!

Instant QuoteBraided flexible busbar

It is usually made of metal materials such as copper wire, aluminum wire or copper clad aluminum wire through a braiding process. The braiding method and material selection of these cables directly affect the conductive performance, flexibility and mechanical strength of the flexible busbar. Provides multi-layer conductors bonded together by heat-activated insulation layers. They can be easily applied to customers' products to provide alternating conductor layers and insulation layers, and provide a variety of insulation materials.

Our braided flexible busbars offer excellent flexibility and vibration resistance — perfect for dynamic industrial applications. Get a personalized consultation today!

Instant QuoteChalco – the perfect combination of product diversity and processing capabilities

With strong R&D and production capabilities, we not only provide flexible busbars of various materials (such as copper, aluminum, copper-clad aluminum, etc.), but also have diversified processing capabilities and can provide customized services according to customer needs. Whether in product design, precision processing or high-performance surface treatment, Chalco can provide excellent solutions to ensure that every customer can get the best power transmission experience.

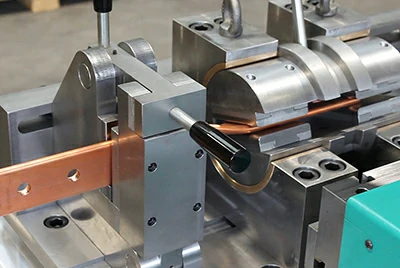

Instant QuoteProduction and processing equipment

- Efficient production equipment: automated production line, semi-automatic busbar processing

- Precision equipment: high-pressure water jet cutting, CNC milling machine, turret punching, stamping

- Large-scale production capabilities: ensuring efficient manufacturing and precision for large-volume orders

Precision processing and customized services

- Various processing services: Waterjet high-pressure water cutting, CNC milling, turret punching, cutting, bending, stamping

- Customized solutions: current carrying capacity, size, shape, surface treatment customization

Various surface treatments and high performance requirements

- Surface treatment technology: anodizing, electroplating (silver, tin, nickel), spraying

- Corrosion resistance and conductivity: Improve the corrosion resistance and conductivity of the product, improve the appearance and ensure long life

Advanced insulation treatment technology

- Insulation technology: PVC coating, heat shrink tubing, epoxy resin coating

- Electrical isolation: meets the safety and stability requirements of different working environments and effectively prevents electrical short circuits

Copper Clad Aluminum (CCA) technical advantages

- Manufacturing technology: explosive welding process, rolling cladding technology, hot dip coating technology

- Application advantages: It has excellent conductivity and mechanical properties, suitable for high-load, high-current power systems and high-demand industrial equipment

The main application areas of flexible busbars

With strong product production capacity and precision processing technology, Chalco's flexible busbars are widely used in many key fields. The flexible busbars we provide not only have excellent conductivity, flexibility and reliability, but can also be customized according to the needs of different application scenarios to meet the strict requirements of various industries in terms of power transmission, space layout and safety performance.

Instant QuoteElectric vehicles and battery packs

Flexible busbars ensure stable module connections, enhance vibration resistance, and improve system safety and durability.

They support BMS integration and optimized layout design, helping boost energy density and vehicle performance.

Renewable energy systems (solar and wind power systems)

Provide compact, adaptable power connections for solar panels, turbines, and energy storage units.

Withstand high currents, ensure stable transmission, and perform reliably in harsh outdoor environments.

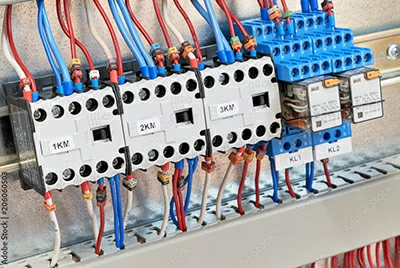

Power distribution and switchgear

Ensure safe, high-load connections in substations and switch cabinets with compact layout and easy maintenance.

Improve wiring flexibility, reduce system failure risk, and support long-term stable operation.

Industrial equipment and mechanical systems

Support high-power current transmission in automated and heavy-load systems with complex layouts.

Resist vibration and frequent load changes, meeting durability needs in demanding industrial conditions.

Data center and communication equipment

Deliver reliable power in high-load environments with space-saving wiring solutions.

Offer strong heat resistance and stable performance to reduce failure risk under extreme conditions.

Technological specification of flexible busbar

| Technical Parameters of Copper Flexible Busbar | |

| Parameter | Specification |

| Material | 99.9% high purity copper |

| Electrical conductivity | ≥98% IACS |

| Resistivity | ≤0.01724 Ω·mm²/m |

| Rated current carrying capacity | 190A - 1040A |

| Short circuit withstand capability | 30kA - 105kA |

| Operating temperature range | -40℃ ~ +105℃ |

| Tensile Strength | ≥200 MPa |

| Elongation | ≥20% |

| density | 8.92 g/cm³ |

| Technical Parameters of Aluminum Flexible Busbar | |

| Parameter | Specification |

| Material | Highly conductive aluminum (1060 or 1350 aluminum alloy) |

| Electrical conductivity | ≥60% IACS |

| Resistivity | ≤0.0282 Ω·mm²/m |

| Rated current carrying capacity | Moderate, about 60% of copper busbar |

| Short circuit withstand capability | than copper busbar |

| Operating temperature range | -40℃ ~ +105℃ |

| Tensile Strength | ≥100 MPa |

| Elongation | ≥15% |

| density | 2.7 g/cm³ ( 50% lighter than copper ) |

| Technical Parameters of CCA Flexible Busbar | |

| Parameter | Specification |

| Material | Copper clad aluminum (CCA, copper layer thickness can be customized) |

| Electrical conductivity | ≥75% IACS |

| Resistivity | ≤0.022 Ω·mm²/m |

| Rated current carrying capacity | Between copper busbar and aluminum busbar |

| Short circuit withstand capability | Moderate, slightly higher than aluminum busbar |

| Operating temperature range | -40℃ ~ +105℃ |

| Tensile Strength | ≥150 MPa |

| Elongation | ≥18% |

| density | 3.5 - 4.0 g/cm³ (30%-40% lighter than pure copper) |

| Technical Parameters of Laminated Flexible Busbar | |

| Parameter | Specification |

| Material | Multilayer high conductivity copper/aluminum |

| Electrical conductivity | ≥97% IACS (copper) / ≥58% IACS (aluminum) |

| Resistivity | ≤0.018 Ω·mm²/m |

| Rated current carrying capacity | 420A - 1040A (customizable) |

| Short circuit withstand capability | 65kA - 105kA |

| Operating temperature range | -40℃ ~ +125℃ |

| Tensile Strength | ≥200 MPa (copper) / ≥120 MPa (aluminum) |

| Elongation | ≥20% (copper) / ≥15% (aluminum) |

| Insulation layer withstand voltage | 3.5 kV (IEC 61439 standard) |

Product advantage of flexible busbar

- Superior flexibility for complex systems

- High conductivity, improving power system efficiency

- Space saving, light weight, easy to install

- Strong shock resistance, suitable for high vibration environment

- Reduce installation and maintenance costs

| Advantages | Flexible busbar | Traditional busbar |

| Flexibility and adaptability | High flexibility, adaptable to complex spaces | Rigid structure, high space requirement |

| Conductivity and energy consumption | High conductivity, low resistance, reduced loss | Higher resistance, greater energy loss |

| Ease of installation | Lightweight and easy to install, no need for bulky brackets | Requires more support and fixings |

| Shock resistance | Strong anti-seismic performance, suitable for high vibration environment | Weak earthquake resistance, easily damaged |

| Installation and maintenance costs | Short construction period and low maintenance cost | Complex construction and high maintenance costs |

Flexible busbars are an ideal solution for complex power systems due to their excellent flexibility, high conductivity and low maintenance costs. If you are looking for a power connection solution that can improve system efficiency and reduce operating costs, contact us for professional flexible busbar customization services to improve your project performance immediately!

Instant QuoteFlexible aluminum busbar product knowledge center and frequently asked questions (FAQ)

Rigid busbar vs flexible busbar

| Rigid Busbar | Flexible Busbar |

| Fixed shape, cannot be bent. | Bendable to adapt to complex environments. |

| The installation is complex and requires precise measurement and support. | Easy to install, suitable for small spaces. |

| Suitable for long-term fixed equipment. | Suitable for dynamic devices and changing scenarios. |

| It is heavier, which increases the difficulty of transportation and installation. | Lightweight, easier to transport and install. |

| Strong current carrying capacity, suitable for high power applications. | Moderate current carrying, suitable for low to medium power applications. |

| Suitable for static environment, not resistant to vibration. | Adapt to vibration and dynamic environments. |

| Additional support and fixing system required. | No support required, easy to route. |

| Strong durability and long service life. | Easy to maintain, but relatively short lifespan. |

Laminated flexible busbar vs woven flexible busbar

| Laminated flexible busbar | Braided flexible busbar |

| Strong conductivity: Made of multiple layers of metal foil, suitable for high current applications. | Extremely high flexibility: Provides excellent bending ability through braided wire. |

| Good electrical isolation: Good electrical insulation performance, adaptable to high temperature environment. | Strong vibration resistance: can effectively eliminate the impact of vibration and is suitable for dynamic occasions. |

| Suitable for high current: Suitable for industrial equipment and power systems with high current. | Suitable for small spaces: Suitable for installation in small or irregular spaces. |

| Strong thermal stability: able to withstand higher operating temperatures. | Convenient installation: suitable for installation in environments with large space restrictions. |

| Strong structure: Provides high mechanical strength and heat dissipation capabilities. | Lightweight: Relatively light, suitable for applications requiring high portability. |

Purchase FAQ

How to choose suitable flexible busbar products?

When choosing a flexible busbar, you need to consider the following factors:

- Current carrying capacity: Choose the appropriate current carrying capacity based on your power needs.

- Size and shape: Choose the appropriate size based on the size and shape of the installation space.

- Environmental conditions: Select insulating materials and surface treatment processes (such as anodizing, electroplating, etc.) that are suitable for the working environment.

- Installation requirements: If flexible installation is required, flexible busbars will be more suitable.

Can the flexible busbar be customized?

Yes, we provide customized services. We can customize the size, shape, current carrying capacity and surface treatment process according to customer needs. Please contact us with detailed requirements and we will provide you with the most suitable customized solution.

What is the delivery cycle of flexible busbars?

The specific delivery time depends on the order quantity, customization requirements and production schedule. We will provide an accurate delivery time after receiving the order.

How to ensure product quality?

We strictly implement international quality standards, and all products have undergone multiple tests, including conductivity test, temperature rise test, and high voltage insulation test. We have also passed ISO, UL and other international certifications to ensure the reliability and stability of each product.

Can you provide samples for testing?

Yes, we can provide samples for customers to test and verify the performance of the product. Please contact our sales team to specify the type and quantity of samples required.

What is the price of the product?

Prices will vary according to specific customization requirements, quantity and shipping methods. Please provide detailed requirements and we will provide you with a competitive quotation.

Do you provide after-sales service?

Yes, we provide comprehensive after-sales services, including product installation guidance, technical support and product warranty. We promise to repair or replace any quality problems during the warranty period.

Choose Chalco Aluminum's flexible busbar

In the field of flexible busbars, Chalco Aluminum relies on advanced production technology, strict quality control and strong customization capabilities to provide excellent products and services to global customers. Whether it is large-scale production, customized needs or special industry applications, Chalco is a trustworthy partner.

Instant QuoteStrong production capacity and fast delivery: multiple automated production lines with a monthly production capacity; efficient supply chain management to ensure timely delivery.

Strict quality control and international certification: comply with ISO, UL and other international certification standards; conduct conductivity and temperature rise tests to ensure stable product performance.

Customized solutions to meet specific needs: provide a variety of processing services, such as cutting, bending, stamping, etc.; meet special requirements of different sizes, shapes, and surface treatments.

Rich experience in flexible busbar applications: covering multiple industries such as electric vehicles, renewable energy, and power equipment; accumulated years of industry experience, providing professional solutions for different application scenarios.

Trusted partner of world-renowned customers: long-term cooperation with many well-known brands, quality and service have won wide recognition; provide flexible customization and supply chain support to meet the continuous needs of customers.

The surface is smooth without burrs and the oxide layer is uniform: a variety of surface treatment processes are provided to ensure superior product performance; beautiful appearance and excellent corrosion resistance.

Multiple packaging options to ensure transportation safety: provide a variety of packaging solutions to prevent damage during transportation; flexibly adjust the packaging method according to customer needs.

Whether it is large-scale bulk purchases or customized flexible busbar solutions, Chalco can meet your needs. Contact us to get:

- Tailor-made flexible busbar solutions

- Competitive price and delivery advantages

- Professional technical team provides technical support and after-sales service

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote